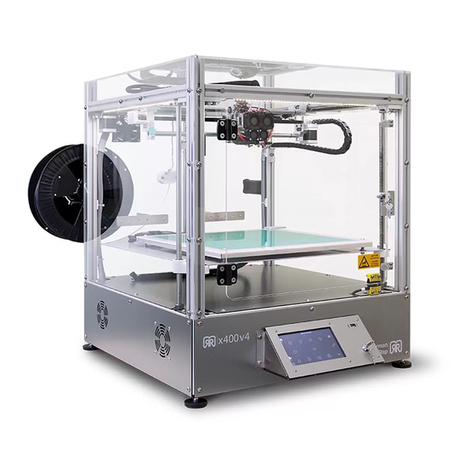

X350 3D-Printer Quick Start Guide

Seite: /29

Stand: 2016/03/24 13:55

© German RepRap GmbH /29

Inhaltsverzeichnis

X350 3D-Printer Quick Start Guide ............................................................................................... 2

Technische Daten ........................................................................................................................... 4

Content ........................................................................................................................................... 4

System requirements ...................................................................................................................... 5

Starting up ...................................................................................................................................... 5

Instructions ................................................................................................................................. 5

Setting up the printer ................................................................................................................. 5

Levelling the printing bed ........................................................................................................... 7

Stripping container, setup and removal ..................................................................................... 8

Case fan control ......................................................................................................................... 9

Network setup ............................................................................................................................ 9

Inserting filament ..................................................................................................................... 10

Directly at the device ........................................................................................................... 10

Through the network ............................................................................................................ 11

Removing the filament ............................................................................................................. 12

Changing the filament .............................................................................................................. 12

Software installation ................................................................................................................. 12

Printing with SD card ................................................................................................................ 13

Removing the printed object .................................................................................................... 14

Cleaning the printing head (extruder) ...................................................................................... 14

Material selection .......................................................................................................................... 14

Download datasheets ............................................................................................................... 15

Materialinfo ................................................................................................................................... 15

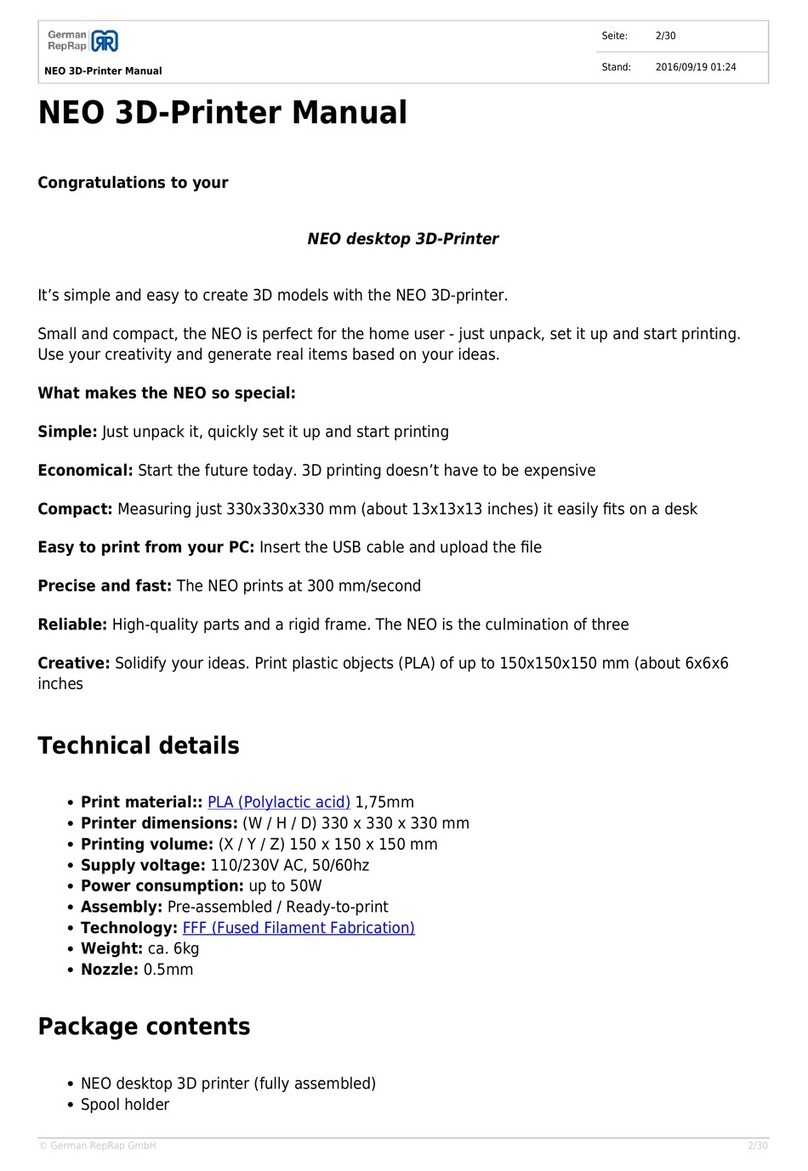

ABS (Acrylonitrile butadiene styrene-copolymer) ......................................................................... 15

Specification ................................................................................................................................. 16

Source ........................................................................................................................................... 16

PLA (Polylactic acid) ...................................................................................................................... 16

Specification ................................................................................................................................. 17

Source ........................................................................................................................................... 17

Troubleshooting ............................................................................................................................ 17

Support ......................................................................................................................................... 18

Documentation ......................................................................................................................... 18

Telephone ................................................................................................................................. 18

Support tickets / E-mail ............................................................................................................ 18

Forum (Community) ................................................................................................................. 19

Important notes ............................................................................................................................. 19

Return / Original wrapping ............................................................................................................ 20

Operation ...................................................................................................................................... 20

Other matters ............................................................................................................................... 20

Toxic fumes ................................................................................................................................... 20

Safety cut-off ................................................................................................................................ 20

Maintenance ................................................................................................................................. 20

Safety notes ................................................................................................................................... 21

Power supply ................................................................................................................................. 22

Cleaning ........................................................................................................................................ 22

Playing children ............................................................................................................................ 22

Mains voltage ................................................................................................................................ 22

Humidity, solar radiation, heat, open fire ..................................................................................... 22

Ventilation ..................................................................................................................................... 23

Long absence, thunderstorms, accessibility of the power plug ..................................................... 23

Installation site ............................................................................................................................. 23

Disposal ........................................................................................................................................ 23