Afinia H400 User manual

User Manual

V 0.1

Download the full user manual at www.afinia.com/support

Index

Chapter 1 Product Description

Chapter 2 Prepare for Your First 3D Print

Chapter 3 Machine Settings

Chapter 4 Print Settings

Chapter 5 Calibration and Other Options

Chapter 6 Techniques and Troubleshooting

Safety Precautions

1\ The Afinia H400 3D printer requires the power adapter provided by the original

manufacturer, otherwise the machine could become damaged or cause a hazard. Please

keep the power adapter away from water and out of high temperature environments.

2\ During printing, the nozzle of the printer will

reach 260°C and the print platform could reach

over 70°C. Please do not touch these parts with

your bare hands while they are hot—not even

with the heat resistant gloves included with the

machine—as the temperature could damage

the gloves and injure your hands.

3\ During printing, the printhead and other

mechanical parts move at high speeds.

Touching these parts while they are moving

could cause injuries.

Warning label:

High Temperature,

do not touch!

Warning Label:

Moving parts, do not

touch!

4\ Please wear goggles when removing the supporting material from models and detaching

models from the perf board.

5\ When printing with ABS and PLA, the plastics will create a light odor. Please run the printer

in a well-ventilated environment. We also suggest you put the printer in an environment with

a stable temperature as unwanted cooling could cause adverse effects to the print quality.

When the printer is extruding filament, make sure there is enough space between the

print head nozzle and the platform. Otherwise the nozzle could become blocked.

Printing Environment

As light odor will be produced during printing, please run the printer in a well-ventilated

environment and keep the doors closed on the printer.

The Afinia H400's ideal working temperature is between 15°C and 30°C with a relative

humidity between 20–50%. Printing at temperatures out of this range could cause adverse

effects to the printing process. When using the “Extrude” function, keep at least 50mm

between the nozzle and the platform. If too close, the nozzle may become blocked.

Afinia 1-Year Limited Warranty

Below is the one-year limited warranty included with this Afinia product. Afinia prides itself on its outstanding

product line and its technical support. If for some reason, your product fails, Afinia, a division of Microboards

Technology, LLC, stands behind its warranty and assures you the best service possible in a quick and timely

manner.

Afinia warrants to the original purchaser that this product is free from defects in material and workmanship.

Afinia will for one year, at its option, repair or replace at no charge for parts and labor from the date you

purchased the product from an authorized Afinia reseller. Nozzles and Cell/Perf Boards are warranted for

ninety (90) days.

- Warranty registration must be completed within 30 days of receipt of the product in order to validate the

warranty.

- Afinia, a division of Microboards Technology, LLC, reserves the right to determine the validity of all warranty

claims.

- Warranty is void if the product serial number has been altered or removed.

- Warranty is void if the product has been misused or damaged or if evidence is present that the product was

altered, modified, or serviced by unauthorized service people.

The above stated warranty is exclusive and replaces all other warranties, express or implied, including those of

merchantibility and fitness for a particular purpose. Afinia, a division of Microboards Technology, LLC, will not

be liable for any other damages or loss, including breach of warranty or negligence.

This product has been thoroughly tested and inspected at the factory prior to shipment. Nevertheless, inspect

your product completely for any damage or loss of parts that may have occurred during shipment. Notify the

delivering carrier promptly if damage claims are to be filed.

Afinia reserves the right to modify or update its product without obligation to replace any equipment delivered

prior to any such change.

Compliance FCC CE ROHS

FCC ID:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Changes or modications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

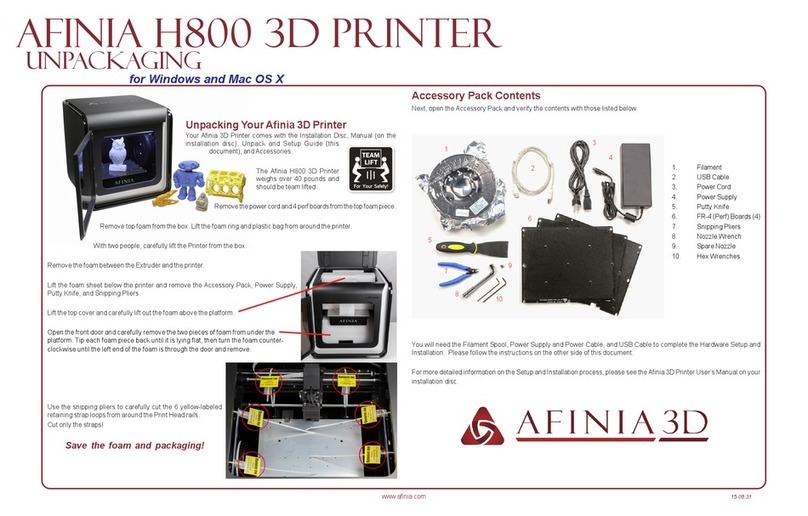

Unpacking

Remove the cushioning foams from the inside

the printer before use.

Rear View

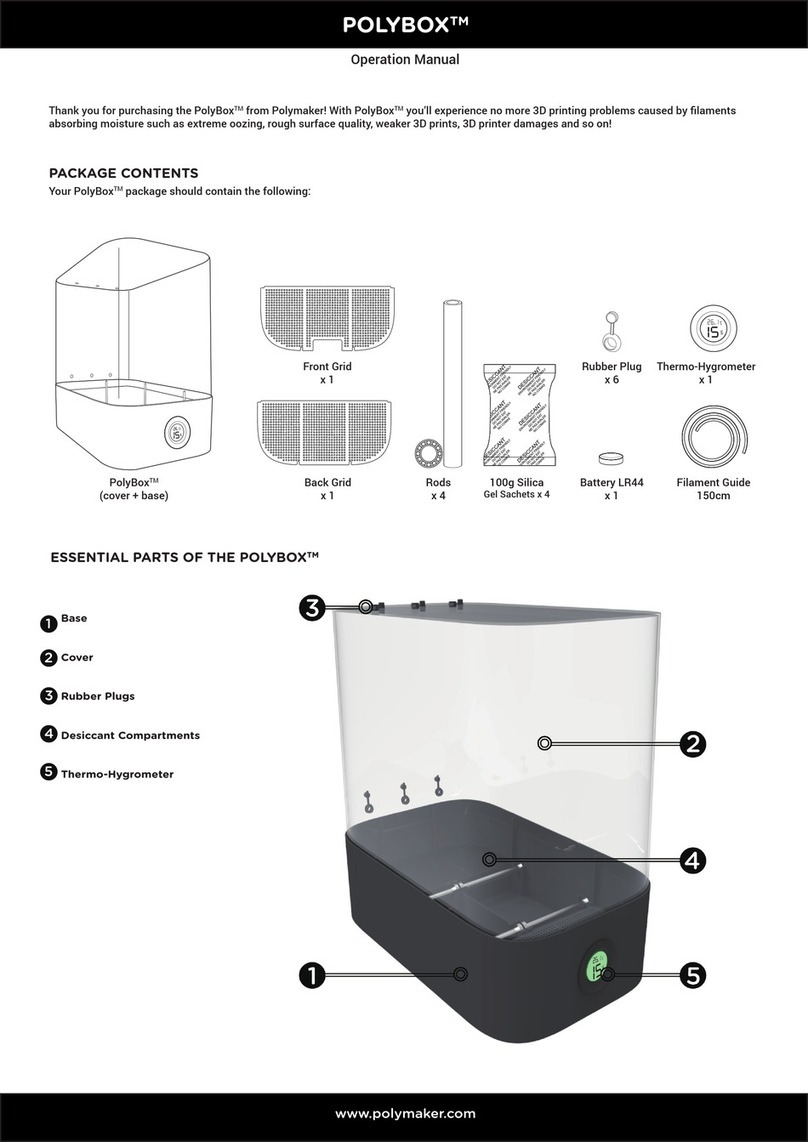

Package Content

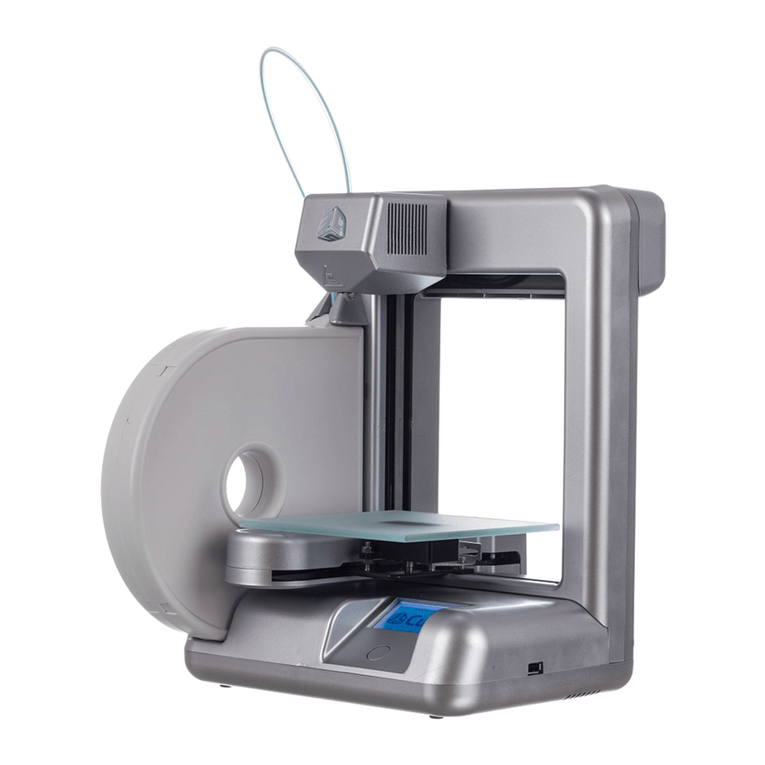

Afinia H400 Spool and Toll Holder

Protective Gloves Power Adapter Power Cable Scraper

USB Cable Hex Keys

2.0mm, 2.5mm

Plier

ABS Filament

Nozzle Wrench Perforated Print Board

(Perf Board) Flex Print

Board

Print Head Nozzle

1-1

Product Description

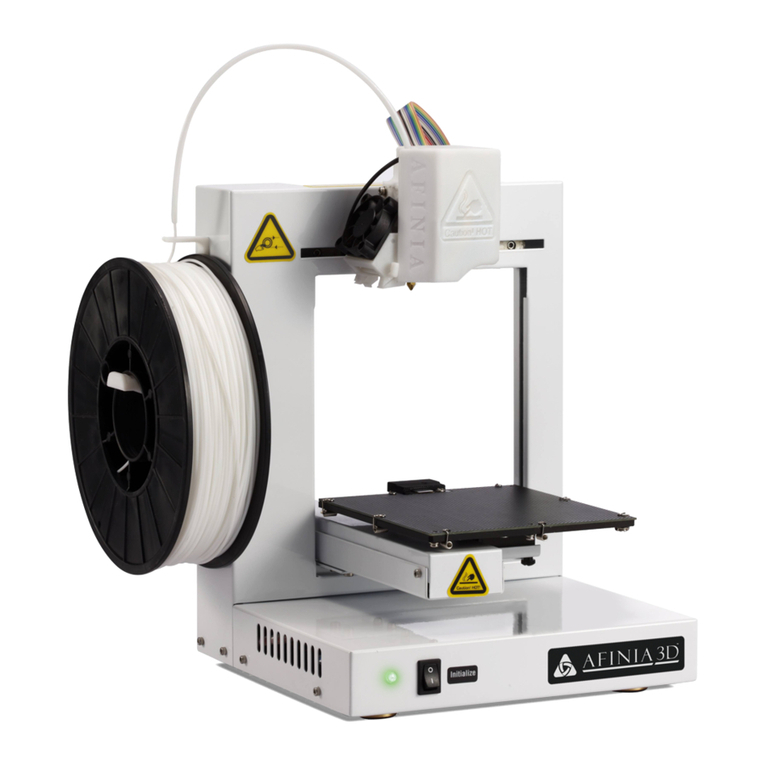

Front Side

Magnetic Top Lids

Back Door

Front Door

Handle

LCD Touch Screen Initialization Button

Back Side

Filament Insertion Hole

Back Door

Power Switch

Power Supply Connector

USB Connector

1-2

Filament Spool Holder

Spool Hold Lid

Filament Guiding Tube

Filament

Filament Spool

Tool Drawer

1-3

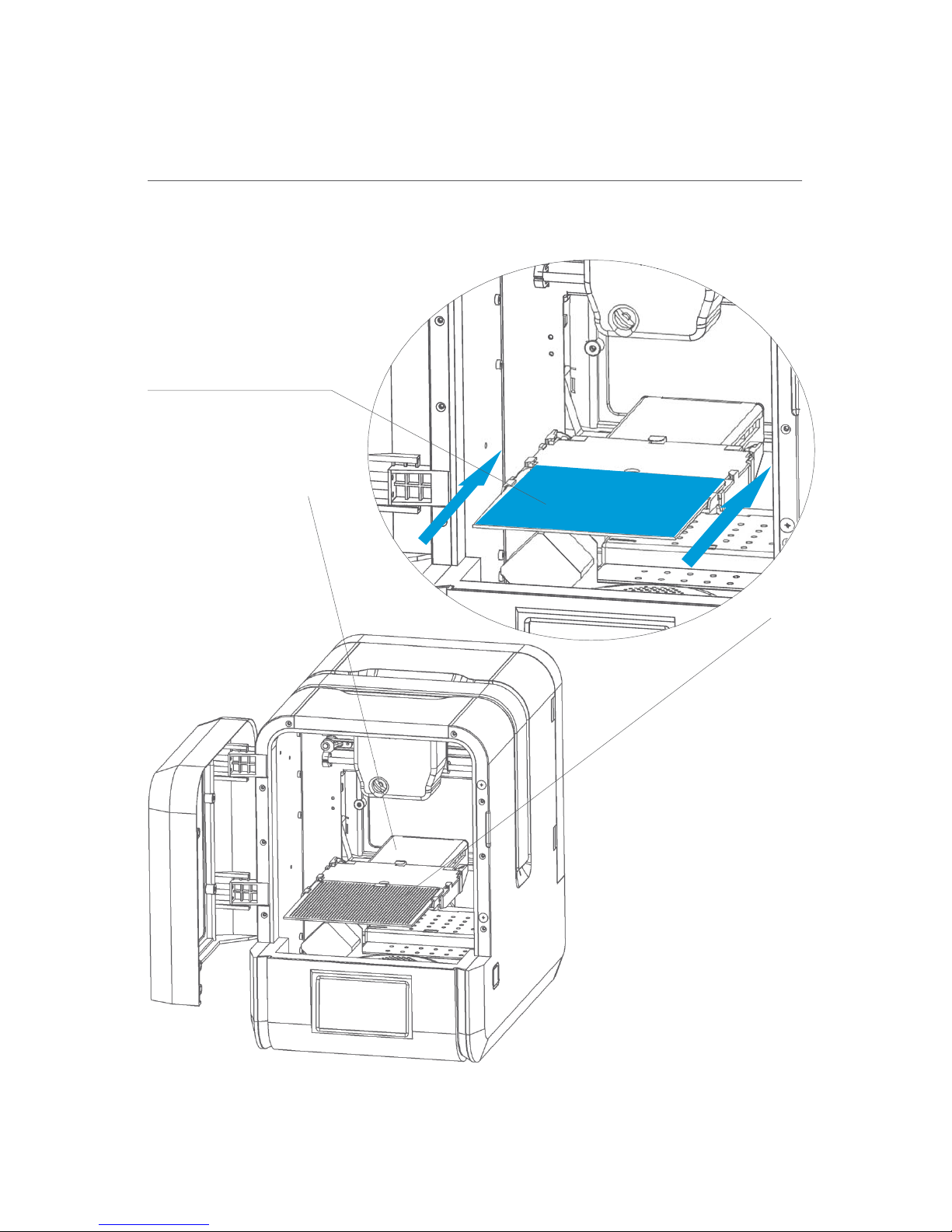

Installation of Print Board

Slide print board into the

platform

2-1

Print Head Installation 2-2

Cooling Adjustment

knob

Open front door, back door

and top covers

Nozzle

Print Head Mount

Print Head Mounting

Plate (on rear of extruder)

Print Head Installation 2-3

Slide the print head

into the slots.

Plug in the print head cable.

Install Studio

Download the Studio software by going to www.afinia.com/support/downloads,

then install it on your computer.

Minimum hardware

requirements

Intel Pentium 4 or better CPU 4GB RAM

Display card support OpenGL 2.0

Software 2-4

Software Interface

Printer Status Other Options

Home

Load File

Print

Initialize

Calibrate

Maintenance

Build Platform

Model Adjustment Wheel

Move Mirror Back to Menu 1

Rotate

Auto Place

Scale

To Menu 2

Merge

Fix

Save

Delete

Undo View Angles Undo Reset

Menu 1 Menu 2

2-5

Initialization of Printer

Initialization is required for every time the

machine is switched on. During initialization,

the print head and print platform move slowly

and hit the endstops of the XYZ axes. This is

essential as the printer needs to find the end-

point of each axis. Many software options will

light up and become available for use only

after initialization.

There are three ways to

initialize your printer:

1. Hold the initialization button on the printer.

2. Clicking the "Initialize" option in the software

menu (shown above).

3. When the printer is idle, press the initialize

button on touch screen.

Other functions of Initialization

Button:

Stop the current print job:

1. During a print, press and hold the button.

2. Reprint the last job: Double-click the button.

3. Turn on/off internal lighting: Single-click the

button.

Initialization

Button

Touch Screen

Initialization

button

PC client

2-6

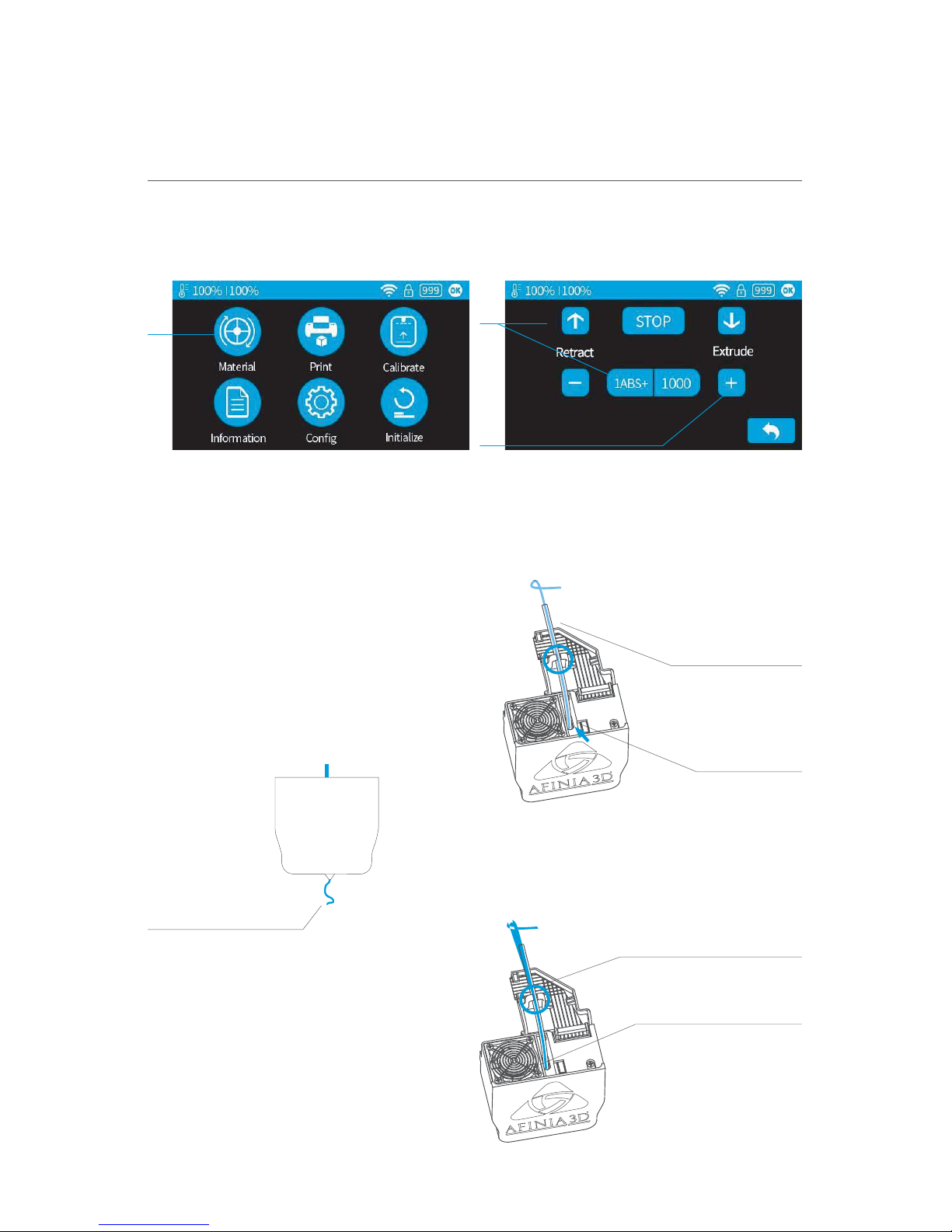

Touch Screen Control

Change printing

Material Print a stored project Machine settings

including Wi-Fi

Printer Info, reset to

factory and choose

language

Nozzle Height Detection

Initialize the printer

Nozzle Temperature

WIFI Status Remaining

material

Platform Temperature

Private

setting

status

Printer

status

2-7

The printer was calibrated before leaving the factory, but users are recommended to

update the nozzle height value using the automatic nozzle height detection function

on the touch screen before the first print.

Press the“Calibrate” button to enter Nozzle

Height setup page.

Press the “Auto” button to start the

automatic process.

128

Auto

During nozzle height detection, the

print head nozzle will touch the nozzle

detector to make the measurement.

2-8Prepare for Printing - Update Nozzle Height

Prepare for Printing - Load Filament 2-9

Install the filament and guiding tube shown in blue.

To printer

Push the guiding tube into the rubber ring as shown above.

Prepare for Printing - Load Filament

Back Side

Filament Guiding Tube

insert into the filament

entrance.

From spool

2-10

Prepare for Printing - Load Filament

1\ Insert the filament from the spool into guiding tube; arrange the guiding tube as

shown in previous page. Press the Material button on the touch screen.

1\ 2\

3\

2\ Choose the printing material as ABSby press theWheel button to switch between

different materials input the filament weight by using the +/- buttons.

3\ Click "Extrude." The print head will start to heat up, within 3 minutes. Its

temperature will reach 260°C, then the printer will beepand the print head will start to

extrude.

4\ Gently insert the filament into the

small hole on the print head. The

f i lam e n t will be fed into the print head

automatically when it reaches the

extruder gear inside the print head.

Guiding Tube

Filament

Filament extrusion

5\ Check the nozzle for plastic extrusion.

If plastic is coming out from the nozzle, the

filament is loading correctly and the printer

is ready for printing (the extrusion will stop

automatically).

6\ Finally insert the guiding the tube in

to the filament entrance and press

the tube into the holding clip on the

print head mount.

Press the guiding tube

into the clamp

Guiding Tube

b

2-11

Loading a 3D Model

Load Model Button

2-12

Print a Model

Make sure printer is connected to computer through USB or WIFI (go to section 3-1for

details about WIFI setting) and load a model.

Click print button to open

the print interface

Set Layer Thickness

Select Infill Type

Select Print Quality/Speed

Advanced Options

Shell: No infill, Surface: No Hollow Big Hole Loose Fill Solid Fill

normal wall. top and bottom

layers, no infill,

single perimeter.

When the software is slicing or sending data to the printer, the progress is displayed on

the status bar on top of the software interface. Do not unplug the USB cable as this

will disrupt the data transfer and result in a print failure. The USB cable can be

unplugged after the data transfer is finished.

2-13

Table of contents

Other Afinia 3D Printer manuals