AFLOWT BUF M User manual

BATTERY POWERED

ULTRASONIC FLOW METER

AFLOWT BUF M

VERSION

BUF-310

OPERATION MANUAL

ISO 9001:2015

2

* * *

Manufacturer quality management system is certified to

ISO 9001:2015

* * *

URL: http://www.aflowt.com

3

TABLE OF CONTENTS Page

INTRODUCTION.....................................................................................................4

1. DESCRIPTION AND OPERATION.....................................................................5

1.1. Application.............................................................................................5

1.2 Specifications..........................................................................................6

1.3. Metrological characteristics....................................................................7

1.4. Contents of the delivery package...........................................................8

1.5. Design and operation.............................................................................9

1.5.1. Operation principle.................................................................................9

1.5.2. Design .................................................................................................10

1.5.3. Access levels.......................................................................................11

1.5.4. Recording of operation results.............................................................12

1.5.5. Information output................................................................................13

1.6. Flow meter design................................................................................16

1.7. Marking and sealing.............................................................................16

2. INTENDED USE................................................................................................17

2.1. Operational restrictions........................................................................17

2.2. Safety measures..................................................................................18

3. INSTALLATION OF THE FLOW METER..........................................................19

3.1. Transportation......................................................................................19

3.2. Installation requirements for the flow meter.........................................19

3.3. Requirements for the length of straight sections..................................20

3.4. Installation on the pipeline ...................................................................20

3.5. Electrical installation of the flow meter.................................................21

3.6. Dismantling the flow meter...................................................................22

4. OPERATION.....................................................................................................23

4.1. Setting up before operation..................................................................23

4.2. Pre-commissioning ..............................................................................28

4.3. Operating procedure............................................................................29

5. READING DATA WITH A SMARTPHONE........................................................30

5.1. Hardware requirements .......................................................................30

5.2. Installing the AFLOWT BUF monitor application..................................30

5.3. Connecting to the flow meter ...............................................................32

5.4. Reading parameters ............................................................................33

5.5. ABOUT UNIT tab.................................................................................34

5.6. MEASUREMENTS tab.........................................................................35

5.7. ARCHIVES tab ....................................................................................36

6. MAINTENANCE................................................................................................42

6.1. Technical condition monitoring ............................................................42

6.2. Troubleshooting...................................................................................43

7. PACKING, STORAGE AND TRANSPORTATION............................................44

APPENDIX A. Appearance of the flow meter..............................................45

APPENDIX B. Wiring diagrams ..................................................................48

APPENDIX C. Parameters available for editing in Monitor BUF (310)

application............................................................................................50

APPENDIX D. Relative length of straight runs............................................53

APPENDIX E. Flow straightener design .....................................................55

4

INTRODUCTION

This document covers battery powered ultrasonic flow meter

"AFLOWT BUF M" of BUF-310 version and contains the information

about its design, operation and installation.

Due to continuous improvement of product policy actual flow meter’s

specifications may differ from the data specified in this manual. However,

this will not affect the metrological characteristics and functionality.

LIST OF ABBREVIATIONS

CP

SMC

DN

ER

LCD

PC

PS

PEA

SPS

USS

- Primary converter

- Secondary measuring converter

- Nominal diameter

- Error

- Liquid crystal display

- Personal computer

- Pipeline section

- Electro-acoustic converter (transducer)

- Secondary power source

- Ultrasonic signal

NOTE. Words in the text marked in bold, for example, Low, corre-

spond to the items displayed on the flow meter's screen or PC display

when running Monitor BUF (310) program.

* * *

Validation documents are available on website www.awlowt.com.

5

1. DESCRIPTION AND OPERATION

1.1. Application

1.1.1. AFLOWT BUF M battery powered ultrasonic flow meter of BUF-310 ver-

sion is designed to measure average volumetric flow rate and volume of

bidirectional flows of cold water.

The flow meters may be used as part of metering systems and com-

plexes, in heat metering systems, automatic process control systems in

power industry and municipal, etc.

1.1.2. AFLOWT BUF M battery powered ultrasonic flow meter of BUF-310 ver-

sion performs the following functions:

- Measuring average volumetric flow rate in either forward or reverse flow

directions

- Totalizing volume of forward and reverse flows independently or calcu-

lating their algebraic sum regarding flow direction

- Determining the current value of flow velocity and flow direction

- Output of measurement results to the frequency/pulse or logic output

- Output of measurement data on the indicator, as well as through the M-

Bus interface or Wireless M-Bus interface

- Output of measuring, diagnostic, installation, archive and other infor-

mation via RS-485 serial interface or NFC radio transponder according

to ISO 15693

- Archiving of measurement results and setting parameters in energy-inde-

pendent memory

- Possibility of entering setting parameters by means of software, consid-

ering individual features and characteristics of the measurement object

- Automatic control and indication of emergencies and failures, as well as

recording of their type and duration in the archives

- Protection of the archival and adjusting data from unapproved access.

6

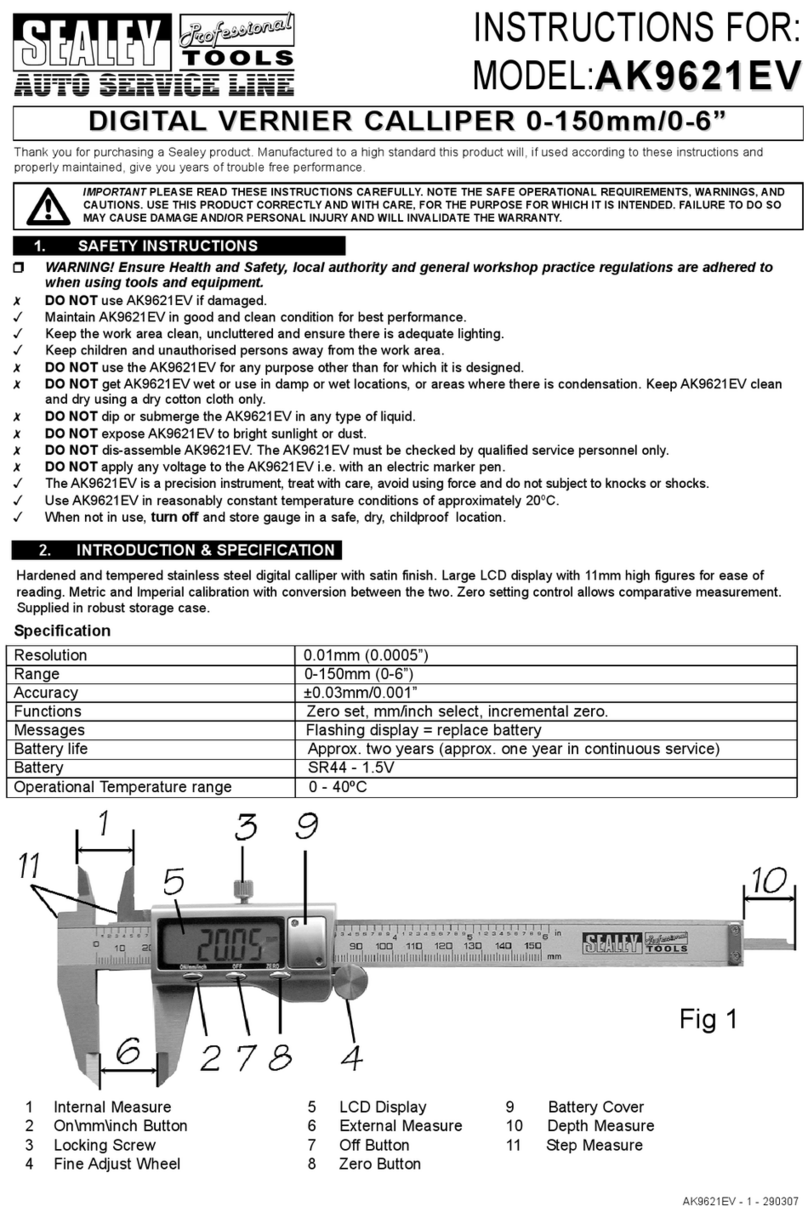

1.2 Specifications

1.2.1. Specifications of the flow meter AFLOWT BUF M of BUF-310 version are

listed in Table 1.

Table 1

Parameter

Value

Notes

1. Nominal diameter of the pipeline, DN

80

2. Minimal measured average volumetric flow rate

Qmin, m3/h

0.25

3. Maximal measured average volumetric flow rate

Qmax, m3/h

90.0

4. Sensitivity threshold, m3/h

0.057

5. Maximal pressure in the pipeline, MPa

1.6

6. Properties of working fluid:

- temperature, °C

- density, kg/m3

- gas occlusion content, % of volume

0 to 50

700 to 1200

no more than 5

7. Power supply voltage, V

3.6

see clause

1.2.6

8. Mean time to failure, h

75000

9. Mean life time, years

12

1.2.2. The flow meter provides indication of the measured parameter values with

the digit specified in clause 1.5.5.1 of this manual.

1.2.3. The flow meter provides that the results of measurements can be output-

ted to:

- Universal output in the form of frequency, pulse or logic signal

- logic output

- RS-485 and M-BUS interface

- Wireless M-Bus interface

- NFC interface.

1.2.4. The flow meter provides storage of measurement results in the following

logs:

- Hourly log –1440 records (hourly records) –60 days

- Daily log –460 records (daily records)

- Monthly log –48 records (monthly records)

- Mode log –up to 1000 record

- Operating mode log –up to 4000 records.

When powered off, the flow meter stores measurement results and

configuration settings for no less than 1 year.

1.2.5. Environmental resistance:

- To climatic influences –the ambient temperature range is from 5 to 50 °C,

relative humidity is not more than 80% at temperatures up to 35 °C, with-

out moisture condensation

- To mechanical stress –vibration in the frequency range from 10 to 55 Hz

with an amplitude of not more than 0.35 mm

7

- Atmospheric pressure ranges from 84.0 to 106.7 kPa.

The degree of protection of the flow meter corresponds to the IP67

or IP68. The required degree of protection of the device is determined

when ordering.

1.2.6. The power supply of the flow meter is provided from an internal lithium C

size battery with a nominal voltage of 3.6 V.

1.2.7. Appearance, overall dimensions and weight are given in Appendix A.

1.3. Metrological characteristics

1.3.1. The limits of permissible error in measuring the average volumetric flow

rate, the volume of liquid in any direction of flow do not exceed the values

given in table 2.

Table 2

Error formula

Relative error limit value

v

0.1

0.95δ

1.0 % at v > 2.00 m/s

1.5 % at v > 0.19 m/s

2.0 % at v > 0.10 m/s

3.0 % at v > 0.05 m/s

4.0 % at v > 0.033 m/s

where v –flow velocity, m/s.

1.3.2. The diagram of real measurement error of the flow meter is shown in

Fig.1.

+4%

+2%

-4%

-2% v,m/s

0.033 5

+1%

-1% 0.01 2

Fig.1. Diagram of real measurement error of the flow meter

8

1.4. Contents of the delivery package

Items of the delivery package are specified in Table 3.

Table 3

Item

Qty

Notes

1. Flow meter

1

Note 1

2. Installation kit

1

Note 2

3. Passport

1

4. Operation manual

1

Note 3

NOTES:

1. The size and the protection rating of the flow meter, the types of interfaces

are set on request.

2. The required items of the delivery package are specified in the order

sheet.

3. Operating documentation and order sheets for this product and other

products are available on: www.aflowt.com.

4. To connect the device with external devices via RS-485 interface, it is

possible to supply a USB signal adapter –RS-232 / RS-485 on request.

9

1.5. Design and operation

1.5.1. Operation principle

1.5.1.1. The flow meter is designed on the base of a pulse-phase method of ul-

trasonic flow measurement. Its operation principle is based on measuring

the time difference between the time it takes for an ultrasonic signal

(USS) to travel through the liquid with the direction of flow and against it.

1.5.1.2. The peculiarity of this type of ultrasonic flow meter is alternating supply of

electrical probing pulses generated by the secondary converter (SMC) to

the converters PEA1 and PEA2 (Fig.2).

Fig.2. Diagram of the pipeline section with PEA installed

USS generated by one PEA is projected through the liquid flowing in the

pipe and is received by the other PEA. Because of liquid flow, a sound

wave is shifted, which in turn leads to the difference in upstream and

downstream times of USS travel: it takes less time for an ultrasonic signal

to travel in the flow direction (from PEA1 to PEA2) than that in the oppo-

site direction (from PEA2 to PEA1). The difference in upstream and

downstream time of USS travel through an acoustic path dT is propor-

tional to flow velocity of fluid v and, correspondingly, to volumetric flow

rate Q.

1.5.1.3. The flow rate value Q is calculated only if the following condition isfulfilled:

Q ≥ Qmin,

where Qmin–minimal value of the flow rate at which the measured flow

rate value in the flow meter is set to zero, the volume accumulation and

pulse output at the universal output stops.

The recommended value of low flow cutoff corresponds to the flow

meter's sensitivity threshold.

If Q > Qmax condition (where Qmax responds to the flow velocity value

of 5 m/s) condition is fulfilled, flow measurement continues, but volume

accumulation, archiving and pulse output at the universal output stops.

10

1.5.2. Design

The block diagram of flow meter AFLOWT BUF M of BUF-310 ver-

sion is shown in Fig.3.

Fig.3. Block diagram of flow meter

The BUF-310 flow meter consists of a primary converter (CP) and a

secondary converter.

The primary flow converter is a pipeline section (pipe section with

pipe connections for PEA installation and flanges for pipe connection)

with two PEAs installed on it (Fig.A.1 of Appendix A).

The PEA operates in two modes: radiation, when the electrical pulse

signal from the secondary converter is converted into ultrasonic vibra-

tions, and reception, when the ultrasonic vibrations of the liquid are con-

verted into an appropriate electrical signal.

The secondary converter contains a processing module that acts as

a meter and calculator as well as a display module. The processing mod-

ule controls the electro-acoustic sounding, processes the measurement

signals from the PEA and performs the secondary processing of the

measurement information and ensures the storage of the measurement

results.

External communications of the flow meter are provided by means

of universal and logic outputs available on the processing module as well

as optional RS-485 serial interface modules, M-Bus interface or Wireless

M-Bus interface installed in the processing module.

The measuring information is displayed on a graphical liquid crystal

display (LCD) located on the display module. LCD provides output of two

lines of alphanumeric information at 16 characters per line. The infor-

mation output is controlled by means of an optical button located on the

front panel next to the LCD.

11

Before commissioning, the flow meter is set up using a personal

computer (PC) via RS-485 interface.

1.5.3. Access levels

1.5.3.1. The flow meter has three levels of access to setting and calibration pa-

rameters.

The access levels differ in the information displayed, possibilities to

change the setting and calibration parameters of the flow meter and are

referred to as WORK, SERVICE and ADJUSTMENT modes.

Mode applications:

- ADJUSTMENT –adjustment and verification mode;

- SERVICE –preparation for operation mode;

- WORK –operation mode (user mode).

Modes differ in the level of access to information and possibilities to

change the settings of the flow meter via RS-485 interface.

Maximum rights are granted in ADJUSTMENT mode. The mode al-

lows the user to view all parameters and to modify all configuration set-

tings. Minimum rights are given in WORK mode.

The set of parameters displayed does not depend on the set opera-

tion mode.

1.5.3.2. The operation mode is definedbya combination ofthe presence/absence

of a short-circuit using the contact pair jumpers J1 and J2 located on the

processing module (see Fig.A.3 of Appendix A).

Correspondence of combinations to operation modes is resulted in

table 4, where "+" is presence of contact pair closing, and "-" is absence

of closing.

Table 4

Operation mode

Contact pair

Mode application

J1

J2

WORK

-

-

Operation

SERVICE

-

+

Preparation for operation

ADJUSTMENT

+

-

Adjustment

1.5.3.3. WORK mode is a flow meter operation mode on the site.

WORK mode allows the user to view the data.

1. With the indicator: current date and time, values of measured parameters

(volume flow rate, volumes accumulated during forward and reverse flow

direction, as well as their algebraic sum), status line of emergencies and

software version number.

2. With RS-485, M-Bus or Wireless M-Bus interfaces:

a) Values of measured parameters: volume flow rate, volumes accumulated

in the forward and reverse flow direction, as well as their algebraic sum,

fluid velocity, and current velocity of USS

3. With RS-485 interface:

a) The contents of the archives and event log

b) Configuration parameters: current date and time, characteristics of uni-

versal and logic outputs

12

c) Operation parameters:

- Signal processing characteristics (median averaging, arithmetic averag-

ing, etc.)

- Communication parameters via RS-485 interface

- Types of emergency situations.

The WORK mode allows the user to change communication param-

eters via RS-485 interface (network address of the device, exchange rate

from 1200 to 4800 baud).

1.5.3.4. SERVICE mode is a mode of preparation of the flow meter for operation

on the site.

SERVICE mode additionally (in relation to WORK mode) allows via

RS-485 serial interface to:

a) View:

- The configuration of the pipeline section (base, axial base, nominal diam-

eter)

- Setting parameters for the ultrasonic signal

- Zero offset value and additional USS delay

b) Change:

- Operation modes and parameters of the universal and logic outputs

- Flow and volume measurement units (m3/h; l/min, m3, l)

- Device clock readings

- Device clock transition mode to "winter"/"summer" time

c)Adjust LCD contrast, operating time and measurement information update

period

d) Start the calculation of conversion factor or pulse weight for the universal

output

e) Zero accumulated volumes and archives.

1.5.3.5. ADJUSTMENT mode allows to view and modify all parameters without

exception.

Also, ADJUSTMENT mode allows to record the factory number of

the device via RS-485 serial interface.

1.5.4. Recording of operation results

1.5.4.1. The results of measurements and calculations are recorded in the internal

archives: hourly, daily, monthly, with the depth of the archives, given in

clause 1.2.4. Access to the archives is carried out through the RS-485,

M-Bus or Wireless M-Bus interfaces and NFC radio transponder.

Hourly, daily and monthly archives are cyclical and have the same

structure.

The values of the following parameters are recorded in each record:

- V+ –total volume in the direct flow direction over the archiving interval,

m3(l)

- V- –total volume in the reverse flow direction over the archiving interval,

m3(l)

- ER –error code

- ER time –total time, during which there was no accumulation of volumes

in the archive

13

- Worktime –operating time for the archiving interval.

1.5.4.2. Changes in the operating mode of the device are recorded in the mode

log, which can contain up to 1000 records.

Each mode log entry records:

- Sequence number of the record

- Name of the set operating mode of the device

- Date and time of mode setting.

1.5.5. Information output

1.5.5.1. Liquid crystal indicator

The list of parameters, which are displayed on the flow meter's indi-

cator, is shown in Table 5.

Table 5

Designa-

tion

Parameter

Measurement

units (format)

Number of display symbols

integral part

fractional part

Time

Current time

= XX:XX

Data

Current date

XX.XX.XX

Q

Current volume flow rate regarding

flow direction

m3/h, l/min

up to 4

4

V+

Direct flow volume (cumulative total)

m3, l

up to 9

4

V-

Reverse flow volume (cumulative to-

tal)

m3, l

up to 9

4

ΣV

Total volume (cumulative total)

m3, l

up to 9

4

Err

Status bar

––––––

Tw

Total operating time

XXX:XX h:m

3

2

Tner

Fault-free operation time

XXX:XX h:m

3

2

K1

Calibration factors

X.XXXXXX

1

6

P1

-X.XXXXXX

K2

X.XXXXXX

P2

-X.XXXXXX

Soft

Software version number

XX.XX.XX.XX

CRC

Software checksum

0xA8D9

NOTES:

1. The flow rate in the reverse flow direction as well as the negative values

of the total volume and the volume of the reverse flow are indicated with

a minus.

2. The total volume is defined as the sum of the volumes accumulated in the

forward (positive) and reverse (negative) flow direction, considering the

sign of the flow direction.

3. An overflow of counters occurs if V2109m3. After the counter is full,

the display continues from zero.

In the SERVICE and ADJUSTMENT modes, the indicator is always

on. In the WORK mode, the indication is switched on by pressing the

button and is switched off after the last pressing it in the interval set in the

Worktime field in the Service tab of the Monitor BUF (310) application.

Switching the indication of the parameters given in Table 5 is per-

formed on the ring by sequential pressing the button located on the front

panel of the device.

14

NOTE. Using the optical button in the flow meters has the following

features:

- The button works "slowly", i.e. its touching should last more than 1 s

- The button is triggered when the finger is taken off.

1.5.5.2. RS-485 interface

RS-485 serial interface allows to read out measuring, archival, instal-

lation and diagnostic information, to modify setting parameters. RS-485

interface supports ModBus protocol (RTU ModBus and ASCII ModBus)

RS-485 interface provides cable communication in a group of several

subscribers, one of which can be a PC, with a communication line length

of up to 25 m.

At the time of release from production the network address is rec-

orded in the flow meter –1. Using switches SK1 and SK2 on the interface

module (see Fig.A.3), you can change the network address of the device

according to Table 6.

Table 6

Switch position

Network address

SK1

SK2

1

2

2

2

1

3

1

1

4

When both switches are set to position 2 on the interface, you can

set any network address of the device (from 1 to 255).

The RS-485 baud rate and other communication parameters are set

programmatically.

1.5.5.3. M-Bus interface

The M-Bus interface complies with EN 13757. The interface allows

the readout of measured data, such as: current flow rate, accumulated

direct, reverse and total volumes, operating time, as well as the presence

of emergencies under the numbers 1 ... 3 (see Table 7).

By default, the flow meter has a network address of 1 and an ex-

change rate of 2400 baud. The interface is connected via two wires, the

polarity of the connection is not important. The M-Bus interface baud rate

is set programmatically.

WARNING: Power supply of the flow meter and M-Bus modem from

one power source is prohibited.

1.5.5.4. Wireless M-Bus interface

The Wireless M-Bus interface complies with EN 13757-4. The inter-

face allows the transmission of measured and archived data to a receiver

(WM-Bus dongle interface box, hub, etc.).

T1 mode is implemented in the protocol: the flow meter works only

for transmission without requests from the data acquisition device. The

transmission period is 16 seconds and the carrier frequency is 868 MHz.

Each parcel transmits a Wireless M-Bus identifier, which includes the

serial number of the flow meter, which determines which metering device

(from which consumer/subscriber) received the data.

15

1.5.5.5. Universal output

The flow meter has a non-isolated universal output that can operate

in frequency, pulse and logic modes.

The functions of the universal output, operating modes, output pa-

rameters and output disconnection are defined by the software settings.

The diagram of the output terminal stage and the description of its

operation are given in Appendix B.

In the frequency mode, a pulse sequence of meander type with a

duty cycle of 2 is given to the open output, the frequency of which is pro-

portional to the current value of the flow rate. It is possible to scale the

frequency output operation by software setting the Maximum output fre-

quency or Output conversion factor, as well as the lower and upper

flow limit values of Lower limit by flowrate and Upper limit by flowrate,

corresponding to the sequence frequency of 0 Hz and the maximum fre-

quency, respectively. The maximum possible value of Maximum output

frequency is 1000 Hz in ADJUSTMENT mode and 10 Hz in WORK and

SERVICE modes.

Error frequency is pulse sequence frequency (not more than 10

Hz), which will be formed at the output if the measured value of the flow

rate exceeds the value of Qmax for this DN flow meter. The target value of

Error frequency must be at least equal to the target value of Maximum

output frequency. To disable the alarm frequency output function, set

Error frequency to 0 Hz.

In pulsed operation mode, a pulse burst isgiven to the open output

every second, the number of which, considering Pulse weigt, corre-

sponds to the volume value measured in the previous second. The max-

imum possible pulse repetition rate in the burst (of meander type with a

duty cycle of 2) is 1000 Hz in ADJUSTMENT mode and 10 Hz in WORK

and SERVICE modes.

For correct operation of the flow meter's universal output there is

a procedure of automatic calculation of KP parameter (pulse/m3) in fre-

quency mode and Pulse weigt parameter (m3/pulse) in pulse mode.

KP parameter is calculated based on user-defined values of Q lower

limit,Q upper limit and Fmax, Pulse weigt parameter is calculated on

the basis of defined values of Q upper limit and Pulse width in the

range:

- From 1 to 1000 ms –in ADJUSTMENT mode

- From 100 to 1000 ms –in WORK and SERVICE mode.

In the logic mode, the presence of an event (or its certain condi-

tion) at the output corresponds to one level of electrical signal at the out-

put, and the absence of an event (or its other condition) –to another level

of signal.

The active signal level (Active level), i.e. the level of the signal cor-

responding to the presence of an impulse (event), is set by setting the

High or Low value in any operation mode. The electrical parameters of

the signal levels are given in Appendix B.

When released from production, the typical values of universal out-

put parameters are set: pulse type, passive mode, pulse weight –0.0025

m3/pulse.

16

1.5.5.6. Logic output

The flow meter has a non-isolated logic output. Operation modes,

parameters and electrical characteristics of the logic output are similar to

those of the operation modes, parameters and electrical characteristics

of the universal output in the logic mode.

1.6. Flow meter design

1.6.1. The primary flow converter and the secondary measuring converter form

a single design of the flow meter (see Fig.A.1 of Appendix A).

The pipeline section (PS) of the primary converter is made of high-

strength plastic PA66-GF30. The ends of the PS are fitted with pipe

flanges for connection to the counter flanges.

1.6.2. The plunge PEA used in the flow meter is cylindrical, the end of the PEA

has a radiating plane in the form of a disk. The converters are installed in

the pipeline section in such a way that the radiating PEA plane is in con-

tact with the liquid to be monitored. The PEAs supplied with CP are de-

signed for pressures up to 1.6 MPa.

1.6.3. PEA and the secondary converter are connected by communication ca-

bles hidden inside the enclosure.

1.6.4. The secondary converter is mounted directly on the flow meter's pipeline

section. The processing module board is placed in the secondary con-

verter enclosure, and the indication module board with indicator –in the

front panel. The modules are connected to each other by a signal loop.

1.6.5. After installation of the interface cable and the universal output, the sec-

ondary flow meter converter with IP68 protection is completely filled with

Hensel GH 0350 type compound. The design of the device is not disas-

sembled.

1.6.6. The appearance of the flow meter may differ from that given in Appendix

A without changing its operational and metrological characteristics.

1.7. Marking and sealing

1.7.1. The marking on the front panel of the SMC contains the designation and

name of the flow meter, the manufacturer's trademark and the approval

mark of the measuring device type. In addition, the maximum tempera-

ture of the liquid to be measured, the supply voltage and the size (DN) of

the flow meter are marked on the individual labels.

The factory numbers of the PEA and pipeline section are indicated

on their enclosures.

1.7.2. After verification of the flow meter the contact pair of the permission to

modify the calibration parameters is sealed. Also, the screws of fixing the

protective cover of the processing module are sealed with the manufac-

turer's seal.

1.7.3. The contact pair of the permission to modify the service parameters can

be sealed after the commissioning.

In addition, the cover of the secondary converter can be sealed with

two hinged seals to prevent unauthorized access during transport, stor-

age or operation.

17

2. INTENDED USE

2.1. Operational restrictions

2.1.1. The flow meter should be operated under the conditions of influencing

factors and parameters of the controlled medium, which do not exceed

the permissible values specified in the operating documentation.

2.1.2. The flow meter can be installed in vertical, horizontal or inclined piping.

2.1.3. Precise and reliable operation of the flow meter is ensured if the following

conditions are met at the CP installation site:

- Fluid pressure in the pipeline and its operation modes exclude gas for-

mation and/or accumulation of gas (air)

- The internal volume of PS must be filled with liquid during operation

- Sections of the pipeline up to the flow meter should not contain devices

or structural elements that cause changes in the structure of the fluid flow.

2.1.4. Type and composition of the controlled liquid (presence and concentra-

tion of suspended solids, foreign liquids, etc.), operation mode and con-

dition of the pipeline should not lead to corrosion and/or deposits that

affect the performance and metrological characteristics of the flow meter.

2.1.5. Flow meter should be installed on the site in accordance with the section

"Installation of the flow meter" of this manual.

2.1.6. Lightning protection of the device site protects the device from failure in

the presence of lightning discharges.

2.1.7. The requirements for the operating conditions and the selection of the

installation site given in these operating instructions take into account the

most typical factors affecting the operation of the flow meter.

Factors that cannot be predicted, evaluated or checked and which

the manufacturer could not consider in the development of the flow meter

may exist or occur during its operation.

If such factors occur, they must be eliminated or a different place of

operation must be found where these factors do not exist or do not affect

the operation of the product.

18

2.2. Safety measures

2.2.1. The flow meter can be operated by the personnel who have studied the

documentation for the product.

2.2.2. When operating the flow meter, dangerous factors are:

- Pressure in the pipeline (up to 1.6 MPa)

- Other dangerous factors related to the nature and characteristics of the

facility where the flow meter is operated.

2.2.3. If external damage to the device or communication cables is detected,

disconnect the device until a specialist determines that it can be used

again.

2.2.4. During installation, commissioning or repair of the flow meter is prohibited

to:

- Make connections to the flow meter, switching operation modes when the

power supply is on

- Dismantle the flow meter on the pipeline until the pressure is completely

relieved in the section of the pipeline where the work is performed

- Use electrical devices and power tools without connecting their enclo-

sures to the protective grounding line, as well as to use the listed devices

in a faulty condition.

19

3. INSTALLATION OF THE FLOW METER

3.1. Transportation

The flow meter must be transported to the installation site in its orig-

inal packaging.

After transportation to the place of installation at a negative temper-

ature and introduction into the room with a positive temperature, the flow

meter should be kept in the package at least 3 hours to avoid moisture

condensation.

When unpacking the flow meter, check its completeness in accord-

ance with the passport for this device.

3.2. Installation requirements for the flow meter

3.2.1. To install the device on the site it is necessary to have a free section in

the pipeline for installation of the flow meter.

The following conditions must be met at the CP installation site:

- Liquid pressure and pipeline operation modes exclude gas formation

and/or accumulation of gas (air)

- The internal volume of the CP must be filled with liquid during operation;

- there are no or minimum pulsations and swirls of liquid.

CP may be installed in horizontal, vertical or inclined piping (Fig.4).

The CP (PEA) must not be located at the highest point of thepipe section.

The most suitable place for installation, if any, is the upstream or down-

stream section of the pipeline.

Fig.4. Recommended installation locations for the CP of flow meter

NOTE. If it is not possible to install the flow meter in the recom-

mended places, it is possible to install the device at the top of the pipeline.

It is necessary to install an air valve (air vent) at a point above the upper

point of the flow meter, for example, in the expansion of the pipeline.

WARNING: Ensure that the air valve is in good working order. Cor-

rect operation of the flow meter is possible only when there is no air in

the duct.

3.2.2. The difference between the inner diameters of the pipeline and the CP

pipeline section at the jointing points must not exceed 0.05·DN.

3.2.3. When installing the CP on a pipeline, it is recommended that the longitu-

dinal plane of PEA (the plane passing through a pair of PEA along the

20

pipe axis) be positioned at an angle of = 45-90to the vertical plane

(Fig.5).

Fig.5. Recommended PEA positions when installing the flow meter

3.3. Requirements for the length of straight sections

3.3.1. If there are hydraulic resistances at the installation site, normal operation

of the flow meter is provided by straight sections of the pipeline before

the first and after the last one PEA in the stream. The minimum values of

the relative length of straight sections for different types of hydraulic re-

sistances are given in Table D.1 of Appendix D.

The length of the straight section L (mm) is determined by the for-

mula:

DNN=L

,

where N is the relative length expressed by the number of DNs and shown

in Table D.1;

DN –nominal diameter of CP, mm.

WARNING: When measuring the reverse flow rate, all PEAs are the

first in the flow and the lengths of the straight sections must be deter-

mined from this position.

3.3.2. When installed in the pipeline in front of the primary flow straightener con-

verter (Appendix D), the straight input length of the CP can be reduced

by up to two times.

3.4. Installation on the pipeline

3.4.1. Before starting work on the pipeline in the place of installation of the flow

meter, fix pipe sections that may deviate from the coaxial position after

cutting the pipeline with clamps to the fixed supports.

WARNING: Before installing the flow meter it is necessary to drain

the liquid and cover the section of the pipeline, where the installation

works will be carried out.

3.4.2. A section of the required length is cut out at the selected pointof the liquid-

free pipeline, and counter flanges of the appropriate diameter are welded

to the pipe ends. Ensure the alignment and parallelism of the flanges,

between which the CP of flow meter is installed.

3.4.3. The flow meter should be installed in the pipeline, and the direction of the

arrow on the CP should coincide with the flow direction or the forward

direction for reverse flow. The joints between the flanges are sealed with

gaskets and the flanges are bolted together.

This manual suits for next models

1

Table of contents

Other AFLOWT Measuring Instrument manuals