X500pro

3D printer manual

DRAFT

German

RepRap

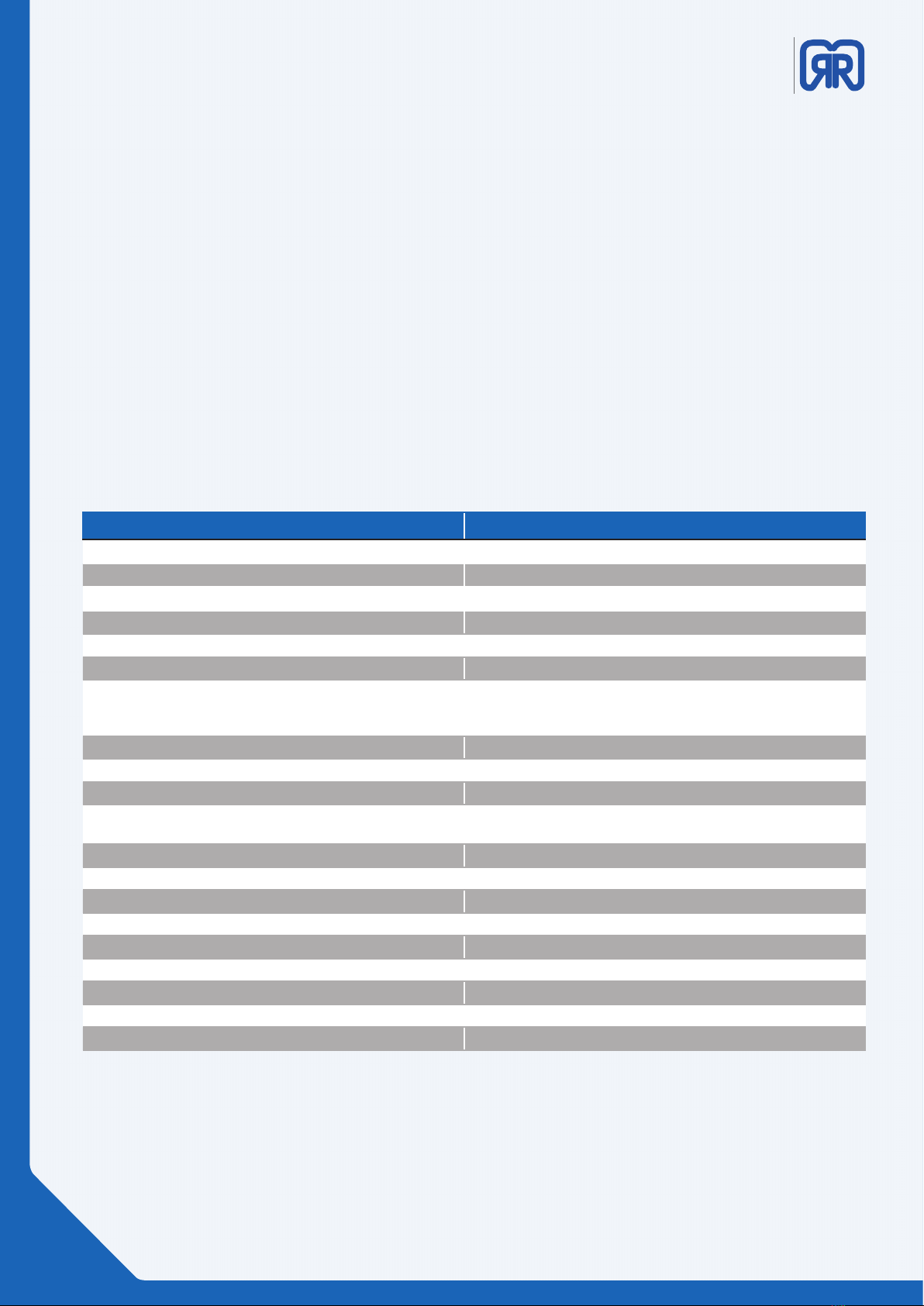

Table of Content

1. General Information

1.1 Specications ............................................................................................................................... 06

1.3 Additional Options.....................................................................................................................07

2. Unpacking and Installation

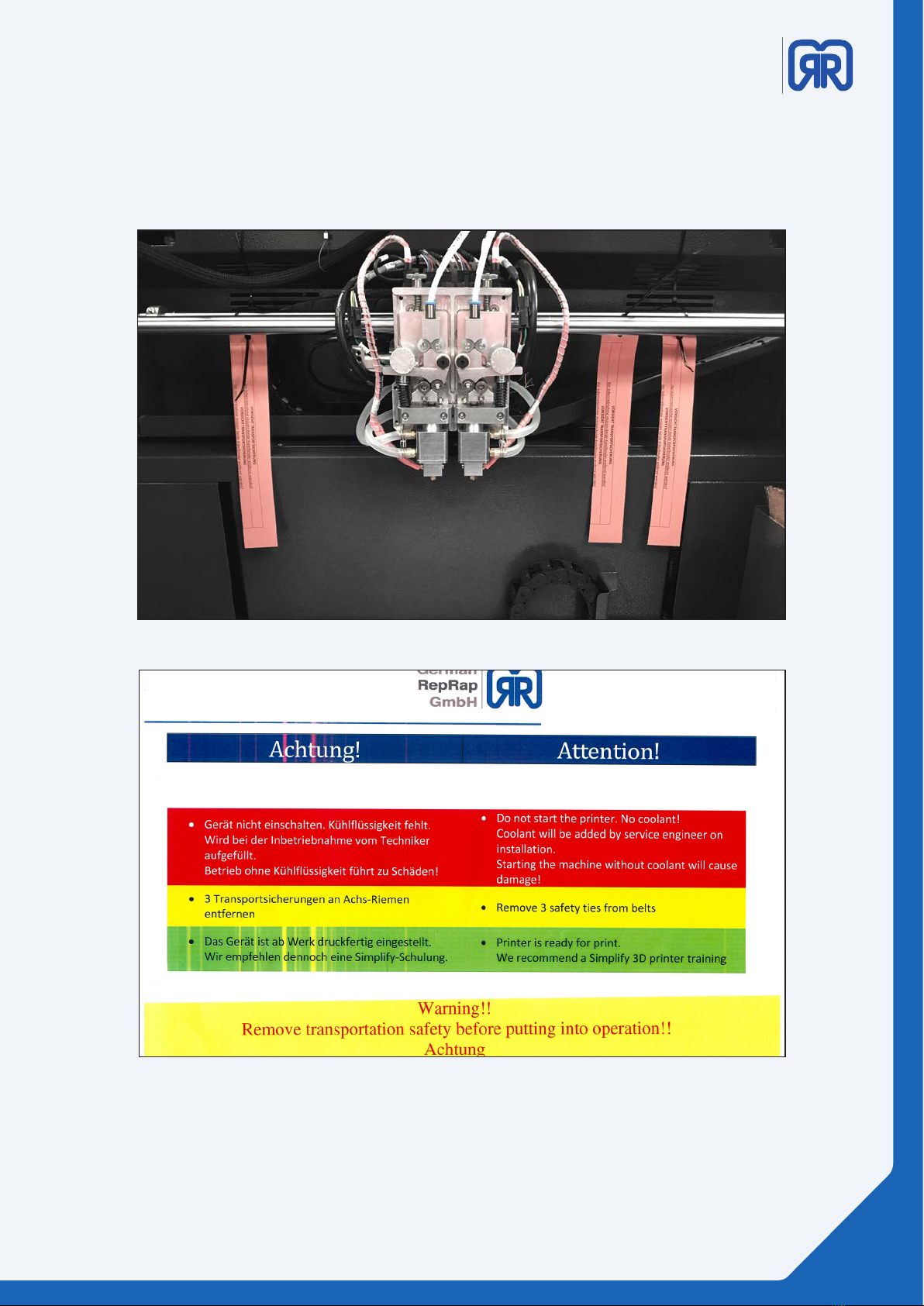

2.1 Removal Securing Devices ......................................................................................................08

2.2 Installation Site ............................................................................................................................ 10

3. Commissioning

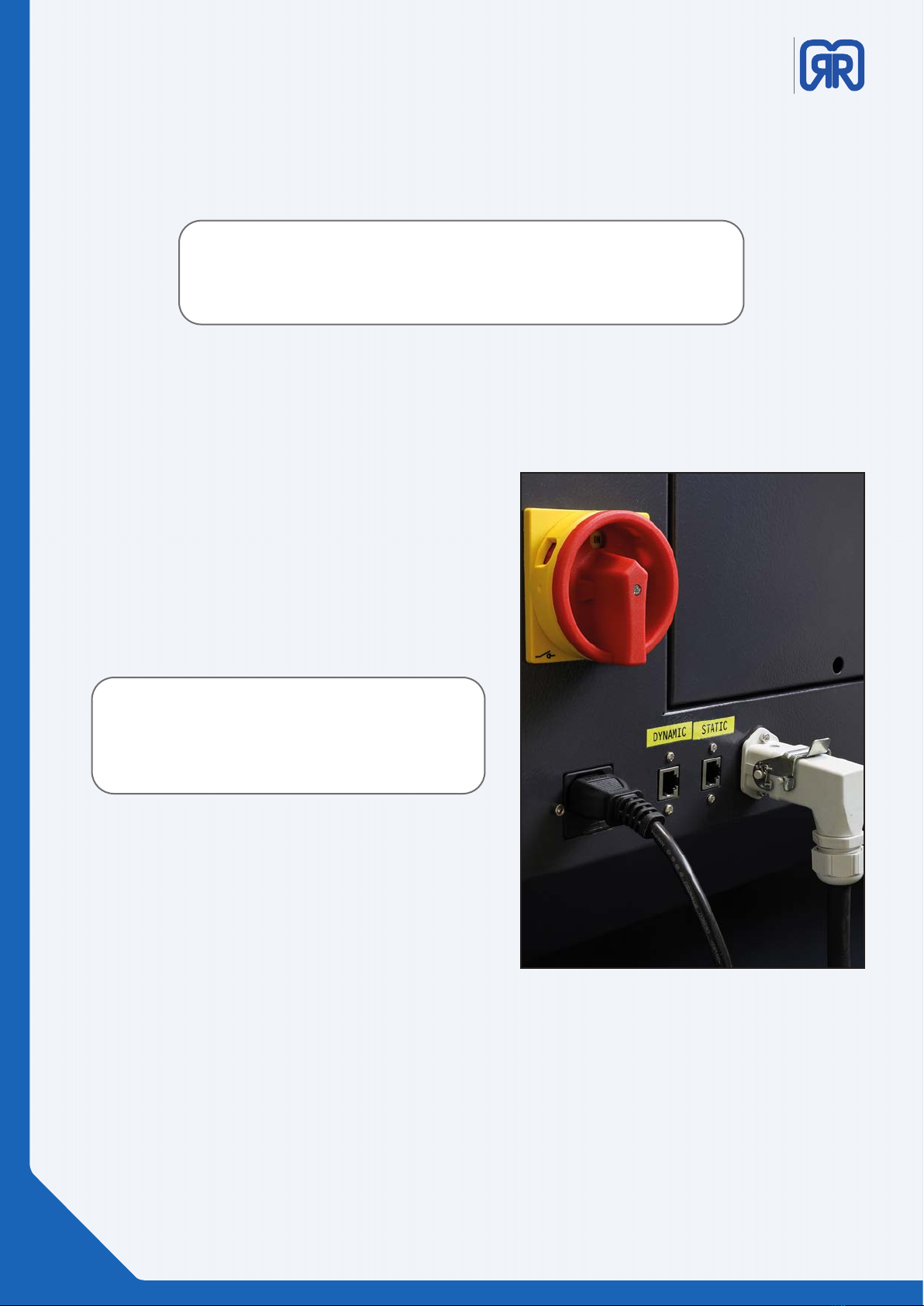

3.1 Connecting.................................................................................................................................... 10

3.2 Keys and Modes...........................................................................................................................10

3.3 Turn 3D Printer On/ O ............................................................................................................12

3.3 Touch Display/ Preparation ....................................................................................................14

3.4 Heating Elements........................................................................................................................14

3.5 Traverse Movements and Machine-Zero............................................................................15

3.7 Z-Oset - Distance Extruder and Printing Bed.................................................................16

3.6 PET-Foil for Print-Bed Coating................................................................................................ 16

3.8 Extruder and Filament Guidance .......................................................................................... 17

4. Starting a 3D Print

4.1 Standalone 3D Print................................................................................................................... 19

4.2 3D Printing via Repetier-Server ............................................................................................. 20

5. Workow and Operation

5.1 Simplify 3D .................................................................................................................................... 21

5.2 Features.......................................................................................................................................... 21

5.3 Quick Start Guide........................................................................................................................ 22

5.4 The Interface Layout ..................................................................................................................24

6. Network and Printer Set Up

6.1 Establishing a Network Connection (DHCP-Based)........................................................30

6.2 Establishing a Direct Connection (Via Router)................................................................. 30

7. Repetier-Server

7.1 Web interface ............................................................................................................................... 30

7.2 Dashboard.....................................................................................................................................31

7.3 Verifying Printer Settings ......................................................................................................... 32

7.4 Device Panel ................................................................................................................................. 36

7.5 Device Panel - Control...............................................................................................................36

7.6 EEPROM.......................................................................................................................................... 39

7.7 LOG-Files ........................................................................................................................................40

7.8 Firmware Update .......................................................................................................................41

7.9 External Manual........................................................................................................................... 42

7.10 API Key.......................................................................................................................................... 42

7.11 G-Code Management ............................................................................................................43

7.12 G-Code Download ................................................................................................................... 44

8. Tool Heads and Consumables

8.1 Tool Head Wiring.........................................................................................................................45

8.2 DD4 Extruder................................................................................................................................ 45

03/83