Afriso EURO-INDEX Unimes E User manual

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Umweltschutz

Lindenstraße 20

DE-74363 Güglingen

Phone: +49(0)7135-102-0

Service: +49(0)7135-102-211

Telefax: +49(0)7135-102-14

7

E-Mail: info@afriso.de

Internet: www.afriso.de

Read instructions before using device!

Observe all safety information!

Keep instructions for future use!

Version: 10.2007

Id. no.: 854.001.0422

Operating Instructions

Mechanical Tank Contents Gauge with

Electronic Remote Indication

Type: Unimes E

Part no.: 52130

2 Unimes E

Contents

1This instruction manual............................................................................................4

1.1 Precautions...................................................................................................4

1.2 Explanation of symbols and typeface...........................................................4

2Safety.......................................................................................................................5

2.1 Intended use.................................................................................................5

2.2 Predictable incorrect application ..................................................................5

2.3 Safe handling................................................................................................5

2.4 Staff qualification ..........................................................................................6

2.5 Modifications to the product..........................................................................6

2.6 Usage of spare parts and accessories .........................................................6

2.7 Liability information.......................................................................................6

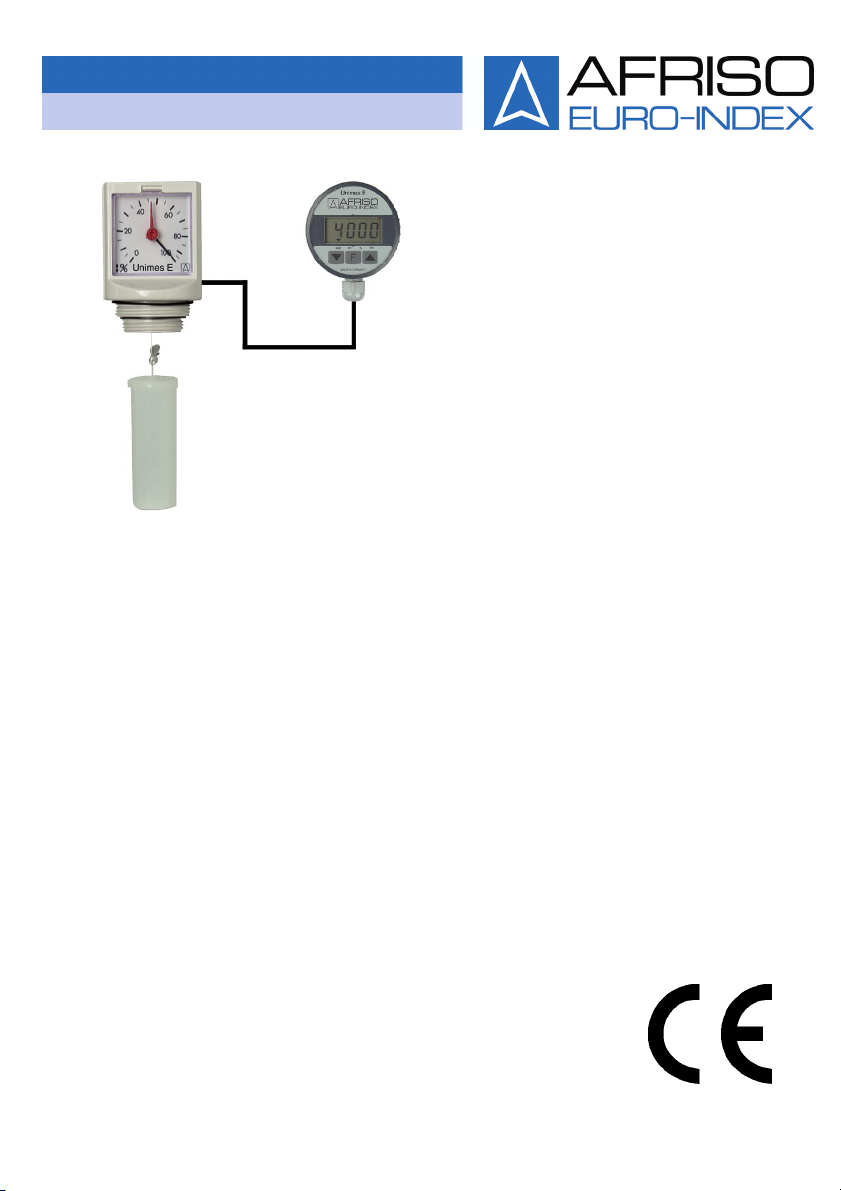

3Product description ..................................................................................................7

3.1 Scope of delivery ..........................................................................................7

3.2 Function........................................................................................................8

3.3 Application example .....................................................................................8

4Technical specifications...........................................................................................9

4.1 Approvals, tests, conformities.....................................................................10

5Transport and storage ...........................................................................................10

6Mounting and commissioning ................................................................................11

6.1 Determining the tank data ..........................................................................11

6.2 Mounting the wall bracket for the remote indicator ....................................12

6.3 Adjusting the float .......................................................................................12

6.4 Adjusting the tank height at the direct indication gauge.............................12

6.5 Connecting the direct indication gauge and the remote indicator ..............13

6.6 Connecting the battery of the remote indicator ..........................................13

6.7 Zero point adjustment at the remote indicator............................................14

6.8 Entering the tank data at the remote indicator ...........................................15

6.9 Mounting the direct indication gauge..........................................................16

7Operation ...............................................................................................................16

7.1 Switching Unimes E on and off ..................................................................16

7.2 Display formats of the remote indicator......................................................17

7.3 Correcting the tank data of the remote indicator ........................................17

7.4 Subsequent zero point adjustment at the remote indicator........................17

8Maintenance ..........................................................................................................18

8.1 Maintenance times .....................................................................................18

8.2 Replacing the battery of the remote indicator.............................................18

9Troubleshooting .....................................................................................................18

Unimes E 3

10 Shutting down, disposal ........................................................................................ 19

11 Spare parts and accessories ................................................................................ 19

12 Warranty................................................................................................................ 20

13 Copyright............................................................................................................... 20

14 Customer satisfaction ........................................................................................... 20

15 Addresses ............................................................................................................. 20

This instruction manual

4 Unimes E

1 This instruction manual

This instruction manual is part of the product.

Read this manual before using the instrument.

Keep this manual during the entire service life of the product

and always have it readily available for reference.

Always hand this manual over to future owners or users of the

product.

1.1 Precautions

WARNING TERM

Type and source of the danger are shown here.

Precautions to take in order to avoid the danger are shown

here.

There are three different levels of warnings:

Warning term Meaning

DANGER Immediately imminent danger!

Failure to observe the information will result in

death or severe injuries.

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or severe injuries.

CAUTION Dangerous situation!

Failure to observe the information may result in

minor or severe injuries as well as damage to

property.

1.2 Explanation of symbols and typeface

Symbol Meaning

Prerequisite for an activity

Activity consisting of a single step

1. Activity consisting of a several steps

Result of an activity

• Bulleted list

Text Indication on display

Highlighting Highlighting

Safety

Unimes E 5

2 Safety

2.1 Intended use

Unimes E is only suitable for continuous level measurement in tanks

containing fuel oil EL, diesel and other low-viscosity media which do

not attack the materials used (refer to chapter 4, page 9). For tank

heights from 900 to 2000 mm.

Any use other than the application explicitly permitted in this instruc-

tion manual is not permitted.

2.2 Predictable incorrect application

Unimes E must never be used in the following cases:

• Hazardous areas (ex)

• Applications involving persons and animals

2.3 Safe handling

Unimes E represents state-of-the-art technology and is made ac-

cording to the pertinent safety regulations. Each device is subjected

to a function and safety test prior to shipping.

Operate Unimes E only when it is in perfect condition. Always

observe the operating instructions, all pertinent local and na-

tional directives and guidelines as well as the applicable safety

regulations and directives concerning the prevention of acci-

dents.

Unimes E is not safety equipment. It does not replace the func-

tion of a level sensor at the fuel oil tank.

Unimes E may only be installed in unpressurised tanks. An ap-

proved tank vent and a fully functional level sensor must be in-

stalled.

The measured values displayed, in particular the values of the

litre indication, must not be used for billing purposes. The accu-

racy of the measured values displayed depends on the accu-

racy of the tank data determined and entered. Therefore, the

accuracy required for billing purposes cannot be guaranteed by

the manufacturer.

Extreme environmental conditions have negative effects on the func-

tion of the product.

Protect the product from shocks.

Only use the product in rooms.

Protect the product from humidity.

Safety

6 Unimes E

2.4 Staff qualification

The product may only be mounted, commissioned, operated, main-

tained, shut down and disposed of by qualified, specially trained

staff.

Electrical work may only be performed by trained electricians quali-

fied in accordance with the local and national directives such as

VDE.

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to malfunctions and are prohibited for safety reasons.

2.6 Usage of spare parts and accessories

Usage of unsuitable spare parts and accessories may cause dam-

age to the product.

Use only genuine AFRISO-EURO-INDEX GmbH spare parts

and accessories (refer to chapter 11, page 19).

2.7 Liability information

AFRISO-EURO-INDEX GmbH shall not be liable in any form

whatsoever for damages and consequential damages resulting from

failure to observe the technical instructions, guidelines and

recommendations.

The manufacturer or the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this device, in particular in case of improper use of the

device, misuse or malfunction of the connection, malfunction of the

device or of connected devices. The manufacturer or the sales

company shall not be liable for any damage whatsoever resulting

from any use other than the use explicitly permitted in this instruction

manual.

AFRISO-EURO-INDEX GmbH shall not be liable for misprints.

Product description

Unimes E 7

3 Product description

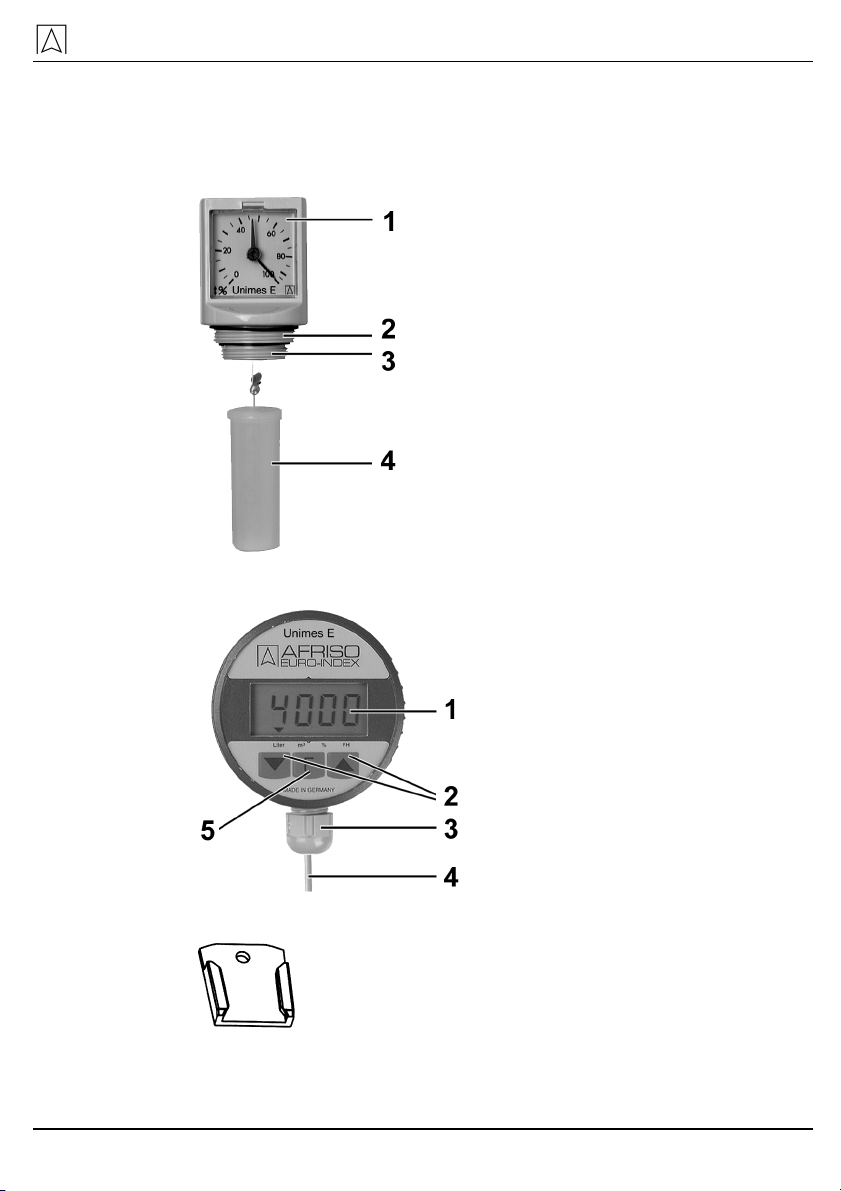

3.1 Scope of delivery

• Direct indication gauge with float

1 Direct indication gauge

2 G2 thread

3 G1½ thread

4 Float

• Remote indicator with battery and connection cable

1 Display

2 Programming keys

3 PG cable gland

4 Connection cable

5 Function key

• Wall bracket for remote indicator

Product description

8 Unimes E

3.2 Function

The direct indication gauge is a universal mechanical tank contents

gauge. It features a fully adjustable brass and nickel silver gear train

mechanism. The pointer movement is always 270° when the tank is

full. The level is indicated in percentage of height. An electronic sen-

sor is located at the movement. It supplies the remote indicator with

a signal that is proportional to the level.

The remote indicator is connected to the mechanical gauge by

means of a 3-core screened cable and plug. The remote indicator is

operated by means of a long-lasting battery. It is only switched on to

read the level (push-to-read function). Diverse tank shapes are

stored in a microprocessor so that the level is indicated either in liq-

uid level or volume, as desired.

This combination of devices allows you to check the supply directly

next to the tank and from an easily accessible, different location.

The measurement signal is transmitted to the remote indicator via

the cable. Using this signal, the electronic system of the remote indi-

cator calculates the tank contents which can be displayed in litres,

cubic metres, percentage or liquid level. The display mode is se-

lected by means of function key F. The two programming keys

and are used to enter the tank data.

3.3 Application example

Fig. 1: Application example

Technical specifications

Unimes E 9

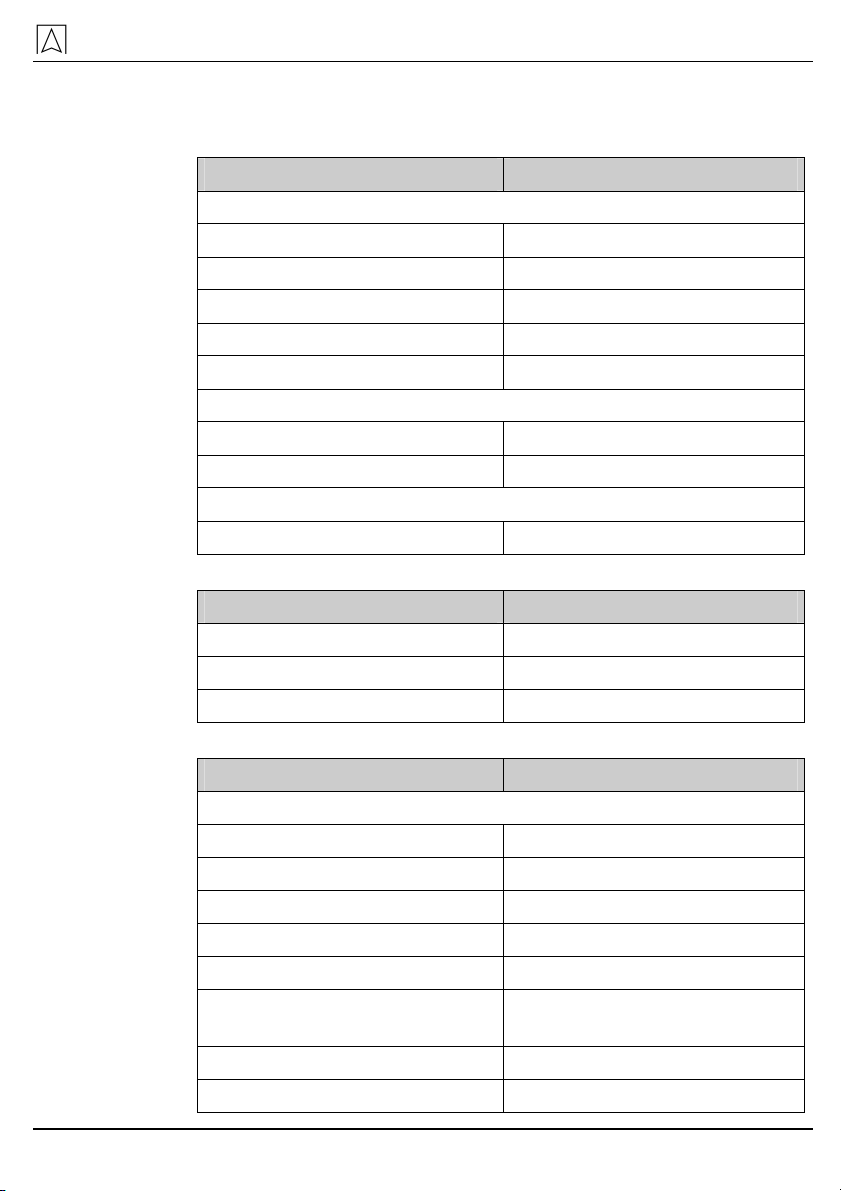

4 Technical specifications

Table 1: Direct indication gauge

Parameter Value

General specifications

Housing dimensions (ø x H) 80 x 100 mm

Weight 180 g

Housing material Impact-resistant ABS

Display Percentage (%)

Mounting Double thread G2-G1½

Operating temperature range

Medium 0 °C to +60 °C

Storage -5 °C to +80 °C

Electrical safety

Protection IP 30 EN 60529

Table 2: Float

Parameter Value

Housing dimensions (ø x H) 42 x 100 mm

Weight 95 g

Housing material PE-HD

Table 3: Remote indicator

Parameter Value

General specifications

Dimensions (ø x D) 75 x 50 mm

Weight 380 g

Cable length 10 m

Housing material PA6 15 % glass loaded

Supply 3.6 V lithium battery

Service life of battery Max. 8 years (if F key is

pressed once per month)

Display 4-digit LC display

Resolution 14 bits

Transport and storage

10 Unimes E

Parameter Value

Measurement input 0 to 3.6 V

Accuracy* < ± 1.0 % FSO, IEC 60770

Operating temperature range

Ambient 0 °C to +45 °C

Storage -5 °C to +80 °C

Electrical safety

Protection IP 51 EN 60529

Electromagnetic compatibility (EMC)

Interference According to EN 50081-1

Noise immunity According to EN 50082-1

Accuracy of the complete system*: < ± 5 % FSO, IEC 60770

* relating to indication of the liquid level in mm.

4.1 Approvals, tests, conformities

Unimes E complies with the EMC directive (89/336/EEC und

92/31/EEC).

5 Transport and storage

CAUTION

Damage to the device due to improper transport.

Do not throw or drop the device.

CAUTION

Damage to the device due to improper storage.

Protect the device from shock when storing it.

Store the device in a clean and dry environment.

Only store the device within the permissible temperature

range.

Mounting and commissioning

Unimes E 11

6 Mounting and commissioning

6.1 Determining the tank data

Before Unimes E can be installed, you must determine the tank data.

For safety reasons and to facilitate subsequent checks, you should

document the tank data on this page.

Tank shape

Determine the tank shape code using the table below.

Example for linear indication: tank shape code 1.

Tank shape

code

Tank shape Description

1 Linear tank Rectangular tanks, upright cylin-

ders, steel tanks welded in the

basement and all other linear

measuring applications

2 Cylindrical tank Vertically mounted cylinders

3 Ball-shaped tank Tanks with the shape of a ball

4 Plastic battery

type tank

Plastic battery type tanks with

straps or bulges

5 Oval tank Oval basement tanks, e.g. glass-

fibre re-enforced tanks or sheet

metal tanks

6 Plastic tank with

recess

Plastic tanks with larger recesses

in the tank centre (manufacturers:

e.g. Roth, Werit)

Determined tank shape code:

Tank volume

Determine the total volume of the tank facility.

Determined tank volume: litres

Tank height (max. liquid level)

Determine tank height.

Determined tank height: mm

Current liquid level

Determine the current liquid level as accurately as possible.

Determined liquid level: mm

Mounting and commissioning

12 Unimes E

6.2 Mounting the wall bracket for the remote indicator

Mount the wall bracket to the wall where you want to position

the remote indicator using the enclosed screw (4 x 30 mm) and

a dowel, if required (6 mm).

6.3 Adjusting the float

A free connection G1½ or G2 is available at the tank.

The float wire has three lead seals. Lead seal 1 is located at the end,

lead seal 2 is located 15 cm higher. The moving lead seal 3 is lo-

cated between these two lead seals.

1 Lead seal 1: fixated

2 Lead seal 2: fixated

3 Lead seal 3: moving

Fig. 2: Float wire

Tank without manhole or flange connection piece

Push the float up to lead seal 2 and press lead seal 3 together

to fixate the float.

Tank with manhole or flange connection piece

1. Deduct the excess length of the manhole or the flange connec-

tion piece with reference top the wire length from probe 2 to-

wards probe 1.

2. Mark the point, push the float up to the mark and press lead

seal 3 together to fixate the float

6.4 Adjusting the tank height at the direct indication gauge

The direct indication gauge is factory-adjusted to the maximum

height which corresponds to a tank height or diameter or 200 cm.

Mounting and commissioning

Unimes E 13

1. Adjust the length of the float wire to the tank height according to

the illustration below:

1 Height of flange

connection piece

2 Fixed lead seal

3 Ø or height

2. Hold the float wire in this position.

3. Turn the adjustment screw to set the pointer to zero.

The direct indication gauge is now adjusted to the tank.

6.5 Connecting the direct indication gauge and the remote indi-

cator

Plug the connector of the connection cable into the rear side of

the direct indication gauge.

6.6 Connecting the battery of the remote indicator

1. When the direct indication gauge and the remote indicator are

electrically connected, open the housing of the remote indicator

by turning the upper part all the way to the stop and pulling it

open.

Mounting and commissioning

14 Unimes E

2. Press mini button (1) and hold it down. Plug the two-pole battery

plug into the two-pole socket (2) on the PCB.

1 Mini button

2 Socket

Fig. 3: PCB

WARNING

Danger of explosion due to short circuit of lithium battery

Do not short-circuit the lithium battery.

3. Release the mini button.

6.7 Zero point adjustment at the remote indicator

The pointer of the direct indication gauge points to zero.

1. Close the housing of the remote indicator by pushing the hous-

ing parts together.

The remote indicator was switched on when the battery was con-

nected. The display toggles between "Zero" and the current offset of

the complete system. The upper left corner of the display shows the

two arrows to indicate that the instrument is in calibration mode.

2. Press the two keys and simultaneously in order to correct

the offset to the value 0.00.

In this state, zero calibration can be performed any number of

times.

3. Press the F key in order to terminate zero calibration.

An arrow pointing to the unit "Litres" is displayed at the bottom

of the display.

Mounting and commissioning

Unimes E 15

6.8 Entering the tank data at the remote indicator

Zero calibration has been performed.

The pointer of the direct indication gauge points to 100 %.

Tank shape

The arrow at the bottom of the display points to the unit "Litres".

The display shows the code of the selected tank shape. When

the unit is commissioned for the first time, the displayed code is

0. Code 0 means that no tank shape has yet been selected.

1. Use the keys and to set the code of the tank shape deter-

mined. Refer to chapter 6.1, page 11.

2. Press the F key to accept the setting and continue with the tank

volume.

Tank volume

The arrow at the bottom of the display points to the unit m³.

The display shows the currently selected tank volume. 0000

means that no tank volume has yet been entered.

1. Use the and keys to enter the total volume of the tank fa-

cility. By pressing the key, you can select the digit to be

changed. The key allows you to change the selected digit

within a range from 0 to 9.

2. Up to a volume of 9999 litres, the volume is entered in litres

without decimal places. In the case of volumes of > 9999 litres,

the value is entered in cubic metres with a decimal place (1000

litres = 1 cubic metre). The decimal place is moved with the

key.

3. Press the F key to accept the setting and continue with the tank

height.

Tank height

The arrow at the bottom of the display points to the unit "Per-

cent". The display shows the currently selected tank height.

0000 means that no tank height has yet been entered.

1. Set the tank height in mm with the keys: By pressing the

key, you can select the digit to be changed. The key allows

you to change the selected digit within a range from 0 to 9.

2. Press the F key to accept the setting and continue with the cur-

rent level.

Operation

16 Unimes E

Maximum liquid level

The pointer of the direct indication gauge points to 100 %.

The arrow at the bottom of the display points to the unit "Level"

(FH). The display shows the maximum liquid level in mm meas-

ured by the direct indication gauge.

1. Overwrite the displayed value to correct the displayed maximum

liquid level: Set the liquid level in mm with the and keys.

By pressing the key, you can select the digit to be changed.

The key allows you to change the selected digit within a

range from 0 to 9.

2. Press the F key to accept the setting.

You have now entered all the tank data and the remote indicator

switches to normal measurement mode.

The symbol in the upper left corner of the display is no

longer shown.

6.9 Mounting the direct indication gauge

1. Slowly lower the float into the tank.

2. Screw the direct indication gauge into the tank.

7 Operation

7.1 Switching Unimes E on and off

Direct indication gauge

The direct indication gauge is always on.

Remote indicator

Press the F key to switch on the display of the remote indicator.

The remote indicator automatically switches off approx. 2 ½

minutes after the last time a key was pressed.

The display shows OFF.

In this mode, the battery is not discharged. By pressing the F key,

you switch on the remote indicator for another 2 ½ minutes, i.e. the

level is indicated.

Operation

Unimes E 17

7.2 Display formats of the remote indicator

Direct indication gauge

The liquid level is displayed in %.

Remote indicator

Keep pressing the F key to select one of the four available units

for the level:

• Indication of volume in litres.

The arrow at the bottom of the display points to "Litres".

• Indication of volume in m³.

The arrow at the bottom of the display points to m³.

• Indication of volume in % of total contents.

The arrow at the bottom of the display points to %.

• Indication of liquid level in mm.

The arrow at the bottom of the display points to FH.

7.3 Correcting the tank data of the remote indicator

If the measured value exceeds the set tank data (e.g. due to incor-

rect tank data), the display starts to flash. The display toggles be-

tween the displayed value and "----". Only the current liquid level in

mm is displayed permanently.

1. Hold down the keys simultaneously for 3 seconds to acti-

vate the "Enter Tank Data" mode.

The upper left corner of the display shows the symbol .

2. The individual tank data can be checked and/or overwritten as

described in chapter 6.1, page 11.

If you do not want to change tank data, press the F key four

times to return to the normal measurement mode.

The upper left corner of the display no longer shows the symbol

.

7.4 Subsequent zero point adjustment at the remote indicator

The pointer of the direct indication gauge points to zero.

1. Unplug the battery connector from the PCB.

2. Proceed as described in chapter 6.6, page 13, to chapter 6.8,

page 15.

If you press the mini button when connecting the battery con-

nector, all tank data is cleared.

Maintenance

18 Unimes E

8 Maintenance

8.1 Maintenance times

When Activity

is shown on the display of

the remote indicator.

Replace the battery as de-

scribed in chapter 8.2, page

18.

8.2 Replacing the battery of the remote indicator

1. Remove the old battery and connect the new battery (refer to

chapter 6.6, page 13).

2. To protect the environment, used batteries must not be dis-

posed of together with the normal household waste. Return

empty batteries to the point of purchase or to special collecting

points.

Saved tank data is not lost when the battery is replaced.

9 Troubleshooting

Repairs may only be performed by specially trained, qualified staff.

Table 4: Troubleshooting

Problem Possible reason Repair

"OFF" is shown on

the display of the

remote indicator.

Automatic shut-

down after 2 ½

minutes.

Press F key to

read the liquid

level.

is shown on the

display of the re-

mote indicator.

Battery voltage

below critical

value.

Replace battery

(refer to chapter

8.2, page 18).

The battery is not

connected.

Connect the bat-

tery (refer to chap-

ter 6.6, page 13).

Display of the re-

mote indicator is

blank.

The battery con-

nector is not con-

nected to the

printed.

Check the battery

connector.

The display toggles

between the dis-

played value and "---

-".

Incorrect tank data

entered.

Correct the tank

data (refer to chap-

ter 7.3, page 17).

Shutting down, disposal

Unimes E 19

Problem Possible reason Repair

Incorrect indication

of level at remote

indicator.

Incorrect tank data

entered.

Correct the tank

data (refer to chap-

ter7.3, page 17).

The display toggles

between the "9999"

and "----".

Cable break or

remote indicator

not connected to

direct indication

gauge.

Check cable and

connection.

Display of the re-

mote indicator

shows "0" in spite of

contents > 0.

Short circuit in the

connection cable

between direct

indication gauge

and remote con-

nector.

Check cable.

Other malfunctions – Send the device to

AFRSIO.

10 Shutting down, disposal

1. Dismount the device (see chapter 6, page 11, reverse sequence

of steps).

2. To protect the environment, this device must not be disposed

of together with the normal household waste. Dispose of the de-

vice according to the local conditions and directives.

This device consists of materials that can be reused by recycling

firms. The electronic inserts can be easily separated and the device

consists of recyclable materials.

If you do not have the opportunity to dispose of the used device in

accordance with environmental regulations, please contact us for

possibilities to return it.

11 Spare parts and accessories

Part Part no.

Direct indication gauge with float 06 15 07

Remote indicator 06 15 000010

3.6 V lithium battery 68309

Bracket for wall mounting 00 24 000111

Warranty

20 Unimes E

12 Warranty

The warranty of AFRISO-EURO-INDEX GmbH for this product is 24

months after the date of purchase. This warranty shall be good in all

countries in which this device is sold by AFRISO-EURO-INDEX

GmbH or its authorised dealers.

13 Copyright

AFRISO-EURO-INDEX GmbH retains the copyright to this manual.

This manual may only be reprinted, translated, copied in part or in

whole with the prior written consent of AFRISO-EURO-INDEX

GmbH.

We reserve the right to technical modifications with reference to the

specifications and illustrations in this manual.

14 Customer satisfaction

Customer satisfaction is the prime objective of AFRISO-EURO-

INDEX GmbH.. Please get in touch with us if you have any ques-

tions, suggestions or problems concerning your AFRISO product.

15 Addresses

The addresses of our worldwide representations and offices can be

found on the Internet at www.afriso.de.

Table of contents

Other Afriso EURO-INDEX Measuring Instrument manuals