Advantage Engineering TRANS PRO X Series User manual

OPERATIONS MANUAL

TRANS PRO

SERIES

Advantage Engineering® TRANS PRO X-Series™ Table of Contents

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 1

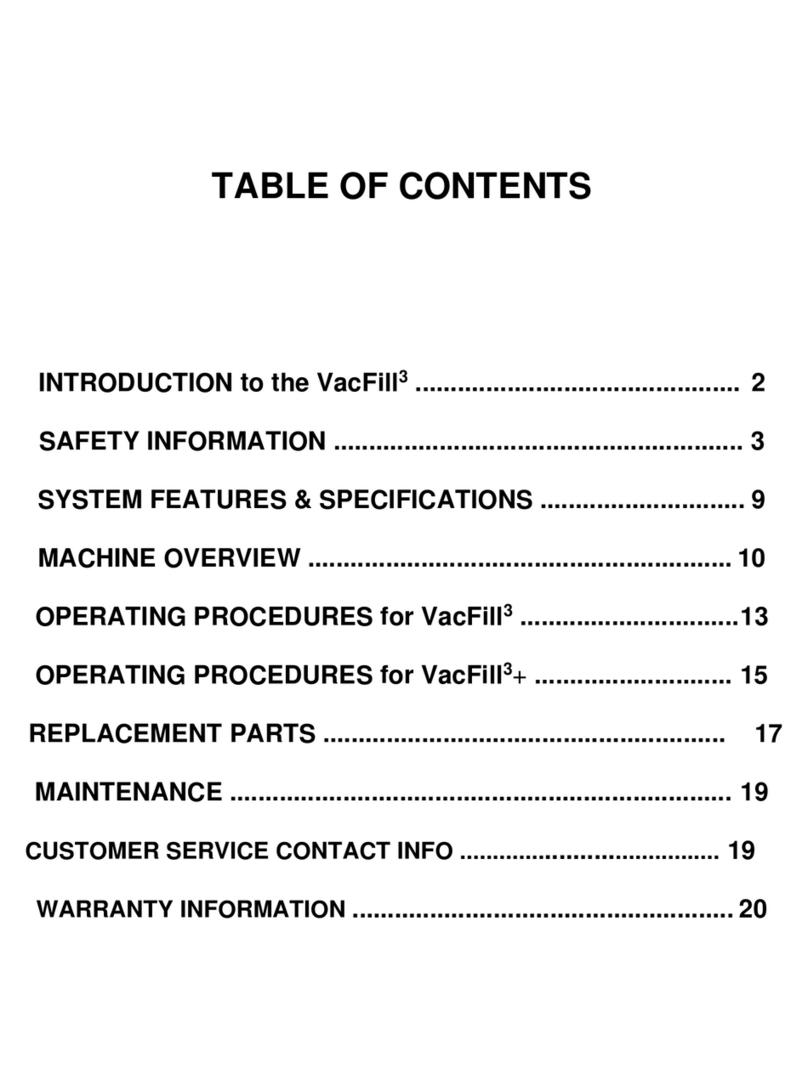

TABLE OF CONTENTS

I. INTRODUCTION to the TRANS PRO X-SERIES ....................2

II. SAFETY INFORMATION ............................................................3

- Section 1.01: Important Safety Notice .........................................3

- Section 1.02: Important Safety Instructions.................................5

III. SYSTEM FEATURES & SPECIFICATIONS ...............................9

- Section 2.01: Features..................................................................9

- Section 2.02: Dimensions & Technical Specifications................10

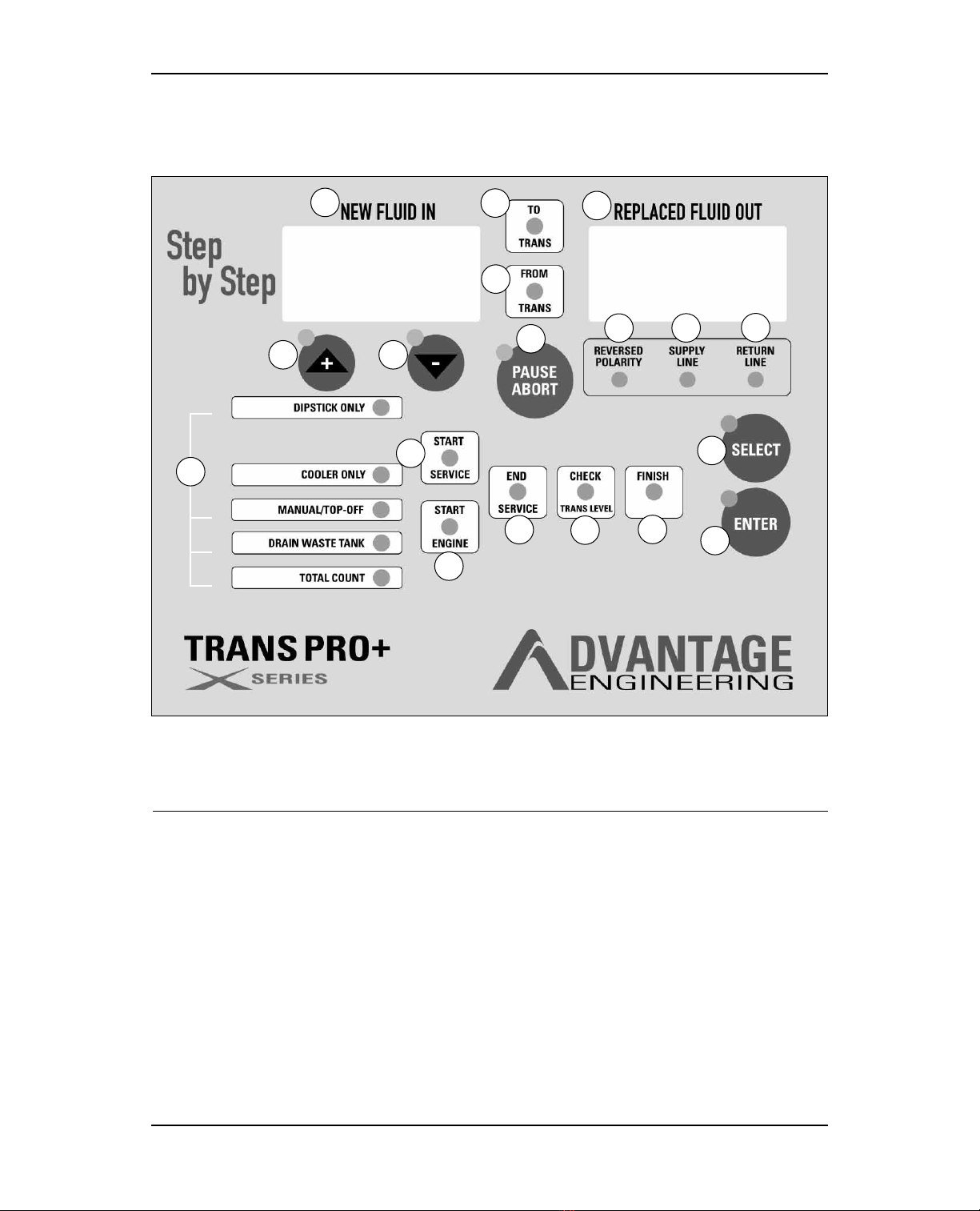

- Section 2.03: Machine Overview................................................11

- Section 2.04: Control Panel Overview........................................12

IV.OPERATING PROCEDURES ...................................................14

- Section 3.01: Tool Usage / Battery Voltage Chart......................14

- Section 3.02: Overview of TRANS PRO Service Modes

of Transmission Fluid Exchange ..........................15

- Section 3.03: Dipstick Mode ......................................................16

- Section 3.04: Cooler Only Mode (TRANS PRO+ feature) ..........18

- Section 3.05: Manual/Top Off Mode ..........................................20

- Section 3.06: Drain Waste Tank Mode .......................................22

- Section 3.07: Total Count ...........................................................23

V. TROUBLESHOOTING & ADDITIONAL HELP.........................24

- Section 4.01: Troubleshooting Guide .........................................24

APPENDIX A - ADAPTERS (TRANS PRO+ feature)............................26

- Section 5.01: Adapters...............................................................26

APPENDIX B - REPLACEMENT PARTS .......................................28

- Section 5.02: Replacement Parts...............................................28

APPENDIX C - MAINTENANCE.....................................................32

- Section 6.01: Maintenance Procedures .....................................32

WARRANTY INFORMATION ..........................................................33

I. Introduction Advantage Engineering® TRANS PRO X-Series™

2Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

I. INTRODUCTION TO THE

TRANS PRO X-SERIES

Congratulations on the purchase of your TRANS PRO system.

The TRANS PRO system is a technologically advanced fluid exchanger that

allows convenient, quick, thorough, and accurate automatic transmission fluid

(ATF) exchanges. Utilizing unique and visible dual wheel flow meters it accu-

rately monitors fluid movement to and from the transmission.

Logically arranged, the TRANS PRO’s fully electronic and intuitive control

panel allows three (3) modes of operation. TRANS PRO+ offers the addition of

Cooler Line only mode.

• Dipstick only

• Cooler Line only (TRANS PRO+ feature)

• Manual/Top Off

• Drain Waste Tank

The high flow rate of the TRANS PRO system allows most automatic trans-

mission fluid exchanges through the dipstick under 15 minutes.

With this approach, used ATF in the transmission pan is first replaced by new

ATF in the static service phase. This significantly reduces dilution time, mini-

mizes transmission fluid degradation, and optimizes the comprehensiveness

of the ATF service.

Improvements in mileage, transmission life, and power delivery are typically

realized as the result of periodic ATF exchanges. Recommended by most

manufacturers, it should be performed periodically and at the specified inter-

vals to maintain your vehicle’s efficiencies.

Advantage Engineering® TRANS PRO X-Series™ II. Safety Information

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 3

II. SAFETY INFORMATION

DANGER

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury to the operator or to bystanders.

• Safety Messages

Safety messages in this section contain three different type styles:

•Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of not avoiding the hazard.

Indicates a situation which, if not avoided, may result in damage to the

TRANS PRO system or the vehicle being serviced.

1.01 IMPORTANT SAFETY NOTICE

For your safety, read this manual thoroughly before operating your TRANS PRO system.

Your TRANS PRO system is intended for use by properly trained, skilled professional

automotive technicians. The safety messages presented below and throughout this

user’s manual are reminders to the operator to exercise care when using this unit.

Before using your TRANS PRO system, always refer to and follow the safety messages

and applicable service procedures provided by the manufacturer of the vehicle being

serviced.

• Read All Safety Instructions

Read, understand and follow all safety messages and instructions in this manual.

Safety messages in this section of the manual contain a signal word with a three-part

message and, in some instances, an icon.

• Signal Words

The signal word indicates the level of the hazard in a situation:

WARNING

Indicates a potentially hazardous situation which, if not avoided, may

result in death or serious injury to the operator or to bystanders.

CAUTION

IMPORTANT

Indicates a potentially hazardous situation which, if not avoided, may

result in moderate or minor injury to the operator or to bystanders.

II. Safety Information Advantage Engineering® TRANS PRO X-Series™

4Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

Risk of Fire Read Instructions Before Use

Risk of Explosion Mandatory Eye Protection

Risk of Entanglement Mandatory Protective Gloves

Dangerous Fumes Mandatory Protective Clothing

Do Not Pull or Move

• Safety Symbols

A safety symbol, when present, gives a graphical description of the

potential hazard, and how to avoid the hazard:

Advantage Engineering® TRANS PRO X-Series™ II. Safety Information

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 5

1.02 IMPORTANT SAFETY INSTRUCTIONS

Vehicle gases contain Carbon Monoxide, which is a colorless & odorless lethal gas.

• Only run engines in well ventilated areas and avoid breathing exhaust gases.

Extended breathing of exhaust gases will cause serious injury or death.

Improper use and operation.

• Read, understand and follow all safety messages and operational

procedures in this manual before operating the TRANS PRO system.

• This equipment should be operated only by qualified personnel.

• Use this equipment only as described in this manual.

Improper use and operation of this product can result in injury.

DANGER

WARNING

Exhaust gases, moving parts, hot surfaces, and potent chemicals may be present during use

of the transmission fluid exchange equipment.

• When using chemicals and fluids always refer to the MSDS sheets and manufacturer's

instructions for the proper procedure to handle emergency medical treatment,

cleanup, handling, and storage requirements.

Improper use of the equipment or exposure to exhaust gases, moving parts,

hot surfaces, or moving parts may cause injury.

WARNING

II. Safety Information Advantage Engineering® TRANS PRO X-Series™

6Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

Risk of expelling pressurized fluids.

• Keep the service hoses away from hot or moving engine parts. Hoses can split or

burst causing fluid to be expelled.

• Tighten all connections properly.

Chemicals and fluids may cause repiratory tract and/or skin and eye irritation.

•Use safety glasses and protective clothing when handling fluids.

•Do not ingest chemicals or breathe vapors

• Treatment methods are as follows:

Eyes: Flush eyes with plenty of water.

Skin: Wash with soap and water.

Inhalation: Move to uncontaminated area.

Ingestion: If large amount, get medical attention.

If any irritation persists, get medical attention.

• Dispose of used fluid according to environmental laws and regulations.

Although transmission fluids pose no significant health hazards, some individuals may

experience adverse reactions upon contact. Pressurized fluid can cause serious injury.

WARNING

Transmission systems may maintain residual pressure in lines after the engine has been

turned off.

• Wear safety glasses, chemical resistant gloves, and protective clothing when

connecting and disconnecting lines and adapters.

• Confirm ZERO pressure before connecting and disconnecting lines and adapters.

Exposure to liquids and vapors can cause injury.

WARNING

Batteries produce explosive gases and can explode.

• Keep sparks and flames away from the battery.

• Do not lay tools, equipment, or other conductive items on the battery.

• Connect the positive lead of the equipment to the positive lead of the battery first.

• Connect the negative lead of the equipment to vehicle ground as far away from

the battery as leads will allow to prevent sparking and igniting of battery gases.

• Keep battery acid away from skin and eyes. In case of eye contact, flush with

clean water for 15 minutes and get medical attention.

Battery explosion and ignited gases can cause injury.

WARNING

Advantage Engineering® TRANS PRO X-Series™ II. Safety Information

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 7

Engine has moving parts. Risk of entanglement.

• Do not place tools on fenders or other places in engine compartment.

• Keep yourself, clothing, adapters and service hoses clear of moving parts

such as fan blades, belts and pulleys.

•Wear safety goggles (user and bystanders).

Moving components can cause injury.

Risk of unexpected vehicle movement.

• Block drive wheels before starting vehicle’s engine to begin an exchange.

• Unless instructed otherwise, set parking brake and put gear selector in park.

• Do not leave a running vehicle unattended.

A moving vehicle can cause injury.

WARNING

WARNING

Risk of burns.

• Wear gloves when working near hot engine components.

• Do not touch hot exhaust systems, manifolds, engines, radiators, etc.

Hot components can cause injury or discomfort.

WARNING

II. Safety Information Advantage Engineering® TRANS PRO X-Series™

8Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

Risk of equipment damage.

• Servicing, transporting, or storing this machine in an attitude other than the normal

operating position can result in fluid spillage and/or component damage.

• Use only the manufacturer’s recommended attachments.

• The TRANS PRO system is fully automatic. Refer to your control panel at

all times.

• Never pull on the power cord or service hoses to transport the TRANS PRO

system. Damage may occur to these components, or machine may tip over.

• Periodically clean the machine by wiping down with a clean, soft, dry cloth.

Improper operation of equipment may result in damage to machine or components.

SAVE AND FOLLOW THESE INSTRUCTIONS!

CAUTION

Risk of injury.

• This equipment should be operated by qualified personnel only.

• Use this equipment only as described in this manual.

• Loop the power cord loosely in its proper location when machine is not in use.

• Do not operate equipment with a damaged power cord or hoses, or if the

equipment has been dropped or damaged, until it has been examined by a qualified

service representative.

• Care should be taken to arrange the power cord and service hoses so that they

will not be tripped over or pulled.

• Never pull on the power cord or service hoses to transport the TRANS PRO

system. Damage may occur to these components, or machine may tip over.

• Keep area of operation clear of unnecessary tools and equipment. Utilize storage

area on the top of the machine and drawers.

• Never leave the machine running unattended.

• The TRANS PRO system is not designed for any other purpose than the

exchanging, filling, and draining of automatic transmission fluids.

Operation of your TRANS PRO system by anyone other than qualified personnel may result in

injury.

WARNING

Advantage Engineering® TRANS PRO X-Series™ III. System Features & Specifications

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 9

2.01 FEATURES

Application

• Exchanges automatic transmission fluid (ATF) in most transmission systems

• Restores power delivery, helps improve fuel economy, and maximizes

transmission service life.

Functions

• Intuitive, fully electronic microprocessor controlled panel with internal fuses, overload,

and ground protection

• Step by step guided operation

• User selectable modes: Dipstick, Cooler Line (TRANS PRO+ feature), manual/top-off,

drain waste tank, total count

• Visible signal for polarity check

• Bright seven segment LED displays function, fluid volume in and out, process

progression and service count

• Board mounted LEDs display indicate available procedures and fluid direction

• Audible alarm and LED display prompt technician involvement to START service,

START engine, CHECK ATF fluid level, and END service

• Waste tank level indicator

• Emergency PAUSE/ABORT button (also used to “reset”)

Cabinet Features

• Composite cabinet

• Ergonomically correct working height

•9” rigid rear wheels

•4” swivel casters with brakes

•Large new ATF reservoir with readily visible sight gauge

• 8’ external nylon reinforced Hytron hoses

• Bi directional high flow rate pump

•Flexible nylon hose for ATF evacuation and filling via dipstick mode

• Two (2) accurate readily visible dual wheel flow meters

III. SYSTEM FEATURES & SPECIFICATIONS

III. System Features & Specifications Advantage Engineering® TRANS PRO X-Series™

10 Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

Specifications

• Eight (8) U.S. gallon tanks for new and used ATF

• 8’ external nylon reinforced Hytron hoses

• 9” rigid rear wheels

• 4” swivel caster with brakes

• Electrical Requirement: Fully charged 12 VDC Automotive Battery.

• Weight (uncrated): 91 lbs. (42 kgs) TRANS PRO

(uncrated): 99 lbs. (45 kgs) TRANS PRO+

• Dimensions: 18” (46 cm) wide

24” (61 cm) deep

60” (152 cm) high

• One (1) year limited warranty

Standard Accessories

•Dipstick tube 75”, 6300-00-75-5 (2 pcs.)

• Dipstick tube 42”, 6300-00-42-5 (1 pc.)

2.02 DIMENSIONS & TECHNICAL SPECIFICATIONS

Advantage Engineering® TRANS PRO X-Series™ III. System Features & Specifications

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 11

Control Panel

Rigid 9” Wheels

4” Locking

Caster Wheels

Flow Meters

New Fluid

Reservoir

Dipstick Adapter

TRANS PRO+ adapters shown

2.03 MACHINE OVERVIEW

III. System Features & Specifications Advantage Engineering® TRANS PRO X-Series™

12 Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

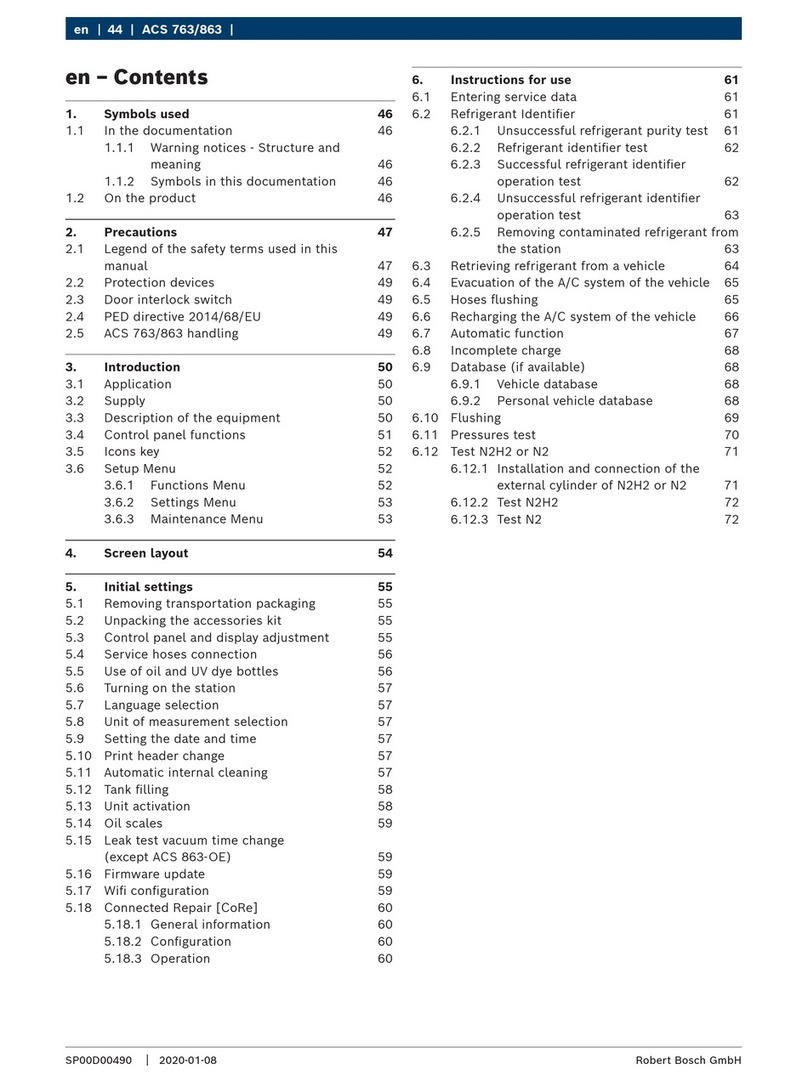

2.04 CONTROL PANEL OVERVIEW

1

6

8

12

13

14

17

18

910

7

15 16

2

3

4

5

KEYS NAME/FUNCTION DETAILS

1 NEW FLUID IN

Display (3 digits) LED Indicates fluid in (in tenths of a quart)

Indicates count in TOTAL COUNT mode

2REPLACED FLUID OUT

Display (3 digits) LED Indicates fluid out (in tenths of a quart)

Indicates count in TOTAL COUNT mode

3TO TRANS Indicates direction of fluid

LED

4FROM TRANS Indicates direction of fluid

LED

11

TRANS PRO+ panel shown.

Advantage Engineering® TRANS PRO X-Series™ III. System Features & Specifications

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 13

KEYS NAME/FUNCTION DETAILS

5 ADD (ARROW UP)

Button - LED Add volume in 1 quart increments

(in CHECK TRANS LEVEL mode, .1 quart increments)

6SUBTRACT (ARROW DOWN)

Button - LED Reduce volume in 1 quart increments

(in CHECK TRANS LEVEL mode, .1 quart increments)

7 PAUSE/ABORT

Button - LED To pause, abort, or reset

8 REVERSED POLARITY

LED (red) Lights when leads are improperly connected to 12V power source

9 SUPPLY LINE Lights to indicate flow problem in supply line.

LED (red)

10 RETURN LINE Lights to indicate flow problem in return line.

LED (red)

11 MODE

LED (green) Lights to indicate mode selected

12 START SERVICE

LED (red) Lights to prompt beginning of fluid exchange process

13 START ENGINE

LED (red) Lights to prompt engine start during fluid exchange process

14 END SERVICE

LED (red) Lights to prompt “stop engine” during fluid exchange process

15 CHECK TRANS LEVEL

LED (red) Lights to prompt check of transmission fluid level during fluid

exchange process

16 FINISH

LED (red) Lights when service is complete

17 SELECT

Button (LED – green) Depress to select mode

18 ENTER

Button (LED – green) Depress to confirm selection

IV. Operating Procedures Advantage Engineering® TRANS PRO X-Series™

14 Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

• Frequently inspect and clean any tools used, and lubricate all non-sealed

ratchet mechanisms with light oil.

• The use of any other accessories not specified in this manual may create a hazard.

• Read, understand and follow Safety Instructions in the front pages of this manual

and on product safety labels

3.01 TOOL USAGE

IV. OVERVIEW AND

OPERATING PROCEDURES

CAUTION

BATTERY VOLTAGE CHART

IMPORTANT: A charged battery is required for

proper machine function.

VOLTAGE % CHARGE

12.6 to 12.72 VDC 100

12.45 VDC 75

12.30 VDC 50

12.15 VDC 25

@ 80º Fahrenheit (27º Celsius)

Advantage Engineering® TRANS PRO X-Series™ IV. Operating Procedures

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 15

The TRANS PRO can perform an ATF exchange, drain the transmission pan, and/or top off

ATF levels in vehicles that have a dipstick. A fluid exchange service is possible in the cooler

line mode (TRANS PRO+ feature). The mode selected when performing an ATF exchange

may determine the comprehensiveness of the service.

Dipstick Only – no adapters to the cooler lines are used

Dipstick adapter is inserted into transmission’s dipstick tube

(used ATF and new ATF are transferred through the transmission’s dipstick to the trans-

mission system with this mode)

Step 1: Technician selects the quantity of ATF to be used for the service (default is 12

quarts). Minimum is 6 quarts, maximum is 32 quarts.

Step 2: With engine off, TRANS PRO extracts used ATF from the transmission

pan through the transmission’s dipstick tube.

Step 3: With engine off, TRANS PRO pumps back the same volume of new

ATF to the transmission’s pan through the transmission dipstick tube.

Step 4: The engine is started, circulating new ATF through the transmission fluid circuits;

returning old system fluid to the transmission pan.

Step 5: TRANS PRO extracts one (1) quart of now diluted ATF, and returns one (1)

quart of new ATF through the dipstick to the transmission pan. This step is repeated

until the ATF volume selected for the service is reached.

Cooler Only (Trans Pro+ feature) – adapters to the cooler lines are used

(used ATF and new ATF are transferred through the transmission’s cooler line with this

mode)

Step 1: Technician locates cooler line, points of connection, and adapters for this mode.

Adapters are connected with the engine off.

Step 2: Technician selects the quantity of ATF to be used for the service (default is 12

quarts). Minimum is 6 quarts, maximum is 32 quarts.

Step 3: After the Trans Pro+ is activated and the engine is started, the Trans Pro+ X-series

senses pressure from transmission and allows transfer of 1 quart used ATF through

cooler line. Trans Pro+ X-series returns 1 quart new ATF through cooler line. This

to/from continues until the ATF volume selected for the service has been transferred.

MANUAL/TOP OFF

(used ATF and new ATF are transferred through the transmission’s dipstick to the trans-

mission system with this mode)

This mode is used commonly used when the transmission pan needs to be removed (to

change gaskets or replace filter). It is also used to top off the ATF fluid level when necessary.

3.02 OVERVIEW OF TRANS PRO X-SERIES AUTOMATIC

TRANSMISION FLUID EXCHANGING SERVICE MODES

IV. Operating Procedures Advantage Engineering® TRANS PRO X-Series™

16 Manual Printed in the U.S.A. for AEC GROUP INC. Operations Manual

3.03 DIPSTICK MODE – OPERATING PRODECURE

(used ATF and new ATF are transferred through the transmission’s dipstick to the trans-

mission system with this mode)

NOTE: Confirm vehicle and transmission are at operating temperature before

initiating service!

Power up. Connect power cord to 12.0 VDC battery. REFER TO BATTERY VOLTAGE

CHART ON PAGE 14. Connect the positive lead of the equipment to the positive lead of the

battery first. Connect the negative lead of the equipment to vehicle ground as far away from

the battery as the leads will allow to prevent sparking and igniting of battery gases. Note:

The REVERSED POLARITY LED will light if connected improperly.

The TRANS PRO will self test. The buzzer will sound, all LEDs and display segments will

light briefly, the dipstick tube holder will be evacuated, and software version will be dis-

played.

The SELECT key and DIPSTICK ONLY, MANUAL/TOP-OFF, DRAIN WASTE TANK, and TOTAL

COUNT LEDs will light and flash (additional COOLER LINE LED visible on TRANS PRO+

model).

Remove dipstick from transmission. Note dipstick length. Insert flexible nylon dipstick tube

to length of dipstick being mindful that it may be necessary to insert slightly farther until the

bottom of the pan is reached.

Depress the SELECT key until the LED for the proper function is lit. (Note: The lit LED will

move from option to option i.e. MANUAL/TOP-OFF, DRAIN WASTE TANK, and TOTAL

COUNT, etc. each time it is depressed). When the LED for the DIPSTICK ONLY mode is lit

and flashing, pause for one second.

The ENTER key LED will then light and flash. Depress ENTER to confirm.

The left display indicating the quantity of new ATF for the service will show “12.”

Select the quantity of ATF to be used for the service (default is 12 quarts; minimum is 6

quarts, maximum is 32 quarts). Add or subtract in one (1) quart increments by depressing

the ADD (ARROW UP) or SUBTRACT (ARROW DOWN) buttons below the display. Depress

ENTER key to confirm the quantity displayed.

The alarm will sound and the START SERVICE and ENTER LEDs will flash. Depress ENTER

to start the ATF exchange.

With engine off, TRANS PRO purges its internal fluid lines and then extracts used ATF from

the transmission pan through the transmission’s dipstick until empty. The cumulative volume

extracted is shown on the right display.

Advantage Engineering® TRANS PRO X-Series™ IV. Operating Procedures

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 17

With engine off, TRANS PRO pumps back the same volume of new ATF to the transmission’s

pan through the transmission dipstick. The cumulative volume of new fluid selected LESS

the volume of new ATF pumped to the transmission is shown on the left display.

The alarm will sound and the START ENGINE and ENTER LEDs will flash. Start the engine,

depress brake pedal, and shift through gear range, holding each gear for three to five sec-

onds before returning gear selector to Neutral or Park. Block wheels and set

emergency/parking brake. Depress ENTER to confirm that the engine is now running.

ATF circulates through the transmission system (torque converter and cooler lines) when the

engine is running.

TRANS PRO extracts one (1) quart of now diluted ATF, and returns one (1) quart of new ATF

through the dipstick to the transmission pan. The volume of extracted fluid from and new

fluid pumped to the transmission are reflected on right and left displays respectively.

This step is repeated until the ATF volume selected above for the service is reached.

The buzzer will sound and the END SERVICE and ENTER LEDs will light. Confirm by

depressing ENTER. CHECK TRANS LEVEL LED will light.

Check the ATF level in the pan. Remove the flexible nylon dipstick tube. Insert the dipstick

and note level.

Adjust the ATF level. Depress ENTER. The TO TRANS, FROM TRANS, and FINISH LEDS

will light. Depress SELECT to toggle to the appropriate function.

If the level is too low depress SELECT until TO TRANS LED is lit. If too high, depress

SELECT until FROM TRANS LED is lit. Confirm by depressing ENTER.

Depress the ADD (ARROW UP)) button. The left display will indicate a cumulative one-tenth

(.1) quart adjustment each time the ADD (ARROW UP) button is depressed.

Reinsert dipstick tube to transmission. Depress ENTER key to complete level adjustment

sequence.

If level is satisfactory, depress SELECT until FINISH LED is lit.

Wait for one second. Depress ENTER key when it flashes to confirm the function. Depress

ENTER again.

The buzzer will sound and the TRANS PRO will display “SR FIN” “Service Finished.”

IV. Operating Procedures Advantage Engineering® TRANS PRO X-Series™

18 Manual Printed in the U.S.A. for Snap-on Tools ® Operations Manual

3.04 COOLER ONLY MODE – OPERATING PRODECURE

(Used ATF and new ATF are transferred through the cooler lines to the transmission

system with this mode

NOTE: Confirm vehicle and transmission are at operating temperature before initiating service!

Power up. Connect power cord to 12.0 VDC battery. REFER TO BATTERY VOLTAGE

CHART ON PAGE 14. Connect the positive lead of the equipment to the positive lead of the

battery first. Connect the negative lead of the equipment to vehicle ground as far away from

the battery as the leads will allow to prevent sparking and igniting of battery gases. Note:

The REVERSED POLARITY LED will light if connected improperly.

The TRANS PRO+ will self test. The buzzer will sound, all LEDs and display segments will

light briefly, and software version will be displayed.

Identify and select an appropriate Automatic Transmission cooler line. Disconnect and

attached appropriate adapters to the previously selected cooler line, either at transmission or

at radiator, whichever is most convenient.

Attach cooler line adapters to TRANS PRO+ selector valve assembly. Disconnect TRANS

PRO+ red and black hoses from dipstick nozzle assembly and attach lines to fittings on

selector valve assembly.

The SELECT key and DIPSTICK ONLY, COOLER ONLY, DRAIN WASTE TANK, AND TOTAL

COUNT LEDs will light and flash.

Depress the SELECT key until only the LED for the COOLER ONLY function is illuminated.

Pause for one second.

The ENTER key LED will then light and flash. Depress ENTER to confirm.

The left display indicating the quantity of new ATF for the service will show “12” and the

ADD (ARROW UP) and SUBTRACT (ARROW DOWN) LEDs will flash.

Select the quantity of ATF to be used for the service (default is 12 quarts; minimum is 6

quarts, maximum is 32 quarts). Add or subtract in one (1) quart increments by depressing

the ADD (ARROW UP) or SUBTRACT (ARROW DOWN) buttons below the display. Depress

ENTER key to confirm the quantity displayed.

The alarm will sound and the START ENGINE and ENTER LEDs will flash. Press ENTER to

start the ATF service, then start the engine.

Advantage Engineering® TRANS PRO X-Series™ IV. Operating Procedures

Operations Manual Manual Printed in the U.S.A. for AEC GROUP INC. 19

When conditions are correct (i.e. fluid temperature up to operating temperature and correct

gear range selected), ATF circulates through the transmission system when the engine is

running.

TRANS PRO+ extracts 1 quart used ATF from the cooler line. The TRANS PRO+ then pumps

back the same amount (1 quart) of new fluid through the other cooler line. This continues

until the ATF volume selected for the service is reached.

NOTE: If flow from transmission is too slow, depress brake pedal and shift transmission to

neutral. Block wheels to secure vehicle in Neutral range.

When selected amount of fluid has been exchanged, TRANS PRO+ will go into a bypass

mode in which the circulating transmission fluid “bypasses” the machine but continues to

safely flow through the cooler circuit. Buzzer will sound and END SERVICE and ENTER LEDs

will flash. Confirm by depressing ENTER.

CHECK TRANS LEVEL LED flashes. Buzzer sounds five (5) times. CHECK TRANS LEVEL

LED then goes solid. TO TRANS, FROM TRANS, FINISH, AND SELECT LEDs flash.

Adjust the ATF level. Depress ENTER. The TO TRANS, FROM TRANS, and FINISH LEDS

will light. Depress SELECT to toggle to the appropriate function. If the level is too low

depress until TO TRANS LED is lit. If too high, depress until FROM TRANS LED is lit.

Depress the ADD (ARROW UP)) button. The left display will indicate a cumulative one-tenth

(.1) quart adjustment each time the ADD (ARROW UP) button is depressed.

If level is satisfactory, depress until FINISH LED is lit.

Wait for one second. Depress ENTER key when it flashes to confirm the function.

Depress ENTER again.

The TRANS PRO+ will display SR FIN “Service Finished.” Confirm by depressing ENTER.

This manual suits for next models

1

Table of contents