AEM Dryflow Quick start guide

AEM Induction Systems 1 (800) 992-3000 WWW: http://www.aemintakes.com

Equipped with AEM®Dryflow™ Filter

No Oil Required!

INSTALLATION INSTRUCTIONS

PART NUMBER: 21-447

1998-2001 CHEVROLET Cavalier L4-2.2L Manual trans. Requires 20-455 C.A.R.B. E.O. # D-670-6

2000-2002 PONTIAC Sunfire L4-2.2L Manual trans. Requires 20-455 C.A.R.B. E.O. # D-670-6

The installation of this AEM®intake system on manual transmission model year vehicles will also require

the installation of the AEM® clutch reservoir bracket, part # 20-445. The clutch reservoir bracket is

necessary as it is needed to properly support the clutch fluid reservoir.

* NOTE: Legal in California only for racing vehicles which may never be used upon a highway

2

PARTS LIST

Description

Qty.

Part Number

Element Parts Kit 2.75 X 5" Dry Ele.

1

21-202DK

Lower Pipe

1

2-552

Upper Pipe

1

2-553

Hose, Silicone 2.75x3" Blk.

1

5-275

Hose, Hump 2.75/2.75x3.00"

1

5-575

Hose; 1/2"ID X 12"L

1

5-5012

Mount, Rubber 5/8" X 6mm

1

1228598

Grommet, 1/2"

1

784634

Zip Tie,8" Tree Push-Mnt.

2

1-127

Spacer, 1.00 OD X .250 ID X .6

1

2-647

Neoprene, 1/16" X 6" X 1" Adhes.

1

8-121-1

Bolt, Hex M6-1 X 35mm

1

1-2002

Washer; 1"D X 1/4 Hole Fender

4

08160

Nut, M6 Hex Serrated

3

444.460.04

1/2" Bnd. Hose Clamp, 2.31-3.25"

4

9444

Hose Clamp, 3/4"

2

4093-5

1/2" Bnd. Hose Clamp,2.56"-3.50"

1

9448

3

Read and understand these instructions BEFORE attempting to install this product.

Failure to follow installation instructions and not using the provided hardware may

damage the intake tube, throttle body and engine.

The AEM®intake system is a performance product that can be used safely during mild

weather conditions. During harsh and inclement weather conditions, you must return

your vehicle to stock OEM air box and intake tract configuration. Failure to follow these

instructions will void your warranty.

1. Preparing Vehicle

a.Make sure vehicle is parked on level surface.

b.Set parking brake.

c. If engine has run in the past two hours, let it cool down.

d.Disconnect negative battery terminal.

e.Raise the front of the vehicle with a jack. Refer to your owner’s manual for proper jack and jack stand

placement to properly support vehicle. Support your vehicle using properly rated jack stands before wheel

removal or while working under the vehicle.

NEVER WORK UNDER A VEHICLE WITHOUT USING JACK STANDS.

f. Remove front driver side wheel.

g.Do not discard stock components after removal of the factory system.

2. Removal of stock system

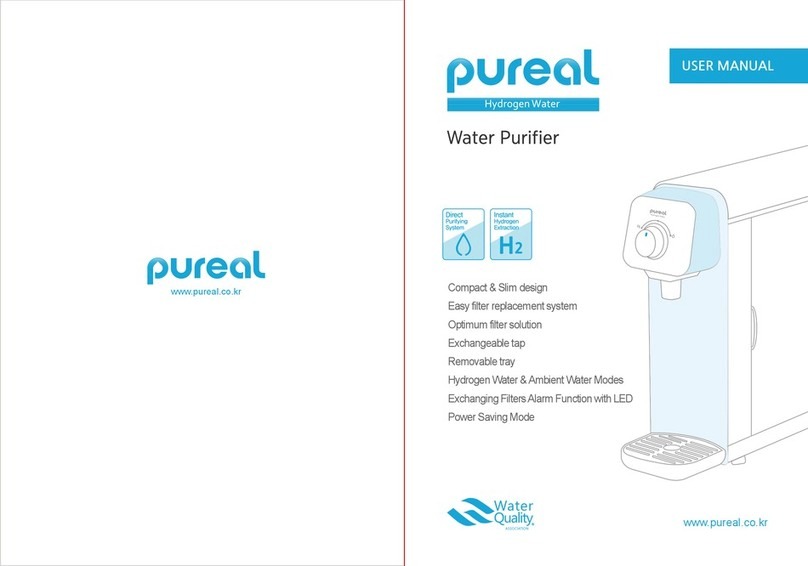

a. Factory air box system installed.

b. Release the clip on top of the inlet pipe.

4

c. Loosen the hose clamp at the air box.

d. Remove bolt. Release the breather hose from the

valve cover.

e. Loosen the hose clamp at the throttle body.

f. Gently pull the inlet air temperature (IAT) sensor from

the inlet pipe. Remove the upper air box from the

vehicle.

NOTE: Do not pull by wires.

5

g. Remove the battery by first releasing the tie down

bolt.

h. Release the two wire clips on the air box.

i. Remove the plastic clip that secures the fuse block.

j. If equipped with a manual transmission, remove the

clutch fluid reservoir from the air box. Secure it to the

firewall with AEM®part # 20-445 (sold separately).

Remove the air box from the vehicle.

6

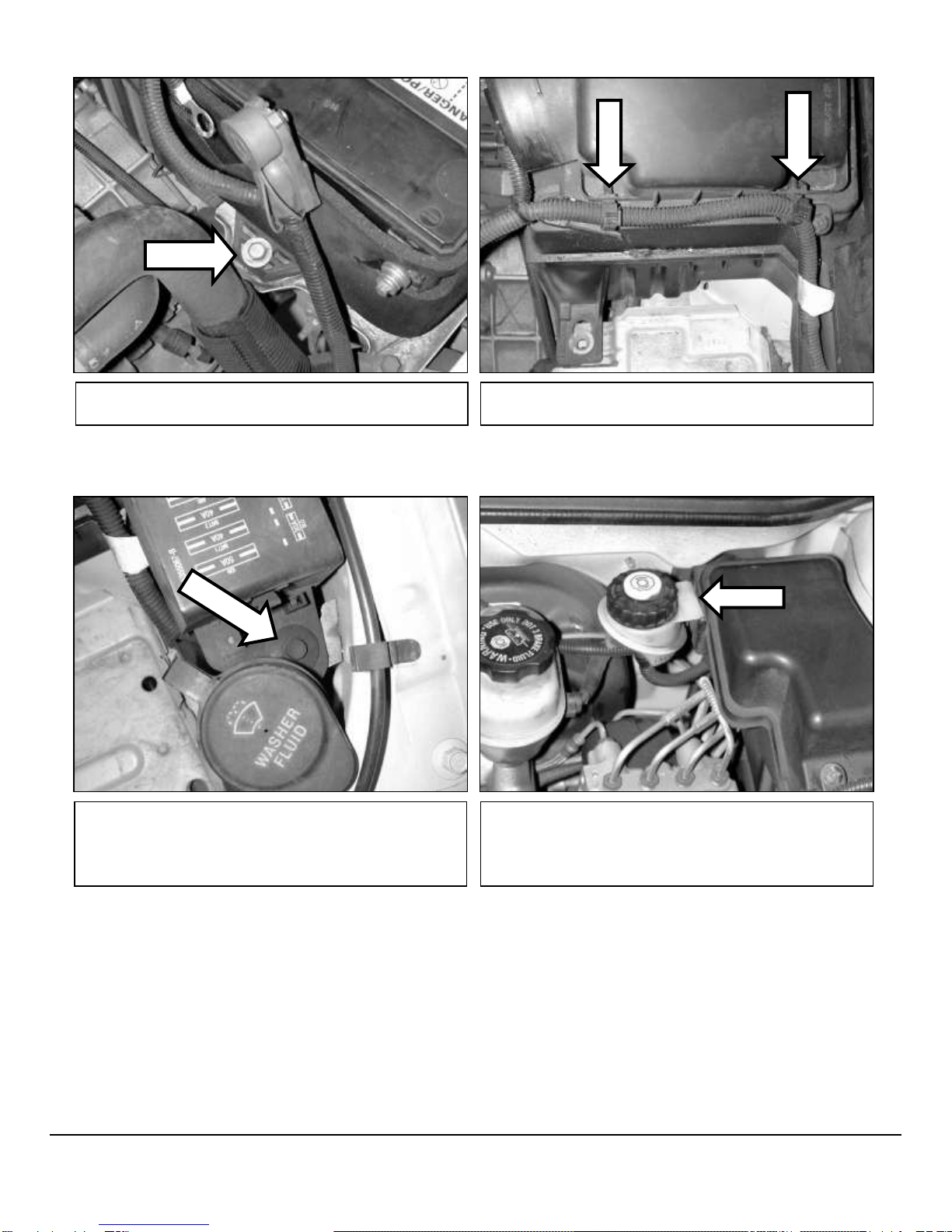

l. Release the two wire clamps on the back of the

washer fluid bottle.

k. Remove the left fender liner to expose the lower air

box / washer bottle assembly.

m. Unplug the washer motor. Pull the washer fluid

hose off of the motor and drain the fluid into a clean

suitable container.

n. Remove the bolt that secures the washer bottle to

the fender.

7

p. Remove the upper bolt near the front of the washer

bottle. This picture was taken through the front grill.

q. Remove the washer bottle from the vehicle. Loosen

the bolt connecting the bottle to the lower air box.

r. Loosen the positive lead on the fuse block. Rotate it

as shown. Tighten the lead.

o. Remove the lower bolt near the front of the washer

bottle.

8

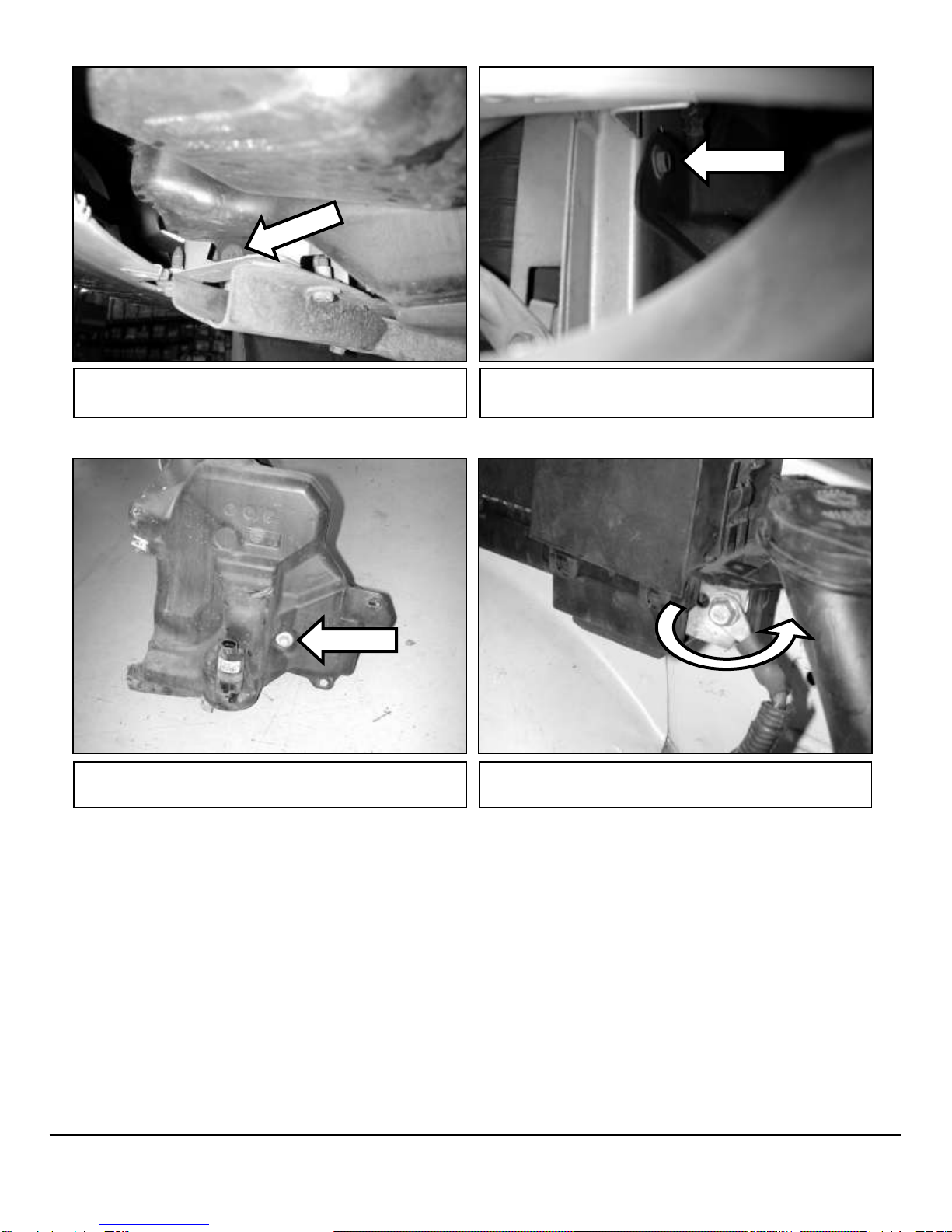

3. Installation of AEM®intake system.

a.When installing the intake system, do not completely tighten the hose clamps or mounting hardware until

instructed to do so.

b. Install supplied bolt and washer through fender as

shown. This picture was taken from inside the fender

well.

c. Install spacer as shown. Install the lower pipe in the

engine bay. Center the pipe in the hole in the fender

and tighten the nut on the spacer.

Mark pipe here.

And here.

e. Reinstall the washer bottle without the lower air box.

Reattach the washer fluid hose and plug in the washer

motor.

d. Mark the pipe approximately ½” above and below

the hole in the fender. Remove the pipe and apply the

adhesive neoprene material as shown. Reinstall the

intake pipe as previously directed.

9

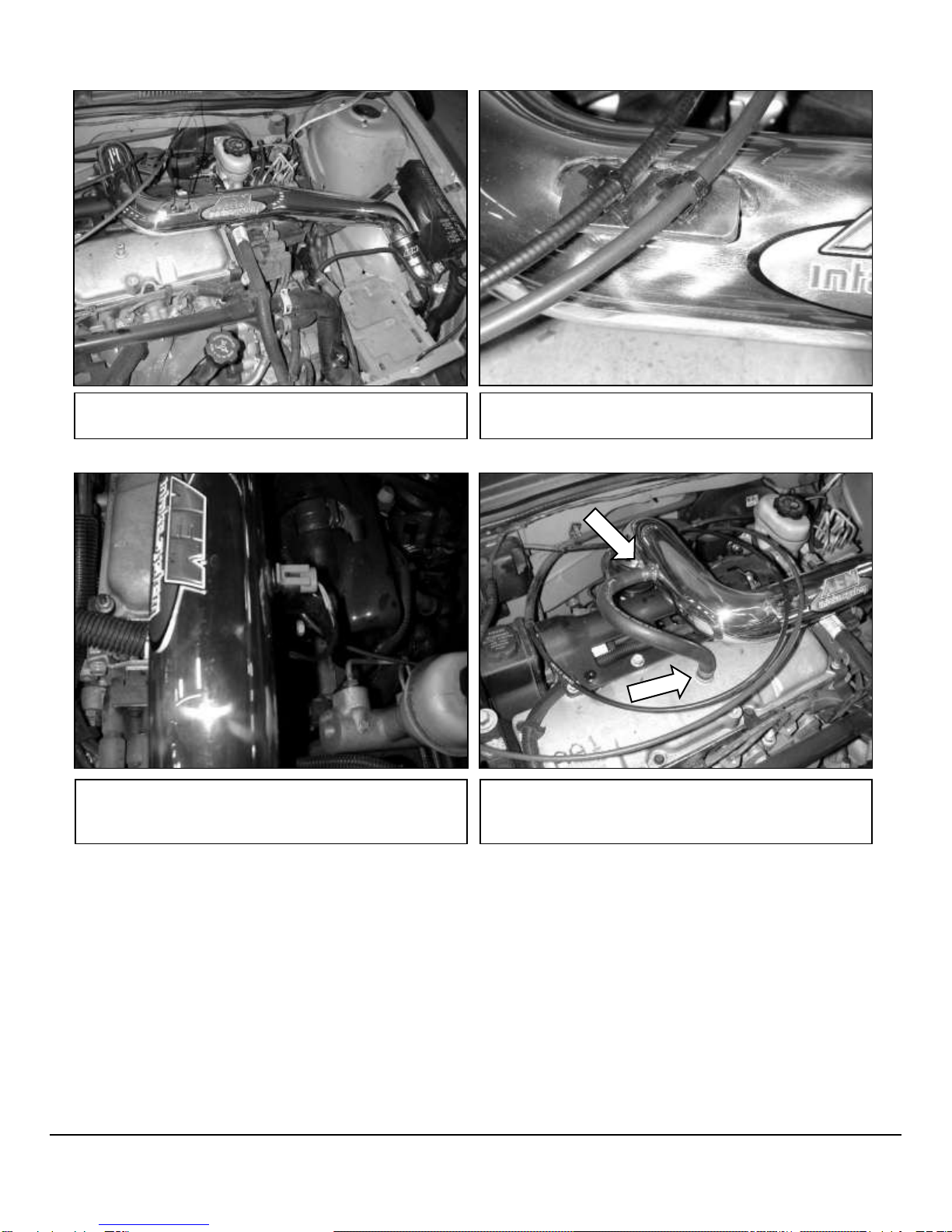

f. Install the supplied silicone hose as shown. Orient

the hose clamp screws away from the battery tray as

shown.

g. Attach the rubber mount to the tab near the washer

bottle filler neck using the supplied washer and lock

nut.

h. Install the hump hose to the throttle body as shown.

Cruise control only.

i. Install the supplied grommet in the hole on the upper

pipe. Insert the zip tie into the hole on the upper pipe

bracket (use two zip ties if the car has cruise control).

10

j. Place the upper intake pipe in the engine bay as

shown.

k. Secure the throttle/cc cable(s) to the upper pipe with

the zip tie(s) installed earlier. Cut off excess material.

l. Insert the IAT sensor through the grommet in the

upper pipe. Do not push the grommet into the pipe.

m. Install the supplied breather hose between the valve

cover and intake pipe. Secure it with the supplied hose

clamps.

11

4. Reassemble Vehicle

a. Fender liner: Install the fender liner and any hardware that was removed in steps 2k.

NOTE: Failure to install the fender liner will result in diminished performance and increase the

potential for engine damage due to water ingestion in rainy conditions.

b. Wheel: Install the driver’s side wheel using the factory torque specification (see owner’s manual).

c. Washer Bottle: Refill the washer bottle with the washer fluid that was drained in step 2m.

d. Position the inlet pipes for the best fitment. Be sure that the pipes or any other components do not contact

any part of the vehicle. Tighten the rubber mount, all bolts, and hose clamps.

e. Check for proper hood clearance. Re-adjust pipes if necessary and re-tighten them.

f. Inspect the engine bay for any loose tools and check that all fasteners that were moved or removed are

properly tightened.

g. Reconnect battery terminals and start engine. Let the vehicle idle for 3 minutes. Perform a final inspection

before driving the vehicle.

n. Check the fitment of the pipes and tighten all hose

clamps. Secure the fuse block to the rubber mount

with the supplied lock nut and washer.

o. Reinstall the battery. Confirm that the positive lead

from the fuse box is on top of the intake pipe and is not

pinched between the battery and the intake pipe.

p. Install the air filter onto the end of the intake pipe.

AEM®intake system installed

12

For technical inquiries

e-mail us at

sales@aemintakes.com

or

call us at

800.992.3000

5. CARB Sticker Placement

a. The C.A.R.B. exemption sticker, (attached), must be visible under the hood so that an emissions

inspector can see it when the vehicle is required to be tested for emissions. California requires testing

every two years, other states may vary.

6. Service and Maintenance

a. AEM Induction Systems requires cleaning the intake system’s air filter element every 100,000 miles. When

used in dusty or off-road environments, our filters will require cleaning more often. We recommend that you

visually inspect your filter once every 25,000 miles to determine if the screen is still visible. When the screen

is no longer visible some place on the filter element, it is time to clean it. To clean, purchase our Synthetic air

filter cleaner, part number 99-0624 and follow the easy instructions.

b. Use window cleaner to clean your powder coated AEM®intake tube.

NOTE: DO NOT USE aluminum polish on powder coated AEM®intake tubes.

7. Notes on installing AEM bypass valve (part # 20-402S –sold separately)

Cut here.

And here

Suggested location to cut intake pipe to install AEM®

bypass valve. Be sure to follow the installation

instructions included with the AEM®Bypass Valve to

ensure proper installation.

AEM®bypass valve installed.

13

AEM Air Intake System Warranty Policy

AEM®warrants that its intake systems will last for the life of your vehicle. AEM will not honor this warranty due to

mechanical damage (i.e. improper installation or fitment), damage from misuse, accidents or flying debris. AEM will

not warrant its powder coating if the finish has been cleaned with a hydrocarbon-based solvent. The powder

coating should only be cleaned with a mild soap and water solution. Proof of purchase of both the vehicle and AEM

intake system is required for redemption of a warranty claim.

This warranty is limited to the repair or replacement of the AEM part. In no event shall this warranty exceed the

original purchase price of the AEM part nor shall AEM be responsible for special, incidental or consequential

damages or cost incurred due to the failure of this product. Warranty claims to AEM must be transportation prepaid

and accompanied with dated proof of purchase. This warranty applies only to the original purchaser of product and

is nontransferable. Improper use or installation, use for racing, accident, abuse, unauthorized repairs or alterations

voids this warranty. AEM disclaims any liability for consequential damages due to breach of any written or implied

warranty on all products manufactured by AEM. Warranty returns will only be accepted by AEM when accompanied

by a valid Return Merchandise Authorization (RMA) number. Credit for defective products will be issued pending

inspection. Product must be received by AEM within 30 days of the date RMA is issued.

If you have a warranty issue, please call (800) 992-3000 and our customer service department will assist you. A

proof of purchase is required for all AEM warranty claims.

10-7022C

04/19/12

Table of contents

Other AEM Water Filtration System manuals