3. Insert the TRDDB into its designated slot ensuring the edge connector seats firmly into the backplane.

4. After insertion the TRDDB will run a self-test and synchronization phase during which all LEDs

undergo an On/Off sequence. Refer to Status LEDs for descriptions.

5. After synchronization, which may take up to 90 seconds, the following LED indication will show:

■SYNC LED - Green

■All other LEDs will be Off until network occurrences cause them to turn On.

If LEDs in step 5 are as noted, proceed with loop testing per specifications.

If LEDs in step 5 are in any other configuration, refer to TROUBLESHOOTING GUIDE.

Hardware vs Software Provisioning

When SW1 is used for option selection those options take effect when the card is first inserted in the

channel bank. Subsequent software provisioning can override hardware options. Depressing the AP

pushbutton will toggle between the hardware and software option set. Option changes to either set can

be made when the set is active or inactive.

Typical Multipoint Deployment

CONTROL PORT OPERATION

The TRDDB can be remotely controlled via the craft interface on the TROCU-R. The terminal interface

operates at baud rates from 1.2 to 19.2 kbps, asynchronous, 8 data bits, no parity, and one stop bit.

Terminal sessions provide access to screen menus for the following:

■Provisioning

■Testing

■Performance Monitoring

Upon terminal connection, depress the space bar three times to access screens. Directions on the screens

guide craft personnel through the various menus.

Remote Provisioning and Diagnostics

The TRDDB responds to or supports the following:

■ADTRAN Digital System 6 Message Protocol.

■TPI 108/109 and 105 portable test sets.

■Hekimian React 2001 Release 1.900.

■ANSI Standard T1.107-1995 “Digital Hierarchy Format Specifications Annex G”.

TROUBLESHOOTING GUIDE

No Power at the TROCU-R

■Ensure TRDDB is supplying necessary voltage to power the TROCU-R. Measure T/R voltage at the

frame (Tip to Ground = -130 Vdc or less depending on voltmeter impedance, Tip to Ring = -125 to

-130 Vdc, ring to ground = 0). The Total Reach DDS system is not polarity sensitive.

■If no voltage is measured at the TRDDB, replace the unit.

■Remove the TROCU-R from the housing. Measure T/R voltage at the T200 mounting. Tip to Ring =

-125 to -130 Vdc.

■If voltage is not present at the TROCU-R, check continuity of cable pair.

■If voltage is measured at the TROCU-R, replace the unit.

JOBAID

61291004L2-22A

0009

D4 TRDDB

CLEI: D4C4EEHB_ _

D4 TOTAL REACH DDS (TRDDB)

FRONT PANEL OPERATION & FEATURES

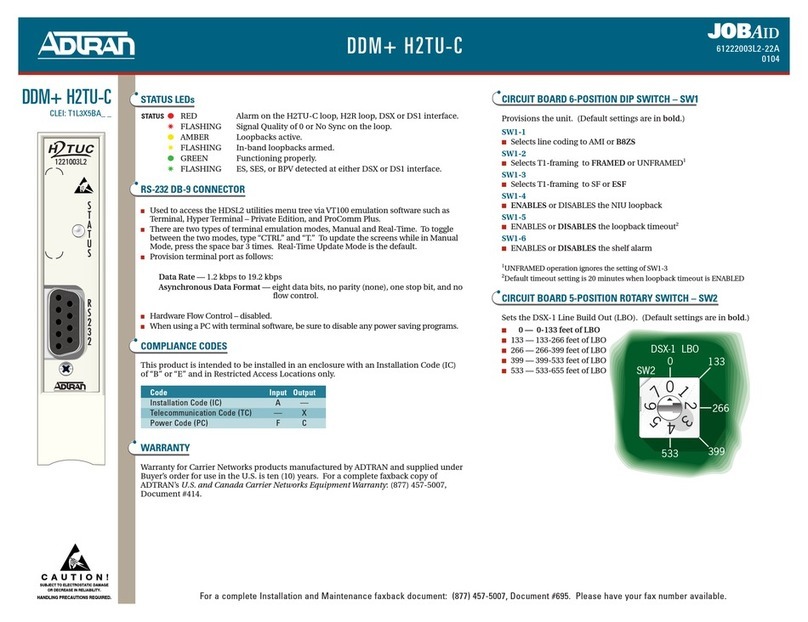

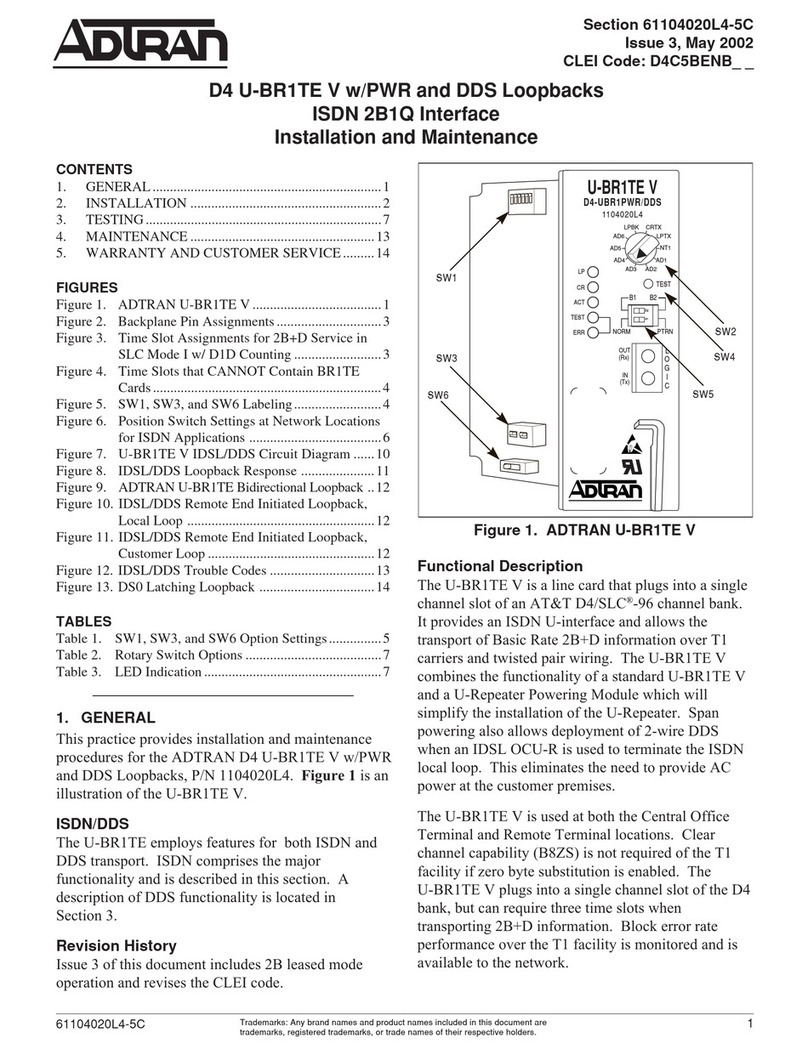

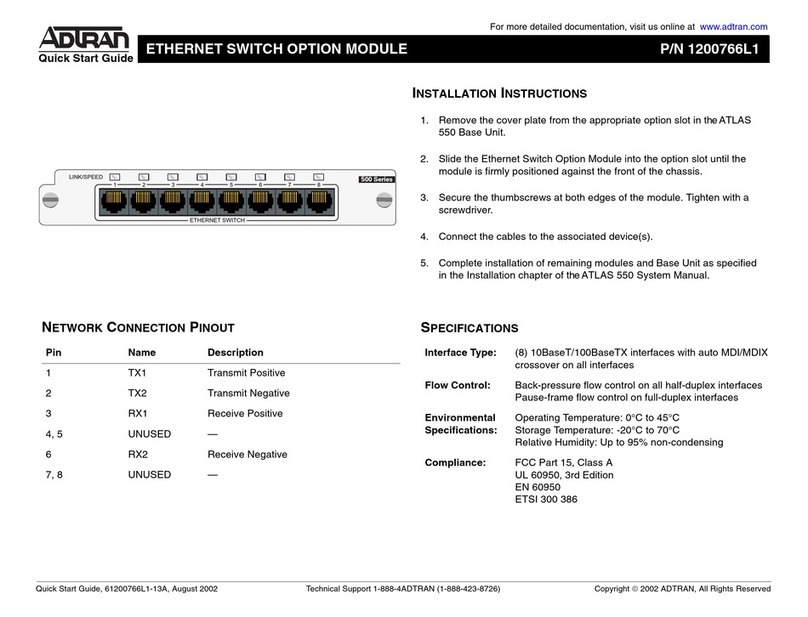

Status LEDs

NO SX ●On No sealing current on local loop.

✷Flashing Short circuit on 2-wire loop.

SYNC ●Green Loop synchronized.

●Red Loop not synchronized.

CRC ●On Errors on 2-wire loop.

QM DISC ●On Quality Monitor Disconnect occurred.

REM ●On Software option set in effect.

✷Flashing Remote control link active.

●●Off Hardware option set in effect.

NO DSU ●On Customer CSU/DSU not detected/installed.

LBK ●On DS0, OCU, or CSU loopback exists.

✷Flashing TRDDB in loopback towards customer.

NOTE: All LEDs OFF indicates loss of power or other malfunction.

Front Panel DIP Switch SW1

Dip switch SW1 options should be made prior to installing the TRDDB circuit card.

SW1-1 - Latching Loopback On Responds to DS0 latching loopback (LLBK) sequences.

Translates OCU & CSU LLBK to TROCU-R

SW1-2 - Quality Monitor On TRDDB monitors incoming 2-wire loop and 4-wire

customer interface for errors. Excessive errors cause a

trouble code to be sent to the network: ASC (4-wire

errors) or alternating MOS and ASC (2-wire errors)

SW1-3 - 2.4 On Selects 2.4 kbps data rate

SW1-4 - 4.8 On Selects 4.8 kbps data rate

SW1-5 - 9.6 On Selects 9.6 kbps data rate

SW1-6 - 19.2 On Selects 19.2 kbps data rate

SW1-7 - 56 On Selects 56 kbps data rate

SW1-8 - 64 On Selects 64 kbps data rate

SW1-9 - SC On Enables secondary channel

NOTE: At 64 kbps LLBK is automatically enabled. SW1-1 then controls LLBK protection:

Off enables and On disables LLBK protection.

Front Panel AP Pushbutton SW2

Depressing the Alternate Provisioning pushbutton for five seconds will toggle between hard-

ware and software option settings. The REM LED shows which set is in effect.

Front Panel Bantam Jacks

Logic level Bantam jacks provide access to the transmit and receive sides of the data stream

for testing with a portable test set.

DEPLOYMENT GUIDELINES

■All loops must be non-loaded.

■Maximum Loop Loss measured at a Nyquist of 13.3 kHz is 50 dB AML or 47 dB EML

(135 Ωtermination).

■Maximum Loop Loss measured at a Nyquist of 28 kHz is 65 dB AML or 62 dB EML

(135 Ωtermination).

■Bridged tap length should not exceed 12 kft.

■Background noise level should not exceed 34 dBrn.

■Impulse noise should not exceed -40 dBm (+50 dBrn).

INSTALLATION & TURN UP

Installation assumes the TROCU-R is installed.

1. Wire 2-wire loop to T/R pair, pins 24 and 51 of the D4 backplane. Connect the DS0 input

pair to the MA/MB pair, pins 46 and 48, and the DS0 output pair to the EA/EB pair, pins

45 and 19.

2. Select required/desired options on SW1.