Page 3

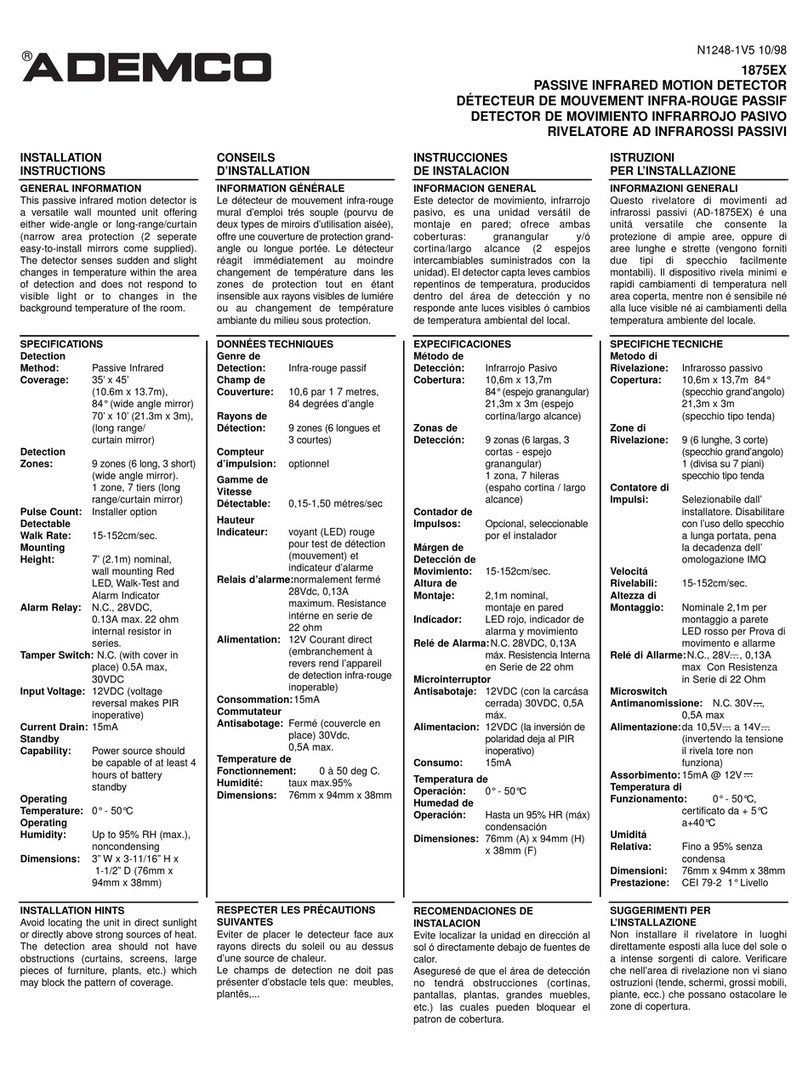

The angle of the PIR pattern may be vertically positioned between

-10° and +2° by loosening the Vertical Adjust screw and sliding the

circuit board up or down. Moving the board up will angle the pattern

downward.Tightenthescrew snug when positioning is completed.

NOTE: The pattern may be moved ±10° horizontally by moving the lens

to the left or right.

Establishing Microwave Coverage

NOTE: Itis important to wait one minute afterremoving/replacing the

cover so the microwave portion of the detector can settle, and to

wait at least 10 seconds between the following walk testing

procedures.

• The tri-color LED should be OFF before walk testing.

• Walk test across the pattern at the intended coverage’s farthest end.

Startwalkingfromoutside the intended protection area and observe the

tri-color LED. The edge of the microwave pattern is determined by the

first yellow, microwave activation of the LED (or the first red activation if

the green PIR LED activates first).

• Ifadequaterangecannotbereached,increasetheMicro-

waveRangeAdjust slightly. Continue testing (waiting one

minute after removing/replacing the cover) and adjusting

the range until the farthest edge of desired coverage has

beenaccuratelyplaced.

Do not adjust the microwave range higher than required. Doing so

will enable the detector to catch movement outside of the intended

coverage pattern.

• Walktesttheunit from all directions to determine all the detection pattern

boundaries.

Establishing Detector Coverage

• With no motion in the protected area, the tri-color LED should be OFF

beforewalktesting.

• Walk test the unit from all directions to determine the detection bound-

aries. A detector alarm is signaled by the first red activation of the tri-

colorLED after an initial green/yellow activation.

Supervision Features

Thesupervision features function as follows:

•PIR/Microwave: If the PIR or microwave subsystem fails, the tri-color

LEDwill flash red four times per cycle.The complete circuit operation of

these subsystems is checked approximately every 12 hours.

•Default: The detector will default to PIR technology protection if the

microwavesubsystem fails. When defaulting to PIR, thePIR signal pro-

cessing will change from INT to STD.

Other Information

Maintenance: Atleast once a year, the range andcoverage should be

verified. To ensure continual daily operation,the end user should be

instructed to walk through the far end of the coverage pattern. This

ensures an alarm output prior to arming the system.

Pattern Masking: The PIR coverage pattern may be masked using

masking tape or electrical tape on the inside of the lens.

NOTE: Maskingonly eliminates the PIR portion of the coverage and has

noeffectonthe microwave pattern.

U.S. Patent Numbers: #4,660,024,#4,764,755,#5,077,548,#5,208,567,

#5,262,783, #5,450,062,and#5,670,943.Otherpatentspending.

TO THE INSTALLER

Regularmaintenance and inspection (at least annually) bythe installer

and frequent testing by the user are vital to the continuous satisfactory

operationof any alarm system.

Theinstaller should assume the responsibility ofdeveloping and offeringa

repairmaintenance program to the user,as well as acquaintingthe user

withthe proper operation and limitations of the alarm system and its

componentparts. Recommendations must be included for aspecific

program of frequent testing (at least weekly) to insure the systems

operationatall times.

WARNING!

THE LIMITATIONS OF YOUR

MICROWAVE/PASSIVE MOTION DETECTOR

Whilethis Intrusion Detector is a highly reliable intrusion device, it does

notofferguaranteedprotectionagainstburglary.AnyIntrusionDetection

device is subject to compromise or failure to warn for a variety of reasons.

Forexample:

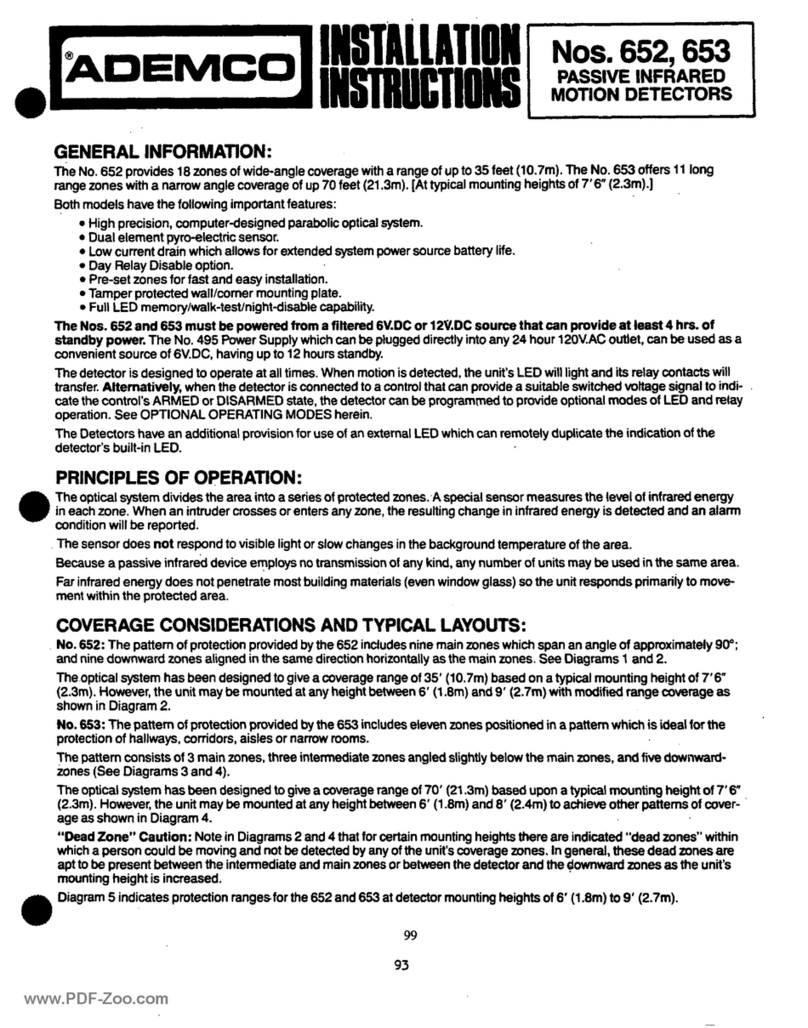

• TheseMotion Detectors can only detect intrusion withinthe designated

rangesasdiagrammedin this installation manual.

• The passive infrared sensor in this Motion Detector does not provide

volumetric area protection. It does create multiple beams of protection,

and intrusion can only be detected in unobstructed areas covered by

thosebeams.

• Passive Infrared Detectors cannot detect motion or intrusion that takes

placebehind walls, ceilings, floors, closed doors, glasspartitions, glass

doors, or windows.

• Metalobjects(orotherreflectors,suchasfoilfaced insulation or water in

bottles)can alter the microwave sensor’sprotectionpattern.

• Mechanicaltampering,masking,paintingor spraying of any material on

the lenses, windows or any part of the optical system can reduce the

detectionability of the Passive Infrared Motion Detector.

• PassiveInfraredDetectorssense changes in temperature; however,as

theambienttemperatureofthe protected area approaches the tempera-

turerangeof 90° to 105°F (32° to 40°C),thedetectionperformance can

decrease.

• The detector will not operate without appropriate DC power connected

to it, or if the DC power is improperly connected (i.e., reversed polarity

connections).

• TheseDetectors,likeotherelectricaldevices,aresubjecttocomponent

failure. Even though this equipment is designed to last as long as 10

years, the electronic components could fail at any time.

We have cited some of the most common reasons that this Motion

Detector can fail to catch intrusion. However, this does not imply that

these are the only reasons, and therefore it is recommended that weekly

testing of this type of unit, in conjunction with weekly testing of the entire

alarm system, be performed to ensure that the detectors are working

properly.

Installing an alarm system may make the owner eligible for a lower

insurance rate, but an alarm system is not a substitute for insurance.

Homeowners,property owners and renters should continueto act

prudentlyin protecting themselves and continue toinsure their lives and

property.

Wecontinueto develop new and improvedprotection devices. Users of

alarm systems owe it to themselves and their loved ones to learn about

thesedevelopments.

www.PDF-Zoo.com