INDEX

INDEX..................................................................................................................................3

SAFETY...............................................................................................................................5

SAFETY INFORMATION ........................................................................................................ 5

EXPLOSION HAZARDS 5

HEAT/FREEZING HAZARDS 5

GENERAL SAFETY MESSAGGE 6

FUME HAZARDS 7

ADDITIONAL SAFETY INFORMATION 7

HOSES CONNECTION........................................................................................................... 8

SAFETY DEVICES 8

REFRIGERANT AND LUBRICANT - PERSONAL PROTECTIVE EQUIPMENT AND

PRECAUTIONS ...................................................................................................................... 8

PRECAUTIONS FOR HANDLING AND USE OF R134a or R1234yf FLUID .......................... 8

INTRODUCTION.................................................................................................................9

CERTIFICATION..................................................................................................................... 9

ABOUT THIS MANUAL........................................................................................................... 9

ABOUT YOUR AIR CONDITIONING SERVICE CENTER....................................................... 9

CONDITIONS OF WARRANTY.........................................................................................10

GENERAL INFORMATION ...............................................................................................11

PRINCIPLES OF OPERATION .........................................................................................12

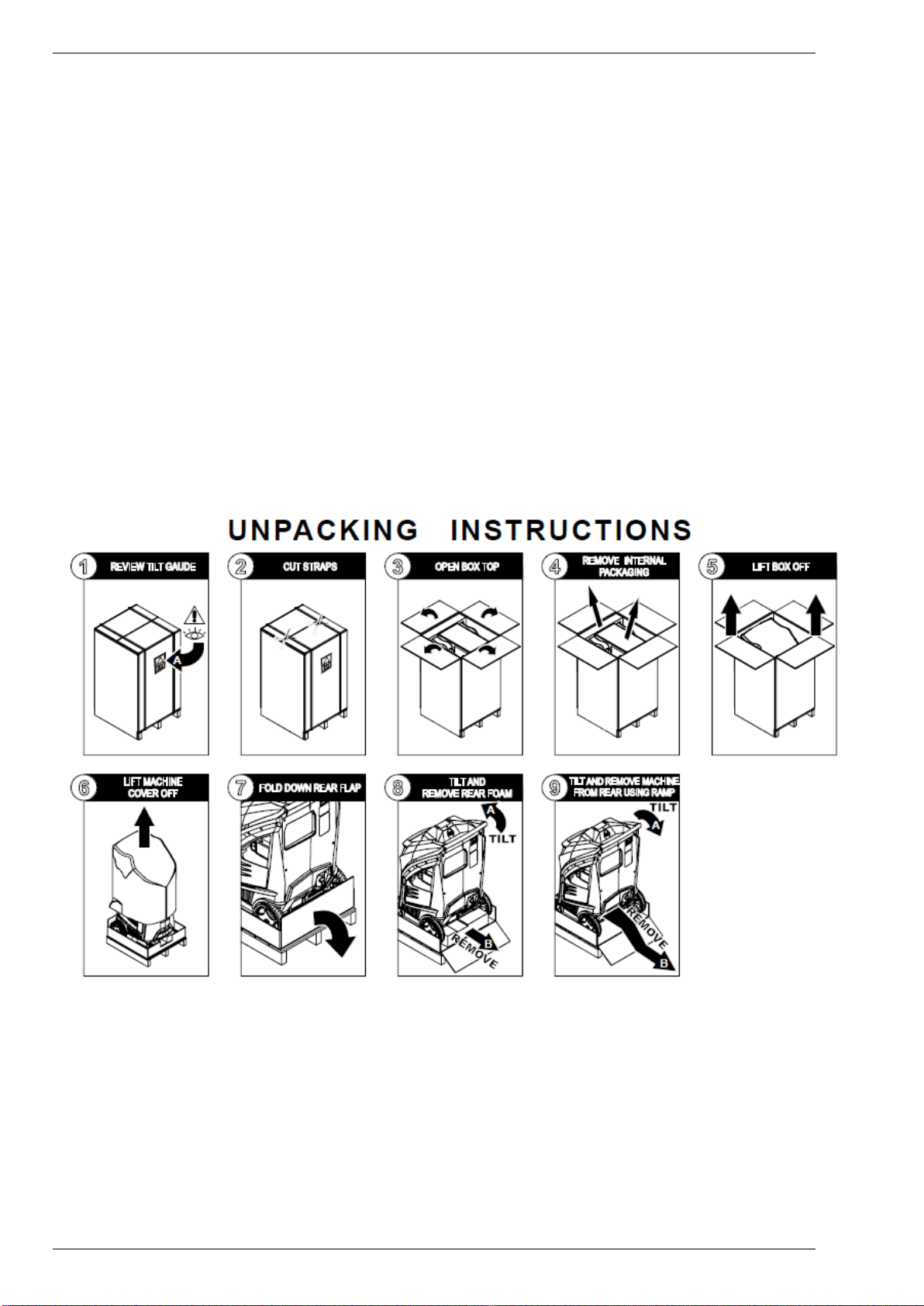

SETUP...............................................................................................................................13

HOSES MOUNTING ............................................................................................................. 13

RELEASE REFRIGERANT SCALE....................................................................................... 13

LOCK REFRIGERANT SCALE ............................................................................................. 13

THE MACHINE..................................................................................................................15

PLASTIC COVER................................................................................................................. 15

CONTROL PANEL................................................................................................................ 16

DISPLAY ICONS................................................................................................................... 17

BASIC COMPONENTS......................................................................................................... 18

ALARMS ............................................................................................................................... 25

ERROR CODES.................................................................................................................... 25

PRELIMINARY OPERATIONS..........................................................................................26

QUICKSETUP....................................................................................................................... 27

AUTOMATIC PROCEDURE..............................................................................................28

EDIT VACUUM DATA:.......................................................................................................... 28

EDIT OIL DATA (ECO NEXT ONE only):.............................................................................. 29

EDIT GAS FILLING DATA:.................................................................................................... 29

START AUTOMATIC PROCEDURE:.................................................................................... 30

MANUAL PROCEDURE....................................................................................................36

RECOVERY.......................................................................................................................... 36