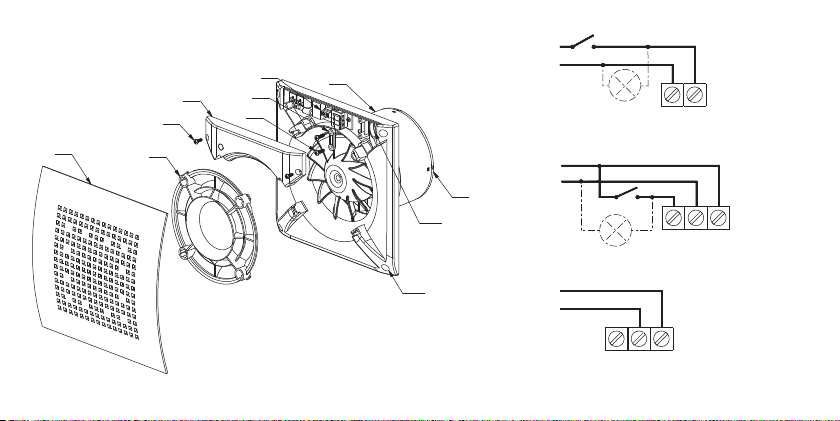

The air humidity sensor detects humidity between 40% (“HIGRO” potentiometer turned maximum to the left) and 90% (“HIGRO”potentiometer turned maximum to the

right) of relative humidity. The system is additionally equipped with a timer. The operation of the fan depends on the power supply connection method. If connected as

shown in Fig.4, the fan will start automatically when the air humidity level exceeds the set value of the humidity sensor. Next, the fan will switch o when the air

humidity level is reduced below the set value, plus the switch-o delay time set with the timer elapses. Switch-o delay time is regulated by the “CZAS/TIME”

potentiometer in the range of 3-30min (the minimum switch-o delay time is obtained by turning the potentiometer maximum to the left).

If connected as shown in Fig. 3, the fan can also be started with its standard light sensor or operating the separate on/o switch. Depending on the setting of the

“DELAY” slider on the controller, the fan will start operating when voltage is detected on the“SL” terminal or after 2 minutes after voltage is detected. After a signal loss

at the “SL” terminal due to switching o the light or the on/o switch, the air exhaust fan will stop after the stop delay time set with the potentiometer if the humidity

level in the room is below the level preset on the potentiometer. The humidity detection system is the master system.

NOTE: When the green diode located in the electronic system is on, it means that the humidity level in the room is higher than the preset on the potentiometer

controlling the humidity level adjustment. As long as the diode is on, the fan will not start counting down the stop delay after which the fan is switched off. It will

take place only after the humidity level in the room drops and the green diode goes off.

INSTALLATION

The fan shall only be installed, connected to electrical mains and commissioned

for use by qualified personnel in accordance with applicable laws!

Assembly

•

Precisely determine where the fan will be installed.

•Prepare the power cable. Use NYM-O 2x1.5 mm² (H07V-K 2x1.5 mm²) or NYM-O 3x1.5 mm² (H07V-K 3x1.5 mm²) with a maximum outside diameter of 8 mm,

depending on the version of the equipment.

NOTE: Before starting work, make sure that the power cord is not live.

•Measure and drill holes for the fan and ø6 mm mounting pins included with the product.

•Remove the front panel (1) and the rotor cover (2). The latches are released by turning them counterclockwise.

14

EN