4 / 40

TF6401_E Aereco S.A.

The Heat Recovery Unit : DXA Unit

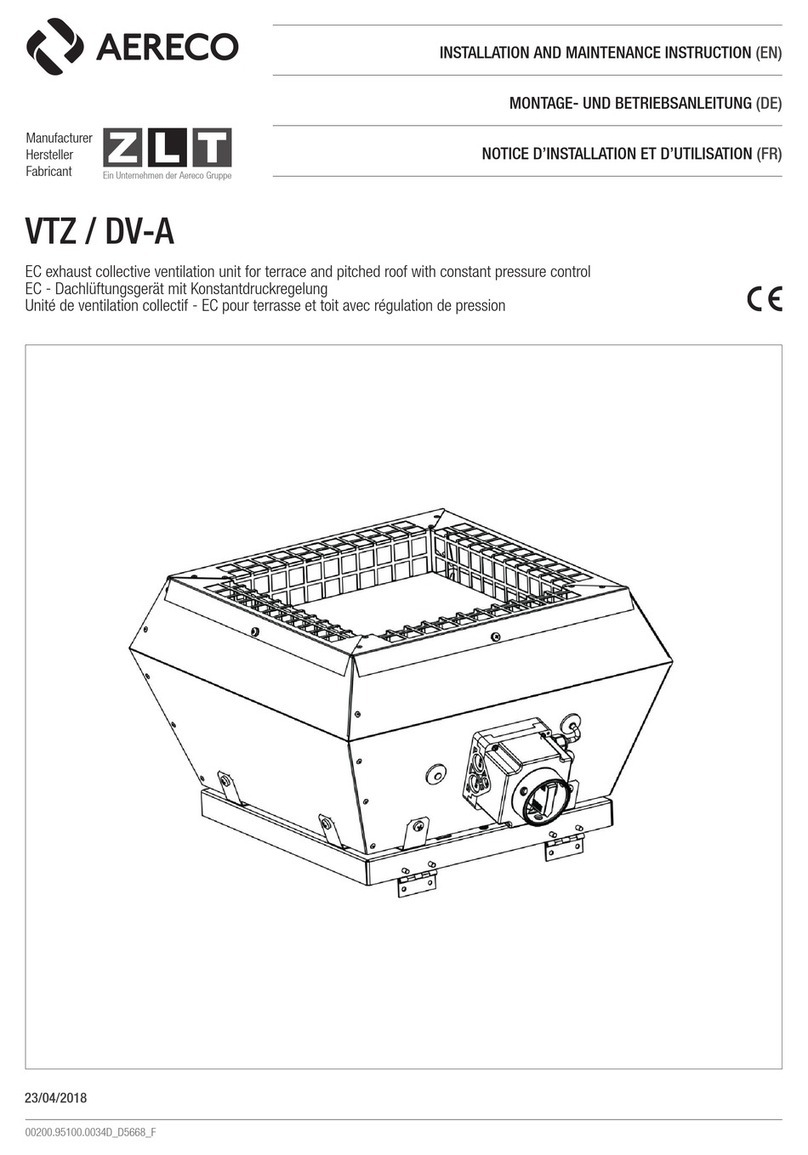

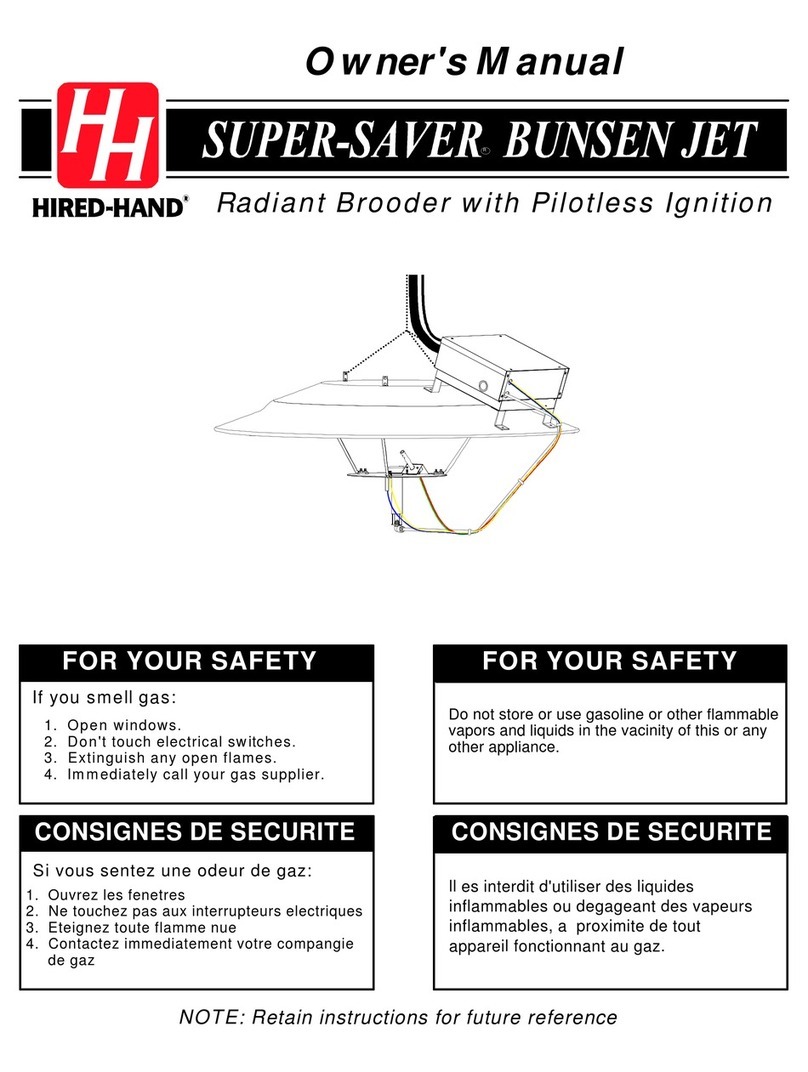

The DXA has been specifically designed for

wall or cupboards installation. Thanks to

its wellfitted dimensions, the DXA can be

installed in technical rooms, wallmounted.

A creamy white metal sheet covers the front

face of the the DXA which allows it to be

unnoticed as a technical equipment. The DXA

unit is compatible with two demand control

strategies used in the DX System “Premium”

and “Excellence”.

2. DESCRIPTION

2.1. GENERAL INFORMATION

The DX System is a range of smart heat recovery ventilation systems that continually supply pollen-free and dust-free preheated fresh air to living areas,

ensuring a comfortable feel-good climate.

The DXA is a heat recovery unit with demand-controlled airflows for vertical installation (on the wall) in the apartment or in the house, from 2to 5 main

rooms, and from 1 to 5 technical rooms (kitchen, bathroom, others wet rooms). The dwelling has to be limited to 2 floors (1 ground floor and 1 floor

maximum), and has a maximum surface of 210m². This HRVsystem can also be used in oces, hostels, etc., if the required airflow is in accordance

with the one oered by the system.

General working of the DX System, Excellence Version

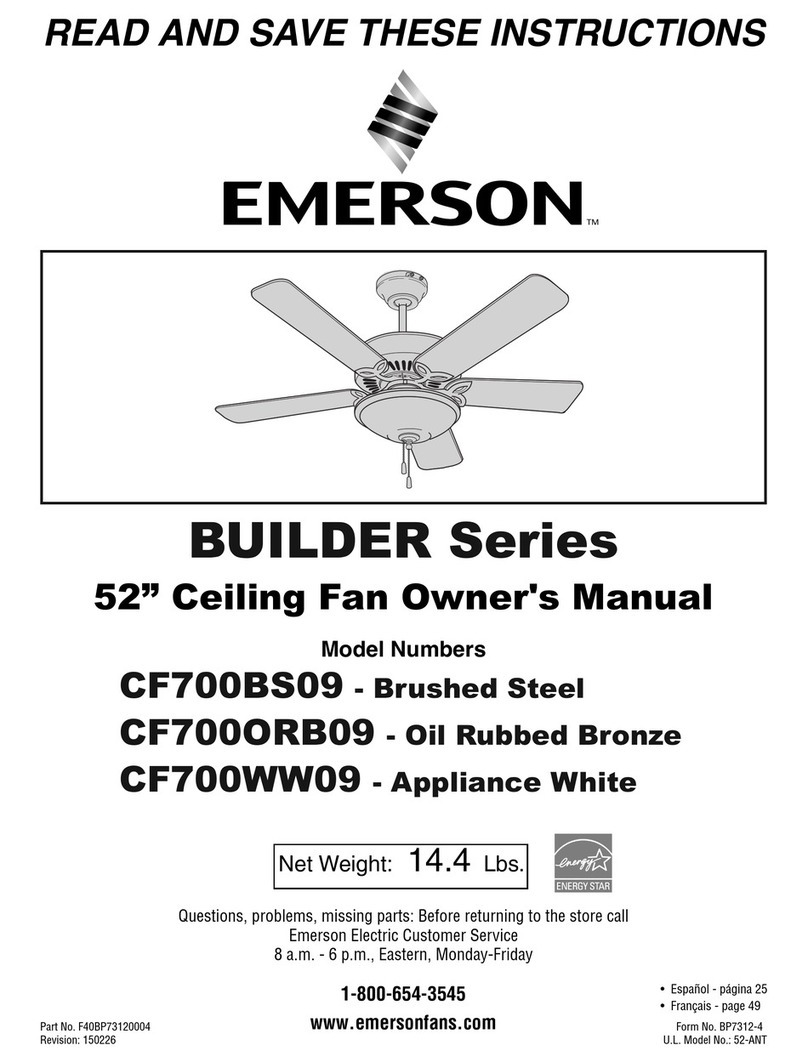

The DX System is comprised of a heat recovery unit (DXA Unit 1 )

connected to exhaust and supply ductworks. The counter-flow heat

exchanger, integrated into the main unit, ensures the recovery and transfer

of most of the energy from the exhaust air to the supply air, thus limiting

the energy required to heat the fresh air.

Airflows are automatically controlled according to the needs of each

dwelling’s room (room-by-room DCV): Outdoor filtered air is supplied 3

in the bedrooms and in the living room. Stale air is extracted 6from the

kitchen, bathroom and WC. On the supply side, the dierent sensors 5

adjust the airflow room-by-room based on the CO2level or based on the

presence detection. On the exhaust side, the BXC units adjust automatically

the airflow, according to parameters read by various sensors: humidity

(used in the kitchen, in the bathroom and in WC), presence (can be used

in WC). Versions with switch, presence, remote, CO2or VOC sensors can

also be used for exhaust units.

At all times, total supply airflows and total exhaust airflows are measured

by the heat recovery unit. These airflows are balanced thanks to an

exhaust controlled compensation valve 8. This valve can be located

in the bathroom or in the kitchen. An additional compensation valve,

integrated in the DX Hub 2, adjusts supply compensation airflow,

supplying preheated 9fresh air in the living room, in the kitchen or in

a corridor. Compensation valves are linked to dedicated compensation

exhaust unit 7or dedicated compensation supply unit 4The use of an

exhaust compensation valve is also a solution to increase the airflows.

This scenario is used in order to get a very ecient over-ventilation mode,

also called free-cooling mode.

To reach the required supply airflows in each main room (bedrooms or

living room), dedicated dampers located in the DX Hub 2modulate

room by room supply airflows according to the information sent by each

electronic sensors placed in the main rooms. For example, when the main

rooms are occupied, the presence or CO2sensors that are located in these

rooms send the information to the system to adapt the airflow according

to the demand. To reach the required exhaust airflows in each technical

room (kitchen, bathroom, WC, ...), dampers located in the exhaust units

modulate room by room extract airflows according to the passive or active

sensor placed within each exhaust unit.

Supply airflows and exhaust airflows are measured by the use of accurate

pressure sensors placed in the heat recovery unit. This allows to calculate

with a high accuracy supply and exhaust airflows, without influence of

clogging filters or ductwork pressure drop. It ensures the highest eciency

for the system. So that, energy savings are at their maximum.

CO2 detection

Based on the level of CO2in the room, a

consequence of people occupancy, CO2 sensors

are a really good indicators to modulate the

supply airflows and allow reliable measurement

of the concentrations of CO2in a zone. The

analysis principle consists in measuring the

absorption of infrared light in order to determine

the concentration in a room. This method gives

a very accurate response and is not aected by

any other pollution (humidity, dust, etc.).

Presence detection

The presence sensors located in the main

rooms (at least 1 sensor in the main rooms)

send the information to the system (presence

detected or not) with a timer that depends on

the period through luminosity measurement

(day or night). This timer keeps the detection

at the maximum level during 20 or 45minutes

after the last detection, to optimize the quality

of detection. Timer day = 20 min ; Timer

night= 45min. When there is detection, the

local supply airflow is increased to ensure the

best air quality. If there is no detection, the local

supply airflow is reduced to optimize energy

savings.