brand, may result in a risk of battery burst causing personal injury and property damage.

4. Be sure that the battery is installed correctly and tightly before operating the tool.

5. Always wear protective devices to avoid personal injury.

6. Hold tool by insulated gripping surfaces when performing an operation on wall and floor

where the cutting tool may contact hidden wiring. Contact with a “live” wire will also

make exposed metal parts of the tool “live” and shock the operator.

7. Use appropriate detectors to determine if utility lines, such as electric lines, gas lines and

water lines, are hidden in the work area before screwing or drilling on the wall, floor or

ceiling.

8. Keep working area well ventilated. Non-specified or damaged battery may produce

poisonous gases causing personal injury.

9. Always be sure to have a firm footing and hold the tool firmly.

10. Be sure no one is below when using the tool in high locations.

11. Keep hands away from rotating parts.

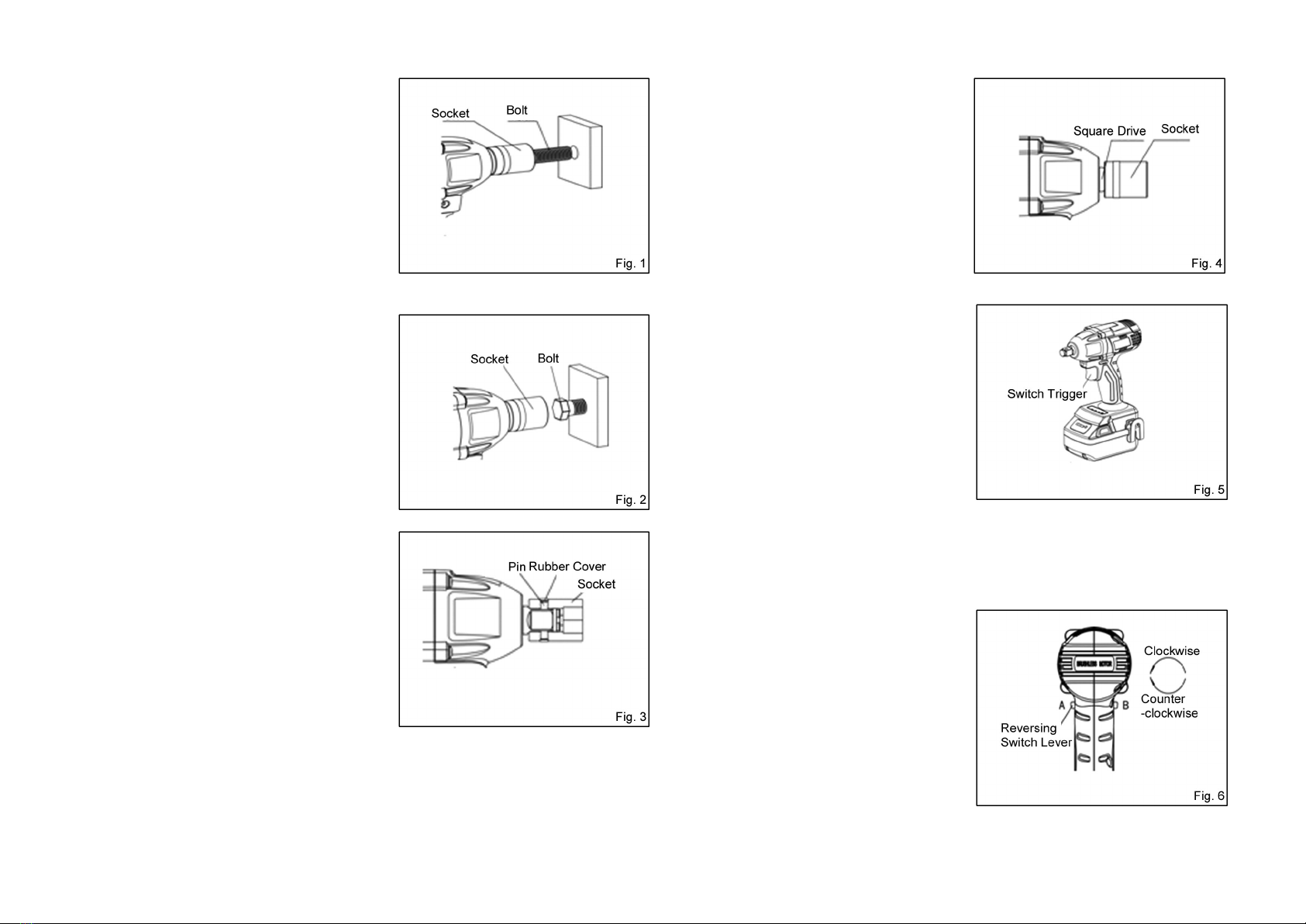

12. Switch off the tool immediately once the drill bit is blocked as the motor or the battery

maybe damaged because of overloaded. Free the drill bit by reversing the rotation of the

drill bit which can be controlled by the switch.

13. Do not leave the tool running. Operate the tool only when hand-held.

14. Do not touch the drill bit or the workpiece immediately after operation; they may be

extremely hot and could burn your skin.

15. Do not overload the tool; it may result in a risk of overheating.

16. Some material contains chemicals which may be toxic. Take caution to prevent working dust

inhalation and skin contact. Follow material supplier safety data.

17. Always disconnect the battery from the tool before making any work on the tool.

18. Before performing any kind of work on the tool (e.g. maintenance, bit change, etc.) as well as

when transporting and storing it, always set the reversing switch lever to the center position.

Unintentional activation of the On/Off switch may result in personal injury.

19. Only use soft and dry cloth to wipe the body of the tool. Do not clean the tool with wet cloth,

thinner, gasoline or other volatile solvents.

20. The damaged tools, accessories and waste packaging should be sorted for environmentally

friendly recycling and in accordance with local laws.

SAVE THESE INSTRUCTIONS.

WARNING! MISUSE or failure to follow the safety rules stated in this instruction manual may

cause serious personal injury.

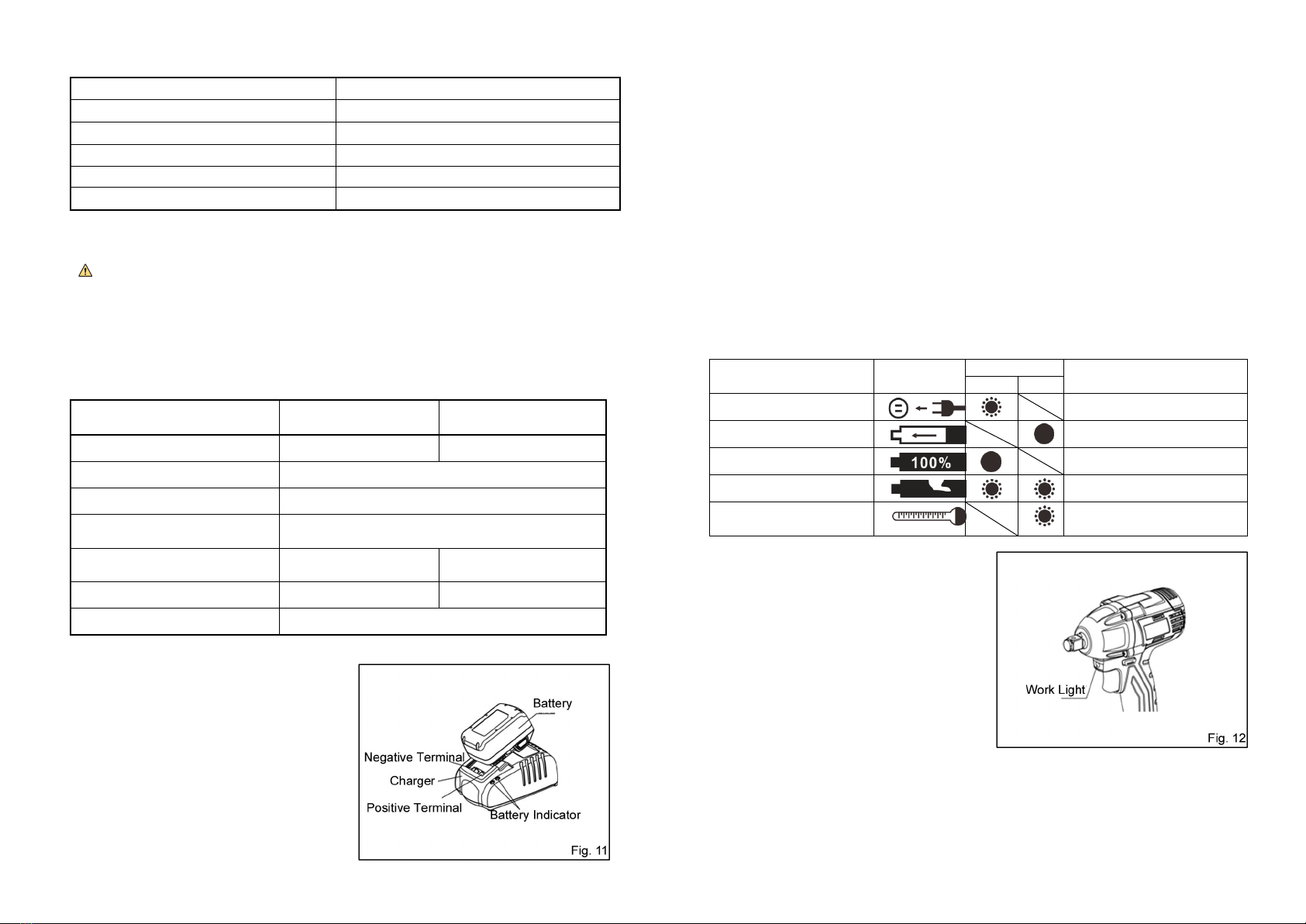

IMPORTANT INSTRUCTIONS FOR BATTERY & CHARGER

1. Do not overdischarge the battery. Stop operating the tool when it’s run out of normal power.

2. Do not charge for damaged battery.

3. Wait till the battery cools down before charging.

4. It’s normal that the battery and charger will become warmer while in charging.

5. When charging finished, unplug the charger firstly and then remove the battery from the

charger. Do not leave the battery in the charger for long time.

6. Do not put the battery in the charger when the tool is not in use.

7. Keep battery far from fire and high temperature, THERE IS A DANGER OF EXPLOSION!

Never place battery on radiator or expose it under continuous sun irradiation, it may be

damaged by overheated.

8. Avoid overheating the battery by overloading or exposing it under continuous sun

irradiation. Avoid putting the battery in a cold area, which will cause the temperature of

the battery too low and damage the battery.

9. Be careful not to drop, shake or strike the battery. Never try to use the battery cartridge

as a hammer. Striking on the battery may cause unexpected short-circuit and results in a

risk of fire or explosion.

10. Do not short-circuit the battery:

a)Do not touch the terminals with any conductive material.

b) Avoid storing battery in a container with other metal objects such as nails, coins, etc.

c)Never expose battery to water, rain or snow.

11. If operating time with a battery has become excessively shorter after charging, stop

operating immediately and replace with a new one. Continuous using of a worn out

battery may result in a risk of overheating, possible burns and even an explosion.

12. Overheating or overusing of the battery may cause liquid escape and come into contact