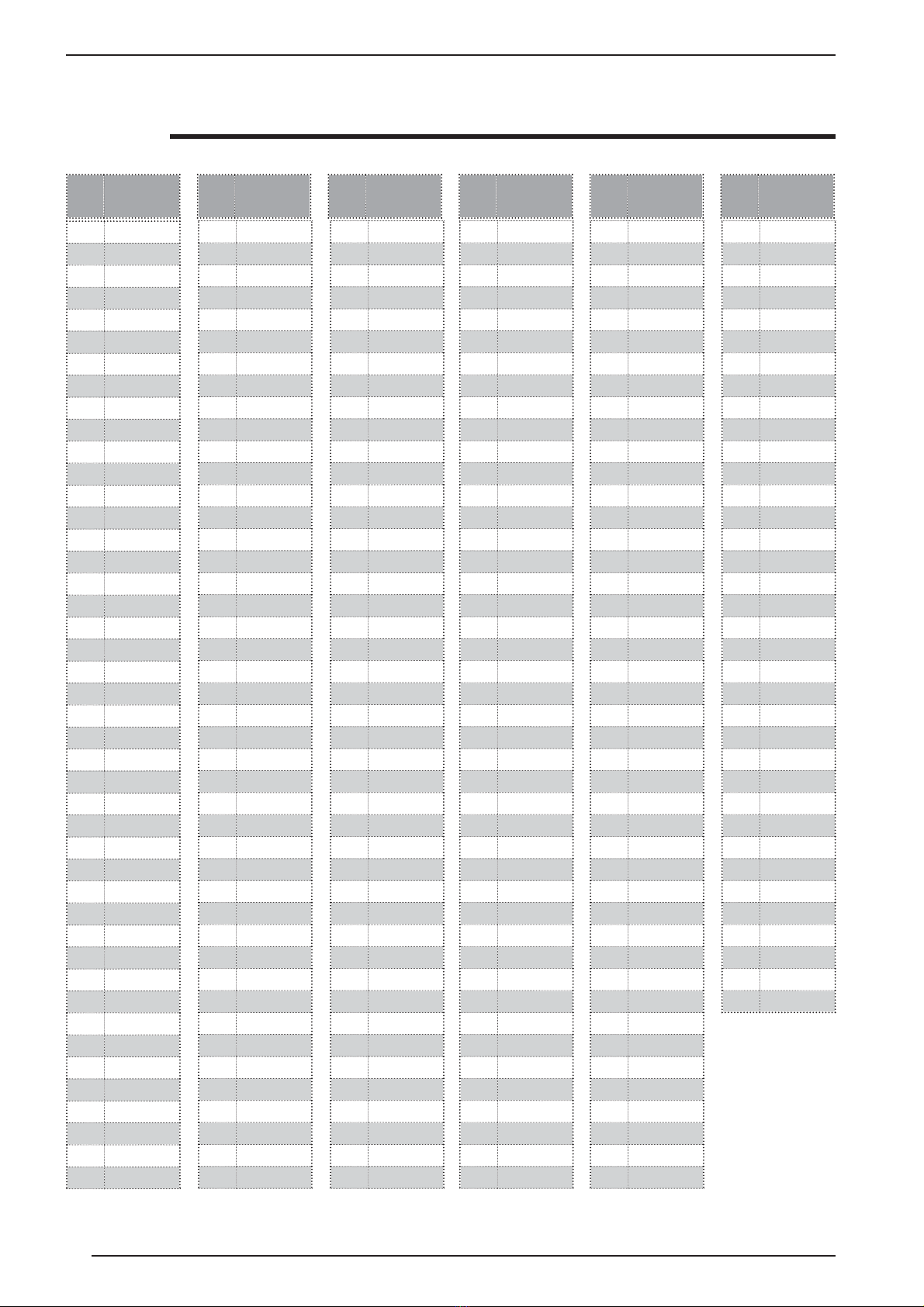

Addresses table for BMS implementation

Below are the addresses foreseen by the protocol and the cor-

responding meaning in terms of the machine. The addresses

that are not listed are reserved or not used and therefore

commands related to addresses that are not listed cannot

be used as this could lead to the malfunction or breakage

of the machine.

ID Data description

0 Standby/On command (toggle) 0=OFF 1=ON

1 Cooling/Heating mode command (toggle) 0=COLD 1=HOT

2 Safety reset command 1=RESET

3 Local/remote command (toggle) 0=LOCAL 1=REMOTE

4 Defrosting status, circuit 1

5 Defrosting status, circuit 2

6 Circuit 1 alarm summary condition

7 Circuit 2 alarm summary condition

8 Flow switch alarm

9 Condenser pump heating alarm

10 Evaporator pump heating alarm

11 Efficiency alarm

12 Circuit 1 compressor heating alarm

13 Low circuit 1 pressure alarm

14 High circuit 1 pressure alarm

15 Circuit 1 antifreeze alarm

16 Circuit 1 fan heating alarm

ID Data description

17 Circuit 1 oil pressure switch alarm

18 Probe alarm circuit 1

19 Circuit 2 compressor heating alarm

20 Low circuit 2 pressure alarm

21 High circuit 2 pressure alarm

22 Circuit 2 antifreeze alarm

23 Circuit 2 fan heating alarm

24 Circuit 2 oil pressure switch alarm

25 Probe alarm circuit 2

26 Voltage monitor alarm

27 Circuit 1 pumpdown alarm

28 Circuit 2 pumpdown alarm

29 Eprom alarm

30 Clock calendar alarm

31 Evaporator pump load

32 Pressure bypass valve load

33 Condenser pump load

34 Circuit 1 compressor load

Table DIGITAL READ (Code 01)

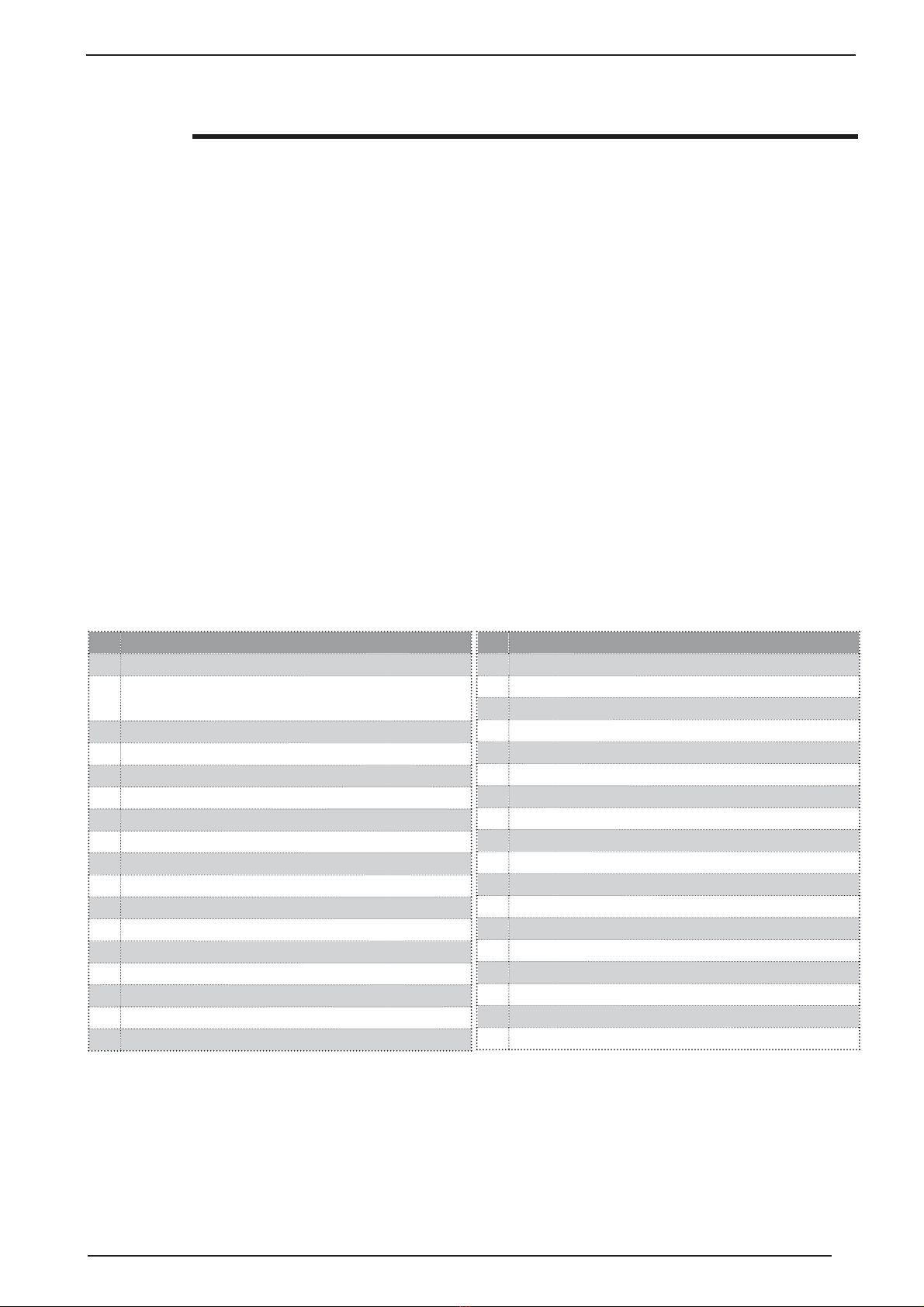

REFERENCE GUIDE FOR MODBUS RTU PROTOCOL

The Modaer communication protocol is the communication

standard made available by Aermec for the connection betwe-

en machines of the chiller series and centralised supervision

or control systems (see the Aermec products guide to see on

which machine this protocol is available).

The protocol allows both the point to point connection (machi-

ne * supervisor), as well as several machines (max 255) on

the same bus link to a supervisor, because it manages one

address for each machine.

The system uses a master-slave communication mode, there-

fore the supervision system is master and the machine slave.

This means that the machine only responds to the enquiry

made by the supervisor.

SERIAL CONFIGURATION:

9600 baud

1 start bit

no parity

1 stop bits

19