AFLOWT MF Pro M Series User manual

ELECTROMAGNETIC

FLOW METER

AFLOWT MF

Version “Pro-×××M×”

INSTALLATION MANUAL

ISO 9001:2015

2

* * *

Manufacturer quality management system is certified to

ISO 9001:2015

* * *

URL: http://www.aflowt.com

3

TABLE OF CONTENTS

INTRODUCTION.....................................................................................................3

1. SAFETY INSTRUCTIONS ..................................................................................5

2. MOUNTING PREPARATION..............................................................................5

3. MOUNTING.........................................................................................................6

3.1. General Requirements...........................................................................6

3.2. Mounting the Flow Meter into the Pipeline.............................................6

3.3. Wiring the Flow Meter..........................................................................12

4. DISMOUNTING.................................................................................................14

5. PUTTING INTO OPERATION...........................................................................15

APPENDIX А. Carbon steel structures for mounting flow meters

into the pipeline…… ..............................................................................................16

APPENDIX B. Holder to Fix Metal Sleeves for Power

and Communication Cables..................................................................................25

4

The present manual covers procedures for on-site mounting and

dismounting of AFLOWT MF electromagnetic flow meters, Pro-×××М×

version, Pro-112MI, -122MI, -212MI, -222MI, -111MA,-121MA, -211MA,

-221MA, -112MC, -122MC, -212MC, -222MC models. In the course of

work, also refer to the "AFLOWT MF electromagnetic flow meter.

Version Pro-×××М×. Operation manual" document.

LIST OF ABBREVIATIONS

DN

MB

MF

- Nominal Diameter

- Measuring Block

- Electromagnetic Flowmeter

CAUTION!

1. Flow meter can be mounted into metal hot fluid pipeline only if mount

components of the pipeline allow for pipeline expansion to prevent

deformation of the flow meter flow pipe.

2. DO NOT touch electrodes in the flow pipe inner channel at any time

when working with the electromagnetic flow meter.

3. When the flow meter is energized, DO NOT perform electric welding in

the room if pipeline where the flow meter is installed is not filled with

liquid, and on the pipeline where the flow meter is installed.

4. While welding, passing of weld current through the flow meter case is

STRICTLY FORBIDDEN.

5. While welding, DO NOT use the flow meter as an installation tool. Install

the flow pipe dimension simulator provided in the delivery package.

6. When mounting and using the flow meter, DO NOT remove protection

rings from the flow pipe. Protection rings are installed to protect

projecting fluoroplastic lining.

7. DO NOT rotate the flow meter mounted in the pipeline around the

pipeline axis.

8. If flow pipe is covered with fluoroplastic and protection rings are

removed, DO NOT remove the tightening stud (bolt) and clamping

plates from the flow meter for more than 10 minutes. The clamping

plates shall be removed right before mounting the flow meter into the

pipeline.

9. When moving, DO NOT lift the flow meter by its measuring block.

5

1. SAFETY INSTRUCTIONS

1.1. The flow meter should be mounted (dismounted) by technicians:

- Certified for performing work of this type

- Having the right to work with electrical installations up to 1000 V

- Familiar with all the instructions outlined for the flow meter and auxiliary

equipment used for mounting and dismounting.

1.2. When working with the flow meter, the dangerous factors are as follows:

- AC voltage (RMS value up to 264 V, frequency 50/60 Hz)

- Pipeline pressure (up to 2.5 MPa)

- Medium temperature (up to 150С).

1.3. In the course of mounting (dismounting) DO NOT:

- Connect to the MF, switch over modes or replace electronic

components when the flow meter is powered up

- Remove the MF from the pipeline until pressure in the pipeline section

worked on is fully released

- Use electronic devices and electric tools them without proper

grounding, and also use the listed devices in a faulty condition.

1.4. Prior to performing work, make sure with use of the appropriate

equipment that no dangerous AC/DC voltage that may cause injury or

death is applied to pipeline section to be worked on.

2. MOUNTING PREPARATION

2.1. The MF should be transported packed in the manufacturer’s box.

2.2. After the MF has been moved to the mounting location from a cold

environment into a warm one (with ambient temperature above zero), it

shall be left in the manufacturer’s box for at least 3 hours to make sure

that no moisture will condensate inside.

2.3. When unpacking, check that the delivery package contains all items

specified in the Equipment Certificate.

6

3. MOUNTING

3.1. General Requirements

When mounting the MF on site, a free pipeline section should be

provided. It is used to mount the flow meter and straight pipe runs of

appropriate length upstream and downstream the flow pipe.

Overall dimensions and weight of the MF are given in Appendix A

of the Operation Manual.

CAUTION! You must choose a mounting location for MF so

that the conditions meet the requirements specified in the

Operation Manual.

3.2. Mounting the Flow Meter into the Pipeline

3.2.1. Mounting considerations:

- The MF may be mounted into horizontal, vertical, or sloping pipeline

without need of dirt traps or special filters

- To prevent air accumulation at the mounting location, the MF should not

be placed at the upper point of the pipeline or in the open-ended

pipeline; the best place to mount the MF (if applicable) is the lower or

the uprising pipeline run (see Fig.1)

- The liquid pressure in the pipeline shall be chosen so that to prevent

gas development

- The MF should be mounted in the pipeline where liquid pulsation and

turbulence are minimal.

MF

Fig.1. Recommended MF locations.

7

- Straight pipe runs with nominal diameter (DN) equal to nominal

diameter of the MF should be provided upstream and downstream the

MF. Length of the runs should not be less than specified in Table 1.

The runs must not include devices or components that may disturb flow

structure

- When the MF is operated, the flow pipe inner channel should be fully

filled with liquid

- When mounting the MF into horizontal or oblique pipeline, position the

axis of the measuring block (MB) stand in vertical plane going through

the pipeline axis. Maximum deflection is ±30°

- Intensity of external magnetic field (commercial frequency) should not

exceed 400 A/m.

Table1. Length of straight pipe runs

Unidirectional flow

Bidirectional flow

upstream MF

downstream MF

upstream MF

downstream MF

5DN

2DN

5DN

3DN

3.2.2. The assembly-welded structure can be used to mount the flow meter

into the metal pipeline. The structure is assembled from fittings and

included in the delivery package.

Fittings provided on request can be used to mount the flow meter

into the plastic (metal-plastic) pipeline.

3.2.3. Fitting assembly to mount into the metal pipeline.

3.2.3.1. A fitting assembly for the assembly-welded structure includes:

- Flat weld flanges (modified)

- Flow pipe dimension simulator of appropriate size and design (flanged

or wafer type)

- Gaskets

- Fasteners.

The simulator overall mounting dimensions and DN correspond to

the dimensions of the flow meter flow pipe to be mounted with this

fitting assembly. The simulator is installed instead of the MF when

performing mounting or welding or dispatching the MF for regular

verification or repair.

In addition, the assembly may include straight pipe runs of

appropriate length (DNs equal to DN of the MF) and concentric

adaptors to provide connection from pipeline greater DN1 (DN2) to the

lesser DN of the MF.

View of assembly-welded structures made of stainless steel and

fully assembled from all components, reference linear dimensions, and

types of flange modifications are specified in Appendix A.

NOTE. It is prohibited to reduce length of supplied straight pipe

runs to meet requirements for length of straight pipe runs provided in

Table 1.

8

Delivery package is agreed with the customer. Set of design

documentation for the fitting assembly is available at customer's option.

3.2.3.2. Welding of assembly-welded structure components and connection of

the components to the pipeline at flow meter location must be

performed in compliance with applicable regulatory documents.

Alignment of the whole unit and flatness/parallel alignment of the

flanges upstream and downstream the flow meter flow pipe must be

provided.

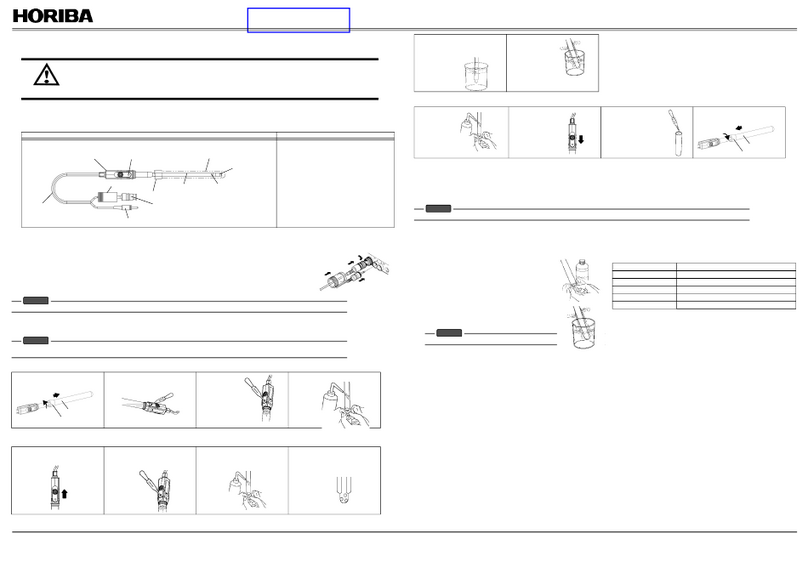

3.2.3.3. The procedure for manufacturing the assembly-welded structure is as

follows:

a) Weld the flanges to the straight pipe runs (pipeline) considering that the

straight pipe run (pipeline) axis should be perpendicular to the flange

plain adjacent to the flow pipe (see Fig.2).

b) If necessary, weld the adaptors to the opposite ends of the pipe runs

(see Fig.3).

Рис.2 Рис.3

Fig.2 Fig.3

CAUTION! Overlaps and undercuts inside the channel are

unacceptable. After completing the work, remove burrs and scales from

the inside.

c) Assemble the whole structure fixing components with bolts (studs), see

Appendix A. Please make sure that the simulator is installed into the

assembly-welded structure instead of the flow meter to provide

alignment between two welded units, to ensure flatness/parallel

alignment of the flanges adjacent to the flow pipe and to avoid

damages of the MF during welding of the structure to the pipeline.

During assembling make sure that mounting gaskets included in the

fitting assembly are installed, all assembling bolts (studs) are used and

all nuts are tightened according to Clause 3.2.8.4 of this Manual.

While assembling, please pay attention to the alignment of

threaded holes M5 on cylindrical surface of the flanges adjacent to the

flow pipe. Holes used to connect wires to the MF case must be located

in line that is parallel to the structure axis and allow easy connection of

the wires.

3.2.4. Fitting assembly to mount into the plastic (plastic-metal) pipeline.

3.2.4.1. The fitting assembly for the assembly structure includes:

- Two straight adaptors of appropriate length with DN equal to the flow

meter DN. Flat flange (modified) is welded to one of the adaptor ends.

9

The other (free) end of the adaptor is threaded with straight pipe outer

thread

- Flow pipe dimension simulator of appropriate size and design (wafer

type)

- Gaskets

- Fasteners.

3.2.4.2. The simulator overall mounting dimensions and DN correspond to the

dimensions of the flow meter flow pipe to be mounted with this fitting

assembly.

Assembly view, reference linear dimensions, and types of flange

modifications are specified in Appendix А.

3.2. 4.3. The procedure for assembling fitting assembly is as follows:

a) Put mounting gaskets included in the fitting assembly into adaptor

flanges.

b) Place simulator between adaptor flanges and assemble the whole

structure fixing components with studs. During assembling use all studs

and tighten nuts according to Clause 3.2.7.4 of this Manual.

While assembling, please pay attention to the alignment of

threaded holes M5 on cylindrical surface of the flanges adjacent to the

flow pipe. Holes used to connect wires to the MF case must be located

in line that is parallel to the structure axis.

3.2.5. Mounting fitting assembly into the metal pipeline.

3.2.5.1. Before mounting an assembly (assembly-welded structure), fix the

pipes that may tip out of their axes after cutting the pipeline to

stationary supports by clamps. Drain liquid from the pipeline, cut it and

mount the fitting assembly considering the following conditions:

- The longer straight pipe run should be the first upstream

- Threaded holes M5 on cylindrical surface of the flanges used to

connect wires to the MF case should be in position allowing easy

connection of the wires.

3.2.5.2. When welding the fitting assembly to the pipeline, the inside of the

assembly and pipeline should be protected from burrs and scales.

After welding the weld joints must be stress relieved by means of

heat treatment.

3.2.5.3. After completion of work, check weld joints and matting faces for

leakages according to current norms specified for pipelines of this type.

Re-weld bad joints and replace gaskets, if necessary.

Wash the system before the simulator is replaced by the flow

meter.

The fitting assembly should not be subjected to stresses and

strains from the pipeline (bending, compression, tension, twisting

caused by disbalance, misalignment or torque nonuniformity). To

prevent this, leave supports of the inlet and outlet ducts and tighten

fastening clamps.

10

3.2.6. Mounting fitting assembly into the plastic (metal-plastic) pipeline.

3.2.6.1. Before mounting drain liquid from the pipeline and cut the pipeline

where the flow meter will be installed. Fix the assembly to stationary

supports by clamps where pipeline is cut considering the following

condition: threaded holes M5 on cylindrical surface of the flanges used

to connect wires to the MF case should be in position allowing easy

connection of the wires.

3.2.6.2. Connect pipeline ends to the fitting assembly using fittings of

appropriate typical size which are installed on plastic (metal-plastic)

pipelines.

An adaptor coupling may be used as confusors/diffusors if a

different diameter of the pipe is necessary.

3.2.6.3. After completion of work put the pipeline into operation to check joints

and connections for leakages according to current norms specified for

pipelines of this type.

Wash the system before the simulator is replaced by the flow

meter.

3.2.7. Mounting the flow meter into the metal pipeline.

3.2.7.1. Position the flow meter so that the axis of the measuring block stand is

arranged in vertical plane with maximum deflection of 30. The arrow

on the flow pipe shall point to the flow direction.

NOTES.

1. Before mounting the flow meter into the pipeline remove protection rings

from the flow pipe lining if liquid under control is aggressive towards the

material of protection rings.

2. The flow meter for measuring bidirectional flow may be installed without

regard to the pipeline flow direction.

3.2.7.2. The non-flanged flow meters of Pro-×1×М× versions with protection

rings are automatically centered relative to companion flanges of the

pipeline since outer diameter of external rings matches the diameter of

flange grooves.

When mounting the MF, put new gaskets provided in the delivery

package into the companion flanges.

To move pipeline flanges apart when installing or removing the MF

(simulator), it is recommended to use a special extension tool.

3.2.7.3. When installing flow meters of Pro-×2×М× versions (flanged flow

meters), put bolts into mating flanges of the flow pipe from the side of

the pipeline flanges. Length of the bolts must provide the distance of

minimum 3 mm from a bolt end to the flow meter assembly.

Alignment of the pipeline and flow pipe inner channel is provided

when flow meter flanges are aligned with pipeline companion flanges.

When the simulator is replaced by the flow meter, put additional

gaskets included in the delivery package to provide leak tightness of

joints between flow meter flanges and pipeline mating flanges (if

necessary).

11

CAUTION! Please make sure that gaskets are aligned relative to

the flow pipe inner channel, i.e. a gasket must not even partly cover the

inner channel. To provide gasket alignment, it is recommended to fix

the gaskets by adhesive.

The flow meter shall be mounted into the pipeline when all

construction, welding and other works are finished.

3.2.7.4. When mounting the MF (simulator) into the pipeline tighten nuts in order

specified in Fig.4, using a torque indicating wrench with maximum

torque value as per Table 2. Exceeding torque value may cause

damage to the flow pipe resulted in leaking of liquid into the inner

cavity of the MF.

To prevent disbalance and misalignment, it is recommended to

tighten nuts in several steps increasing torque step-by-step up to the

value specified in Table 2 while controlling alignment of the mating

flanges.

Table 2

DN, mm

10

15

20

25

32

40

50

65

80

100

150

200

300

Torque, N⋅m

15

15

15

20

25

35

35

40

50

60

80

100

150

Fig.4. Order of tightening flange nuts

DO NOT rotate the MF mounted in the pipeline around the

pipeline axis.

3.2.8. A flow meter is mounted into the plastic (metal-spastic) pipeline the

same way as a construct flow meter of wafer type is mounted into the

metal pipeline.

CAUTION! Follow recommendations of pipe manufacturers when

mounting into plastic (metal-plastic) pipelines.

12

3.3. Wiring the Flow Meter

3.3.1. Power and communication cables are connected to the MF after it is

installed into the pipeline. Cables are passed via corresponding MB

through connections and connected to boards of processor and

communication modules. Schematics of the input and outputs are given

in Appendix B of the Operation Manual.

The MF power supply cables should be connected considering the

operating conditions. As a power cable, you may use any 24 V two-wire

circular section cable with the cross section of at least 0.5 mm2. Cable

length for one MF is up to 500 m.

It is permissible to power several flow meters from one secondary

power source only if there is no difference in potential between

pipelines where flow meters are installed. In this case, permissible

cable length is reduced proportionally.

As a communication cable for a serial interface output and general-

purpose outputs, you can use any two/four-wire circular section cable

with the cross section of at least 0.35 mm2and length of up to 300 m.

Use four-wire cable for simultaneous connection of both general-

purpose outputs.

A cable for the current output is selected considering load rating of

the output as well as the parameters of an input connected to receive

the current signal.

Power and communication cables used shall comply with the flow

meter operating conditions.

3.3.2. Prior to connection, cut isolation from cable ends by 5 mm and solder

them. Attach the socket (cable) connector provided in the delivery

package to the power cable considering polarity, then attach the socket

connector to the plug on the processor module board. Cables for the

control input and general-purpose outputs are directly connected to the

terminals on the communication module board.

The power cable is passed through one cringle next to the sticker

24 V; the communication cable —through the other cringle.

CAUTION! To ensure appropriate protection of IP65 flow

meter, wiring shall be performed according to the following

requirements:

- When mounting the flow meter into a sloping or vertical pipeline install

measuring block with through connections downwards

- Use circular section cables with outer diameter of 6.0–9.5 mm as power

and communication cables

- Seals of the measuring block case should be clean, undamaged and

placed in corresponding grooves without waves and loops

- Plugs shall be installed into unused through connections

- MB cover screws and through connection nuts shall be properly

tightened after wiring.

13

To prevent measuring block from moisture ingress via through

connections when using flat section cables it is necessary to

connect cables so that falling U-loop is formed in the vertical

plane (see Fig.5).

a) horizontal b) sloping c) vertical

Fig.5. Position of cables at the inlet of through connections when

mounting MF into the pipeline

3.3.3. Communication cables and a network cable are fixed on the wall if

possible. To avoid mechanical damages, it is recommended to place

them in a metal tube or sleeve. Communication and power cables may

be placed in the same tube (sleeve).

You may use a holder (see Appendix B) to fix metal sleeves with

power and communication cables to the MB.

DO NOT fix the cables to the pipeline with heat-carrying

medium.

3.3.4. To provide electrical contact, it is necessary to connect sections of the

pipeline that was cut in the MF mounting location by wires via a terminal

located on the MB. Wire cross section should be at least 4 mm2. If the

pipeline has cathode protection, cross section of the wires shall

correspond to the value of cathode protection current.

Use threaded holes M5 on cylindrical surface of the flanges to

connect the jumpers.

3.3.5. The need in protective grounding of the device is determined based on

power supply value and environment conditions.

To avoid device failure do not use a lightning protection system as

protective grounding.

The grounding conductor (mechanically protected copper wire)

cross-section must be at least 2.5 mm2and at least 4 mm2if the

grounding conductor has no mechanical protection.

The grounding conductor is connected to the MB fixing screw.

Wires for connection to the pipeline flanges are also connected to this

screw.

CAUTION! If the pipeline is equipped with cathode protection,

do not ground the flow meter.

14

4. DISMOUNTING

4.1. The order of dismounting the flow meter before dispatching for regular

calibration or repair is as follows:

- Turn off power, then disconnect network and signal cables from the flow

meter

- Disconnect wires from the pipeline flanges

- Cut off liquid at the FS location, make sure that pressure is released

and drain the liquid

- Dismount the flow meter and install the simulator

- Immediately after the MF covered by fluoroplastic without

protection rings is dismounted from the pipeline, install protection

rings or clamping plates with a tightening stud (bolt) on the MF.

4.2. After simulator installation check mating surfaces for leakage. Replace

gaskets, if necessary. In case that no leakages are found, put the

pipeline into operation.

4.3. Remove sediment and liquid residues from the inner channel of the flow

meter flow pipe before packing.

15

5. PUTTING INTO OPERATION

5.1. When putting the flow meter into operation check the following:

- The flow is in the direction of the arrow on the flow meter case

- Lengths of the inlet and outlet straight pipe runs of the MF are relevant

to the flow reversibility

- The flow meter and related equipment are connected in accordance

with the selected wiring diagram

- Flow meter outputs operate in the preset modes

- Power supply voltage corresponds to specifications.

5.2. At first power-up or after a long break in operation, the flow meter

becomes operational after:

- It is washed by medium for 30 minutes

- It is kept powered for 30 minutes.

5.3. To prevent changing of service parameters after putting the device into

operation, you can seal terminal pairs that allow to change these

parameters on the communication module board.

To protect the device from unauthorized access during operation

two fixing screws of the measuring block case cover can be sealed.

If a bypass is installed, it is necessary to seal its gates in closed

position.

16

APPENDIX А. Carbon steel structures for mounting flow meters

into the pipeline

Flow direction

Dy1

Dy2

13

23 124 5

L1

L3

L4

LL2

1 —taper adaptor; 2 —straight pipe run; 3 —mating flange; 4 —MF

(flow pipe dimension simulator); 5 —wires connecting MF case and

pipeline.

Fig.А.1. Assembly-welded structure for mounting flow meters of Pro-×12М×

versions (lined with fluoroplastic) with protection rings (wafer

type) into the pipeline

Table А.1. Dimensions of the assembly-welded structure for MFs of Pro-

×12М× versions with protection rings (mm)

DN

DN1, DN2

L*

L1*

L2*

L3*

L4*

Notes

10

20

93

78

78

249

307

25

367

**

32

337

40

367

**

50

397

**

65

447

**

15

20

93

103

78

274

332

25

392

**

32

362

40

392

**

50

422

**

65

472

**

20

25

114

127

87

328

385

32

385

40

385

50

415

65

555

**

80

565

**

17

Table А.1 (continued)

DN

DN1, DN2

L*

L1*

L2*

L3*

L4*

Notes

25

32

114

152

102

368

425

40

425

50

455

65

595

**

80

605

**

100

615

**

32

40

124

187

122

433

490

50

520

65

540

80

670

**

100

680

**

40

50

134

232

152

518

675

65

725

80

735

100

865

**

125

905

**

150

855

**

50

65

154

288

188

630

767

80

777

100

787

125

827

150

777

65

80

175

363

233

771

918

100

928

125

968

150

918

200

958

80

100

175

438

278

891

1048

125

1088

150

1148

200

1078

250

1328

**

300

1328

**

350

1588

**

100

125

216

538

338

1092

1288

150

1348

200

1278

250

1368

300

1368

350

1788

**

400

1788

**

150

200

236

794

494

1524

1797

250

1877

300

1797

350

1957

400

1957

500

2557

**

* - reference dimensions without processing tolerances

** - adaptor is made of two concentric adaptors

Note. The total length “L*”, mm, of flow meter, lined with polyure-

thane without protection rings reduced to 8 mm.

18

Flat weld flanges (for 2.5 MPa pressure) are used to mount the MF

into the pipeline:

- For DN10-DN20 —flanges of design type B (with a fixing ridge)

- For DN25–DN150 —flanges of design type F (with a notch)

Modification of flanges is needed before welding which means

drilling a threaded hole M5 on the flange cylindrical surface to fix wires

(Fig.A.2).

DN,

mm

D6,

mm

h2,

mm

a,

mm

db,

mm

Initial flange

10

35

Н12

2,5±0,2

26

10

Flange 20-25-01-1-B St25

15

40

Н12

2,5±0,2

26

15

Flange 20-25-01-1-B St25

20

51

H12

3+0.5

3

33

Flange 25-25-01-1-B St25

1 –revision to F;

2 –threaded hole М5 (revision)

Fig.А.2. Modification of flanges to mount MF DN10-DN20

To weld flanges for MFs with DN10-DN20, shown in Fig.A.2, to the

pipeline, adaptors shall be used (see Fig.A.3) with length of no less

than that of the straight pipe run (see Table 1).

After welding the flange to the adaptor, process the surface

adjacent to the flow meter as shown in Fig.A.4. The adaptors and

pipeline sections are welded butt-to-butt.

19

а) DN10, DN15

b) DN20

DN, mm

d1, mm

d2, mm

d3, mm

c, mm

L, mm

L1, mm

10

11,6

26

17

0,5+0,5

75

40

15

15

26

21

75

40

100

65

20

20

32

-

10,5

84

124

Fig.А.3. View and dimensions of adaptor DN10-DN20

20

Flange

Wetted seam

Transitive a

branch pipe

3± 0.2

6.3

Fig.А.4. Flange DN10-DN20 and pipe adaptor welded together

This manual suits for next models

12

Table of contents

Other AFLOWT Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Sokkia

Sokkia SET630R quick start guide

Ziton

Ziton ZR4-RL installation guide

Gossen MetraWatt

Gossen MetraWatt lunasix Operating instructions manual

Heuresis

Heuresis Pb200i Alpha user guide

Thermo Scientific

Thermo Scientific Star Series user guide

LOVATO ELECTRIC

LOVATO ELECTRIC DME D122MID installation manual