Afinia H480 User manual

Afinia

H480 3D Printer

Version 1.3

Afinia H480 3D Printer User’s Manual

2

Afinia H480 3D Printer User’s Manual

3

TABLE OF CONTENTS

Introduction .............................................................................................................................. 5

Safety Precautions .............................................................................................................. 5

Protection ............................................................................................................................ 5

Overview ................................................................................................................................... 6

Un acking the Afinia H480 3D Printer ................................................................................ 7

Installing the A inia H480 3D Printer ...................................................................................... 8

Attaching the Material S ool ............................................................................................... 8

Driver and Software Installation .......................................................................................... 9

Installing the Printer ............................................................................................................ 9

Getting Ready to Print ............................................................................................................ 11

Starting the Afinia 3D Program .......................................................................................... 11

Initializing the Printer .......................................................................................................... 11

Pre aring the Platform ...................................................................................................... 12

Leveling the Print Platform ................................................................................................ 13

Platform Level Calibration ................................................................................................. 13

Calibrating the Nozzle Height ........................................................................................... 16

Loading the Print Material Filament .................................................................................. 18

Other Maintenance O tions .............................................................................................. 18

Printing with the H480 3D Printer ......................................................................................... 20

Loading a 3D Model .......................................................................................................... 20

View O tions ..................................................................................................................... 22

Model transformations ....................................................................................................... 22

Placing Models onto the Build Platform ............................................................................ 24

Print Setu O tions ........................................................................................................... 25

Printing .............................................................................................................................. 28

Print O tions ..................................................................................................................... 29

Save as Project ...................................................................................................................... 30

Model Removal ...................................................................................................................... 31

Removing Su ort Material............................................................................................... 32

Maintenance ........................................................................................................................... 33

Changing the Material ....................................................................................................... 33

Vertical Calibration ............................................................................................................ 33

Cleaning the nozzle ........................................................................................................... 34

Removing / Changing the Nozzle ..................................................................................... 35

Cleaning the Platform ........................................................................................................ 35

Lubrication of bearings ...................................................................................................... 35

S are arts ........................................................................................................................ 35

Tips & Tricks .......................................................................................................................... 36

Status Indicator ...................................................................................................................... 38

Changing Languages ............................................................................................................ 38

Troubleshooting ..................................................................................................................... 39

Solution for "Winusb.dll not found" roblem (Windows) ................................................... 39

Updating the Printer ROM ..................................................................................................... 41

Speci ications ........................................................................................................................ 41

Printer Physical Characteristics ........................................................................................ 41

S ecifications .................................................................................................................... 41

Environmental s ecifications............................................................................................. 41

Technical Support .................................................................................................................. 42

Afinia H480 3D Printer User’s Manual

4

Afinia 1-Year Limited Warranty

Below is the one-year limited warranty included with this Afinia roduct. Afinia rides itself on its outstanding

roduct line and its technical su ort. If for some reason, your roduct fails, Afinia, a division of Microboards

Technology, LLC, stands behind its warranties and assures you the best service ossible in a quick and timely

manner.

Afinia warrants to the original urchaser that this roduct is free from defects in material and workmanshi .

Afinia will for one year, at its o tion, re air or re lace at no charge for arts and labor from the date you

urchased the roduct from an authorized Afinia reseller. Nozzles and Cell/Perf Boards are warranted for

ninety (90) days.

• Warranty registration must be com leted within 30 days of recei t of the roduct in order to validate the

warranty.

• Afinia, a division of Microboards Technology, LLC, reserves the right to determine the validity of all warranty

claims.

• Warranty is void if the roduct serial number has been altered or removed.

• Warranty is void if the roduct has been misused or damaged or if evidence is resent that the roduct was

altered, modified, or serviced by unauthorized service eo le.

The above stated warranty is exclusive and re laces all other warranties, ex ress of im lied, including those of

merchantability and fitness for a articular ur ose. Afinia, a division of Microboards Technology, LLC, will not

be liable for any other damages or loss, including incidental or consequential damages and loss of rofits or

revenues from whatever cause, including breach of warranty or negligence.

This roduct has been thoroughly tested and ins ected at the factory rior to shi ment. Nevertheless, ins ect

your roduct com letely for any damage or loss of arts that may have occurred during shi ment. Notify the

delivering carrier rom tly if damage claims are to be filed.

Afinia reserves the right to modify or u date its roduct without obligation to re lace any equi ment delivered

rior to any such change.

To register your warranty, please visit www.afinia.com/register

FCC ID: 026-H480

This device com lies with Part 15 of the FCC Rules. O eration is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must acce t any interference received,

including interference that may cause undesired o eration.

Changes or modifications not ex ressly a roved by the arty res onsible for com liance could void the

user's authority to o erate the equi ment.

NOTE: This equi ment has been tested and found to com ly with the limits for a Class B digital device,

ursuant to Part 15 of the FCC Rules. These limits are designed to rovide reasonable rotection against

harmful interference in a residential installation. This equi ment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

articular installation. If this equi ment does cause harmful interference to radio or television rece tion, which

can be determined by turning the equi ment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

•

Reorient or relocate the receiving antenna.

•

Increase the se aration between the equi ment and receiver.

•

Connect the equi ment into an outlet on a circuit different from that to which the receiver

is connected.

•

Consult the dealer or an ex erienced radio/TV technician for hel .

Afinia H480 3D Printer User’s Manual

5

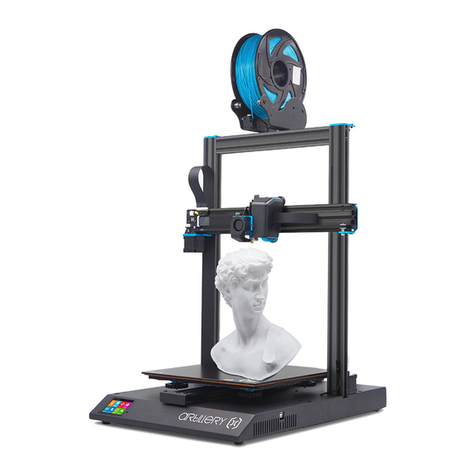

Introduction

Congratulations on urchasing an Afinia H480-Series 3D Printer. The Afinia H480 3D Printers are

designed with ultimate ortability and sim licity in mind. The system and software allow you to

rint great models in a few easy ste s, even if you have never used a 3D rinter before. The

Afinia H480 3D rinters combine years of ex erience and innovation to make rinting 3D models

easy through its reliably sim le hardware and software design.

Sa ety Precautions

Please read this section carefully before using the rinter.

• The rinter can only be used with the ower ada ters su lied by this com any, or the

roduct may be damaged, with a risk of fire.

• To avoid burning or model deformation, do not touch the model, nozzle, or the latform by

hand or any other art of the body while the rinter is working or immediately after it has

finished rinting.

• Protective glasses should always be worn when removing su ort material, es ecially

PLA.

• The brown sections of the currently su lied gloves melt at around 200º C; lease do not

hold the extruder block with the gloves.

• There is a slight smell from ABS when it is being extruded. A well-ventilated room is

recommended; however when rinting, kee the rinter away from any drafts as this can

affect the war ing of ABS rints.

• When ABS is burnt it releases toxic fumes. Never set the nozzle tem erature high enough

to burn the material.

The following classifications are used in this manual:

CAUTION: Indicates a otentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

WARNING: Indicates a otentially hazardous situation which, if not avoided, may

result in serious injury.

GLOVES: When erforming certain maintenance rocedures, the machine may

be hot and gloves are required to avoid burns.

SAFETY GLASSES: Wear safety glasses to avoid injury to your eyes.

Protection

• The rinter must not be ex osed to water or rain, or damage may occur.

• Do not shut down the Afinia H480 3D System or ull out the USB cable when loading a

digital model or the model data may be lost.

• When using the “Extrude” function, kee at least 50mm between the nozzle and the

latform. If too close, the nozzle may get blocked.

• The rinter is designed to work ro erly at an ambient tem erature of between 60°F and

85°F and humidity of between 20% and 50%. O erating outside these limits may result in

low quality models.

Afinia H480 3D Printer User’s Manual

6

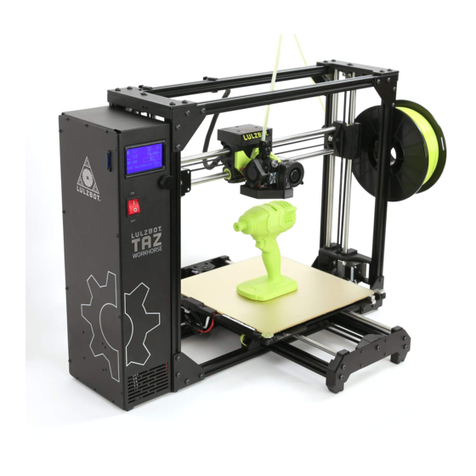

Overview

The Afinia H480 3D Printer consists rimarily of the Extruder, Print Platform, Material S ool, and

Filament, all su orted by the Pedestal. The Printer is initialized with a single switch, and

calibrating the osition of the rint latform is done using the included Afinia software.

The Afinia 3D software sends the rint data from a Mac or PC to the Printer over a single USB

cable. The Print Platform moves both vertically and front-to-back while the Extruder moves

left-to-right, roviding the necessary 3 axes of o eration (see Figure 2). The Extruder delivers the

Filament from the Material S ool into the Nozzle, which heats the filament to rinting tem erature

and de osits it on the Platform.

Data Connection

Z Axis:

Vertical

Platform or X Axis:

Front to Back

Extruder or Y Axis:

Left to Right

Figure 2: Axes of Operation

Figure 1: Front and Back views of the Afinia H 80 3D Printer

Status

Indicator

Power

Switch

USB

Port

Power

Connection

Pedestal

Platform

Nozzle

Extruder

Guard

Filament

Guide

Filament

Tube

Material

S ool

Plastic

Filament

Initialization

Switch

Nozzle

Sensor

Afinia H480 3D Printer User’s Manual

7

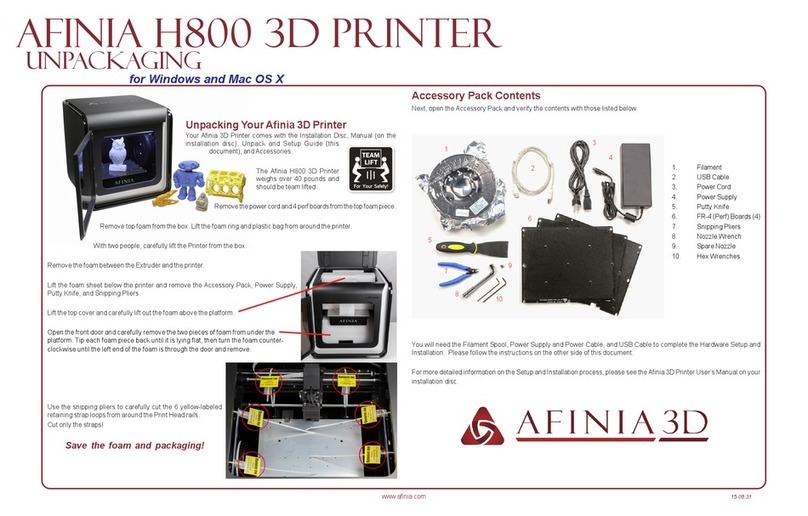

Unpacking the A inia H480 3D Printer

Remove the Installation Disc, Manual, Quick Start Guide, and Accessories Pack from the box.

Next, lift the Afinia H480 3D rinter from the box. Remove the foam from both sides of the Printer

and set the Printer on its base with the back of the Printer facing you.

There are 2 ackaging cli s that rotect the Printer during shi ing

that need to be removed. Both clips should be saved in the event

that you need to ship the Printer in the future!

The first cli to be removed is used to hold the Extruder assembly in

lace during shi ing. Carefully eel the stra ing ta e down, and

then slide the cli down and off the Printer.

The second cli is used to hel kee the Platform Arm secure during

shi ing. To remove the cli , lace your hand under the latform X-axis

arm and gently lift. Do not lift the arm by holding onto the latform!

Once the latform arm has been lifted a few inches, rotate the to of the

cli towards the front of the rinter. Once in the correct osition, the cli

will sli over the Z-axis arm.

Next, o en and check the contents of the Accessory Pack:

• Reel of Filament (1, Natural/White)

• Power Su ly

• Power Cable

• USB Cable

• FR-4 (Perf) Board

• Filament Guide Tube

• Filament Hanger

• Nozzle Wrench

• Hex Wrenches

• S are screws & washers

• Gloves (1 air)

• Putty Knife

• Exacto Knife and blades

• Sni ing Pliers

• Tweezers

• Platform and Nozzle Cable

• Platform Calibration Probe

You will need the Power Su ly and Cable, Hex Wrenches, Filament S ool, Filament Hanger,

Filament Tube, and USB Cable to com lete the Afinia H480 3D Printer installation.

Afinia H480 3D Printer User’s Manual

8

Installing the A inia H480 3D Printer

Attaching the Material Spool

Attach the Material S ool with these ste s:

A. Connect the ower ada ter to the ower

interface and turn on the ower switch.

B. Install the ABS lastic s ool holder and filament guide.

a. Insert the tab on the back of the s ool holder

into the slot on the left side of the rinter.

b. Slide the s ool holder down as far as it will go.

C. Put the ABS Material S ool onto the holder with the

end of the filament ointing u from the back. Thread

the filament through the Filament Guide at the to of

the s ool holder.

D. Insert the end of

filament into one end

of the Filament tube.

Feed the filament

through the tube until

about 4 inches of

filament rotrudes

from the tube.

The filament will be loaded into the extruder later in the installation rocess.

Afinia H480 3D Printer User’s Manual

9

Driver and So tware Installation

Mac

Insert the Installation Disc into your Mac. O en the disc, go into the Mac folder, and

double-click the A inia Mac Setup.pkg icon. Follow the rom ts through the installation. The

drivers will be added and the Afinia software will be installed to the Applications folder.

Windows

Insert the Installation Disc into your PC. If the installer does not launch automatically, start the

Afinia H480 3D Printer setup.exe file in the PC directory on the installation disc and install to

the s ecified directory (default is Program files\Afinia\Afinia 3D Printer).

Note: This installs the Afinia H480 3D Printer software, the Afinia H480 3D Printer drivers, and

the Afinia H480 3D Printer sam le files into your Program files\Afinia\Afinia 3D Printer

folder.

Follow the instructions in the Installer to be sure the drivers and software are all in lace

before attem ting to use the Printer. The instructions below will follow the same order as those

in the Installer.

Installing the Printer

Mac

Sim ly connect the Printer to your Mac using the USB connection on the back of the Printer.

Windows Vista, Windows 7, and Windows 8

As art of the installation, the 3D Printer drivers are re-installed and you will be rom ted to

connect the Printer to your PC. The Printer will be recognized and automatically installed when it is

connected to your PC.

Windows XP

Since XP does not have the driver re-installation ability,

the drivers must be manually installed when the Printer

is connected to the PC. Follow these ste s:

A. Connect the rinter to a com uter with the USB

cable. If the com uter dis lays the “Found New

Hardware Wizard” window, choose No, not this

time, and click the Next button.

B. Choose Install rom a list or speci ic location

(Advanced) and click Next.

USB Connection

Afinia H480 3D Printer User’s Manual

10

C. Select the o tion to Search removable

media; the drivers are located on the

installation disc.

If you are installing from a download, click

Browse, then navigate to C:\Program

files\Afinia\Afinia 3D Printer\Driver, then

Next.

D. If the following dialog box a ears, click

Continue Anyway, and the drivers will install

automatically.

Afinia H480 3D Printer User’s Manual

11

Getting Ready to Print

Starting the A inia 3D Program

If the a lication is not already o en, click the Afinia 3D icon on the deskto (Windows) or in the

A lications folder (Mac). The rogram should o en and a ear as shown below:

Windows version Mac version

Initializing the Printer

Be ore anything can be printed, the printer must be initialized. Click the Initialize o tion from

the 3D Print menu. The rinter will bee and the initialization rocedure will begin. The rinter will

return the latform and rint head to the rinter’s origin and bee again when it is ready.

Windows version Mac version

The front Initialization Switch can also be used for initialization. Hold down the Initialization Switch

for one second to trigger the initialization rocedure.

TIP: If your rinter is not res onding ro erly, the first thing to try is to re-initialize the rinter by

clicking the Initialize o tion from the 3D Print menu.

Afinia H480 3D Printer User’s Manual

12

Preparing the Plat orm

Before you start rinting, the latform must be re ared so that the model adheres to the latform

enough to be rinted without the model moving. At the same time, you will want the model to be

easy to remove from the latform after rinting. There are several o tions for re aring the

latform:

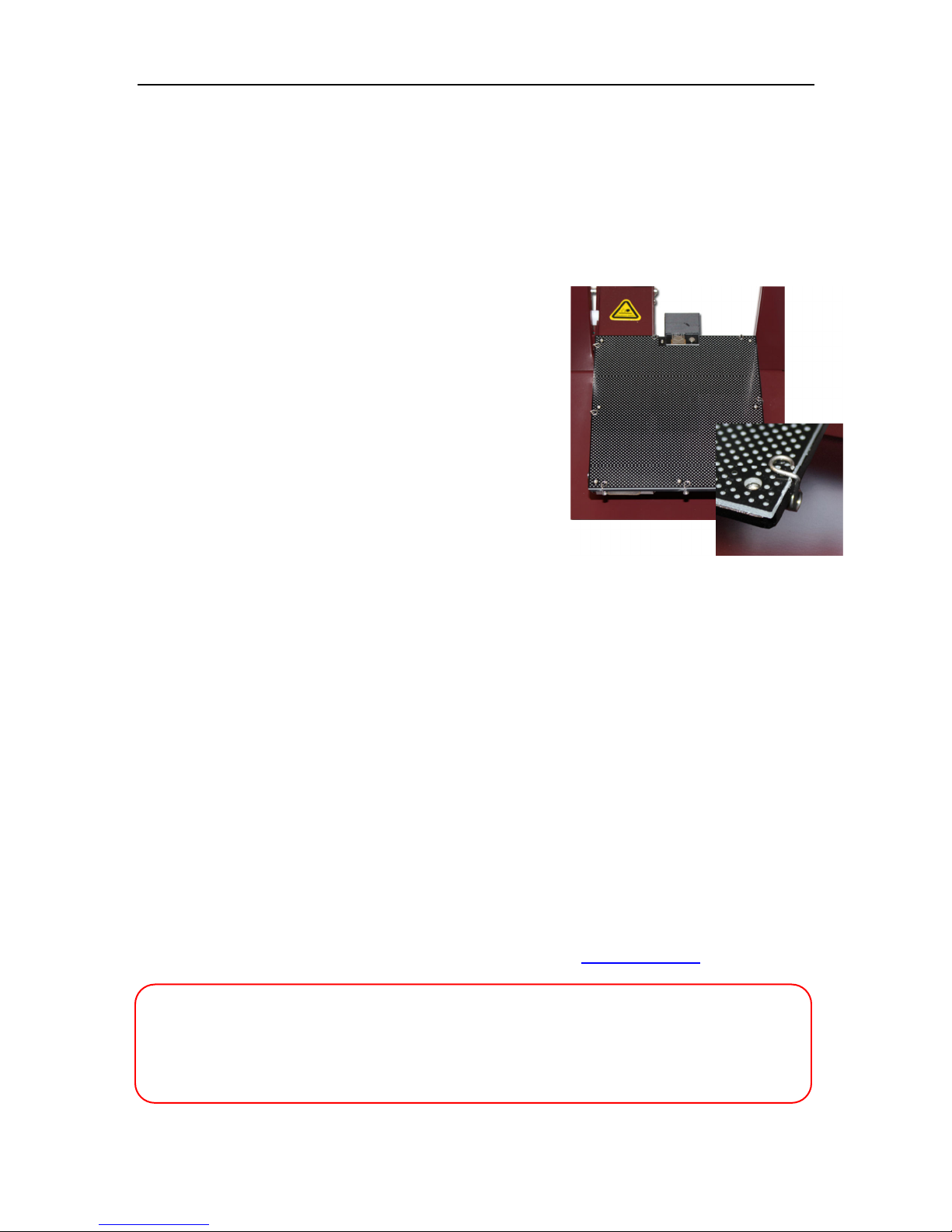

FR-4 Board (Glass-rein orced Epoxy Laminate)

Many users have re orted excellent results by using a iece of FR-4 Board to cover the build

latform. FR-4 Board is a erforated, glass-reinforced e oxy laminate sheet.

When using FR-4 Board, the first layer of the raft ushes

lastic into all the erforations, and this rovides a strong

mechanical bond with the surface that revents it from later

lifting. Attach the FR-4 Board to the latform using the s ring

cli s installed on the latform as shown in the icture to the

right. Make sure that all eight cli s are correctly ositioned,

with the to of the cli over the surface of the FR-4 board.

Some FR-4 Boards may work better than others. For

consistent rinting, it is recommended that you use the FR-4

Board included with the Printer.

Boro loat Glass

Many users have re orted success using Borofloat glass as

the rint surface. In this method, an ABS and acetone slurry is made in advance,

which is lightly brushed onto the glass and allowed to dry into a thin film of ABS.

The ABS film will hold the model to the heated glass, and will release from the glass as the glass

cools. If the model does not easily release, s ray a small amount of an ammonia-based glass

cleaner around the model.

The same glass cleaner can be used to easily clean the film from the glass.

It is recommended that you clean and recoat the rint surface after each rint if you will be rinting

the next model in the same location. Allow the slurry to dry fully before lacing the glass on the

rint latform!

You will need to remove the four corner s ring cli s from the latform and osition the two s ring

cli s on the side under the latform. You can also remove the s ring cli s, but will need to remove

the latform from the rinter to do so; removing the two hex screws underneath the latform is

required for this. Use the glass cli models from the S are Parts folder to hold the glass to the

latform.

BuildTak Print Sur ace

BuildTak is a rint surface that can be adhered to the FR-4 board or to glass, although when

adhering to glass it is very im ortant to be sure that no air is tra ed between the glass and the

BuildTak, as a bubbled surface could lead to rinting roblems.

Be sure to osition the BuildTak surface on the actual rint zone – the FR-4 board is longer than

the surface, with the front and back ends of the board not actually within the rint zone.

Boro loat glass and BuildTak are available at store.a inia.com.

Whichever platform preparation method you use, the factors that most reduce the risk of

warping on large prints are ensuring that the platform is well leveled, ensuring that the

nozzle height is set correctly, and having a well pre-heated print surface.

The next few pages will step you through correctly leveling the platform and setting the

nozzle height.

Afinia H480 3D Printer User’s Manual

13

Leveling the Print Plat orm

Before calibrating the nozzle height, always check the vertical nozzle distance from each corner

and center of the rint latform. O en the Maintenance dialog box from the 3D Print menu and

click the Center button to begin the manual leveling rocess.

If you already know the nozzle height, enter that height minus 2mm in the To: box, then click the

To: button. If your nozzle height is 135.3, for exam le, enter 133.3.

If you do not yet know the nozzle height, Click the To: button to bring the latform to the dis layed

height, then slowly increment the height until the latform is about 2 mm from the nozzle, clicking

To: after each increase.

Use the five osition buttons to check that the latform at all four corners and the center are the

same distance from the nozzle.

If the latform is not the same distance from the nozzle at all five oints, you will need to adjust the

latform until it is as level as ossible. Use the 3 thumbscrews under the latform arm to level the

rint latform.

Loosening a thumbscrew will raise the corner or side of the

latform where the screw is, while tightening the thumbscrew

will lower the same art of the latform. Adjust the thumbscrews

as needed until all four corners and center of latform are the

same vertical distance from the nozzle.

The thumbscrews can heat u while the rinter is running.

Always recalibrate the nozzle height after leveling the latform.

Plat orm Level Calibration

This process is not intended to replace physically leveling the plat orm. The Plat orm Level

Calibration should only be used i your print sur ace itsel cannot be leveled due to warping

or an inconsistent thickness.

If the latform surface cannot be leveled after erforming the manual leveling as described above,

there is a utility in the Afinia software that allows you to adjust the rinting of the raft to level the

model rinting layers by dividing the rint latform into several zones and entering adjustments for

each.

Note: The Platform Level Calibration will only affect rinting when rinting with a raft. If you are

rinting without a raft, this utility will not affect rint leveling.

There are two methods of calibrating the latform, the first automatically, the second manually.

Mac version

Windows version

Leveling screws

Afinia H480 3D Printer User’s Manual

14

Automatic Plat orm Level Calibration

To erform the Automatic Platform Level Calibration, follow these ste s:

1. Attach the Platform Probe to the

bottom of the extruder.

a. Do not attach the probe i the

nozzle is above 80⁰ C!

b. Lower the latform to the bottom of

the rinter by clicking the To Bottom button

in the Maintenance dialog box.

c. The magnet at the to connects to the

bottom of the Extruder Motor with the

slot for the nozzle to the left and the connection

for the data cable to the right.

d. You do not need to remove the Cover to attach the Platform Probe. The images here have

the Extruder Cover removed for clarity only.

2. Connect one end of the data cable to the data

connection n the Probe.

3. Route the cable around the right side of the

rinter as shown to the right and connect the

other end of the data cable to the green data

connection on the back of the Afinia H480

rinter.

NOTE: Do not attem t to ass the cable over or

through the frame of the rinter, as this will

interfere with the calibration rocess.

4. Select Auto Level from the 3D Print menu. The

automatic rocess will check the height of nine calibration oints on

the latform.

These heights are used to determine which of the nine oints is the highest is on the

latform, and what the differences in height are between the highest oint and the other

eight oints.

5. The Automated Plat orm Level

Calibration process will reset

the nozzle height on the printer.

You will be reminded that the

nozzle height needs to be set

be ore printing.

6. After the Calibration is com lete, remove the data cable from the Platform Probe and

disconnect the Probe from the Extruder.

7. If you wish to review the calibration values found during this rocess, o en the Plat orm

Calibrate o tion in the 3D Print menu. Calibration values will be shown in the middle

section of that window.

Platform

Probe

Data Cable

Connection

Platform

Probe ttached

Afinia H480 3D Printer User’s Manual

15

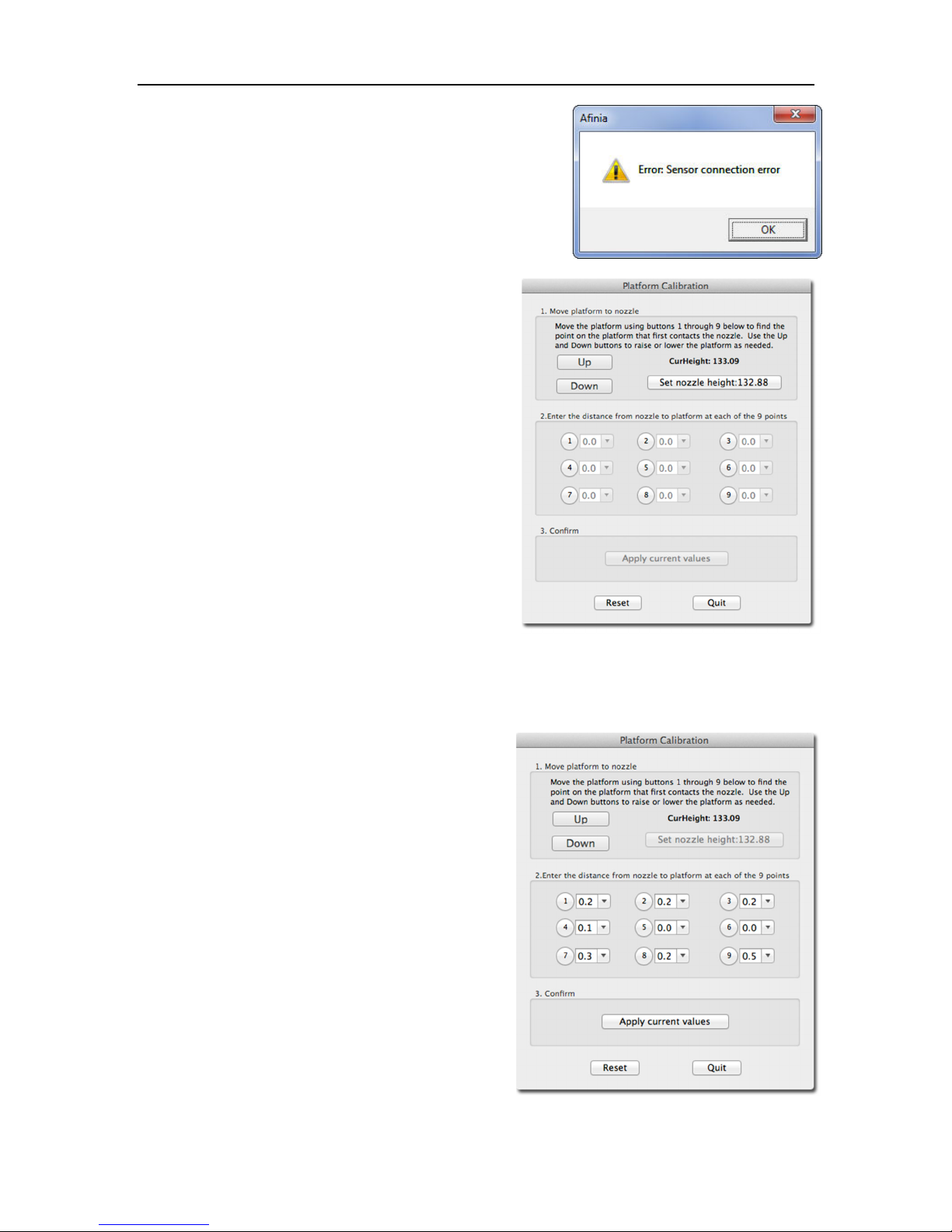

If the message to the right a ears when you choose the

Auto Level o tion, check that the data cable is securely

connected to both the Platform Probe and the data

connection on the back of the rinter. After verifying the

connections, select Auto Level again.

Manual Plat orm Level Calibration

You can also manually calibrate the Platform Level.

Select Plat orm Calibrate from the 3D Print menu to

o en the manual utility.

First, find the highest of the 9 oints on the rint

surface. Click the button labeled 5 to move the nozzle

to the center of the latform. Use the Up button to

raise the latform; holding the button down will move

the latform steadily, while single clicks can be used

to fine-tune the latform height.

Raise the latform until the rint surface is just

touching the nozzle and note the current height.

Next, click the Down button a few times to lower the

latform then click the 1 button to check the rint

surface at the back left corner.

Raise the latform again until the rint surface is just

touching the nozzle. If the current height is lower than

the revious oint when the rint surface and nozzle

first contact each other, use this oint as the

reference.

Re eat these ste s for each of the 9 oints on the latform. Once you have determined the

highest oint on the rint surface, move back to that oint and adjust the latform osition so the

nozzle is again just touching the rint surface. Click the Set nozzle height button to change the

nozzle height setting to that shown.

Once the nozzle height is set, use the 9 buttons to

move to each osition. Select the distance from the

dro -down to the right of the selected osition,

choosing the value that will bring the rint surface

into contact with the nozzle.

Perform this ste with each of the nine ositions. If

you are using cli s to secure the rint surface to the

latform, be careful to osition the cli s so they do

not interfere with the nozzle or wind barrier.

Once all 9 values have been entered, click the Apply

current values button.

If you need to erform this function again, click the

Reset button to clear all values.

Click the Quit button when you are finished.

Afinia H480 3D Printer User’s Manual

16

The adjustments in the exam le shown, for instance, indicate that the rint surface is war ed, with

the center higher than both the front and back edges. Using the Platform Level Calibration utility,

you can correct for this war ing.

This process is not intended to replace manually leveling the plat orm. It should only be

used i your print sur ace itsel cannot be leveled due to warping or an inconsistent

thickness.

Calibrating the Nozzle Height

This section is probably the most important o the entire manual. Please read it care ully to

ensure that you understand the nozzle height setup procedure, as it is vital to success ul

3D printing.

To rint successfully, the latform should be set to start at a distance of 0.2mm from the nozzle. As

each rinter is slightly different, this distance needs to be calibrated before starting to rint.

Like with the automatic Platform Level Calibration, you can set the nozzle height either

automatically or manually.

If you are using any print surface other than the supplied FR- (Perf) Board, you will need to

set the Nozzle Height manually!

Automatic Nozzle Height Calibration

The Automatic Nozzle Height Calibration rocess assumes that you are using the su lied FR-4

erf board as the rint surface. I you are using any other sur ace, or the per board with

BuildTak or any other sur ace adhered to the board, you must manually determine the

nozzle height.

To determine the correct nozzle distance using the automated rocess, lease follow these ste s:

1. Connect the data cable to the Nozzle Sensor, located on the back of

the rint latform. The cable lugs into the data connector.

2. Connect the data cable to the green Data Connection on the back of

the rinter.

3. Select Nozzle Height Detect from the 3D Print menu.

4. The extruder will move to the center of the rinter and the

latform will move forward before the latform lifts. As it nears

the to of the rinter, the latform will slow until the nozzle

contacts the Nozzle Sensor. The detected nozzle height will be

dis layed, and the latform will lower.

5. After the Nozzle Height Calibration is com lete, remove the data

cable from the Nozzle Sensor and from the data connection on

the back of the rinter.

If the message to the right a ears when you choose the Nozzle

Height Detect o tion, check that the data cable is securely

connected to both the Nozzle Sensor and the data connection on the

back of the rinter. After verifying the connections, select Nozzle

Height Detect again.

Afinia H480 3D Printer User’s Manual

17

Manual Nozzle Height Calibration

To manually determine the correct nozzle distance, lease follow these ste s:

1. O en the Maintenance dialog box from the 3D Print menu and click the Center button. The

current nozzle height is indicated as shown in the Maintenance dialog images below. In the

Windows exam le, the latform is currently at the bottom of the rinter; the Mac exam le

has the latform 135.5mm from the bottom.

2. Enter the height to which you want the latform to move to into the textbox and click the To

button. In the above Windows exam le, the latform will move to 121 mm above the

latform’s origin. In the Mac exam le, the latform is already at the height selected.

3. Check the distance between the nozzle and the rint surface. If the latform is currently at

121mm and a ears to be about 12mm away from the nozzle, change the number in the

text box to by 9mm to 130 and click the To button. Use small increments from this oint to

avoid striking the rint surface into the nozzle.

4. Once the rint surface is about 1mm away from the nozzle, increase the number in the text

box by 0.1mm increments and click the To button. Re eat until the rint surface is 0.2mm

from the nozzle.

TIP: An easy way to check the

distance between the nozzle

and rint surface is to fold a

iece of a er in two, which will

be about 0.2mm thick. Use this

as a s acer to gauge the

distance between the nozzle

and rint surface.

5. Once you have the rint surface

within 0.2mm of the nozzle, click the

Set Nozzle Height button to save

the current nozzle height.

6. Check the nozzle height at all four corners of the latform. Re eat the Nozzle Height

Calibration and Platform Leveling rocesses if needed.

You may need to recalibrate the nozzle height i the models are not adhering to the print

sur ace properly or are warping. It is also recommended a ter moving the printer or

changing the print sur ace.

TIP: If the rint surface contacts the nozzle while making height adjustments, it is good ractice to

re-initialize the rinter and before undertaking any other o erations.

Mac version

Windows version

Afinia H480 3D Printer User’s Manual

18

Loading the Print Material Filament

This rocess will be the same on both Mac and

Windows.

A. Launch the Afinia 3D Software (refer to the

software install rocedure if you have not

already installed it), and select Maintenance

from the 3D Print menu. Click the Extrude

button. After the rinter nozzle has warmed u

to 260° C, the rinter will bee ; you can also

monitor the nozzle tem erature in the

Maintenance window under the 3D Print

menu.

B. Be sure the filament is running

through the filament tube between

the spool holder and extruder!

C. Once the nozzle is heated, gently ush

the end of the filament into the hole at

the to of the extruder head until the

extruder motor starts ulling it through

the extrusion head. The extruder will

extrude a thin filament of material for a

short eriod of time.

Other Maintenance Options

The Extrude button is used to load material into the nozzle. Click this button, and the nozzle will

begin to heat. When the tem erature is high enough (260° C), the material is squeezed out of the

nozzle. The system bee s before material starts extruding, and it bee s again when finished.

When changing the material (see age 33), use the Extrude function to load the new material to

the nozzle. It can also be used to test whether the nozzle is working correctly.

Use the Withdraw button to clear the filament from the nozzle when you change the filament or if

the nozzle needs to be cleaned. Once the nozzle is u to tem erature (260°C) and the rinter

bee s, gently ull out the material.

The New Spool button is used by the software to kee track of how much material has been used,

which will warn you if you don’t have enough material left to rint your model.

Click the button and enter the grams of material you have on the current s ool. If it is a new s ool,

the weight should be set to the filament weight of the s ool in grams. You can also s ecify that you

are loading ABS or PLA, which sets the nozzle and latform tem eratures accordingly.

Mac version

Windows version

Afinia H480 3D Printer User’s Manual

19

TIP: An em ty Afinia Premium s ool weighs about 280 grams. If you are installing a artially used

Afinia Premium filament s ool, weigh it, and subtract 280 grams from the weight. Enter that

value into the material Weight text box.

Status

This area dis lays the current tem erature of the nozzle and latform and if either element is

currently being heated.

Nozzle & Plat orm Position Controls

The five buttons (FL, FR, Center, NL, NR) control the osition of the nozzle and the latform. The

nozzle moves to the left and right; the latform moves forward and backward.

The To button controls the height of the latform, and is used in the manual nozzle height

calibration rocedure described on age 17.

The Bottom button returns the latform to the lowest osition.

Set Nozzle Height

Takes whatever value you have in the To box and saves it as the Nozzle height to use during

rinting.

Stop All

Sto s heating and all the movement of the rinter. Once you click this button, the current model

being rinted is cancelled. You CANNOT resume a rint job once the rinter has been sto ed.

After you use the Stop All function, you will need to re-initialize the rinter.

Pause Print

This button allows you to ause a rint in mid- rogress while allowing you to resume the rint job

where it left off. This is very useful if, for exam le, you want to change the material color mid- rint.

Another use for ausing a job mid- rint is to allow fasteners to be inserted into rinted cavities and

then rinted over to lock the fastener into lace.

This o tion is only available when the rinter is actively rinting and above the first four rinted

layers.

Table Heat 1 hr

Click the Table Heat 1 hr button to heat the table for a full hour to the correct tem erature for the

selected filament ty e.

Heating the latform will not take the full hour, but the longer the latform heats, the more the outer

edges of the latform will be heated. For rints extending close to the edge of the latform, this will

hel revent war ing of the model during rinting.

Note: You should always reheat the latform rior to rinting to ensure the best results.

Stop Preheat (Windows) / Stop Heat (Mac)

This button will halt any heating of the table, either the 1 hour heat or the 15 minute reheat from

the 3D Print menu. This o tion only a ears when the table in actively being heated by one of

these two o erations.

Afinia H480 3D Printer User’s Manual

20

Printing with the H480 3D Printer

Loading a 3D Model

Click File / Open or the Open icon on the toolbar

(Windows only) and select the model you want to

o en. The Afinia 3D Printer software only su orts

STL files (which is the standard in ut format for

3D rinting files), the UP3 and UPP formats.

You can o en several models and

rint them all at the same time.

Sim ly re eat the o en model

rocedure for each model you

want to add (see Placing Models

onto the Build Platform, age

24, for more information).

Insert Copy

You can add multi le co ies of the

same model to the latform by

selecting Insert Copy from the

right-click o tions (Windows) or

by selecting Copy from the Tools

menu. Select the number of

co ies from the list.

You will need to re osition the models after the co ies have been added.

Unloading the Model, Windows

Click the left mouse button on the

model to select it, and then click

Unload on the toolbar, or click the

right mouse button while over the

model and a context menu will

a ear. Choose Unload using

the model name or Unload All

models if you have more than one

file o en and want to remove all

of them.

Unloading the Model, Mac

Use either the Unload or Unload All button in the right tool ane. Click the Unload button to

remove the currently selected model, or Unload All to clear all models from the works ace.

Mac version Windows version

Multi le arts,

Windows version

Unload with Right-click

Windows version

Table of contents

Other Afinia 3D Printer manuals