Advanced Lifeline 50-2 Operator's manual

User Instruction Manual

Vertical Lifelines

This manual isintended tomeet the Manufacturer’s

Instructions as required byANSI Z359.1

CSA Z259.2.1 andshould beused as part ofan employee

training program as required by OSHA.

WARNING: This product is part of a personal fall arrest or

restraint system. The user must follow the

manufacturer’s instructions for each component ofthe

system. These instructions must be provided to the user of

this equipment. The user must read and understand these

instructions before using this equipment.

Manufacturer’s instructions must be followed forproper use

and maintenance ofthis equipment. Alterations ormisuse of

this equipment, orfailure tofollow instructions, may result in

serious injury or death.

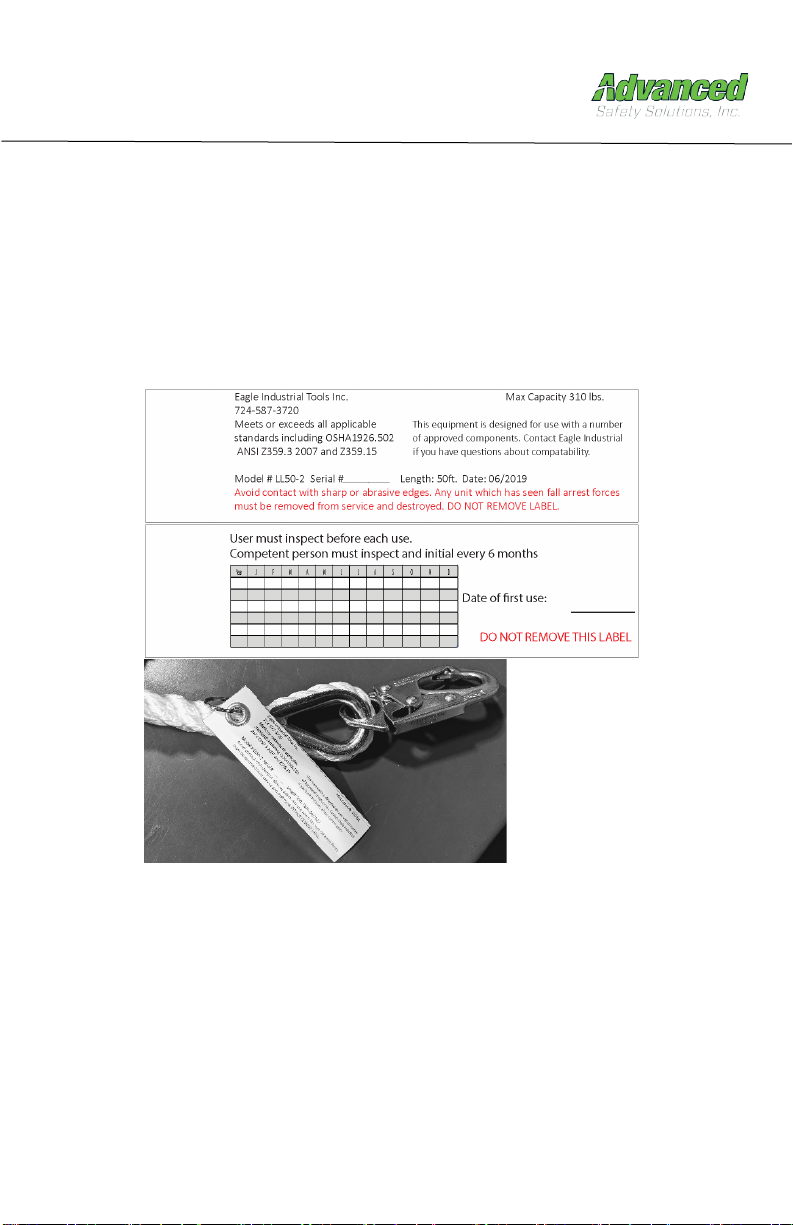

WARNING: Record the product identification information

from the ID label in the inspection and maintenance log in

Section 10 of this manual.

DESCRIPTIONS

Advanced Safety Solutions Inc. Vertical Lifelines are available

invarious styles and configurations.

Following are descriptions oftypical lifelines and lifeline

subsystems. Your model may not be described exactly as

configured.

Vertical Lifeline Assemblies:

50-2: 5/8 inch polyester/polypropylene rope, snap hook at

each end, 50feet long

Advanced Safety Solutions Inc. / Avella, PA/844-657-1750

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

75-2: 5/8 inch polyester/polypropylene rope, snap hook at

each end, 75 feet long

100-2: 5/8 inch polyester/polypropylene rope, snap hook at

each end, 100 feet long

Rope Materials:

5/8 inch diameter, polyester/polypropylene rope

Applications

Purpose: Vertical lifelines are intended to be used as part of

a personal fall arrest or restraint system. These lifelines are

not designed for use in horizontal lifeline systems.

Applications include: Inspection work, construction,

demolition, maintenance, oil production, confined space

rescue, window washing.

A.FALL ARREST: The lifeline or lifeline subsystem is used as

part of a complete fall arrest system, which

typically includes a lifeline, rope grab, lanyard, and full body

harness. Maximum permissible free fall is 6 ft. (1.8 m).

B.RESTRAINT: The lifeline or lifeline subsystem is used as

part of a restraint system. Restraint systems typically include

a full body harness and a lanyard to prevent the user from

reaching a fall hazard (leading edge roof work). No vertical

free fall permitted.

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

LIMITATIONS: Consider the following application limitations

before using this equipment:

A.CAPACITY: This equipment is designed for use by persons

with a combined weight (person, clothing, tools, etc.) of no

more than 310 lbs. (141 kg). No more than one person may

be connected to a single lifeline.

B.FREE FALL: Personal fall arrest systems used with these

lifelines must be rigged to limit the free fall to 6 ft. (1.8 M)

(according to ANSI Z359.1). Restraint systems must be rigged

such that there is no possible vertical free fall.

C.FALL CLEARANCE: Ensure that adequate clearance exists in

your fall path to prevent

striking an object. The amount of clearance required is

dependent on the type of connecting

subsystem (rope grab, lanyard), the anchorage location, and

the amount ofstretch in the

lifeline. See subsystem manufacturer’s instructions formore

information.

D. ENVIRONMENTAL HAZARDS: Use of this equipment in

areas where environmental hazards

exist may require additional precautions toreduce the

possibility of injury to the user or

damage tothe equipment. Hazards may include, but are not

limited to; high heat, caustic

chemicals, corrosive environments, high voltage power lines,

explosive ortoxic gases, moving machinery, orsharp edges.

F. TRAINING: This equipment is intended to be used by

persons trained in itscorrect

application and use.

APPLICABLE STANDARDS: Refer to national Standards

including ANSI Z359 (.0, .1, .2, .3, and .4) family ofstandards

on fall protection, ANSI Z359.15, ANSI A10.32, CSA Z259.2.1,

and applicable local, state and federal (OSHA) requirements

governing occupational safety for more information about

work positioning systems.

SYSTEM REQUIREMENTS

COMPATIBILITY OF COMPONENTS: Advanced Safety

Solutions Inc. equipment isdesigned for usewith a number of

approved components. Substitutions orreplacements made

with non-approved components may jeopardize compatibility

of equipment and mayaffect the safety and reliability of the

complete system.

IMPORTANT: The type oflifeline used is dependent upon the

application and compatibility requirements ofother system

Advanced Safety Solutions Inc. / Avella, PA/844-657-1750

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

components. Contact Advanced Safety if you have any

questions about compatibility.

COMPATIBILITY OF CONNECTORS: Connectors are

considered to be compatible with

connecting elements when they have been designed to work

together in such a way that their sizes and shapes do not

cause their gate mechanisms to inadvertently open

regardless of how they become oriented. Contact Advanced

Safety if you have any questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capable

of supporting at least 5,000 lbs. (22kN). Connectors must be

compatible with the anchorage orother system components.

Do notuseequipment that is not compatible. Non-

compatible connectors may unintentionally disengage.

Connectors must be compatible in size, shape, and strength.

Self-locking snap

hooks and carabiners are required by ANSI Z359.1 and OSHA.

MAKING CONNECTIONS: Only use self-locking snap hooks

and carabiners with this equipment. Only use connectors

that are suitable toeach application. Ensure all connections

are compatible in size, shape and strength. Donotuse

equipment that isnot compatible. Ensure all connectors are

fully closed and locked.

Advanced Safety connectors (snap hooks andcarabiners) are

designed to be used only as specified ineach product’s user’s

instructions. Advanced Safety snap hooks andcarabiners

should not be connected:

A.To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

NOTE: Large throat opening snap hooks should not be

connected to standard size D-rings or similar objects which

will result in a load on the gate if the hook or D-ring twists or

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

rotates. Large throat snap hooks are designed for use on fixed

structural elements such as rebar or cross members that are

not shaped in a way that can capture the gate of the hook.

C. In a false engagement, where features that protrude from

thesnap hook or carabiner catch on the anchor and without

visual confirmation seems to be fully engaged to the anchor

point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the

manufacturer’s instructions for both the lanyard and

connector specifically allow such a connection).

F. To any object which is shaped or dimensioned such that

the snap hook or carabiner will not close and lock, or that

roll-out could occur.

G. In a manner that does not allow the connector to align

properly while under load.

ANCHORAGE STRENGTH: The anchorage strength required is

dependent upon the

application:

A.FALL ARREST: In accordance with ANSI Z359.1, anchorages

selected for fall arrest systems shall have a strength capable

of sustaining static loads applied in the directions permitted

by the system of at least:

• 5,000 pounds (22.2 kN) for non-certified anchorages; or,

• Two times the maximum arresting force for certified

anchorages.

When more than one fall arrest systems is attached to an

anchorage, the applicable strength requirement should be

modified by the number of systems attached to the

anchorage. Per OSHA 1926.500 and 1910.66: Anchorages

used for attachment of personal fall arrest systems shall be

independent of any anchorage used to support or suspend

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

platforms and capable of supporting at least 5,000 pounds

(22.2 kN) per attached user; or, be designed, installed, and

used as part of a complete PFAS which maintains a safety

factor of at least two and is under the supervision of a

qualified person.

B. RESTRAINT: Anchorages selected for restraint and travel

restraint systems shall have a

strength capable of sustaining static loads applied in the

directions permitted by the system of at least:

•1,000 pounds (4.5 kN) for non-certified anchorages; or,

• Two times the foreseeable force for certified anchorages.

When more than one fall arrest systems is attached to an

anchorage, the applicable strength requirement should be

modified by the number of systems attached to the

anchorage.

OPERATION AND USE

WARNING: Do not alter or intentionally misuse this

equipment. Consult Advanced Safety Solutions Inc. when

using this equipment in combination with components or

subsystems other than those described in this manual. Some

subsystem and component combinations may interfere with

the operation of this equipment. Use caution when using this

equipment around moving machinery, electrical hazards,

chemical hazards, and sharp edges.

WARNING: Consult your doctor if there is reason to doubt

your fitness to safely absorb the shock from a fall arrest. Age

and fitness seriously affect a worker’s ability to withstand

falls. Pregnant women or minors must not use Eagle

Industrial Tools Vertical Lifelines or subsystems.

BEFORE EACH USE of this equipment, carefully inspect it

according to steps listed in section 5.0 of this manual.

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

PLAN your fall arrest or restraint system before using this

equipment. Consider all factors that will affect your safety

during use of this equipment. Consider the following points

when planning your system:

A. ANCHORAGE: Select a rigid anchorage point that is capable

of sustaining the loads specified in section 2.3. For fall arrest

applications, select anchorage locations that will minimize

free fall and swing fall hazards. For restraint applications,

locate the anchorages such that no vertical free fall is

possible.

B. FREE FALL: To avoid increased free fall distance, do not

work above the anchorage level. Rig personal fall arrest

systems so that the free fall is limited to 6 ft. (1.8 m) (ANSI

Z359.1). Rig restraint systems such that no vertical free fall is

possible.

C. FALL ARREST FORCES: The personal fall arrest system must

limit fall arrest forces to 1,800 lbs. (8 kN). And deceleration

distance must not exceed 42 in. (1 m). Do not use a body belt

for fall arrest applications.

D. SWING FALLS: Swing falls occur when the anchorage point

is not directly above the point where a fall occurs. The force

of striking an object in a swing fall may cause

serious injury. Minimize swing falls by working as directly

below the anchorage point as possible. Do not permit a swing

fall if injury could occur.

E. FALL CLEARANCE: Ensure sufficient clearance exists in your

fall path to prevent striking

an object during a fall. The clearance required is dependent

upon the subsystem (rope grab

and lanyard, rope grab and carabiner) and lifeline properties.

Synthetic rope is subject to elongation, or stretch. As the

distance between the anchorage and the grab increases, the

portion of the vertical lifeline that is subjected to loads

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

increases, thereby increasing the effects of elongation.

Elongation can be as much as ten percent for rope in wet

conditions. Consideration of elongation must be considered

when estimating fall clearance distances. The Table below

shows the approximate elongation for new lifelines in dry

conditions. The elongation specified is for an applied static

load of 900 lbs. (4 kN). Wet ropes generally have more

elongation than dry ropes. Allow for additional elongation in

wet or humid conditions

Lifeline Elongation

Lifeline

Material

25F

t.

50F

t.

75F

t.

100

Ft.

150

Ft.

200

Ft.

250

Ft.

300

Ft.

5/8”Polye

ster

Polypropy

lene

2.5

Ft.

5Ft

.

7.5

Ft.

10Ft

.

15Ft

.

20Ft

.

25Ft

.

30Ft

.

F.SHARP EDGES: Avoid working where your lifeline, lifeline

subsystem, or other system

components will be in contact with, or abrade against,

unprotected sharp edges. Do not loop

a lifeline around small diameter structural members. If

working with this equipment around

sharp edges is unavoidable, provide protection by using a

heavy pad over the exposed sharp edge.

G.RESCUE: The employer must have a rescue plan and the

ability to implement it.

H.AFTER A FALL: Components which have been subjected to

fall arrest forces must be

removed from service and destroyed.

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

I. GENERAL USE CONSIDERATIONS: Avoid working where

your lifeline may cross or tangle

with that of another worker. Do not allow your lifeline to pass

under your arms or between

your feet.r

MAKING CONNECTIONS When using a hook to connect

components or to an anchorage, ensure roll-out cannot

occur. Self-locking snap hooks and carabiners should be used

to reduce the possibility of roll-out. Do not tie a knot in the

lifeline. Do not attach a snap hook directly to a horizontal

lifeline. Follow manufacturer’s instructions for each

component of the system.

All lifelines either have a self-closing and self-locking snap

hook pre-installed in a thimbled eye at the both ends of the

lifeline or for lifelines with snap hook only on the anchorage

end a thimbled eye will be spliced on the non-anchorage end

to prevent the fall arrester from inadvertently traveling off

the end of the lifeline. Attach the self-closing self-locking snap

hook or carabiner to the anchorage. Attach a minimum five-

pound counter weight to the non-anchorage end to maintain

a taut line. Let the non-anchorage end hang freely. If the rope

passes over an edge of any kind, or any type of rough or

uneven surface, provide abrasion protection.

5 –

A. CONNECTING TO AN ANCHORAGE OR ANCHORAGE

CONNECTOR: Lifelines or

Lifeline subsystems supplied with connecting hooks should be

connected to the anchorage

in accordance with section 3.3. Lifelines supplied without

hooks must have a hook or anchorage connector spliced

directly to the lifeline Connectors attached to synthetic rope

lifelines must be attached using a spliced eye termination and

thimble. The splice must be made with 5 tucks. The

connection must support 5,000lbs.

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

Fall

IMPORTANT: Knots must notbe used for load bearing end

terminations.See ANSI Z359.1.

Some knots reduce lifeline strength fifty percent ormore.

IMPORTANT: If the user splices orforms end terminations,

proper procedures must be followed to ensure compatibility

in size, shape, and strength. Advanced Safety Solutions Inc.

is notresponsible for subsystems notmanufactured by

Advanced Safety Solutions Inc.

B. CONNECTING ROPE GRAB TO LIFELINE: Follow the rope

grab manufacturer’s instructions

for connecting the rope grab tothe lifeline.

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

AFTER USE of this equipment, clean and store according to

section 6.0 of this manual.

TRAINING

4.1 It is the responsibility of the user to assure they are

familiar with these instructions, and are trained in the correct

care and use of this equipment. User must also be aware of

the operating characteristics, application limits, and the

consequences of improper use of this equipment. WARNING:

Training must be conducted without exposing the trainee to a

fall hazard. Training should be repeated on a periodic basis.

INSPECTION

• Before Each Use inspect according to steps listed in section

5.2.

• This Equipment must be inspected according to steps listed

in section 5.2 by a competent

person, other than the user, at least annually. Record the

results of each inspection in

the inspection and maintenance log in Section 10. NOTE:

Cal/OSHA requires personal fall

arrest systems be inspected prior to each use for wear,

damage, and defects and inspected

by a competent person1 at least twice a year, in accordance

with the manufacturer’s

recommendations, with inspection dates documented.

WARNING: If this equipment has been subjected to fall arrest

forces remove from service and destroy.

IMPORTANT: Extreme working conditions (harsh

environments, prolonged use, etc.) may require increasing

the frequency of inspections.

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

Step 1. Inspect lifeline hardware (snap hooks, ferrules,

thimbles, etc.). These items must not be damaged, broken or

distorted. These items must be free of sharp edges, burrs,

cracks,

worn parts, or corrosion. Hook gates must move freely and

lock upon closing.

Step 2. Inspect the lifeline per the following:

SYNTHETIC ROPE: Inspect rope for concentrated wear.

Material must be free of frayed

strands, broken yarns, cuts, abrasions, burns, and

discoloration. The rope must be free

of knots, excessive soiling, paint build-up, and rust staining.

Rope splices must be tight,

with five full tucks, and thimbles must be held firmly by the

splice. Check for chemical

or heat damage; indicated by brown, discolored, or brittle

areas. Check for ultraviolet

damage; indicated by discoloration and splinters and slivers

along the rope surface. All

of the above factors are known to reduce rope strength.

Damaged or questionable rope

should be replaced.

Step 3. Inspect labels. All labels must be present and fully

legible.

Step 4. Inspect each system component or subsystem

according to manufacturer’s instructions.

Step 5. Record the inspection date and results in the

inspection log in Section 10.

If inspection reveals an unsafe or defective condition,

remove equipment from service and destroy, or contact an

authorized service center for repair.

MAINTENANCE, SERVICING, STORAGE

Clean the lifeline with water and a mild detergent. Wipe

hardware dry with a clean, dry cloth and hang toair dry. Do

not force dry with heat. An excessive build-up of dirt, paint,

etc. may prevent the lifeline from working properly, and in

severe cases, weaken the rope.

Additional maintenance and servicing procedures must be

completed by and authorized service center. Authorization

must be in writing. Do not disassemble this equipment.

Store the lifeline in a cool, dry, clean environment, out of

direct sunlight. Avoid areas where chemical vapors may be

present. Thoroughly inspect the lifeline after extended

storage.

SPECIFICATIONS

LIFELINE SPECIFICATIONS: The Tensile strength of Advanced

Safety Solutions Inc. 5/8” diameter polyester/polypropylene

blend 3 strand rope is7000 lbs. The melting point is330

degrees Fahrenheit

HARDWARE SPECIFICATIONS: Snap Hook: Drop forged,

Carbon steel self-locking snap hook, 5,000 lbs. (22.2 kN).

Tensile strength.

Advanced Safety Solutions Inc. / Avella, PA/844-657-1750

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

LABELING All Labeling must be present and fully legible.

Advanced Safety Solutions Inc. / Avella, PA / 844-657-1750

Date of Manufacture:

Model #:

Date of First use:

Inspection Date

Inspection

items noted

Corrective action

Maintenance

performed

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

Approved By:

This manual suits for next models

2

Table of contents

Other Advanced Safety Equipment manuals