ADM RFL-7C-0200 User manual

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

1

RFL-7C-0200

Hand-held Laser Cleaner User

Manual

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

2

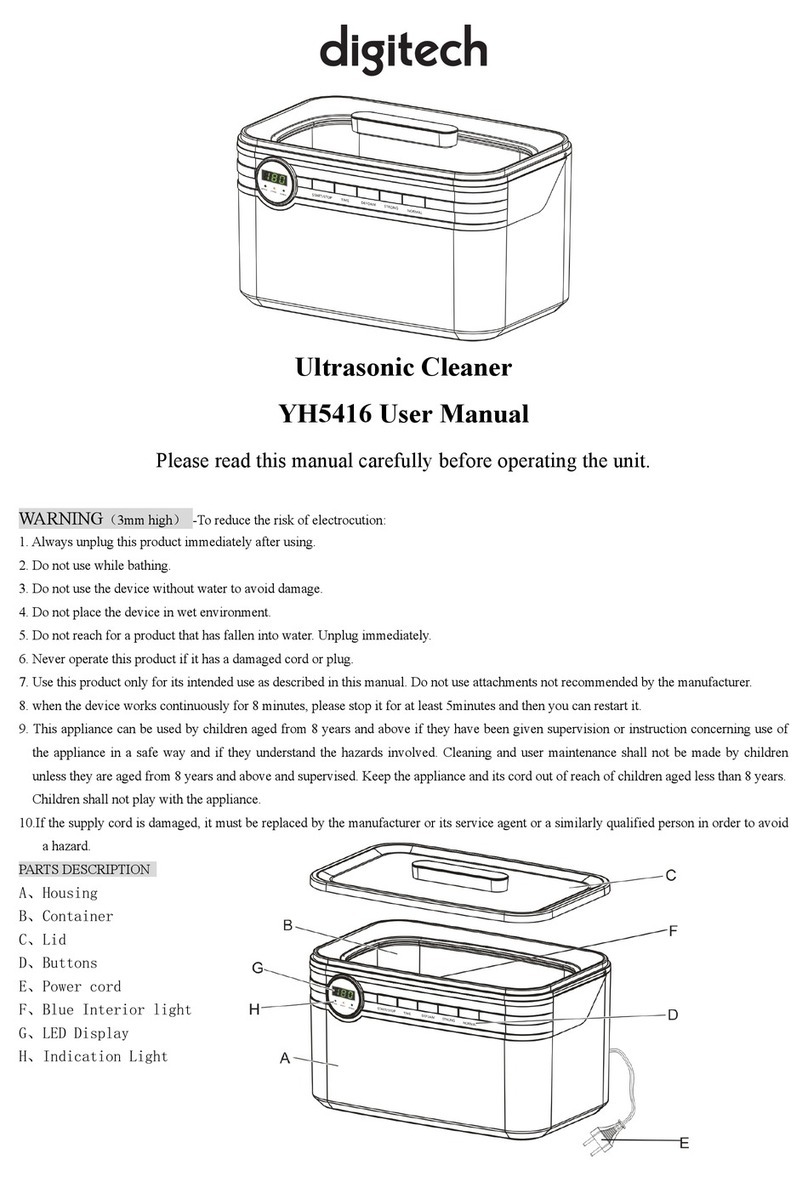

1.Product Description

1.1 Summary

Laser cleaning technology refers to the use of high-power density laser beams to irradiate the

surface of the workpiece, so that the dirt, rust or coating on the surface can be evaporated or

peeled off instantly, thereby achieving a clean process. This cleaning equipment is a high-tech

product of Xinyi's representative surface treatment, which is easy to install, operate and realize

automation. The operation is simple, and it can be cleaned without chemical reagents, media, dust,

and water. It can remove resin, paint, oil, dirt, dirt, rust, coating, plating and oxide layer on the

surface of the object. It has a wide range of applications, including ships, auto repair, rubber molds,

high-end machine tools, rails, and environmental protection. Before using the RFL-7C-0200

handheld laser cleaner, please read the user manual carefully. In the course of use, if you have any

difficult questions, please contact us in time, we will definitely give you a satisfactory answer as

soon as possible. When unpacking the box, please check the user manual in the accessory box. If

the manual is incomplete, please contact our company in time.

1.2 Product dimensions and features

1.2.1. Dimension drawing of cleaning head

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

3

1.2.2. Overall dimensions

1.2.3Product features:

◎Non-contact cleaning, without damaging the part matrix.

◎Precise cleaning can realize selective cleaning with precise position and precise size.

◎No chemical cleaning fluid, no consumables, safety and environmental protection.

◎Easy to operate, just power on, and it can be hand-held or matched with a manipulator to realize

automatic cleaning.

◎High cleaning efficiency, saving time.

◎The laser cleaning system is stable, almost no maintenance

1.3 Operating environment and related parameters

Operating environment

Content

Parameter

Supply voltage

Single-phase 220V±10%, 50/60Hz AC

Whole machine power consumption

2500W (including chiller)

Place the environment

Flat, no vibration, no impact

Working temperature

0℃~40℃

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

4

Working environment humidity

≤80%

Optical parameters

Content

Parameter

Average laser power

≥200 W

Power adjustment range (%)

10-100 (gradient adjustable)

Repetition frequency (KHz)

20-50 (gradually adjustable)

Cleaning efficiency (m2/h)

5

Focal length (mm)

210/160 replaceable

Cooling method

Water cooling

Mechanical parameters

Content

Parameter

Size

1100mm×700mm×1150mm

Weight

270Kg

Optical fiber length

5 meters (10 meters can be customized)

Washing head weight

2.5Kg

Scan width

10-80mm

Move method

Hand held

1.4 Main purpose and scope of application

The RFL-7C-0200 hand-held laser cleaner produced by our company adopts high-power

fiber laser. The photoelectric system is integrated with the hand-held design. The digital control

panel outputs the laser. It has the characteristics of high precision, high efficiency and high cost

performance. It can remove resin, paint, oil, stains, dirt, rust, coating, plating and oxide layer on

the surface of objects, and has a wide range of industry applications, including ships, auto repair,

rubber molds, high-end machine tools, rails, and environmental protection. Note: The range of

material cleaning varies according to the power of the selected laser.

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

5

2.Safety information and precautions

2.1 Summary

Thank you for choosing Raycus fiber laser. This user manual provides you with important safety,

operation, maintenance and other information. Therefore, please read this user manual carefully

before using this product. To ensure safe operation and optimal operation of the product, please

observe the following cautions and warnings and other information in this manual.

2.2 The safety standards involved in this machine

Laser processing equipment and operations should comply with the GB7247-87 laser product

radiation safety, equipment classification, requirements and user guides, and GB10320-88 laser

equipment and facilities electrical safety standards.

2.3 Safety signs

There are no components in the product that need to be used by the operator, please do not try to

open the product cover, otherwise it may cause electric shock injury and the corresponding

warranty will be invalid.

Other safety considerations

1) When the laser is running, do not look directly at the laser output head.

2) Do not use fiber lasers in dim or dark environments.

3) Please strictly follow the product manual to operate the laser, otherwise any damage to the laser

will not be guaranteed.

The product has no built-in usable accessories. All repairs should be performed by Raycus

personnel. To prevent electric shock, please do not damage the label and remove the cover,

otherwise any damage to the product will not be guaranteed.

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

6

2.4 Laser safety notice

The main hazards of laser to human body are eyes and skin. Laser irradiation can cause burns to

any part of the human body. Especially the long-term observation of fiber laser will seriously harm

the eye retina! All operators must strictly wear 1064nm laser protective glasses! It is forbidden to

operate and observe without wearing glasses! Avoid placing any part of the body in the flight light

path of the laser device to avoid injury caused by misoperation.

2.5 Electrical safety

a) Do not touch any switch with wet hands to avoid electric shock. The parts of the machine tool

with lightning signs indicate that these parts have high-voltage electrical appliances or electrical

components. The operator should be extra careful when approaching these parts or opening them

for maintenance to avoid electric shock. Do not open the door of the laser cabinet lightly. It is

forbidden to change the laser parameters and potentiometers that have been set privately. If it

needs to be changed, it must be operated by a professional trained and approved by the equipment

manufacturer, and the parameter value before the change should be recorded so that it can be

restored to the original state when necessary.

b) The laser used for processing generally has a power supply voltage of several thousand volts to

several tens of thousands volts. The high voltage of the laser and the danger of X-ray damage from

the electron tube under the high voltage should be prevented.

2.6 Protective measures for equipment

a)Designate safety administrators, determine their scope of responsibility, and conduct safety

operations and safety protection education for laser processing operators.

b)Designate the laser safety management area, and set up warning signs at the entrance and

exit of the management area, including: the power of the laser processing machine, the type of

laser, the prohibition of outsiders, pay attention to protecting the eyes and the name of the safety

manager.

c)When the laser processing machine is not in use, the switch key should be pulled out and

kept by a dedicated person to avoid hazards caused by misoperation by idle personnel.

d)The smoke, dust and laser working gas generated during the processing should be discharged

to the outdoors through the exhaust pipe, and all gas cylinders should be placed neatly and firmly.

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

7

3. Use and operation

3.1 Operation summary and operation guide

The operation panel of the RFL-7C-0200 handheld laser cleaner is mainly composed of a touch

screen and a host control main operation panel. The operation interface is mainly switched by two

different states: manual mode and linkage mode. The main interface controls the laser power,

frequency, scanning line width and scanning speed.

3.2 Touch screen operation main screen

3.3 Operation guide for washing machine

3.3.1 Installation steps:

Step 1: Open the package and check whether the machine is in good condition and the accessories

are complete.

Step 2: Check the water level of the water tank. If the water level is too low, please add pure water

to the normal range of the scale bar; if the water level is normal, turn the air switch upwards, and

the whole machine is powered on. Check whether the water tank is working normally. The green

normal indicator light is always Bright means normal, and the water tank will make a short "didi"

sound. (Note: When adding water to the water tank and discharging sewage later, please open the

exhaust port first. If the working environment temperature is below 5 degrees Celsius, you can add

antifreeze to the water tank appropriately. After the machine is used, please empty the water in the

water tank; If the working environment temperature is above 5 degrees Celsius, the water in the

water tank is replaced every three months.)

Step 3: Take out the external power cord, connect the black Harting head to the washing machine,

and connect the white plug to the power outlet.

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

8

3.3.2 Use steps:

Step 1: Button operation, as shown in Figure 3.

1) Reset the "Emergency Stop" button;

2) 2) Turn the "Power" key switch to the right, turn on the power of the control system, and the

green "Indicator" is on;

3) Press the "Laser" button, the "Laser" green button lights up

Step 2: Open the cabinet and turn on the laser, as shown in Figure 4.

1) Check whether the "LASER" button is reset, if it is not reset, please reset the "LASER"

button; reset the "Emergency stop" button;

2) Turn the "Power" key switch to the right, and the "POWER" green indicator light is on;

3) After the green indicator light is on for 10 seconds, press the "LASER" button, and the

"LASER" red indicator light is on; Note that if the "ALARM" indicator light is on, the laser is in

alarm state, please turn off and contact the Laser Research Institute.

Step 3: Open the upper cover of the case and take out the cleaning head, as shown in Figure 5. It is

forbidden to face the cleaning head towards people, and it is forbidden for the laser output head to

irradiate the surface of highly reflective materials (such as copper, aluminum, mirror stainless steel

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

9

and other highly reflective materials).

Step 4: Display control operation (manual mode and linkage mode).

Manual mode

1) The startup page is shown in Figure 6;

2) Click the manual mode to enter the parameter setting page, where you can set the power and

frequency, as shown in Figure 7;

3) For parameter setting, click on the number with your finger, and then select the parameter after

the digital meter appears, and finally click "" to confirm;

Linkage mode

Click linkage mode to enter the parameter setting page, you can set power, frequency, speed and

width, the interface operation method is the same as manual operation

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

10

Step 5: Press the "control signal" button in the picture (note: for safety, this button should be

turned off immediately after use).

Step 6: Turn the cleaning head toward the surface of the workpiece to be cleaned, and press the

button on the handle of the cleaning head to start cleaning.

Step 7: There are two working knobs on the side of the cleaning head. The “width adjustment” is

used to adjust the working width, the “speed adjustment” is used to adjust the scanning speed, and

the copper tube at the top of the cleaning head is used to connect the dust collector.

Step 8: After use, turn off the machine in reverse order.

3.3 Matters needing attention in the use of washing machine

1. When the laser cleaning machine is energized, it is forbidden to point the laser output head

toward someone, and it is forbidden to irradiate the laser output head on the surface of highly

reflective materials (such as copper, aluminum, mirror stainless steel and other highly reflective

materials).

2. Wear labor protection equipment according to the regulations, and wear protective glasses that

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

11

meet the regulations near the laser beam.

3. If the laser is not shut down normally, the next time it is turned on, it will be in an alarm state,

which will affect the life of the laser. Check whether the button switches of each function of the

laser are reset before turning on.

4. Check whether the equipment circuit is properly connected before starting up. If not, it is

forbidden to start up and use it.

5. It is forbidden to use the light outlet at a right angle of 90 degrees to the cleaned surface during

use, so as not to affect the life of the equipment using RFL-7C-0200 User Manual.

6. Please add deionized water or purified water to the water tank for the first use, and replace the

water in the water tank within 3-6 months.

7. It is forbidden to bend the corrugated tube. The bending radius of the corrugated tube is ≥

250mm to prevent damage to the optical fiber in the corrugated tube.

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

12

4. Maintenance

4.1 Summary

In order to ensure the normal use of the RFL-7C-0200 handheld laser cleaner, the equipment must

be maintained and maintained daily. As the whole machine is composed of high-precision

components, you must be extra careful during daily maintenance, strictly follow the operating

procedures of each part, and must be maintained by dedicated personnel. Brutal operations are not

allowed to avoid damage to the components.

4.2 Maintenance of the laser

The laser is the core equipment in the handheld laser cleaning machine. It provides the cleaning

light source for the laser cleaning equipment; In order for your laser cleaning system to work

normally and with high quality, while ensuring the reliable operation of your laser and extending

the service life of the laser, Wuhan Raycus Fiber Laser Technology Co., Ltd. warns you to

regularly check and maintain your laser. The fiber laser can basically be maintenance-free, and the

daily main observation is whether the light is normal; whether the voltage is normal! If there is an

abnormal alarm, immediately contact Raycus after-sales service personnel!

4.3 Optical system inspection and cleaning

a. Matters needing attention

1) Do not touch the surface of the optical lens (protective lens, field lens, etc.) directly with your

hands, which may cause scratches on the lens surface. If there is oil stains or dust on the lens

surface, it will seriously affect the use of the lens, and the lens should be cleaned in time.

2) It is strictly forbidden to clean the optical lens with water or detergent. The surface of the lens is

coated with a special film. If you use these to clean the lens, it will damage the surface of the lens.

3) Do not place the lens in a dark and humid place, as this will cause the surface of the lens to age.

4) The surface of the lens is stained with dust, dirt, or water vapor, which can easily absorb the

laser and cause damage to the coating of the lens; in the slightest, the quality of the laser beam is

affected, and in the worst case, no laser beam is produced.

5) If the lens is damaged, it should be sent to the supplier for repair in time. Try not to use the

damaged lens, otherwise it will accelerate the damage to the repairable lens.

6) When installing or replacing the reflector or focusing lens, do not use too much pressure,

otherwise it will cause the deformation of the lens and affect the quality of the beam.

b. How to install or replace optical lens

1) Before installing the optical lens, please pay attention: wear clean, clean your hands with soap

or detergent, and wear white clean and light gloves; it is strictly forbidden to touch the lens with

any part of your hand; when taking the lens, you should wear gloves and Take the side of the lens

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

13

and do not directly touch the coating surface of the lens.

2) When assembling the lens, do not blow into the lens with your mouth; the lens should be placed

on a clean table stably with a few pieces of lens paper underneath. When taking the lens, you

should be careful to prevent bumps and falls, and do not apply any force on the coating surface of

the lens; the lens holder on which the lens is installed should be clean, and clean the dust and dirt

in the lens holder with a clean air spray gun Then, take out the lens and gently put it in the lens

holder.

3) When installing the lens to the lens holder, do not use too much force to fix the lens, so as not to

deform the lens and affect the quality of the beam.

4) Precautions when replacing the optical lens: Take care when removing the lens from the

packaging box to prevent damage to the lens; do not apply any pressure on the lens before the

packaging paper is opened; take out the mirror and focus from the packaging box When taking the

lens, wear clean gloves and take it from the side of the lens; when removing the packing paper

from the lens, avoid dust and other objects on the lens; after taking out the lens, use a spray gun to

remove the dust on the lens, and then Put the lens on the special paper for the optical lens; remove

the dust and dirt on the lens support frame and fixing frame, and avoid other foreign objects

falling on the lens during assembly; when installing the lens on the lens holder, do not use

excessive force to avoid lens distortion; After the assembly is complete, use a clean air spray gun

to remove dust and foreign objects on the lens again.

c. Steps to clean the lens

Different lenses have different cleaning methods. When the mirror surface is flat and there is no

lens holder, use lens paper to clean, such as cleaning the mirror; when the mirror surface is curved

or the mirror surface has a lens holder, use a cotton swab to clean, such as cleaning the focusing

lens.

1) Steps to clean the lens with lens paper: Use a blower to blow off the dust on the surface of the

lens; clean the surface of the lens with alcohol or lens paper. Do not use dry lens paper to drag

directly on the lens surface, but place the lens paper flat Put 2 to 3 drops of high-purity alcohol or

high-purity acetone on the surface of the lens, and slowly pull out the lens paper horizontally

toward the operator. Repeat the above actions several times until the lens surface is clean; if the

lens surface is very dirty, Fold the lens paper in half 2 to 3 times and repeat the above steps until

the mirror surface is clean.

2) Steps to clean the lens with a cotton swab: first use a spray gun to blow off the dust on the

mirror surface; then use a clean cotton swab to remove the dirt; use a new cotton swab moistened

with high-purity alcohol or acetone to move in a circular motion from the center of the lens to

scrub the lens. After wiping for a week, change to another clean cotton swab and repeat the above

operation until the lens is clean. Never use cotton swabs that have been used for operation; clean

the lens with a clean cloth to remove the residual marks on the mirror surface, and be careful not

to Scratch the mirror surface; take the cleaned lens to a well-lit place for observation. If the

reflection of the lens is good, it indicates that the lens has been cleaned. If the reflection of the lens

is not good, continue to clean the lens; remove the cleaned lens , According to the method

described above, place the lens on the lens holder.

d. Storage of optical lenses

1) The optical lens is properly stored to keep the quality of the lens intact.

2) The storage environment temperature is 10~30℃. Do not put the lens in a freezer or similar

Suzhou Alston D.M Laser Technology Co., Ltd

DemonMao

14

environment, otherwise the lens will be easily damaged by condensation and frost when taken out;

the storage environment temperature should not exceed 30℃, otherwise it will affect the coating

on the lens surface.

3) Keep the lens in the box. The lens should be placed in a non-vibrating environment, otherwise

it will easily cause the lens to deform and affect the performance of the lens.

4.4 Maintenance and maintenance during long-term

parking

Pay attention to the placement of the laser head when the handheld laser cleaning machine is

parked for a long time. If necessary, it is best to fix it in one place to avoid collision and smash the

lens in the laser head. Remember to seal the duckbill when the laser cleaning system is not used.

To prevent dust from entering.

Table of contents