Contents

Introduction.23

Extractor

version.

2

3

Filter

version.

2

4

Electrical

connections.25

Safety

warnings

fcfr

electrician.25

Specifications.26

Montage.

2

7

Safety

warnings

for

kitchen

unit

installer.27

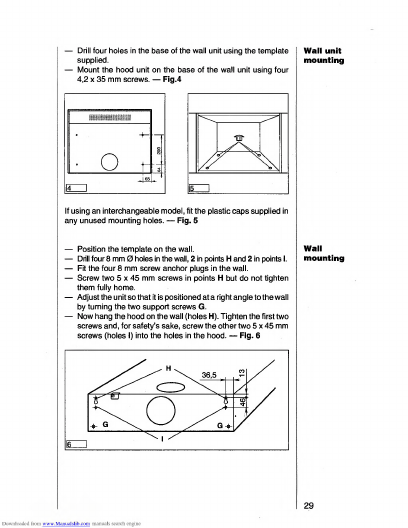

Wall

unit

mounting.29

Wall

mounting.29

Safety

warnings

for

user.30

Hood

operation.31

Controls..31

Setting

the

fan

speed.

3

2

Hood

lighting.32

Intensive

P.33

Fan

timer.33

Switching

off

the

fan

3

4

Hood

operation

before

and

after

cooking.

3

5

Warnings

on

the

activated

carbon

filter.

3

5

Display

warning

on

saturation

of

activated

carbon

filter....35

-

37

Display

warning

on

saturation

of

metal

grease

filters

.38

-

39

Changing

the

light

bulbs

..

.....40

Cleaning...****.,,......,....40

Special

Accessories...

4

1

Technical

Assistance

Service

..

...............

4

1

22

Printed

on

recycled

paper.

AEG

-

putting

words

into

action.