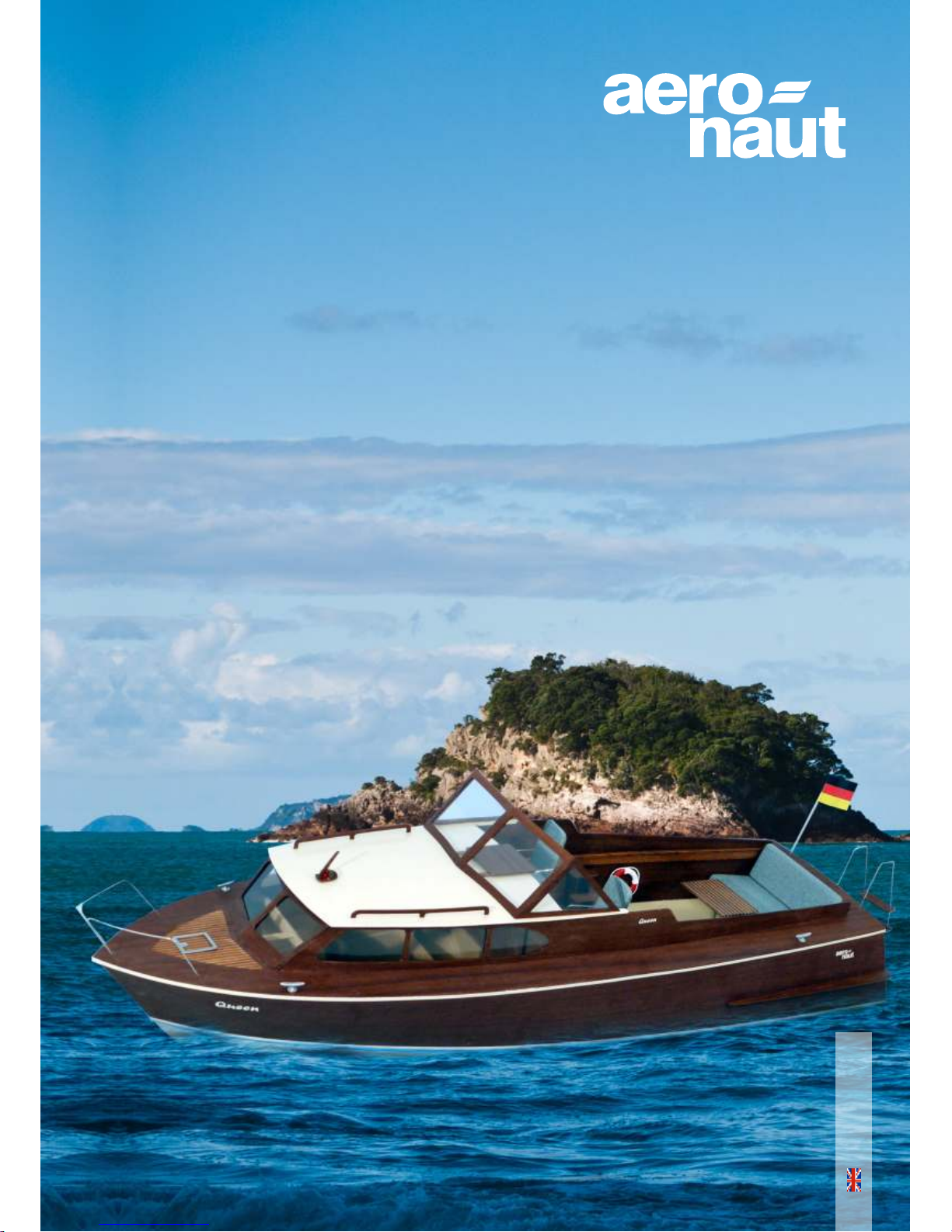

Aeronaut Queen Instruction Manual

Other Aeronaut Toy manuals

Aeronaut

Aeronaut Aero-Maxx Instruction Manual

Aeronaut

Aeronaut Jonny User manual

Aeronaut

Aeronaut Galaxy Instruction Manual

Aeronaut

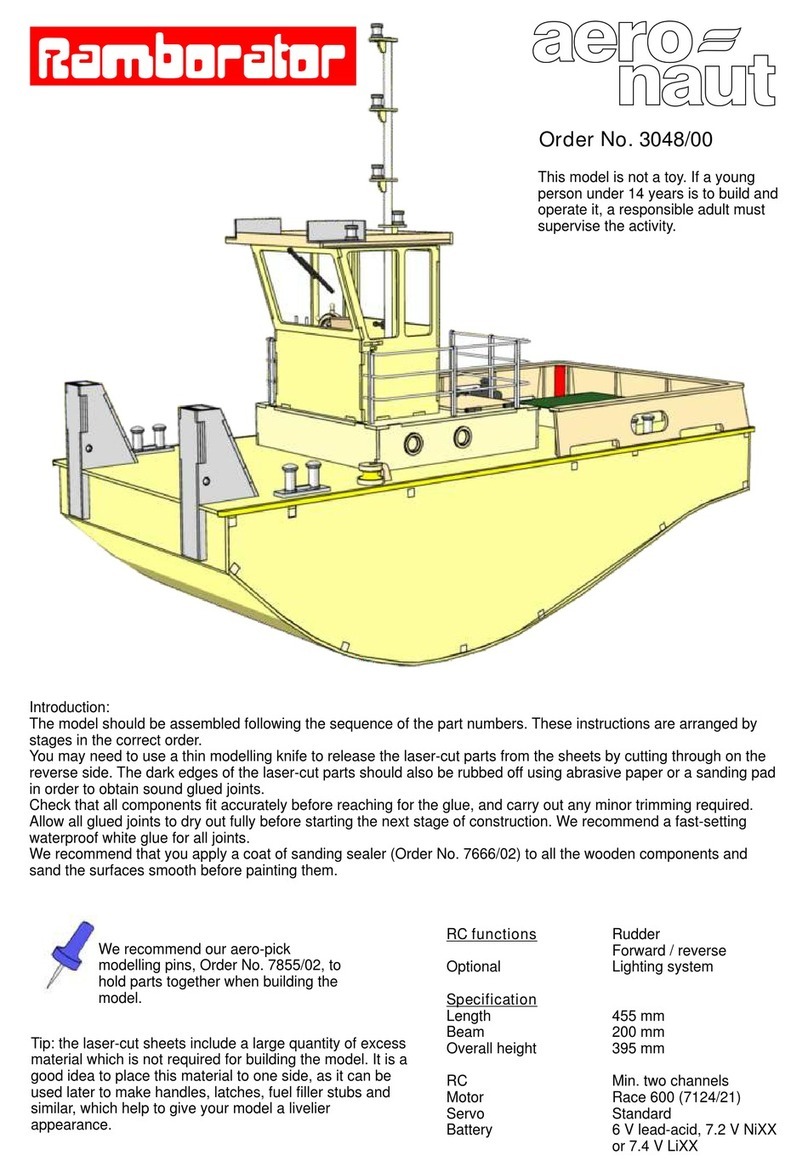

Aeronaut Rambotator User manual

Aeronaut

Aeronaut LT 200 Flex User manual

Aeronaut

Aeronaut 3033/00 User manual

Aeronaut

Aeronaut Quido User manual

Aeronaut

Aeronaut Mowe 2 User manual

Aeronaut

Aeronaut Manta A 02 User manual

Aeronaut

Aeronaut RX-3 User manual

Aeronaut

Aeronaut Twinspeedy User manual

Aeronaut

Aeronaut Scarlet Instruction Manual

Aeronaut

Aeronaut BLADE 2 Instruction Manual

Aeronaut

Aeronaut The Hansa-Jolle Instruction Manual

Aeronaut

Aeronaut SkyMAXX User manual

Aeronaut

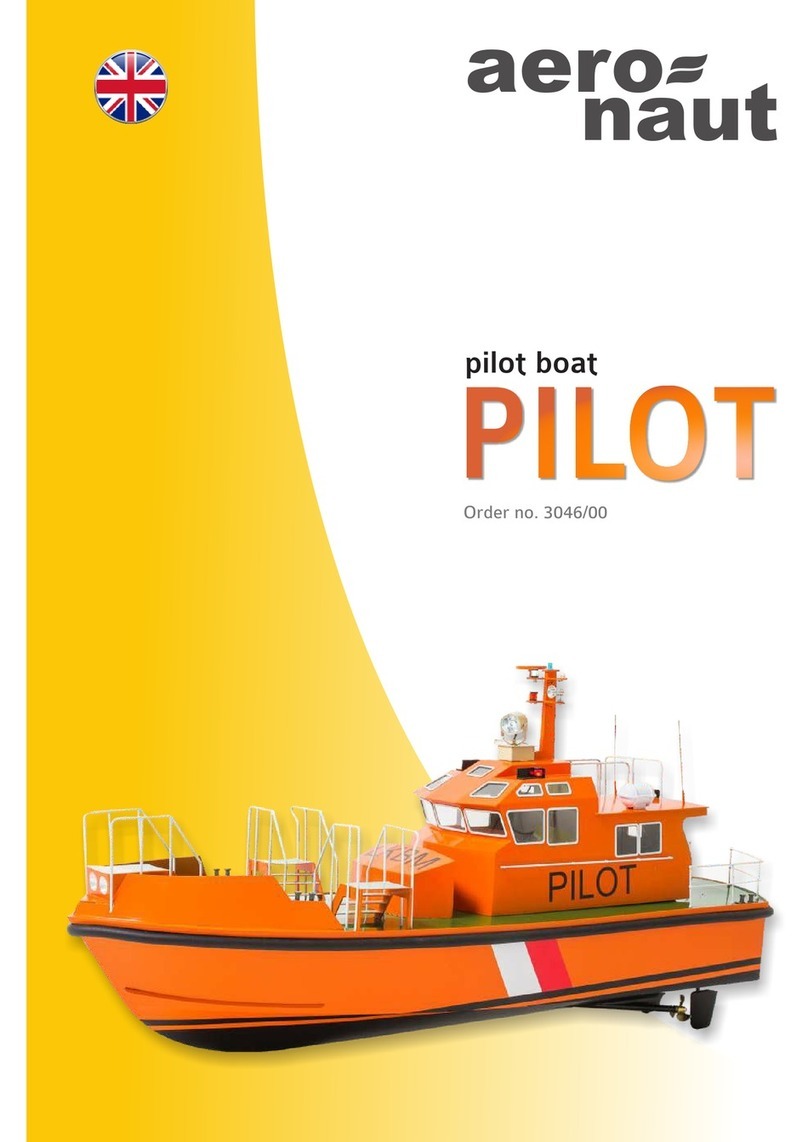

Aeronaut Pilot User manual

Aeronaut

Aeronaut LUXX Instruction Manual

Aeronaut

Aeronaut Lilienthal 40 RC User manual

Aeronaut

Aeronaut Princess User manual

Aeronaut

Aeronaut Sukhoi SU 31M Instruction Manual

Popular Toy manuals by other brands

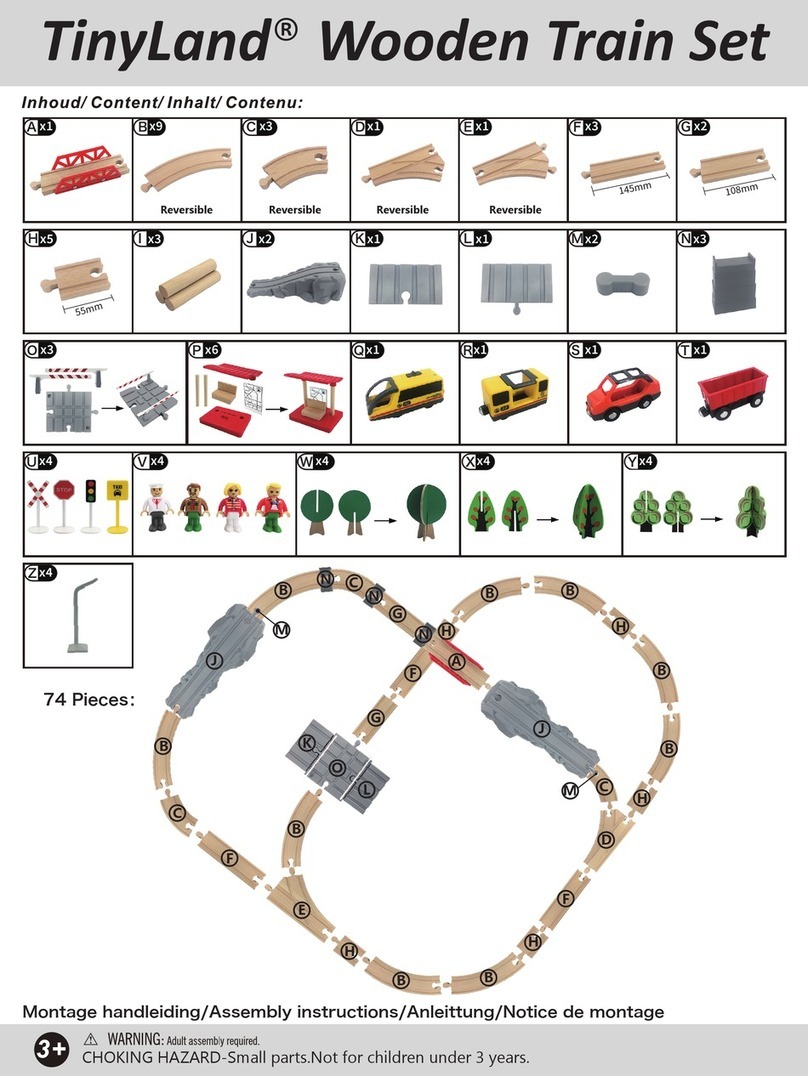

TINY LAND

TINY LAND Wooden Train Set-74 Pcs Assembly instructions

PlayMonster

PlayMonster Roominate Cozy Corner Cafe instructions

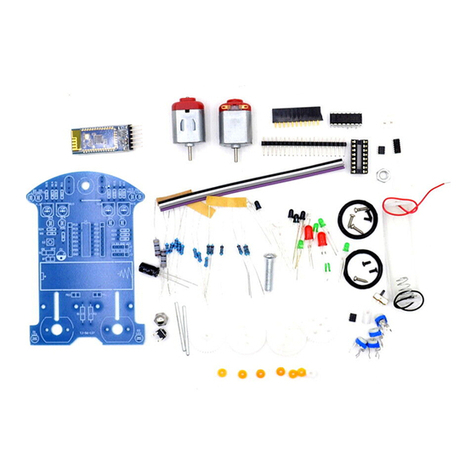

yourDroid

yourDroid D2-6 instructions

Lionel

Lionel 2-8-4 Berkshire Locomotive and Tender owner's manual

Lionel

Lionel 2-8-4 Berkshire Locomotive and Tender owner's manual

RCRCM

RCRCM Hornet Motor Glider Build manual

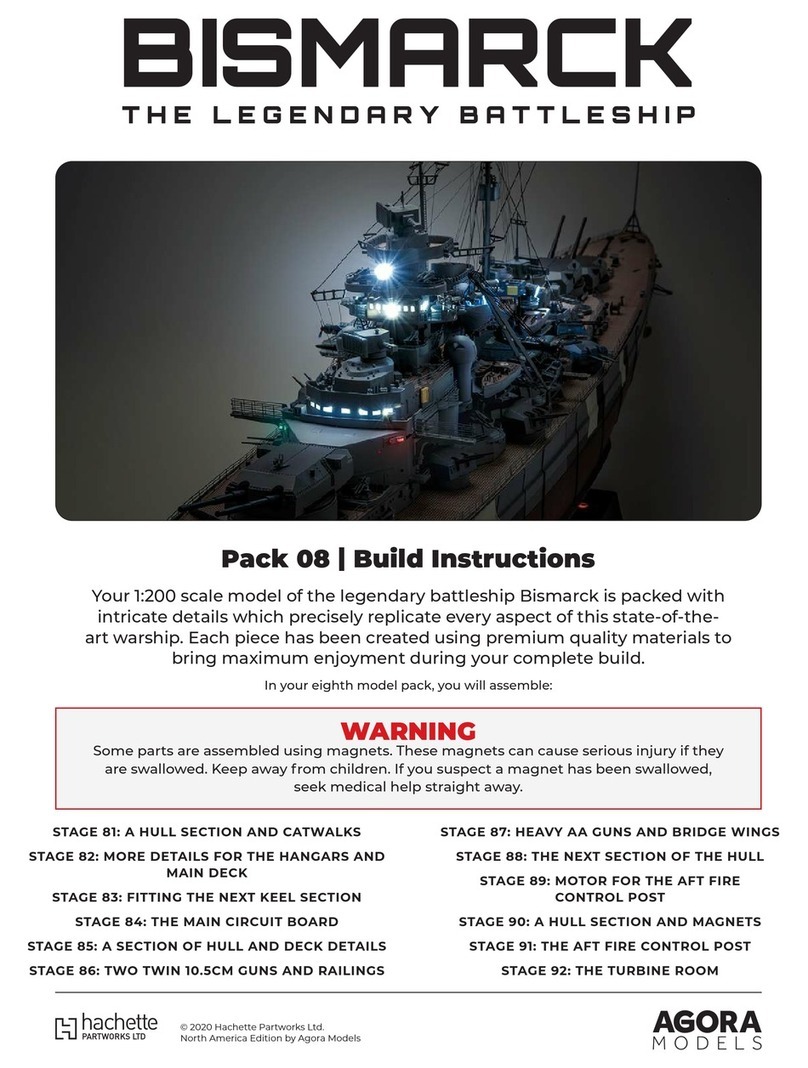

Agora Models

Agora Models Bismarck 08 Build instructions

Black Horse Model

Black Horse Model Sputnik Instruction manual book

Rollplay

Rollplay W461-G Owner's manual and assembly instructions

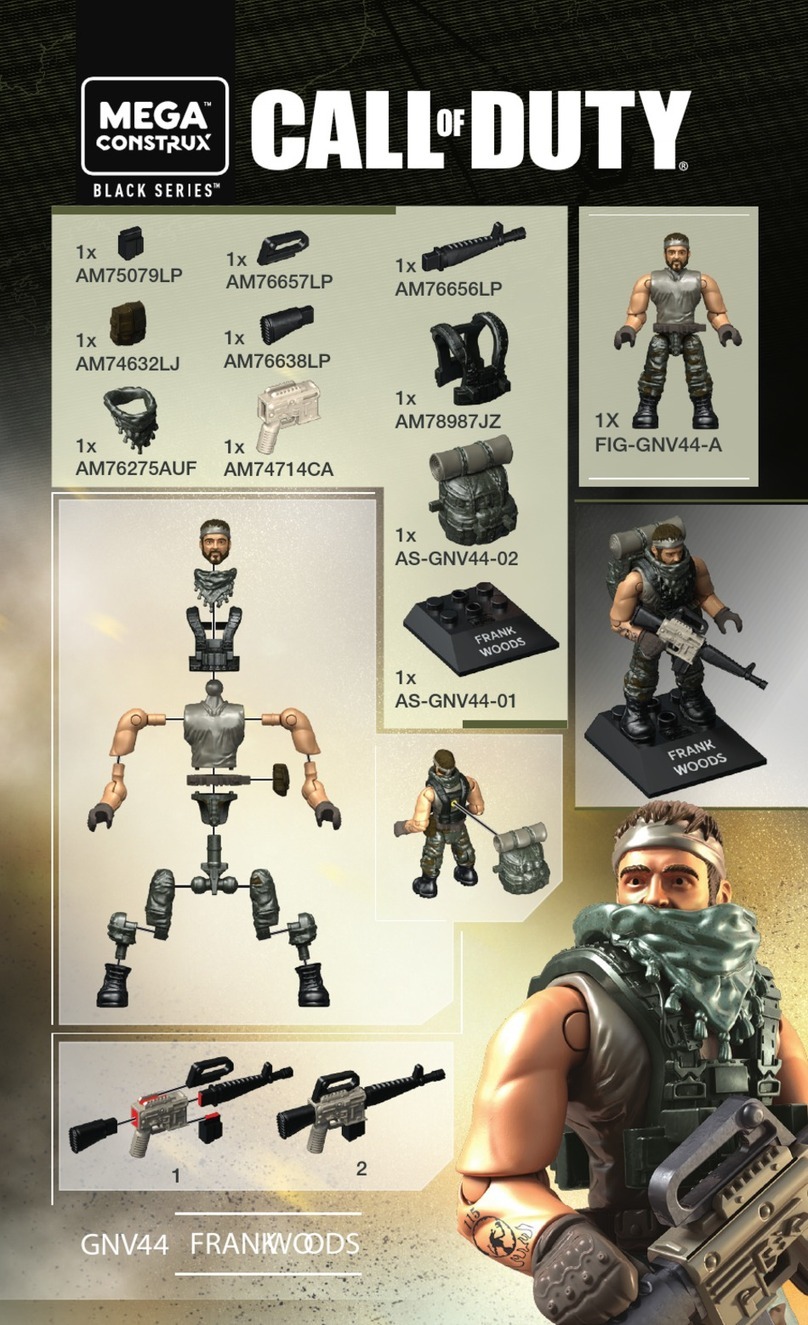

Mega Construx

Mega Construx CALL OF DUTY BLACK FRANK WOODS GNV44 manual

Value Hobby

Value Hobby Piper J3 Cub 40 instruction manual

THE WORLD MODELS

THE WORLD MODELS Extra 300 EP instruction manual