lnpul Voltage:

cumnt Drain:

Standby Capablllty~

6-1lV peak to peak at polling

loop terminals.

Lessthan 1 mA (LED in-

active), 6 mA appror (LED

active)

Power source should be cap-

able of at least 4 hours of bat-

tery standby.

Opemting Tompemtum: 329 - 122’F (0% - 50%).

Opemtlng

Huntldltr:

Up to 85%RH (max.), non-

condensing.

DlmMslom 3-w x 3-llll6”H x I-55-Q

Net Wolghi (76mm x 94mm x 36mm).

3.3 02 (93.5grams).

MAINTAINING PROPER OPERATION

In order to maintain the detector in proper working

condition. it is important that the following be

observed by the user.

1. Power should be provided at all times. Loss of power

to the unit will result in the unH’s lailure to operate.

The unit’s DC source should have standby power

available for at least 4 braof operation during

emergencies.

2. Units should never be m-aimed or relocated without

the advice or assistance of the alarm service

company.

3. The physical surroundings of the protected area

should not be changed. If furniture or stock is

moved. or air conditioning or additional heating is

installed, the system may have to be readjusted by

the alarm service company.

4. Walk teatsshould be conducted frequently (at least

weekly) to confirm continued proper coverage by

each detector.

WARNING

THE LIMITATIONS OF THIS PASSIVE INFRARED MOTION DETECTOR

While the Intrusion Detector is a highty reliable

intrusion detection device, it does not offer guaran-

teed protection against burglary. Any Intrusion

Detection device is subject to compromise or fail-

ure to warn for a variety of reasons:

l

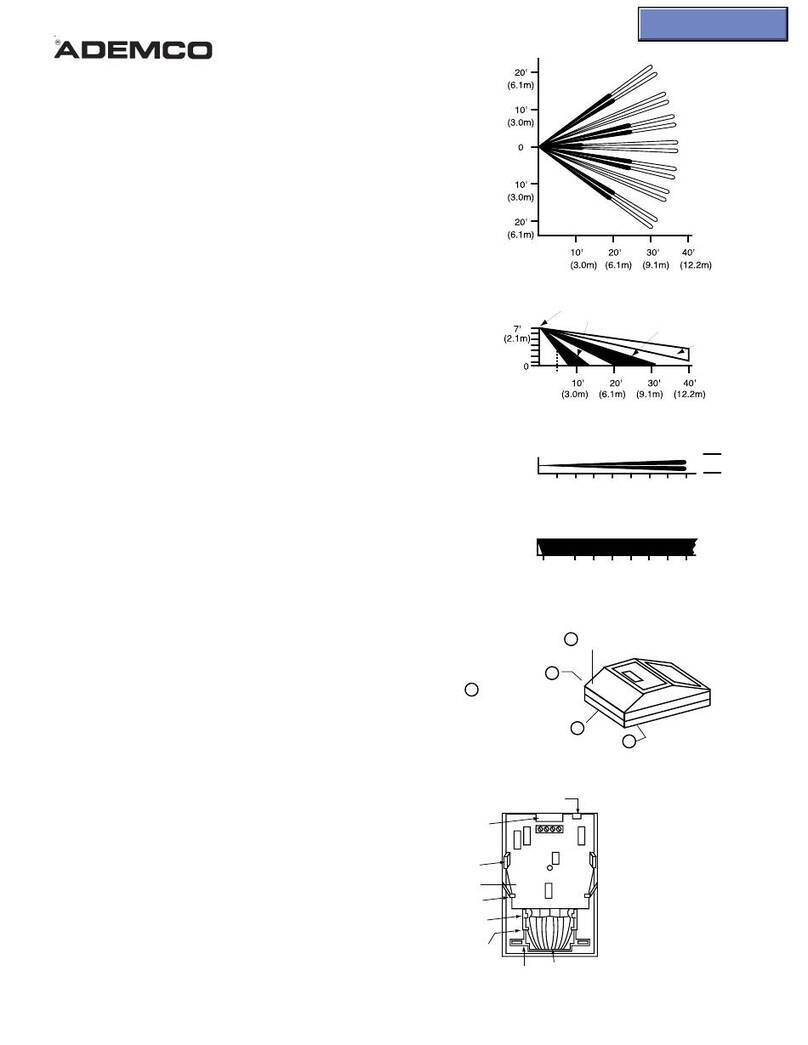

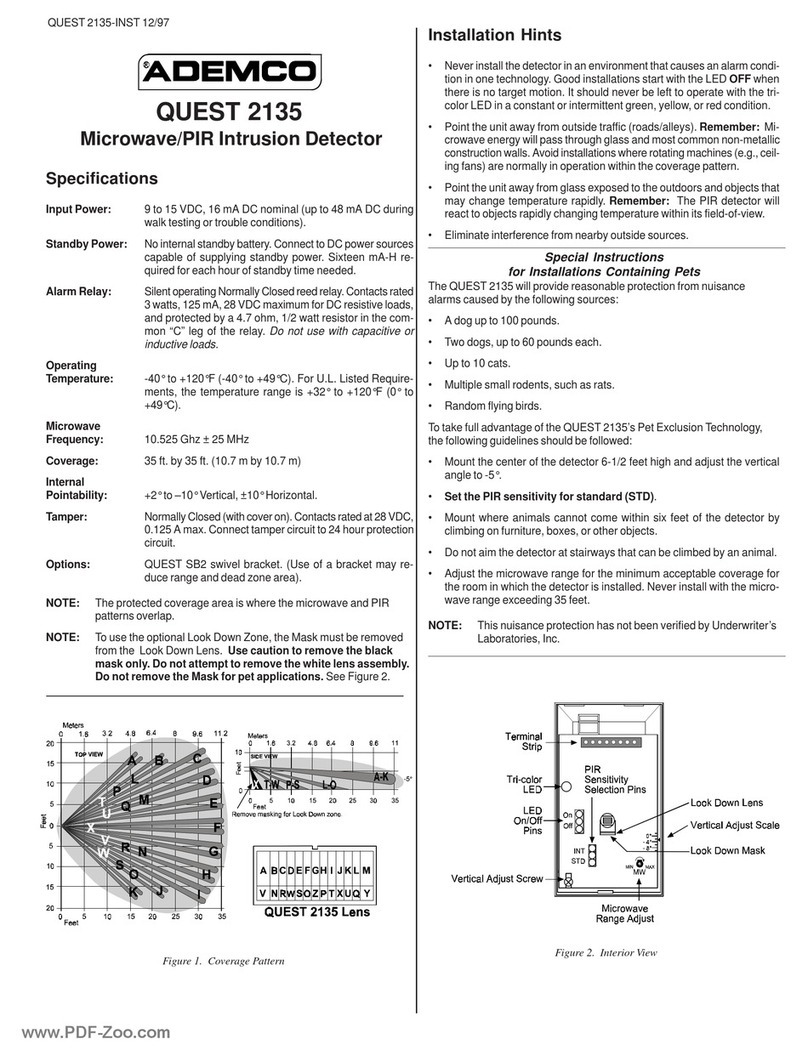

Passive Infrared Motion Detectors can only

detect intrusion within the designed ranges as

diagmmmed in this installation manual.

l

Passive tnfrared Motion Detectors do not provide

volumetric area protection. They do create multi-

ple beams of protection. and intrusion can only

be detected in unobetructed areas covered by

those beams.

l

Passive Infrared Detectors cannot detect motion

or intrusion that takes place behind walls. cell-

ings. loon. closed doom, glass perW8am. gtaw

doors. or windows.

0 Mechanical tampering, masking, painttng or

spraying of any material on the mtrrors. windows

or any part of the optical system can mducs the

detection ability of the PassiveInfnmd Motion

Detector.

l

Passive Infrared Detectom sense changes in

tempemture; however. as the ambient tempera-

ture ot the protected ares approaches the

temperature mnge of gO*to tO6V (32” to 40’ C).

the detection petformance can decrease.

l

This Passive lntmred Detector wilt not operate

without appropriate DC power connected to it, or

If the DC power is improperly connected (i.e..

reversedpolarity connections).

l

Passive tntmred Detectom. like other electrical

devices. are subject to component failure. Even

though this equipment is designed to last as tong

as 10yearn.the electronic components could fail

at any time.

We havecited some of the moat common reasons

that a Passive Infmmd Motion Detector can fail to

catch intruaion. Ho-r. this does not imply that

these am the only reasons,and therefore it is

recommended that weekly testing of this type of

unit in conjunction with weekly testing of the

entire atarm ryetern. be performed to ensure that

the detect00 are w-orkingproperly.

tnstalling an alarm system may make one eligible

for lower insurance mtes.

but

an alarm system is

not a substitute tor insumnce. Homeowners, prop-

erty ownem and rentem should continue to insure

their lives and property.

Wecontinue to develop new and improved protec-

tion devices. Usem of alarm systems owe it to

themselves and their loved ones to learn about

these developments.

5