Ados MWS 897 User manual

ADOS®MWS 897

A D O S GmbH

Instrumentation and Control

Trierer Str. 23-25 @ 52078 Aachen @ FRG

T E L . : +49(0) 241 9769- 0

F A X : +49(0) 241 9769-16

E-Mail : [email protected]

Internet : http://www.ados.de

Est.

1900

Operating Instructions

Multi-channel Gas Warning Unit

Issue: 08/15

Version: 1.1

ADOS GmbH MWS 897 Page I

Contents

Page

1. Introduction .....................................................................1

2. Operating Summary ..............................................................1

3. Equipment settings / Menu .........................................................3

3.1 Navigation ...............................................................3

3.2 Block Diagramm Menu ......................................................3

3.3 Menu Function Service ......................................................4

3.4 Menu Function System-test ..................................................4

3.5 Menu Function Sensor ......................................................4

3.5.1 Menu Function Sensor->Number .......................................4

3.5.2 Menu Function Sensor->Mute ..........................................4

3.5.3 Menu Function Sensor->Limits .........................................4

3.5.4 Menu Function Sensor->Limit-relay .....................................5

3.5.5 Menu Function Sensor->Buzzer ........................................6

3.5.6 Menu Function Sensor->Init ...........................................6

3.6 Menu Function RS232 ......................................................7

3.6.1 Menu Function RS232->Output ........................................7

3.6.2 Menu Function RS232->Baud ..........................................7

4. Maintenance work ................................................................7

5. Technical Data ..................................................................8

6. Cable list .......................................................................9

7. Terminal schematic ..............................................................10

ADOS GmbH MWS 897 Page 1

1. Introduction

The ADOS gas warning unit is a microcontroller-aided multi-channel gas monitoring unit with warning

and control functions.

Various types of sensor can be connected via a 4-20mA current interface, using 2 or 3 wire

technique.

All information significant to operation, is displayed in clear on a 2-line and 16-digit display. The

information includes the actual gas value, measuring point, alarm status or fault.

The alarms and centralised malfunctions are indicated on LED´s. Three floating alarm outputs can be

used optionally for ventilation and alarm control. One relay is responsible for fault indication.

Two keys are used for operating the equipment. These keys, together with menu-assistance, are

used for setting minimal and maximum limit values, the measuring points, as well as other significant

parameters, without any previous knowledge of programming skills. Alarms can be cancelled by

keystroke. The alarm outputs can be tested without any application of gas.

The unit incorporates a RS232 interface for data communications and a voltage output of 0-5V.

The ADOS gas warning unit MWS 897, depending on the model, can be operated on 230 V~, 110 V~

or 24 V= voltage supplies.

The unit is enclosed in a plastic wall mounting housing, protection class IP 54.

2. Operating Summary

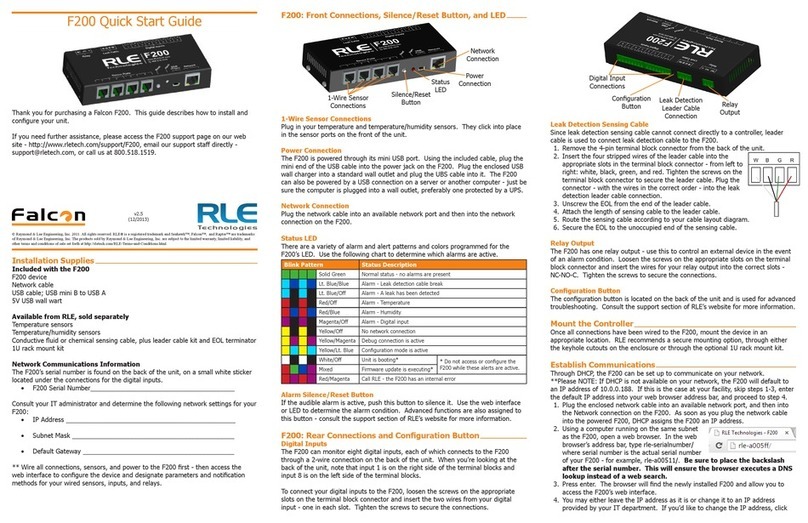

Display and operating controls are located on the frontside of the unit. Two buttons are used for the

basic settings of the unit, stopping the measurement cycle, resetting the alarms and for performing

test routines.

The basic settings of the unit are menu assisted, via the LC-Display and the following keys.

“SELECT” * switching between cyclic and stopping measure mode

* selecting a menu item

* change a value in a menu sub-item

“ENTER” * for selecting a menu item

* to quit an alarm

By simultaneously pressing “ENTER” and “SELECT” keys, entry is made for the input of the code.

After having entered the right code (number of the unit type “897"), entry is allowed into the basic

adjustments. Here, all settings can be checked and modified if required.

A return back to the normal measurement cycle is made pushing the “SELECT” key or automatically

after 90 seconds, if no new key is pressed.

By pushing the “ALARM RESET / ENTER” key during measurement, the internal buzzer can be

prematurely cleared. The alarm (LED & relay outputs) can only be cancelled if the alarm condition is

no longer present. Therefore it is not possible, if the actual gas value > limit.

ADOS GmbH MWS 897 Page 2

After switch-on the unit is automatically ready for normal cyclic measurement operation.

To prevent alarm errors during the stabilising/warm up phase of the gas sensors, the alarm and fault

monitoring is suppressed for approximately 5 minutes after switch on.

The measurement points will be checked periodically. In normal cycle mode each sensor is present

in display for 4 seconds. The fault and alarm management is independent from the actual sensor on

the display. All sensors will be checked permantly.

With the “SELECT” key it is possible to switch between cyclic measure mode and sensor hold on

mode. The hold on mode focusses one sensor on the display. This is indicated by a “*” after the

measuring point.

The first line of the display shows the actual or the average measure value, the gas and the unit. The

second line shows the actual measuring point and the status of this sensor.

In case of a fault or because of special parameters being set, the following messages can occur

instead of the gas concentration:

“????” the sensor is operating below its normal reference point (I < 3,5mA)

“^^^^” the sensor has exceeded its mesurement range (> 110%)

“****” the sensor has been muted and will not be evaluated

Normality, Measure point 2, no faults, no alarm

Third alarm of measure point 4

First alarm, sensor 1 in hold on mode

Display 15 minutes average value, alarm 1 from sensor 1

Input signal from measure point 1 < 3,5mA = fault

Indication through fault LED and K4

CO2: 0.211 VOL%

S2 alarm: 0

CH4: 85 % UEG

S4 alarm: 3

CO: 50 ppm

S1* alarm: 1

15min: 45 ppm

S1* alarm: 1

CO: ???? ppm

S1 fault

ADOS GmbH MWS 897 Page 3

3. Equipment settings / Menu

3.1 Navigation through menu

To modify the basic factory settings, both keys must be hold pressed. The input code is necessary to

protect against unauthorised modification. To enter the code “897", the “SELECT” key must be

pressed to increment the digit. Pressing the “ENTER” key confirms the input and switches to the next

digit.

At the end of input the “ENTER” key must always be pressed for confirmation. With the “SELCT” key

you can browse through the menu without making any modification or you can select a menu item.

After selecting a menu item, press the “ENTER” key and you can change the value with the

“SELECT” key. After confirmation with “ENTER” the value will be saved in memory.

An incomplete modification instruction is not saved without pushing “ENTER”. If no further key is

pressed, after 90 seconds the system returns to normal measuring cycle. If a value was changed by

mistake, enter the menu again and rectify it.

3.2 Block Diagramm Menu

The menu has the following tree structure:

ADOS GmbH MWS 897 Page 4

3.3 Menu Function Service

Switch the maintenance modus “ON” or “OFF” to avoide false alarms during repair or calibrating the

sensors. If the maintenance mode is active, all alarm and faults are supressed. By selecting “ON" the

duration is 60 minutes after leaving the menu.

3.4 Menu Function System-test

In this menu item all alarms can be initiated manually. The alarm relays and LED´s assigned to the

sensor limits are all activated. After this a fault will be generated and the 0-5V analogue output will be

tested. The assignement of the alarm relay (K1, K2, K3) can be changed independently for each

sensor and its limits. The setttings can be changed in the menu function “sensor->limit-relay”.

3.5 Menu Function Sensor

3.5.1 Menu Function Sensor->Number

Set the number of sensors that are connected. After making a change, the equipment must be

reinitialised and the programme makes a restart.

3.5.2 Menu Function Sensor->Mute

This menu item is used when it is required to switch temporarily a measuring point “On” or “Off”. This

function can be of use for example, if a particular section area of the system has to be shut down.

(Caution: Responsibility of the system operator!)

3.5.3 Menu Function Sensor->Limits

Three limit values and characteristics can be set for each measuring point. For every sensor can be

set an average time between 0 and 30 minutes. In the normal cyclic measurement modus the display

switches between actual and average gas value. Zero minutes deactivate the averaging process.

The first line of the display shows the current limit value and in the second line the new modifiable

value is mentioned.

Actuating direction: > alarm, if the limit value exceeds

< alarm, if the level falls below the limit value

Limit value: Possible between 5 and 100% of the measuring range

Reference: Reaction on actual or average gas value

Reset: Set the reset of the limit value to automatic or manual

The alarm reset is only possible, if alarm condition is no longer present.

ADOS GmbH MWS 897 Page 5

3.5.4 Menu Function Sensor->Limit-relay

Assign the alarm relay to the limit value of a measuring point. The allocation is optional, each limit

value can be assigned to a maximum of 3 alarm relays. One alarm relay can also be assigned more

than once (e.g. collective/group alarm). It is not possible to use the fault relay K4 for other functions.

Select measuring point -> select limit -> amount of relay -> assignment

factory settings:

Sensor 1 Limit 1 -> K1

Sensor 1 Limit 2 -> K2

Sensor 1 Limit 3 -> K3

Sensor 2 Limit 1 -> K1

Sensor 2 Limit 2 -> K2

Sensor 2 Limit 3 -> K3

Sensor 3 Limit 1 -> K1

Sensor 3 Limit 2 -> K2

Sensor 3 Limit 3 -> K3

etc.

for example: to generate a group indication with relay K3 use following configuration

Sensor 1 Limit 1 -> K1

Sensor 1 Limit 2 -> K3

Sensor 1 Limit 3 -> 0

Sensor 2 Limit 1 -> K2

Sensor 2 Limit 2 -> K3

Sensor 2 Limit 3 -> 0

the settings can be tested with the menu item “System test”

ADOS GmbH MWS 897 Page 6

3.5.5 Menu Function Sensor->Buzzer

Assigning the internal buzzer to a limit value at a measureing point. Select Level 0 = no function.

The buzzer can always be resetet by pressing the “ENTER” button.

3.5.6 Menu Function Sensor->Init

Base settings for a measurement point: gas, format, unit, range

Gas: setting type of gas

if the type of gas is not avaible, edit the letters of “User”

Format: set the maximum number of digits in front of and after of the decimal place

2.1 -> 00.0

1.2 -> 0.00

3.0 -> 000

Unit: physical size of the measuring range

for example Vol.%, ppm, %LEL, etc.

Range: upper and lower measure range

z.B. ADOS TOX CO 300 ppm -> MIN = 0 und MAX = 300

GTR 196 with ph -> MIN = 2 und MAX = 13

ADOS GmbH MWS 897 Page 7

3.6 Menu Function RS232

This menu is used to set the rate of transfer and the data to be output on the serial interface.

Connections can be made to a qualified printer or pc programm “hyper terminal”. Fixed settings: data

bits 8, stop bits 1, parity none, protocol none

3.6.1 Menu Function RS232->Output

Settting type of output:

OFF: Serial interface is deactivated

single alarm: at every alarm or fault, ouput the relevant measuring

cyclic: The values measured at all measuring points are output at adjustable intervals. The

intervals can be set from 1 to 30 minutes. Also alarms and faults are output as in

single alarm mode

3.6.2 Menu Function RS232->Baud

Select the transfer rate on the RS232 interface. Baud rates of 110 and 57600 are permissible.

4. Maintenance work

The following maintenance work to be carried out, refers to a twice-yearly check that should be

completed only by fully trained personnel.

The owner or operator of the system is offered the possibility of completing a maintenance contract

with the manufacturer, the ADOS GmbH company, which will guarantee a smooth and efficient

servicing by the company's own customer service.

The maintenance work can be divided into checking the sensor functions and checking the complete

gas monitoring unit, MWS897.

Over a period of time, the properties of the sensors can change. Therefore, on all sensors fitted to the

system, the relevant checks must be made as described in the operating instructions, to check the

calibration with zero gas and calibration gas.

Because of the changes that are possible, after establishing that the sensitivity of the sensors is not

sufficient, they must be re-calibrated or where necessary, replaced by new sensors.

The accuracy of the signals on the interface and the function of the output signals from the gas

monitoring unit, must also be checked regularly.

ADOS GmbH MWS 897 Page 8

5. Technical Data

Sensor inputs : 6 two-wire sensors (e.g. ADOS 592 TOX)

or

3 three-wire sensors (e.g. GTR 196)

or

2 three-wire sensors + 4 two-wire sensors

Sensor supply : 19 V= / 300 mA

Measurement ranges : CO 0-300 ppm

NO20- 30 ppm

CH40-100 %UEG

CO20- 10 Vol%

Other ranges on request

Effect of temperature : < 3% for ± 20° C temperature change

Ambient temperature : - 10 ...+ 40° C

Output signals : Serial interface RS 232

Baud : 9600

Data bits : 8

Parity : keine

Stop bits : 1

Protocol : Hardware

Analog output 0 - 5 V

3 alarm relay 230 V~ / 450 VA

1 fault relay 230 V~ / 450 VA

Voltage supply : 230V, 50 Hz

115V, 60 Hz (optional)

24V= (optional)

Power consumption : 14 VA

Dimensions (WxHxD) : 225 x 180 x 105 mm

Weight : ca. 1,5 kg

Protection class : IP 54 (DIN EN 60529)

ADOS GmbH MWS 897 Page 9

6. Cable list

Mains 230V/50Hz : NYM-J 3 x 1,5 mm2

Mains 230V/50Hz

for horns and warning banners : NYM-J 3 x 1,5 mm2

Sensors : J-Y(ST)Y 2 x 2 x 0,8 mm2 , screened

bzw. J-Y(ST)Y 4 x 2 x 0,8 mm2 , screened

Ex-Sensors : NYM (ST)-J 4 x 1,5 mm2 , screened

Warning banners and flash lights : NYM-J 3 x 1,5 mm2

Horns : NYM-J 3 x 1,5 mm2

Warning banners and flash lights : NYM-J 5 x 1,5 mm2

Limit value K1, K2, K3 : NYM-O 9 x 1,5 mm2

Fault K4 : NYM-O 3 x 1,5 mm2

ADOS GmbH MWS 897 Page 10

Drawing no. 890-5622/e : MWS 897 with sensor GTR 196

Drawing no. 890-5622/f : MWS 897 with sensor ITR 498

7. Terminal schematic

ADOS GmbH MWS 897 Page 11

Drawing no. 890-5622/g : MWS 897 with sensor ADOS 592 TOX

Drawing no. 890-5622/h : MWS 897 with sensor LCTR 903

ADOS GmbH MWS 897 Page 12

Drawing no. 890-5622/c : MWS 897 24V DC

Drawing no. 890-5622/d : MWS 897 USV

ADOS GmbH MWS 897 Page 13

Drawing no. 890-5622/i : MWS 897 230V with UPS 2000

Table of contents

Other Ados Security Sensor manuals