Afriso EURO-INDEX D0 User manual

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Um

weltschutz

Lindenstraße 20

74363 Güglingen

Telefon

+49 7135 102-0

Service

+49 7135-102-211

Telefax

+49 7135-102-147

info@afriso.de

www.afriso.com

+Read instructions before using product!

+Observe all safety information!

+Keep instructions for future use!

02.2017 0

854.001.0336

Operating instructions

Bourdon tube pressure gauges

Capsule pressure gauges

Diaphragm pressure gauges

Spring diaphragm pressure gauge for differential

pressure

D0, D1, D2, D3, D4, D5, D6, D7, D8, D9

Nominal size: 40, 50, 63, 80, 100, 160, 250

2 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

Table of contents

1This instruction manual............................................................................................4

1.1 Precautions ..................................................................................................4

2Safety.......................................................................................................................5

2.1 Intended use.................................................................................................5

2.2 Predictable incorrect application..................................................................6

2.3 Safe handling ...............................................................................................7

2.4 Staff qualification..........................................................................................7

2.5 Modifications to the product .........................................................................7

2.6 Usage of spare parts and accessories.........................................................8

2.7 Liability information ......................................................................................8

3Product description..................................................................................................9

3.1Measuring principle Bourdon tube pressure gauge.....................................9

3.2 Measuring principle capsule type pressure gauge.....................................10

3.3 Measuring principle diaphragm pressure gauge........................................10

3.4 Measuring principle spring diaphragm pressure gauge (differential

pressure)....................................................................................................10

4Selection criteria....................................................................................................10

4.1 Range.........................................................................................................11

4.2 Properties of the media..............................................................................11

4.3 Ambient conditions.....................................................................................12

4.4 Overload.....................................................................................................13

4.5 Accuracy classes .......................................................................................13

4.6 Connection.................................................................................................14

4.7 Nominal sizes.............................................................................................14

4.8 Cleanliness.................................................................................................14

5Technical specifications.........................................................................................15

5.1 Approvals, tests and conformities..............................................................20

6Transport and storage...........................................................................................21

7Mounting and commissioning................................................................................21

7.1 Connection thread......................................................................................24

7.2 Measurement arrangements......................................................................25

7.3 Mounting position.......................................................................................26

7.4 Connection types .......................................................................................27

7.5 Mounting types...........................................................................................28

7.6 Pressure tap piece .....................................................................................29

7.7 Measuring line............................................................................................29

7.8 Commissioning the product........................................................................30

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 3

8Operation...............................................................................................................32

8.1 Dismounting the pressure gauge...............................................................32

9Additional equipment.............................................................................................33

9.1 Shut-off unit................................................................................................33

9.2 Pressure gauge holder...............................................................................33

9.3 Siphons ......................................................................................................34

9.4 Chemical seals...........................................................................................34

9.5 Overpressure safety devices......................................................................34

9.6 Pressure gauge with maximum pointer......................................................35

9.7 Electrical contacts ......................................................................................35

10 Type code – design numbers................................................................................38

11 Maintenance..........................................................................................................39

12 Decommissioning, disposal...................................................................................40

13 Returning the device..............................................................................................41

14 Spare parts and accessories.................................................................................41

15 Warranty ................................................................................................................41

16 Copyright ...............................................................................................................41

17 Customer satisfaction............................................................................................42

18 Addresses..............................................................................................................42

19 Appendix................................................................................................................43

19.1 EU Declaration of Conformity.....................................................................43

19.2 Information on the Pressure Equipment Directive .....................................44

This instruction manual

4 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

1 This instruction manual

This instruction manual is part of the product.

Read this manual before using the product.

Keep this manual during the entire service life of the product

and always have it readily available for reference.

Always hand this manual over to future owners or users of the

product.

1.1 Precautions

WARNING

WORD

Type and source of the hazard are shown here.

Precautions to take in order to avoid the hazard are shown here

.

Warning word Meaning

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or severe injuries.

CAUTION Dangerous situation!

Failure to observe the information may result in

minor or severe injuries as well as damage to

property.

Safety

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 5

2 Safety

2.1 Intended use

Bourdon tube pressure gauges

Bourdon tube pressure gauges may only be used to display the

pressure of media which are not highly viscous and which do not

crystallize.

Bourdon tube pressure gauges NS50 with inductive contact

(RF50ExIK1.2/ RF50IK1.2 - D302/D312) are additionally suitable for

the generation of signals within the given adjustment range. These

bourdon tube pressure gauges must always be operated in conjunc-

tion with a suitable isolating switching amplifier (for example, Turck,

MK13-P-EX0/24V).

Bourdon tube pressure gauges with clamp chemical seal (Tri-Clamp,

ISO 2852: RF63Ch-D9xx/RF100E-D9xx with MD60 1½"/MD60 2")

are additionally suitable for highly viscous, perishable and hot media.

These Bourdon tube pressure gauges are particularly suitable for

use in the food and beverages industry, for example, for milk and

dairy products.

Capsule pressure gauges

Capsule type pressure gauges may only be used to display the pres-

sure of dry, gaseous media.

Diaphragm pressure gauges

Diaphragm pressure gauges may only be used to display the pres-

sure of high-viscosity or crystallising media.

Spring diaphragm pressure gauge

Spring-diaphragm pressure gauges may only be used for differential

pressure measurement with low differential pressure and high static

pressure for gaseous and liquid media which are not highly viscous

and not corrosive. Particularly suitable for monitoring filters, pumps

and pipe systems.

Safety

6 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

Media

The fluids used must be compatible with the materials of the product

under the specific measuring conditions (for example, temperature,

atmosphere, immunity of the material against the measured fluid,

etc.) and which do not cause chemical reactions.

•Intended operation as per EN 837-1/-3

•No hot media with temperatures of more than 70 °C in the pres-

sure gauge. Take into account the compression heat that is

generated in the case of rapid pressure changes of gases.

•The pressure gauge is neither subjected to pressure surges nor

to pressure fluctuations.

Pressure gauges with switching contacts may only be used in certi-

fied intrinsically safe circuits as per EN 60079-11.

Any use other than the application explicitly permitted in this instruc-

tion manual is not permitted.

2.2 Predictable incorrect application

The pressure gauges must never be used in the following cases:

•Measurement of pressure exceeding the full scale value of the

pressure gauge

•Operation outside of the specified temperature range

•Use as a part of a safety system to protect against exceeding

permissible limit values (equipment parts with a safety-related

function)

•If used in hazardous areas / Ex zones: operation outside of the

specified intrinsically safe limit values

Safety

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 7

2.3 Safe handling

WARNING

Injury due to escaping fluids or bursting parts as

a result of

leaks or bursting of pressurised parts

Use Bourdon tube safety pressure gauges with blow-out (for

example, blow-out back).

As per EN 837, liquid-filled pressure gauges must have a blow-out

device (version S1, S2 or S3).

Pressure gauges for oxygen and acetylene must be safety pressure

gauges (version S2 or S3 as per EN 837-1 or pressure gauge as per

ISO 5171). All wetted parts must comply with EN 29539 must be free

from oil and grease. Only lubricants suitable for oxygen at maximum

operating pressure may be used. The pressure gauges must never

be exposed to humidity.

Pressure gauges with glycerine filling must not be used for oxygen or

other oxidising process fluids. High-concentration fluorine liquids and

chlorinated liquids (for example, halocarbon) are suitable for such

applications.

You must observe all pertinent directives and guidelines in the case

of refrigerating systems, compressors, etc. as well as hazardous

substances such as

•Oxygen

•Acetylene

•Flammable substances

•Explosive substances

•Toxic substances

After an external fire, measured fluid can escape, in particular at

soft solder connections. Verify and, if necessary, replace all

products before re-commissioning the system.

2.4 Staff qualification

The product may only be mounted, commissioned, operated, main-

tained, decommissioned and disposed of by qualified, specially

trained staff.

Electrical work may only be performed by trained electricians and in

compliance with all applicable local and national directives.

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to malfunctions and are prohibited for safety reasons.

Safety

8 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

2.6 Usage of spare parts and accessories

Usage of unsuitable spare parts and accessories may cause dam-

age to the product.

Use only genuine spare parts and accessories of the manufac-

turer.

2.7 Liability information

The manufacturer shall not be liable in any form whatsoever for

direct or consequential damage resulting from failure to observe the

technical instructions, guidelines and recommendations.

The manufacturer or the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this product, in particular in case of improper use of the

product, misuse or malfunction of the connection, malfunction of the

product or of connected products. The manufacturer or the sales

company shall not be liable for damage whatsoever resulting from

any use other than the use explicitly permitted in this instruction

manual.

The manufacturer shall not be liable for misprints.

Product description

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 9

3 Product description

3.1 Measuring principle Bourdon tube pressure gauge

Bourdon tube pressure gauges contain measuring elements (Bour-

don tubes) which are deformed if pressure is applied. This motion is

transmitted to a movement.

Bourdon tubes are tubes with a oval cross-section, bent into a circle.

The pressure to be measured acts on the inside of the tube so that

the oval cross-section approximates a circular shape. The bending of

the Bourdon tube causes ring tension which bends the tube open.

The loose tube end performs a movement which is a measure of the

pressure.

Circular tubes with an angle of 270° are typically used for pressures

of up to 60 bar; for greater pressures, the tubes with several helical

windings are used.

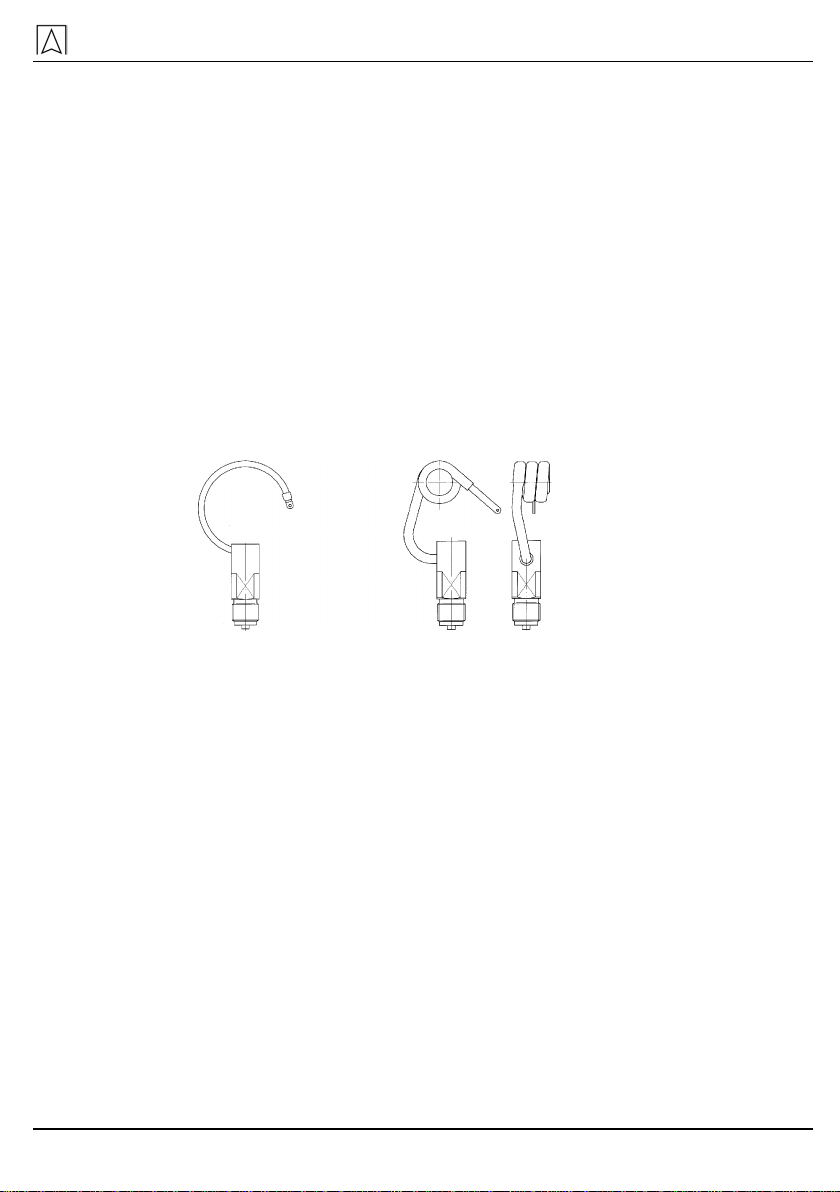

Fig. 1: Circular tube Fig. 2: Helical tube

The Bourdon tubes usually consist of copper alloys or alloyed steel.

Because of their sturdiness and the easy handling, the Bourdon tube

pressure gauge is the most commonly used pressure gauge in tech-

nical pressure measurement.

Bourdon tube pressure gauge NS50 with inductive contact

The inductive contacts used in RF50 Ex IK1.2/RF50 IK1.2 pressure

gauges are non-contacting electric displacement pick-ups (proximity

switches) as per EN 50227 / NAMUR. The output signal is deter-

mined by the presence or the absence of a control flag in the elec-

tromagnetic field of the proximity switch. The electromagnetic field is

concentrated between two opposing coils. The switch is activated

when the control flag moved by the gauge pointer reaches the air

gap between the two coils. The signal is generated without a delay,

according to the motion of the gauge pointer.

If the control flag is outside of the air gap between the two coils, the

system is low-resistance (approx. 1000 Ohm), the current input is

then > 3 mA. If the control flag is in the air gap between the two coils,

Selection criteria

10 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

the system is high-resistance (approx. 7000 Ohm), the current input

is then < 1 mA.

The difference in the current input is used to control a switching am-

plifier. This amplifier converts the input signal into a binary output

signal. Therefore, the switching function of an inductive contact is not

only determined by the inductive contact itself, but also by the

switching amplifier.

3.2 Measuring principle capsule type pressure gauge

Capsule membranes consist of circular corrugated diaphragms

sealed into a single unit. Pressure is applied in the centre and acts

on the inside of the diaphragms. The resulting deformation is propor-

tional to the pressure.

3.3 Measuring principle diaphragm pressure gauge

Diaphragm pressure gauges use circular corrugated diaphragms.

The pressure to be measured is applied at one side. The deflection

of the diaphragm is proportional to the pressure.

3.4 Measuring principle spring diaphragm pressure gauge (dif-

ferential pressure)

The pressures act on two pressure chambers separated by an elas-

tic diaphragm. If there are different pressures in the chambers, the

diaphragm is axially displaced against a compression spring. This is

transmitted to the movement by means of a rod. The differential

pressure is directly indicated by a pointer. The diaphragm is held by

a metallic support which results in an overpressure safety of up to

25 bar at both sides.

4 Selection criteria

WARNING

Injury and damage to the pressure gauge due to unsuitable

pressure gauges

Only use pressure gauges or safety pressure gauges which are

suitable for the actual operating conditions (measuring range,

ambient conditions, materials, over-pressure safety ...).

Verify compliance with all applicable directives, guidelines and

safety requirements as well as the selection criteria (safety as-

pects) as per EN 837-2 in your specific application.

Selection criteria

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 11

4.1 Range

Select the range in such a way that the maximum pressure load

does not exceed 75 % of the full scale value in the case of static

load and 65 % of the full scale value in the case of dynamic

load. This prolongs the service life of the pressure gauge (see

EN 837-2).

4.2 Properties of the media

Pressure surges

Pressure surges must not exceed the application range of the pres-

sure gauges. The measuring element must not be subjected to pres-

sure surges or sudden pressure changes. Such changes considera-

bly reduce the service life of the pressure gauge. For example, such

changes occur if the pressure gauge is mounted to a pump, as indi-

cated by major oscillations of the pointer.

Reduce such pressure surges by installing a damper or an over-

load protection device between the pressure source and the

elastic measuring element.

Throttle elements considerably reduce the inlet cross section which

leads to a delay of the pressure change in the measuring element.

The susceptibility to dirt is a disadvantage of such arrangements.

Damping elements at the movement delay the pointer motion and

cause increased wear of the movement.

Liquid filling cause a damping of the measuring element and de-

creases the wear of the moving parts.

Excessively high temperatures of the fluid in the case of Bour-

don tube pressure gauges

Install a siphon (see chapter 9.3, page 34) or a chemical seal

(see chapter 9.4, page 34) to help protect the pressure gauge

from the hot fluid.

In the case of capsule type pressure gauges and spring diaphragm

pressure gauges, the temperature of the fluid must not exceed the

permissible operating temperature.

Corrosive media

Standard pressure gauges may be used if corrosive media can be

kept away from the measuring device by means of separating ele-

ments. If this is impossible, the material most suitable for the fluid to

be measured and its pressure must be selected.

1. Provide the manufacturer with all information on the materials

that are compatible with the fluid to be measured under the spe-

cific measuring conditions.

Selection criteria

12 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

2. Due to the limited selection of materials for the elastic measur-

ing elements, it may be necessary to use suitable diaphragm

pressure gauges or to install chemical seals made of resistant

materials (see chapter 9.4, page 34).

4.3 Ambient conditions

Mechanical shocks

Pressure gauges must not be subjected to mechanical shocks.

If the installation point is subject to mechanical shocks, install

the pressure gauge in a separate location and connect it by

means of flexible lines.

Vibrations

Vibrations are be indicated by ongoing and frequently unsteady vi-

brations at the tip of the pointer.

The installation site of the pressure gauge is subjected to me-

chanical vibrations.

Install a liquid filled pressure gauge.

In the case of heavy or unsteady vibrations at the installation

point, install the pressure gauge in a separate location and con-

nect it by means of flexible lines.

Ambient temperature

The error limit indicated on the dial applies to an ambient tempera-

ture of +20 °C. Different temperatures have an influence on the accu-

racy; the influence depends on the measuring system.

According to EN 837-1, a deviation of the indication caused by tem-

perature influences is permissible up to the following value with ref-

erence to the full scale value:

•Bourdon tube pressure gauges: 0.04 %/K

•Capsule pressure gauges: 0.06 %/K

•Diaphragm pressure gauges: 0.08 %/K

•Spring diaphragm pressure gauges: 0.05 %/K

Protect the pressure gauge from atmospheric influences in out-

door applications in order to avoid icing up of the gauge at tem-

peratures below 0 °C.

The viscosity of the filling liquid in pressure gauges with liquid filling

increases at decreasing temperatures. This causes a considerable

delay in indication.

Selection criteria

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 13

Corrosive atmosphere

In the case of a corrosive atmosphere, use suitable housings

and assemblies made of resistant materials, for example, spe-

cial surface treatments against external influences.

4.4 Overload

Overloads cause tension in the elastic measuring element which de-

creases its services life and deteriorates the measuring accuracy.

1. Use a pressure gauge whose full scale value is greater than the

maximum static pressure.

The pressure gauge is less sensitive to overload and load

changes (see also see chapter 4.1, page 11).

2. If, for operational reasons, the range must be smaller than the

maximum operating pressure, install an overpressure safety de-

vice, see chapter 9.5, page 34.

Spring-diaphragm pressure gauges may be used up to a maximum

static pressure of 25 bar.

Use a pressure gauge whose full scale value is greater than the

maximum differential pressure.

4.5 Accuracy classes

The accuracy class is the error limit in percent of the measuring

range. The error limit applies to both positive and negative devia-

tions, based on the measured value.

EN 837-1, chapter 6 specifies the error limits of Bourdon tube pres-

sure gauge, EN 837-3, chapter 6 specifies the error limits of capsule

pressure gauges and diaphragm pressure gauges.

Classes 0.1 to 0.6 pressure gauges are primarily used for precision

measurements in laboratories and workshops. Classes 1.0 and 1.6

pressure gauges measure the pressure at machines and production

facilities. Classes 2.5 and 4 pressure gauges are used for monitoring

purposes without special accuracy requirements.

When selecting the accuracy class, take into account the as-

signment of the classes to the nominal sizes (EN 837-1/-3,

chapter 6, table 1).

Selection criteria

14 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

4.6 Connection

Select the size and the type of the connection thread according

to EN 837-1/-3, chapter 7.3 and observe the selection table as

per EN 837-1, chapter 8 (combinations: pressure, thread, nomi-

nal size).

Other connections for special industries and applications must be

agreed upon.

4.7 Nominal sizes

The nominal size according to EN 837-1/-3 relates to the housing di-

ameter in mm. The following nominal sizes are standardised: 40, 50,

63, 80, 100, 160 and 250.

4.8 Cleanliness

Certain applications require pressure gauges which must have been

cleaned in a special way prior to shipment, for example, free from oil

and grease, free from silicone.

1. State cleanliness requirements when ordering.

2. Verify that pressure gauge remains clean during installation.

Technical specifications

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 15

5 Technical specifications

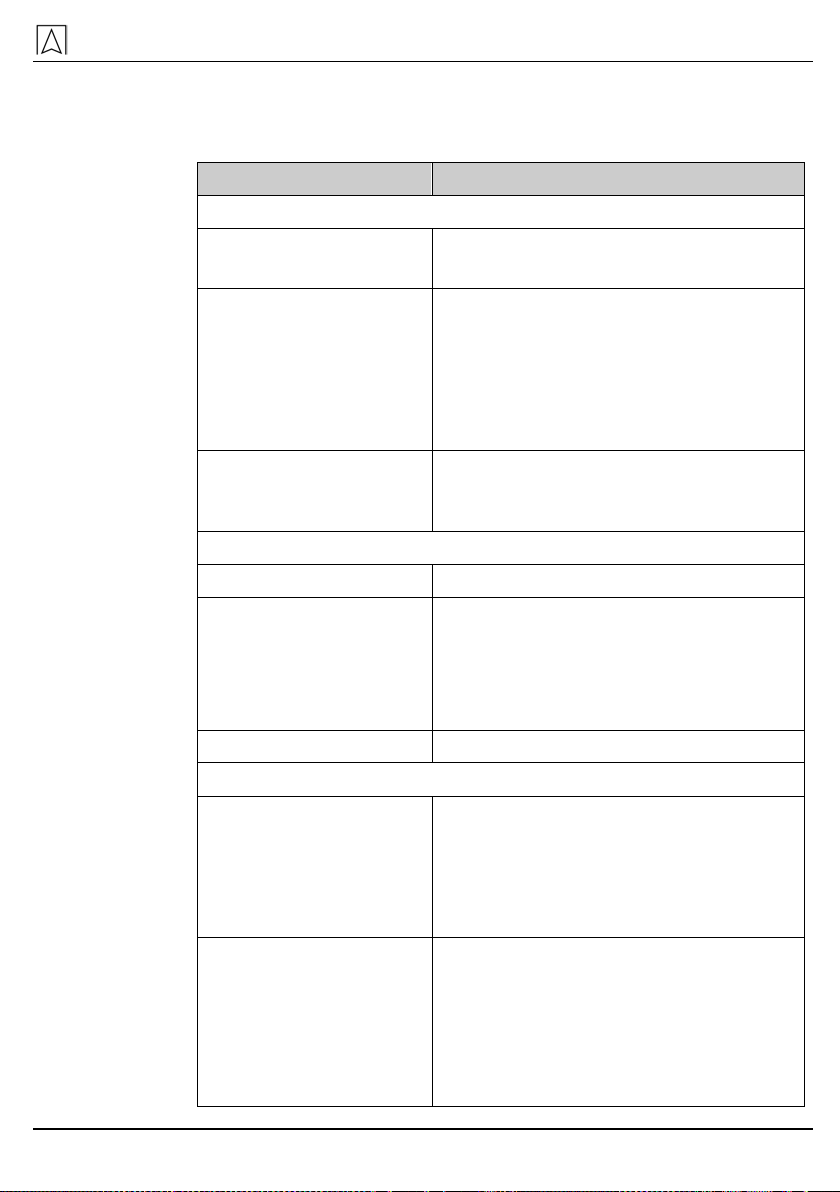

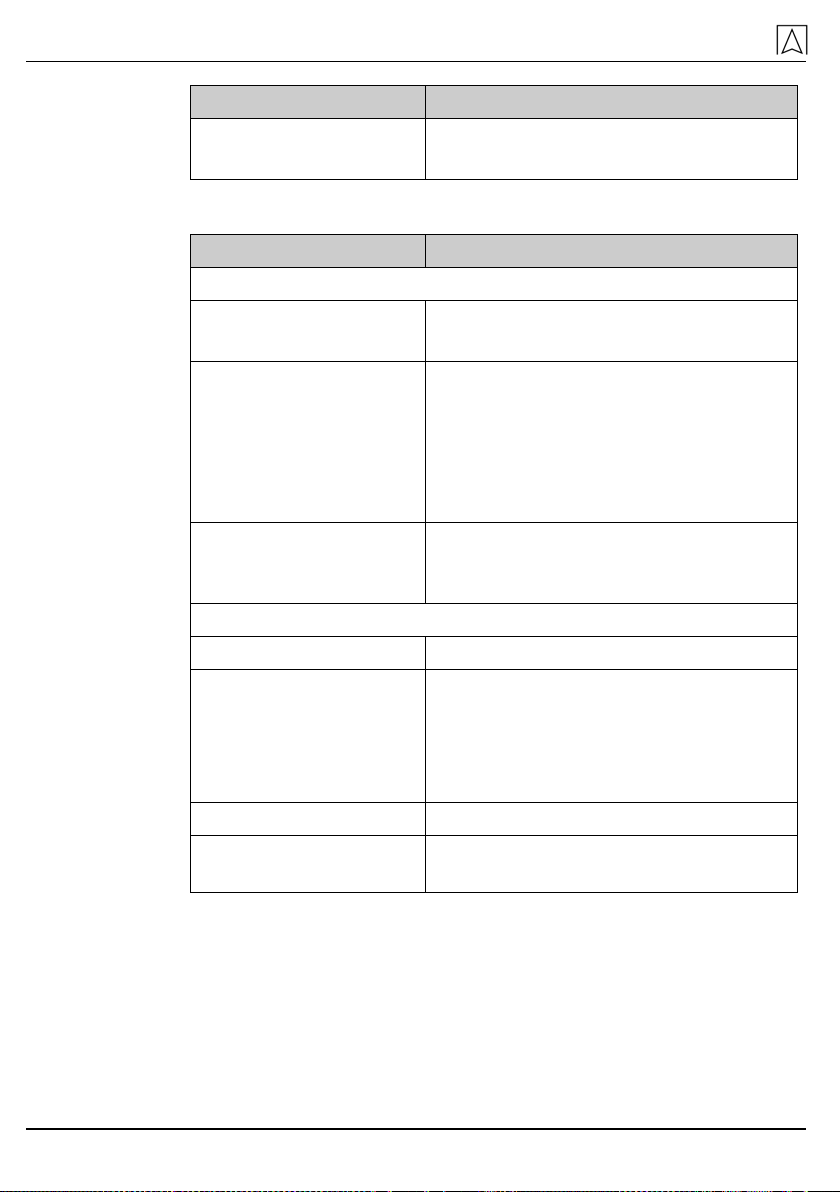

Table 1: Technical specifications Bourdon tube pressure gauges

Parameter Value

General specifications

Measuring ranges -1/0 bar to -1/15 bar

0/0.6 bar to 0/1600 bar

Temperature perfor-

mance Rising temperature approx. +0.4 %/K

Falling temperature approx. -0.5 %/K

(indication error when the temperature

of the measuring system deviates from

the normal temperature of 20 °C, with

reference to the full scale value)

Operating frequency in

hazardous areas (EX

areas).

Max. 0.1 Hz

Operating temperature range

Ambient -20 °C to +60 °C

Fluid Max. +60 °C for liquid filled devices and

devices with soft-soldered Bourdon

tubes

Max. +100 °C for non-filled devices with

hard-soldered or welded bourdon tube

Storage -40 °C to +70 °C

Application area with static load

Up to full scale value

Type: D4, D5, D8

Type: D2, D3

Type: D1

In NS 100, NS 160, NS 250 (cl. 1.0 up

to ≤600 bar)

In NS 100 (cl. 1.0)

In NS 4½"

Up to ¾ full scale value

Type: D1, D6, D7, D9,

D0

Type: D2, D3, D4, D8

Type: D2

Type: D4

All nominal sizes

In NS 40, NS 50, NS 63, NS 80

In NS 100 (cl. 1,6)

In NS 160, NS 250 (cl. 0.6 cl. 0.25

cl. 0.1 and cl. 1.0 > 600 bar)

Technical specifications

16 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

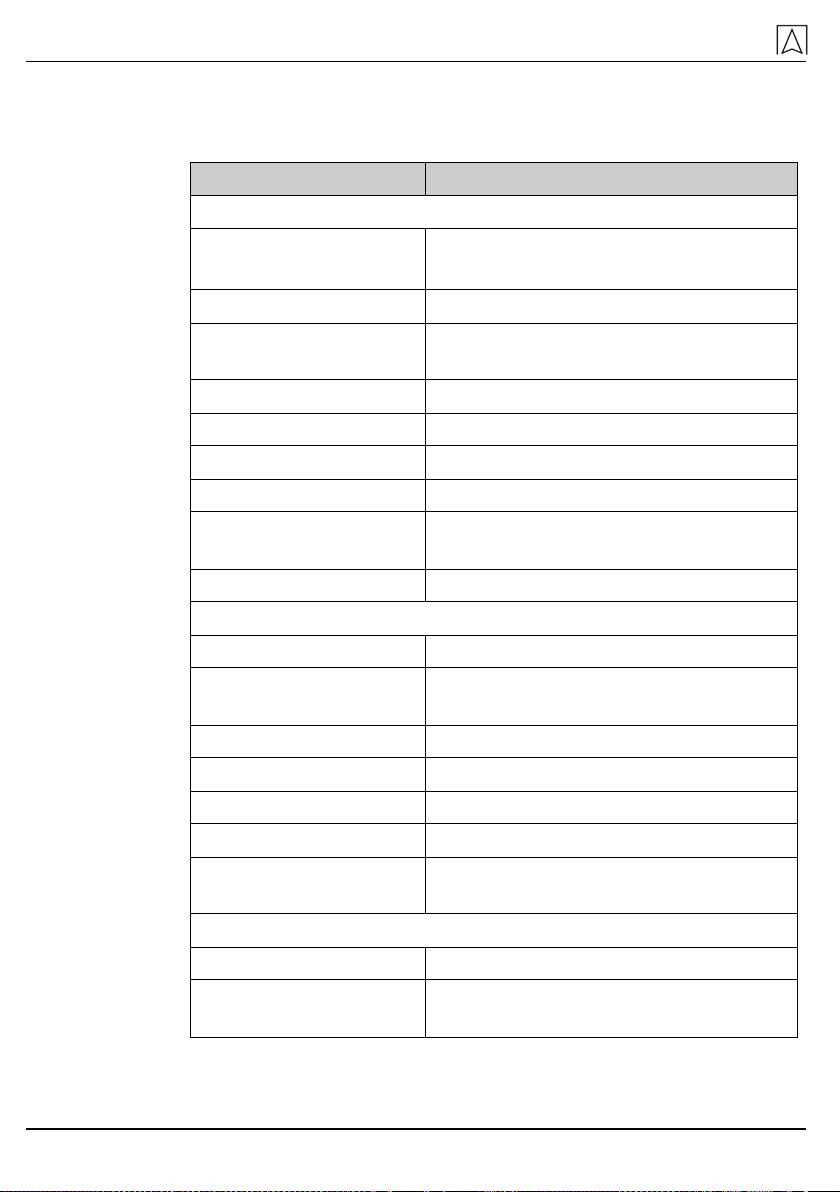

Table 2: Technical specifications Bourdon tube pressure gauge with

clamp type chemical seal

Parameter Value

General specifications

Degree of protection > 25 bar = IP 65 (as per EN 60529)

≤25 bar = IP 54 (as per EN 60529)

Ranges 0.6-40 bar

Permissible operating

pressure Max. ¾ x full scale value

Overpressure safety Full scale value

Connection Clamp as per ISO 2852

Nominal diameter DN 1", DN 1½", DN 2", DN 2½", DN 3"

Surface roughness Ra = 0.8 (wetted surfaces)

Accuracy Cl. 1.6 (as per EN 837-1) at +20 °C;

cl. 1.0 on request

Mounting position Vertical (NL90 ±5° as per DIN 16257)

Materials

All wetted parts 316 L (1.4404/1.4435)

Pressure gauge connec-

tion 1.4571/1.4404

Housing/ crimped bezel 1.4301

Filling plug PUR

Window Safety glass/polycarbonate

Housing seal NBR/PUR

Filling liquid Paraffin oil or silicone oil, (FDA-

compliant)

Operating temperature range

Ambient -20 °C to +60 °C

Fluid +80 °C (when mounted: short-term

+140 °C for sterilisation)

Technical specifications

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 17

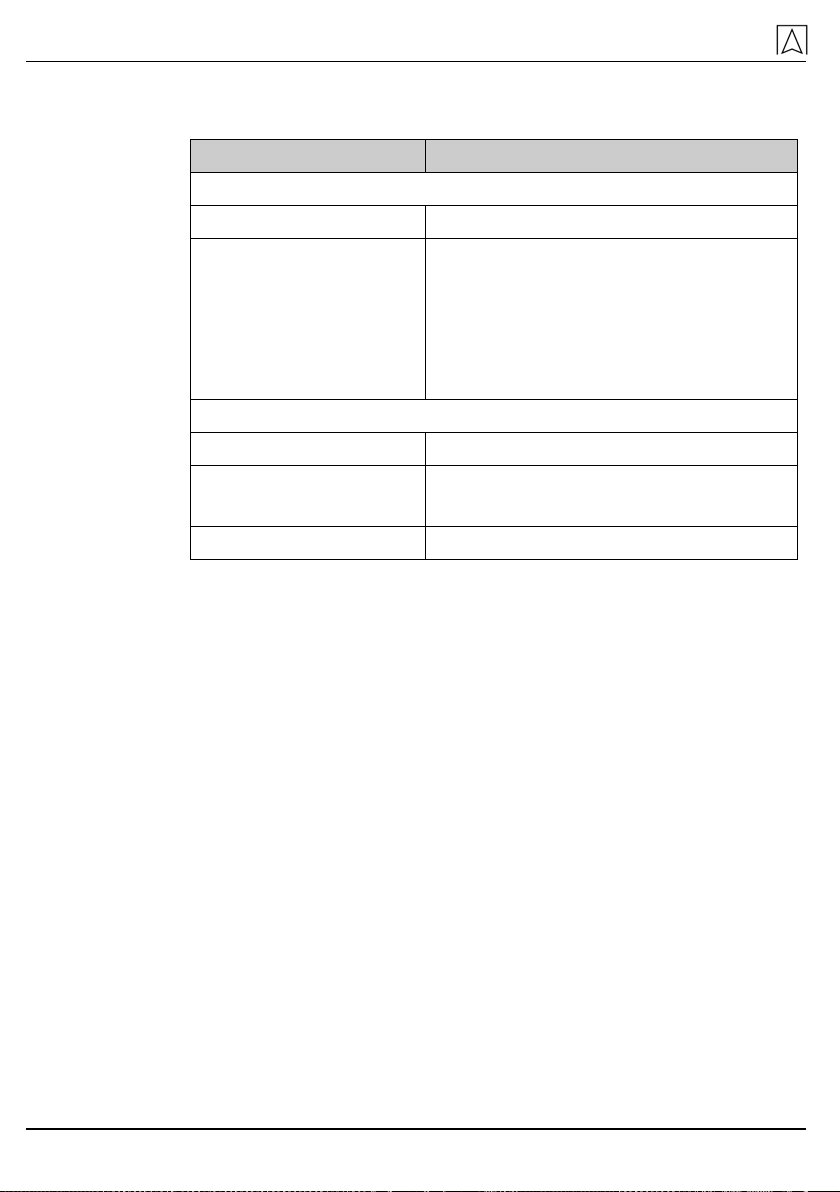

Table 3: Technical specifications Bourdon tube pressure gauge

NS 50 with inductive contact

Parameter Value

General specifications

Nominal operating volt-

age Nom. 8.2 V DC

Current input Active area free > 3 mA

Active area covered < 1 mA

Type of output NAMUR

Degree of protection IP 32 (as per EN 60529)

Permissible operating

pressure Max. full scale value

Overpressure safety Short-term 1.15 x

Connection G¼B or ¼-18 NPT (as per EN 837-1)

Width across flats,

spanner SW 14

Accuracy Cl. 1,6 (as per EN 837-1) at +20 °C

Switching accuracy ±2.5 % of full scale value

Mounting position Vertical (NL90 ±5° as per DIN 16257)

Connection cable

RF50 Ex IK1.2

RF50 IK1.2

2 m, LiYY blue 2 x 0.14 mm²

2 m, LiYY grey 2 x 0,25 mm²

Pin assignment

Grey cable

Blue cable

WH (white)/+ BN (brown)

BL (blue)/+ BN (brown)

Materials

All wetted parts 1.4571/1.4404

Housing 1.4301

Window/rear wall Polycarbonate

Operating temperature range

Ambient -20 °C to +60 °C

Attention: Fluid must not freeze.

Technical specifications

18 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

Parameter Value

Fluid Max. +100 °C

Attention: Fluid must not freeze.

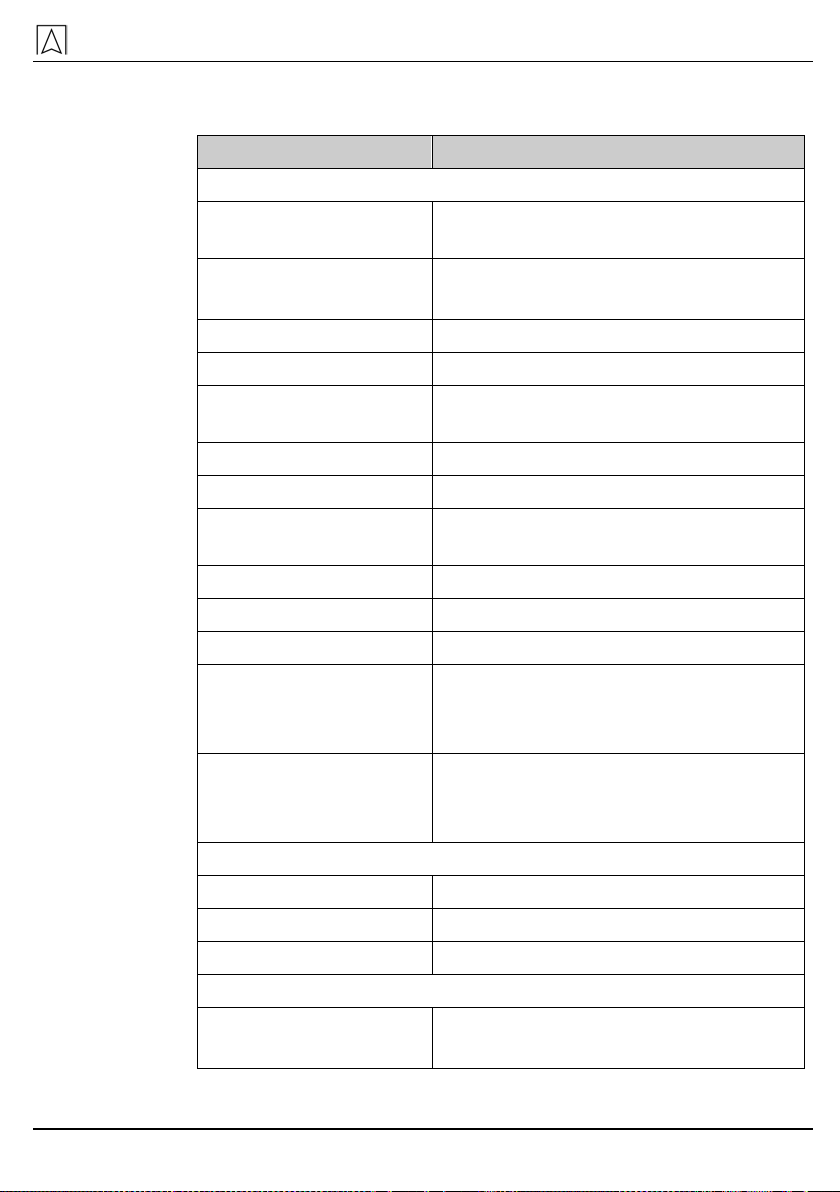

Table 4: Technical specifications capsule pressure gauges

Parameter Value

General specifications

Measuring ranges -25/0 mbar to -1000/0 mbar

0/25 mbar to 0/1000 mbar

Temperature perfor-

mance Rising temperature approx. +0.06 %/K

Falling temperature approx. -0.06 %/K

(indication error when the temperature

of the measuring system deviates from

the normal temperature of 20 °C, with

reference to the full scale value)

Operating frequency in

hazardous areas (EX

areas).

Max. 0.1 Hz

Operating temperature range

Ambient -20 °C to +60 °C

Fluid Max. +60 °C for liquid filled devices and

devices with soldered diaphragms made

of copper alloys

Max. +100 °C for non-filled devices with

welded stainless steel diaphragm

Storage -40 °C to +70 °C

Application area with

static load Up to full scale value

Technical specifications

Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges 19

Table 5: Technical specifications diaphragm pressure gauges

Parameter Value

General specifications

Measuring ranges 0/10 mbar to 0/25 mbar

Temperature perfor-

mance Rising temperature approx. +0.08 %/K

Falling temperature approx. -0.08 %/K

(indication error when the temperature

of the measuring system deviates from

the normal temperature of 20 °C, with

reference to the full scale value)

Operating frequency in

hazardous areas (EX

areas).

Max. 0.1 Hz

Operating temperature range

Ambient -20 °C to +60 °C

Fluid Max. +60 °C for liquid filled devices

Max. +100 °C for non-filled devices

Storage -40 °C to +70 °C

Application area with

static load Up to full scale value

Technical specifications

20 Bourdon tube, capsule, diaphragm, spring diaphragm pressure gauges

Table 6: Technical specifications spring diaphragm pressure gauges

(differential pressure)

Parameter Value

General specifications

Measuring ranges 0/250 mbar to 0/6 bar

Temperature perfor-

mance Rising temperature approx. +0.05 %/K

Falling temperature approx. -0.05 %/K

(indication error when the temperature

of the measuring system deviates from

the normal temperature of 20 °C, with

reference to the full scale value)

Operating temperature range

Ambient -20 °C to +60 °C

Fluid Max. +60 °C

Attention: Fluid must not freeze.

Storage -40 °C to +70 °C

See the current AFRISO catalogue or www.afriso.com for additional

technical specifications

5.1 Approvals, tests and conformities

Bourdon tube pressure gauges comply with the European standard

for pressure measuring instruments EN 837-1, capsule pressure

gauges and diaphragm pressure gauge comply with EN 837-3.

Pressure gauges with a full scale value e500 mbar comply with the

Pressure Equipment Directive (2014/68/EU).

Bourdon tube pressure gauges with clamp chemical seal

The pressure gauges also comply with the US standard 3-A Sanitary

Standard 74-03.

Bourdon tube pressure gauge NS50 with inductive contact

The pressure gauges also comply with the ATEX directive

(2014/34/EU).

This manual suits for next models

9

Table of contents

Other Afriso EURO-INDEX Measuring Instrument manuals