3

TABLE OF CONTENTS

1. Quick reference ...................................................................................p.5

2. Structure of the menus...................................................................p.6

Interacting with the graphic interface ...........................................p.6

Navigating between the program pages......................................p.6

Setting a numerical value for a parameter....................................p.7

Setting a value, selecting it from a list............................................p.7

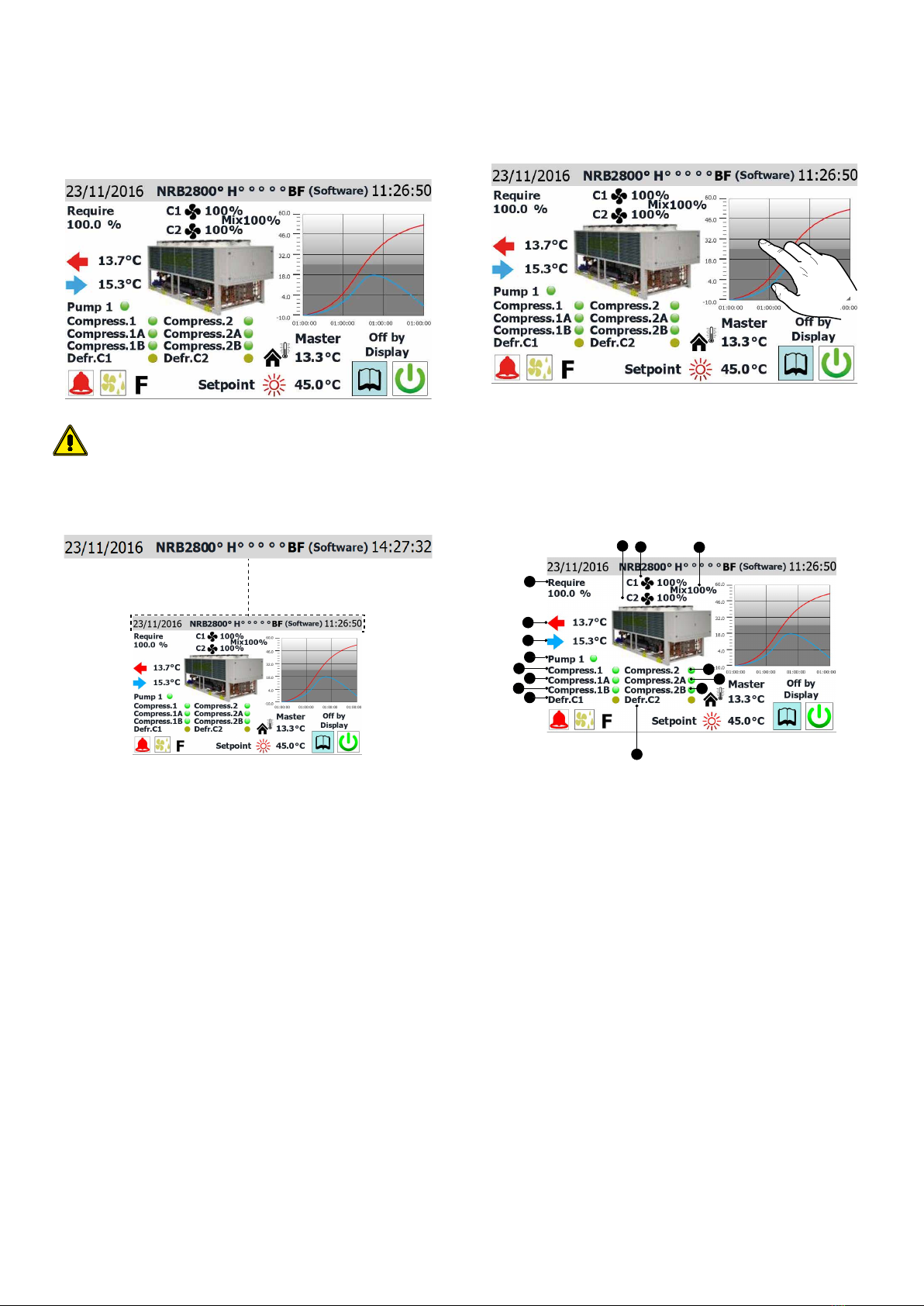

3. Main page (HOME) ............................................................................p.8

Data entered in the upper bar...........................................................p.8

Water inlet/outlet temperature chart.............................................p.8

Unit operating status information (real time data)....................p.8

Data entered in the lower bar, and navigation keys..................p.9

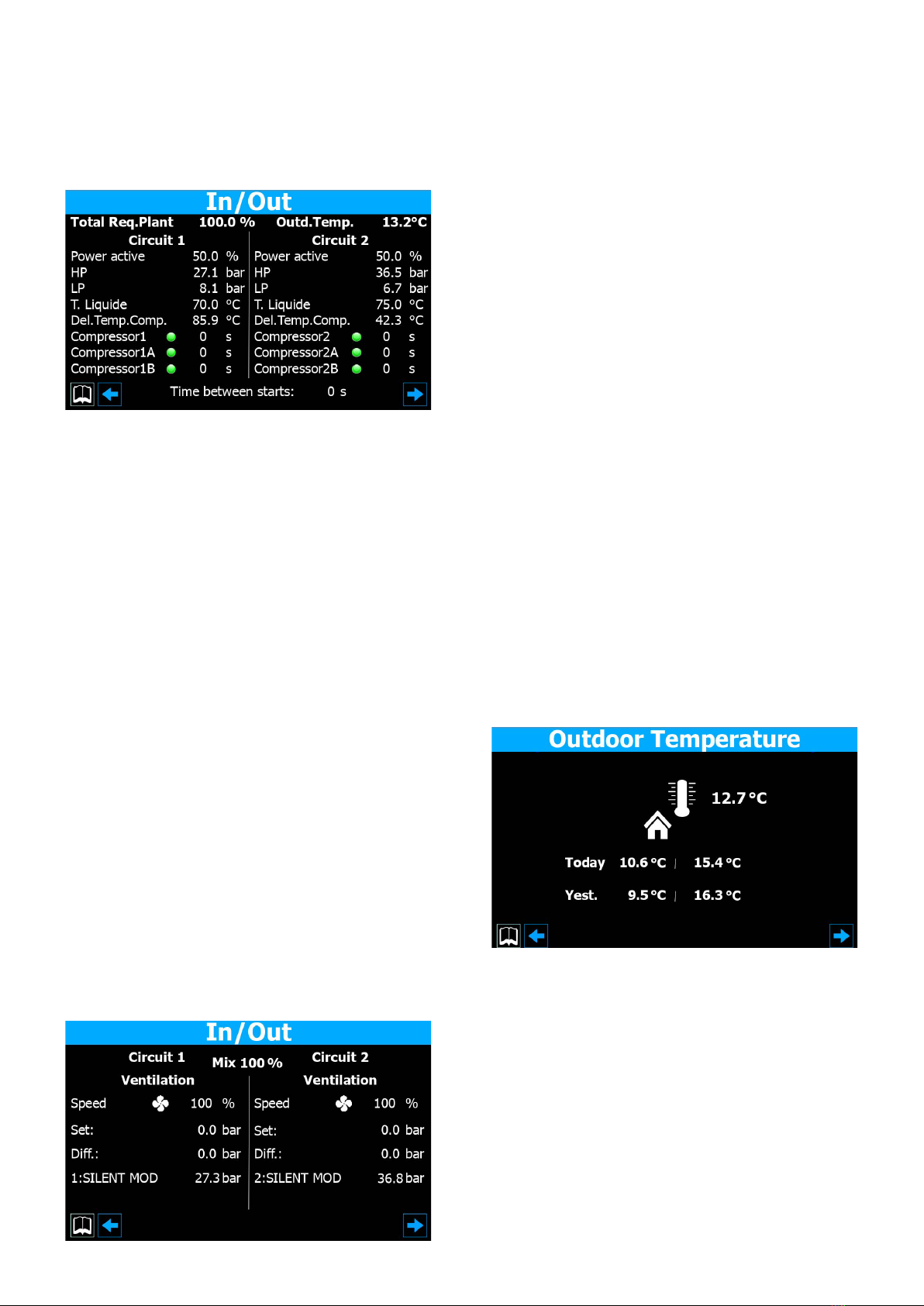

4. Input/output menu........................................................................ p.10

General input/output status ........................................................... p.10

Ventilation status................................................................................. p.10

Outside temperature status ............................................................ p.10

Defrosting status................................................................................. p.11

PCO5 analogue input status............................................................ p.11

uPC analogue input status............................................................... p.11

PCO5 digital input status.................................................................. p.12

PCO5 digital output status............................................................... p.12

uPC digital output status.................................................................. p.13

Status of inputs/outputs for pCOE expansion card ................ p.13

Status of inputs/outputs for total recovery or DK unit.......... p.13

5. ON/OFF menu................................................................................... p.14

Switching the unit ON/OFF ............................................................. p.14

6. System menu..................................................................................... p.14

Setting the operating mode and the main set-points........... p.14

Setting the secondary set-point and recovery (if available)

................................................................................................................... p.15

Setting the outside temperature for automatic

changeover............................................................................................ p.15

Setting the operating mode on the basis of the calendar

................................................................................................................... p.15

7. Installer menu ................................................................................... p.16

Entering the password for accessing the protected menu

................................................................................................................... p.16

Selecting the sub-menus ................................................................. p.16

Enabling On/O via digital input ID17........................................ p.16

Enabling and setting control via the remote supervisor

(BMS)........................................................................................................ p.16

Conguring the thermostat and the type of operating

set-point ................................................................................................. p.17

Conguring the climate curve........................................................ p.17

Conguring the antifreeze conditions ........................................ p.17

Conguring the antifreeze conditions and the recovery

pump (if installed)............................................................................... p.18

Congurazione dei ventilatori........................................................ p.18

Conguring the supplementary heaters and replacement

boiler (if installed) ............................................................................... p.18

Compressor operating log............................................................... p.19

Master Slave - Conguring power control in the case of

two-unit systems................................................................................. p.19

Conguring the Free-cooling unit (if installed)........................ p.19

Conguring the C-Touch clock and the pCO5 clock............... p.19

Conguring the automatic GMT/Daylight Saving Time

changeover............................................................................................ p.20

Conguring the calendar ................................................................. p.20

Software version - Information about the system .................. p.20

8. Alarm Menu........................................................................................ p.21

Main alarm page.................................................................................. p.21

Active alarms page ............................................................................. p.21

Alarm history ........................................................................................ p.21

List of alarms......................................................................................... p.22

9. Diagram menu.................................................................................. p.23