Advanced AS4000 User manual

AS600 - 2018

IRON SLIDER

BEAM ANCHOR

Instruction Manual

INSTRUCTION MANUAL

AS4000 - Iron Slider Beam Anchor

Manual Rev:

AS600R1.3 - 2018

Acopy of this manual must beavailable tousers at all times. Please contact

Advanced Safety for the latest user instruction manual based on date of

manufacture.

UNDER PENALTY OF LAW - IMPORTANT

This manual must be read and understood in its entirety, and used as part of a fall

protection training program, as required by OSHA or any state/local regulatory

agencies. User must read and fully understand the limitations and proper use of the

equipment. All users must be properly trained by their employer prior to use, per

OSHA 29 CFR 1910.66, 29 CFR 1926.503, and applicable local standards.

When used in accordance with instruction specifications, this product meets or

exceeds all applicable OSHA 1926 and ANSI A-10.32-2012 standards for fall

protection. Applicable standards and regulations depend on the application, along

with some state-specific regulations. Consult regulatory agencies for more

information on personal fall arrest systems and associated components.

User Instruction Manuals must always be available to the user of the equipment.

WARNING

Misuseorfailuretofollowwarnings,instructions,andlimitations

ontheuseofthisequipmentmayresultinseriouspersonal

injuryordeath.Forfurtherinstructionsaboutproperuse,refertoasupervisor

orcontact Advanced Safety Solutions, Inc at 1-844-657-1750.

WARNING

•

Use 900 Maximum Average Arrest force (MAAF) ANSI certified energy absorber

lanyard or Leading Edge Self-Retracting Lanyard (SRL-LE). For applications where

anchor point is below the D-Ring connection only use

appropriately rated energy

absorbing lanyards or self-retracting devices.

If you are unsure of compatibility,

please contact manufacturer prior to use of

any fall arrest or restraint equipment.

•

Employees shall be trained in accordance with the requirements of OSHA 29 CFR

1910.66: safe use of the system and its components.

•

Inspect all PFAS equipment prior to each use. Remove defective

equipment immediately.

•

Thoroughly evaluate and plan all elements of PFAS before using it. Calcu- late fall

clearance and swing fall clearance. When calculating distance, be

sure to consider:

•

Deceleration Distance

•

Movement of Harness Attachment (D-Ring)

•

Free-Fall Distance

•

Worker Height

•

Anchorage Connector Elevation

•

Length of Connecting Subsystems

•

Length of D-Ring Connector

•

Length of Full Body Harness Stretch

Do not alter or intentionally misuse this equipment.

COMPATIBILITY LIMITATIONS

Anchorage connector must only be coupled to compatible connectors. OSHA 29 CFR 1926.502 prohibits

snaphooks from being engaged to certain objects unless two requirements are met: it must be a locking type

snaphook, and it must be“designed for” making such a connection. “Designed for” means that the

manufacturer of the snaphook speci

fi

cally designed the snaphook to be used to connect to the equipment

listed. The following connections must be avoided, because they can result in rollout* when a nonlocking

snaphook is used:

•

Direct connection of a snaphook to horizontal lifeline.

•

Two (or more) snaphooks connected to one D-ring.

•

Two snaphooks connected to each other.

•

A snaphook connected back on its integral lanyard.

•

A snaphook connected to a webbing loop or webbing lanyard.

•

Improper dimensions of the D-ring, rebar, or other connection point in relation to the snaphook

dimensions that would allow the snaphook keeper to be depressed by a turning motion of

the snaphook.

*Rollout: A process by which a snaphook or carabiner unintentionally disengages from another

connector or object to which it is coupled. (ANSI Z359.1-2007)

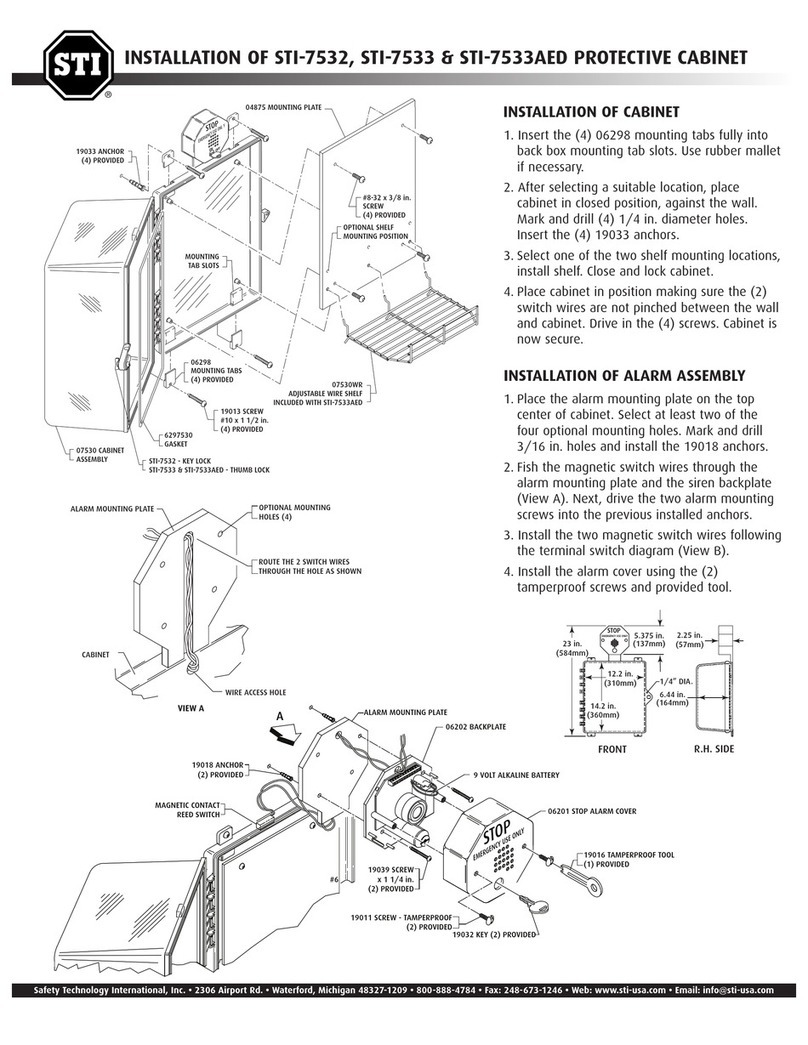

Installation:

1.

Locate a structural steel beam flange capable of withstanding a 5,000-lbf. static load or meeting OSHA

1926.502 requirements for a safety factor of two.

2.

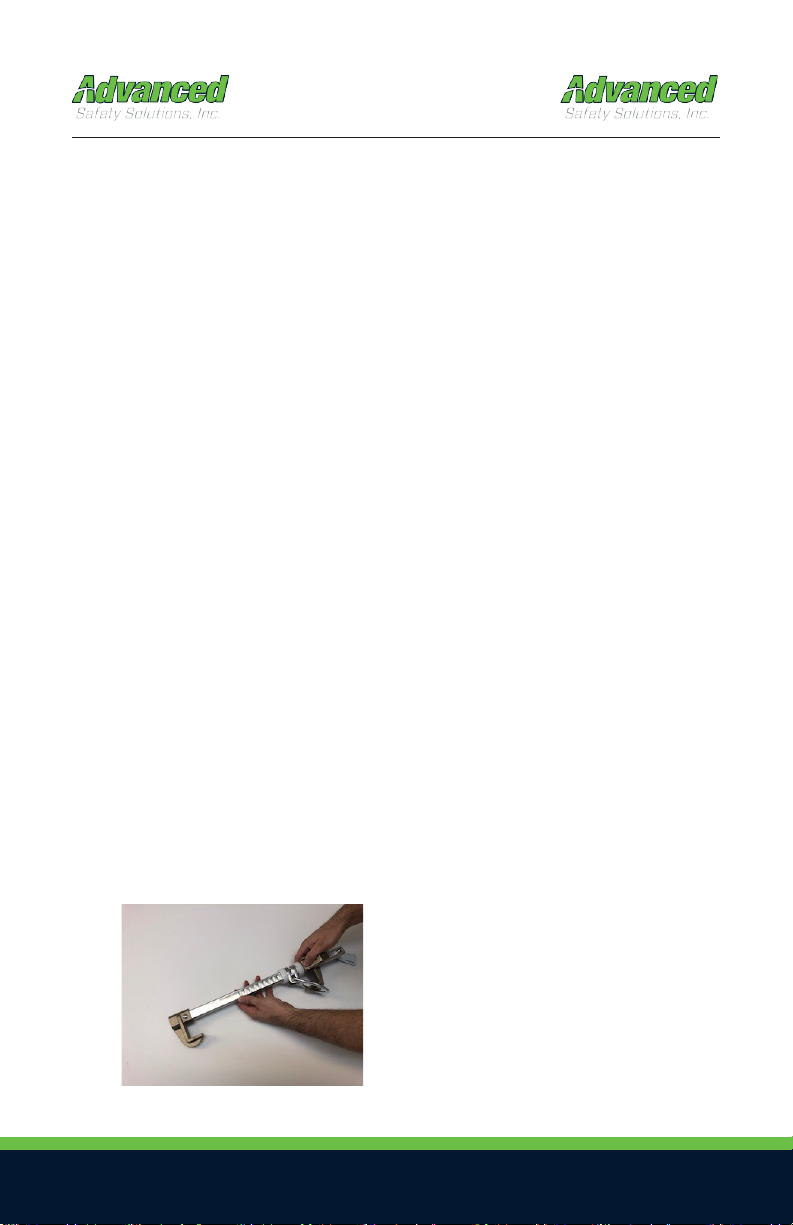

Push in on the latch handle to allow the adjustable hook to move. (fig:1-A)

3.

Keeping the unit perpendicular to the beam, fit the hooks over the edges of the beam flange.

4.

Slide the adjustable hook so that both hooks are snug against the beam flange.

5.

Pull back the adjustable hook to ensure the ratchet teeth are fully seated in the nearest ratchet

notches.

6.

Tug, rock, and twist the anchor in all directions to ensure that it cannot come off of the flange.

*Always re-adjust according to steps 1-6, above when moving to a new or different size beam.

Placement at or below a user’s working height requires integration of a compatible ANSI 359.1 shock-

absorbing lanyard that does not allow the user to extend more than 6 feet (in any direction) from the anchorage

connector before the shock absorber is activated. The beam anchor must be attached to the I-beam flange facing

the user (top flange if worker is above, bottom flange if worker below or underneath the flange, etc.).

fig: 1-A

Beam Flange Width Range: 3.5”-14”

Beam Flange Thickness: .25“ to 1.25”

PERFORMANCE:

Static Tensile Strength: 5000-lbf (22kN)

Maximum Capacity: one worker with max

weight of 310-lbs when used as a single

point anchorage connector for personal fall

arrest or restraint system.

Inspection:

Official periodic inspection must be made at least annually. The inspection must be performed by

a qualified person other than the intended user. If severe weather or conditions exist then

inspections must be carried out more frequently. All inspection results must be logged in the space

provided above. (It is recommended that the anchor device is marked with the date of the next or

last inspection.)

1.

Make sure all labeling is affixed to the unit.

2.

Inspect anchoring system for signs of damage or wear.

3.

Make sure the ring is free to swivel and pivot.

4.

Check for excessive play and wear on the retaining bushing

(Bushing should not wiggle or rotate.)

5.

Insure latches engage and disengageproperly.

6.

Record inspection results in the space provide above.

*If any damage that could affect the strength or operation of the device, or unsafe conditions are

found, proper disposal is required. The anchorage connector must be rendered unusable and

then properly discarded.

fig 2-A

Make sure tags are attached

and legible with original

markings.

Make sure rivets are void of

cracks and are fully seated,

flush with end piece.

Make sure Iron Slider bar is

free from burs and

deformation that would

impede the Iron Sliders

movement.

Compliance:OSHA 1926.502 & 1910.66 / ANSI Z359.1, ANSI Z359.7

CE 0321 / EN 795:1996 (+A1:2000) Class B

Stainless Steel, Aluminum, Zinc Plated Steel, Bronze

WARNING!!!

ALL PERSONS USING THIS EQUIPMENT MUST READ AND UNDERSTAND ALL

INSTR UCTI ONS.

FAI LUR E TODOSOMAY RESU LTI N SER IOUS INJ URY OR DEAT H. USERS SHOULD BE FAMI LIAR

WITH PERTINENT REGULATIONS GOVERNING THIS EQUIPMENT. ALL INDIVIDUALS WHO USE

Max Capacity 310-lbs

DO NOT REMOVE

•

There must be sufficient clearance below the anchorage connector to arrest a fall

before the user strikes the ground or an obstruction. When calculating fall clearance,

account for or a Minimum three-foot safety factor, deceleration distance, user height,

length of lanyard/SRL, and all other applicable factors.

•

This equipment is designed to be used in temperatures ranging from

-40°F to +130°F(-40°C - +54°C).

•

Do not expose this equipment to chemicals or harsh solutions that may

have a

harful effect.

•

All synthetic material must be protected from slag, hot sparks, open flames, or other

heat sources. The use of heat resistant materials is recommended in these

applications.

•

Allowable worker weight limit (including all tools and equipment) is 130–

310 pounds unless otherwise stated on the label or instructions.

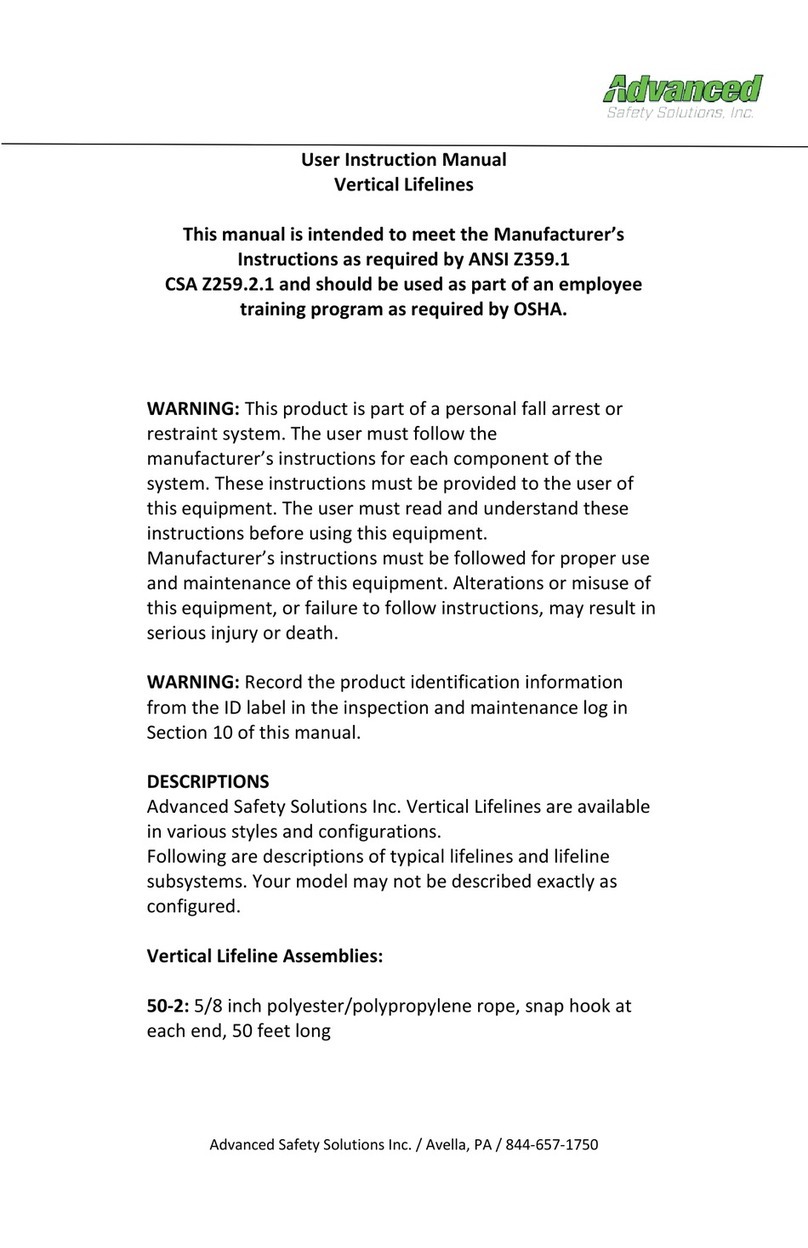

Components and Specifications

Rating: 5,000 lb. static load (minimum

breaking strength).

Materials:

High Strength Bar: Aluminum.

Clamp (Adjustable Versi-Clamp and Fixed

End):

Bronze manganese, or

zinc-plated steel.

D-ring: Zinc-plated steel. Internal

Springs: Stainless steel.

.Meets all ANSI and OSHA standards

Fixed

End Clamp

Nylon

Rollers

High Strength

Aluminum Bar

Sliding D-ring with

Impact Indicator

Adjustable

Versi-Clamp

Labels

CONNECTOR COMPATIBILITY LIMITATIONS

Advanced Safety’s equipment must be combined only to compatible connectors that are

suitable to your application. Ensure all connections are compatible in size, shape and

strength. Ensure all connectors are fully closed and locked. OSHA 29 CFR 1926.502

prohibits the use of snap hooks to engage and attach to objects unless the following

requirements are met:

•

Snap hook must be a locking type snap hook.

•

Snap hook must be explicitly designed for such a connection. “Designed for” means

that the manufacturer of the snap hook specifically created the snap hook to be used

to connect to the equipment in question and for personal fall protection equipment.

Use of a non-locking snap hook can result in rollout (a process by which a snap hook or

carabiner unintentionally disengages from another connector or object to which it is

coupled. ANSI Z359.0- 2007). Advanced Safety’s connectors (snap

hooks and carabiners) are designed to be used only as specified in each product’s user’s

instructions.

Avoid the following types of connections:

•

Connection of two (or more) snap hooks or carabiners to one D-ring.

•

Connection of a snap hook back to its integral lanyard or tied into itself unless

otherwise specifically designed.

•

Direct connection of a snap hook to horizontal lifeline. Connect only to O-rings supplied

by manufacturer.

•

Connection in a manner that results in a load on the gate. NOTE: Large throat opening

snap hooks should not be connected to standardsize

•

D-rings or similar objects, as such use will result in a load on the gate if the hook or

D-ring twists or rotates. Large throat snap hooks are designed for use on structural

elements such as rebar or cross members that are not shaped in such a way that they

may capture the gate of the hook.

•

Connection to snap hooks or carabiners. Two snap hooks or carabiners locked to

one another.

•

Direct connection to webbing lanyard, webbing loop, rope lanyard or tie-back (unless

the manufacturer’s instructions for both the lanyard and connector specifically allow

such a connection).

•

Connection of a snap hook to a D-ring, rebar, or other connection point of improper

dimensions in relation to the snap hook dimensions or configurations that could cause

the snap hook keeper to be depressed by a turning motion of the snap hook, or such

that snap hook or carabiner will not fully close and lock, or that roll-out could occur.

Illustration 2 depicts examples of inappropriate connections:

Illustration 2: Inappropriate Connections

Swing Falls:

Minimize swing fall by working as directly below the anchorage point as possible. Worker

movement should remain within 30 degrees maximum deflection of the lifeline from the

vertical line directly below the anchorage point.

Do not permit a swing fall if injury could occur.

Sharp Edges:

Avoid working where sharp edges may contact the lifeline. Provide sufficient protective

padding if avoiding sharp edges is notpossible.

Corrosive Environment:

Extensive exposure to environments where corrosion may occur will damage metal parts in

the Self-Retracting Lifeline. Use caution when working around corrosive compounds such

as ammonia, sewage, fertilizers, sea water or other corrosives.

Chemical Hazard, High Heat and Severe Cold:

Use extreme caution in environments containing acid or caustic chemicals, particularly at

elevated temperatures, as chemical damage that can impair the functionality of the PFAS is

difficult to detect. Do not use the Multi-Direction Anchor Plate in high-heat environments. Hot

sparks and slag can damage the equipment and impair functionality.

Electrical Hazards:

Use extreme caution to avoid contact with high voltage power lines. Both web and wire

cable model Self-Retracting Lifelines may conduct electricity. Moisture absorbed by the

lifeline can provide a path for electrical current to flow, resulting in potential electrical shock.

Locking Speed:

Use extreme caution when working on low-pitched roofs where a worker may slide, rather

than fall.

Fall Clearance:

Consider the following when calculating fall clearance. Clearance required is dependent

on the following factors:

•

Elevation of Anchorage

•

Connecting Subsystem Length

•

Deceleration Distance

•

Free Fall Distance

•

Worker Height

•

D-ring / connector length

•

Movement of Harness Attachment Element

•

Length of Full Body Harness (FBH) Stretch

•

Working Level

Fall Clearance Considerations

A.

Connecting Subsystem(sEnergy Absorbing Lanyard

shown) Length + Movement of Harness Attachment

+ Length of FBH Stretch

B.

Working Level (thickness)

C.

Worker Height + Connector Length

D.

Free Fall - 6 ft. Max. (per ANSI Z359.1)

E.

Deceleration Distance

F.

Total Fall Distance: Sum of A through E

G.

Lower Level or Obstruction

6 ft. Free Fall Lanyard Example

If there is a risk of a fall or if the only anchorage point is below the attachment points on the

harness, it is essential to use a lanyard provided with an energy absorber.

Before using a shock absorbing lanyard, ensure that there is sufficient fall clearance below the

user to prevent any collision with the structure or the ground. If you are

tying off at your feet

with the AS600 Iron Slider, you must factor in a total clearance of up

to 21.5ft. from where you are

tied off at with the AS600.

Note: Owner is to have a written rescue plan and the means to implement it. System is to

be used for fall protection only. Any other use voids the warranty and renders the system

unusable. Always perform a hazard analysis before use that will identify impact and swing

hazards, or any other hazards that may exist. Address and correct all hazards before use.

Always use the buddy system when using fall protection (the monitor or “buddy” does not

need to be physically on the system, just nearby, supervising).

Never add additional carabiners, D-Rings, shackles, or connecting hardware to this system. If

connecting hardware must be added, compatibility must be verified by a competent person.

CLEANING AND MAINTENANCE

Cleaning after use is important for maintaining the safety and longevity of the Multi-

Directional Anchor Plate. Remove all dirt, corrosives, and contaminants from the Iron Slider

AS600 before and after each use. If the AS600 cannot be cleaned with plain water, use mild

soap and water, then rinse and wipedry.

NEVER clean the Iron Slider AS600 with corrosive substances. When not in use, store the

equipment where it will not be affected by heat, light, excessive moisture, chemicals, or other

degrading elements.

INSPECTION LOG

Date of Manufacture:

Model Name/#:

Serial:

Date of First Use:

Inspection Date

Items Noted

Corrective Action

Approved By

WARRANTY

THE FOLLOWING IS MADE IN LIEU OF ALL WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

Equipment offered by Advanced Safety is warranted against factory defects in workmanship

and materials for a period of one year from date of installation or first use by the original

owner. LIMITED REMEDY: Upon notice in writing, Advanced Safety will repair or replace all

defective items at Advanced Safety’s sole discretion. Advanced Safety reserves the right to

require that the defective item be returned to its plant for inspection before determining the

appropriate course of action.

Warranty does not cover equipment damage resulting from wear, abuse, damage in transit,

failure to maintain the product or other damage beyond the control of Advanced Safety.

Advanced Safety shall be the sole judge of product condition and warranty options. This

warranty applies only to original purchaser and is the only warranty applicable to this

product. Please contact Advanced Safety customer service department for assistance.

LIMITATION OF LIABILITY: IN NO EVENT WILL ADVANCED SAFETY BE LIABLE FOR ANY

INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT

NOT LIMITED TO LOSS OF PROFITS, IN ANY WAY RELATED TO THE PRODUCTS

REGARDLESS OF THE LEGAL THEORY ASSERTED.

Table of contents

Other Advanced Safety Equipment manuals