Afriso EURO-INDEX TankControl 01 User manual

Mess-, Regel- und

Überwachungsgeräte

für Haustechnik,

Industrie und Umweltschutz

Lindenstraße 20

DE-74363 Güglingen

Telefon: +49(0)7135-102-0

Service: +49(0)7135-102-211

Telefax: +49(0)7135-102-14

7

E-Mail: info@afriso.de

Internet: www.afriso.de

Read instructions before using device!

Observe all safety information!

Keep instructions for future use!

Version: 04.2008

ID no.: 854.001.0444

Operating Instructions

Hydrostatic Level Indicator

for Fuel Oil and Diesel

Type: TankControl

TankControl 01 Part no.: 52132

2 TankControl 01

Contents

1 This instruction manual ............................................................................................4

1.1 Precautions...................................................................................................4

1.2 Explanation of symbols and typeface...........................................................4

2 Safety.......................................................................................................................5

2.1 Intended use .................................................................................................5

2.2 Predictable incorrect application ..................................................................5

2.3 Safe handling................................................................................................5

2.4 Staff qualification ..........................................................................................5

2.5 Modifications to the product..........................................................................6

2.6 Usage of spare parts and accessories .........................................................6

2.7 Liability information.......................................................................................6

3 Product description ..................................................................................................6

3.1 Scope of delivery ..........................................................................................6

3.2 Properties .....................................................................................................7

3.3 Application example .....................................................................................7

3.4 Key functions ................................................................................................8

3.5 Overview of the signals ................................................................................8

3.6 Overview of the screen structure..................................................................9

3.7 Overview of the menu structure .................................................................10

4 Technical specifications.........................................................................................11

4.1 Approvals, tests, conformities.....................................................................12

5 Transport and storage ...........................................................................................13

6 Installation..............................................................................................................13

6.1 Electrical connection...................................................................................16

6.2 Zero calibration of the submersible probe ..................................................17

6.3 Installing the submersible probe.................................................................17

6.4 Mounting the submersible probe to the tank ..............................................18

7 Commissioning ......................................................................................................20

7.1 Password ....................................................................................................20

7.2 Setting the date and the time......................................................................21

7.3 Setting the tank data...................................................................................22

7.4 Setting the alarms.......................................................................................24

8 Operation ...............................................................................................................26

8.1 Changing the display language ..................................................................26

8.2 Alarm condition...........................................................................................27

8.3 Statistics function........................................................................................27

9 Troubleshooting .....................................................................................................29

TankControl 01 3

10 Shutting down, disposal ........................................................................................ 29

11 Spare parts and accessories ................................................................................ 30

12 Warranty................................................................................................................ 30

13 Copyright............................................................................................................... 30

14 Customer satisfaction ........................................................................................... 30

15 Addresses ............................................................................................................. 30

This instruction manual

4 TankControl 01

1 This instruction manual

This instruction manual is part of the product.

X Read this manual before using the product.

X Keep this manual during the entire service life of the product

and always have it readily available for reference.

X Always hand this manual over to future owners or users of the

product.

1.1 Precautions

WARNING TERM

Type and source of the danger is shown here.

X Precautions to take in order to avoid the danger are shown

here.

There are three different levels of warnings:

Warning term Meaning

DANGER Immediately imminent danger!

Failure to observe the information will result in

death or serious injuries.

WARNING Possibly imminent danger!

Failure to observe the information may result in

death or serious injuries.

CAUTION Dangerous situation!

Failure to observe the information may result in

minor or serious injuries as well as damage to

property.

1.2 Explanation of symbols and typeface

Symbol Meaning

; Prerequisite for an activity

Activity consisting of a single step

1. Activity consisting of several steps

ª Result of an activity

• Bulleted list

Text Indication on a display

Highlighting Highlighting

Safety

TankControl 01 5

2 Safety

2.1 Intended use

TankControl 01 may only be used for level measurement of the fol-

lowing liquids:

• Fuel oil EL according to DIN 51603-1

• Fuel oil L according DIN 51603-2

• Diesel according to EN 590

Any use other than the application explicitly permitted in this instruc-

tion manual is not permitted.

2.2 Predictable incorrect application

TankControl 01 must never be used in the following cases:

• Hazardous area (Ex)

If the device is operated in hazardous areas, sparks may cause

deflagrations, fires or explosions.

• Use as safety equipment

TankControl 01 does not replace the function of a level sensor

at the fuel oil tank.

• Use as an overfill alarm system

2.3 Safe handling

TankControl 01 represents state-of-the-art technology and is made

according to the pertinent safety regulations. Each device is sub-

jected to a function and safety test prior to shipping.

X Operate TankControl 01 only when it is in perfect condition. Al-

ways observe the operating instructions, all pertinent local and

national directives and guidelines as well as the applicable

safety regulations and directives concerning the prevention of

accidents.

Extreme environmental conditions have negative effects on the func-

tion of the product.

X Protect TankControl 01 from shocks.

X Only use the control unit indoors.

X Protect the control unit from humidity.

2.4 Staff qualification

The product may only be mounted, commissioned, operated, main-

tained, shut down and disposed of by qualified, specially trained

staff.

Product description

6 TankControl 01

Electrical work may only be performed by trained electricians quali-

fied in accordance with the local and national directives.

2.5 Modifications to the product

Changes or modifications made to the product by unauthorised per-

sons may lead to malfunctions and are prohibited for safety reasons.

2.6 Usage of spare parts and accessories

Usage of unsuitable spare parts and accessories may cause dam-

age to the product.

X Use only genuine spare parts and accessories of the manufac-

turer (refer to chapter 11, page 30).

2.7 Liability information

The manufacturer shall not be liable for direct or consequential dam-

age resulting from failure to observe the technical instructions, guide-

lines and recommendations.

The manufacturer and the sales company shall not be liable for costs

or damages incurred by the user or by third parties in the usage or

application of this device, in particular in case of improper use of the

device, misuse or malfunction of the connection, malfunction of the

device or of connected devices. The manufacturer or the sales com-

pany shall not be liable for damages resulting from any use other

than the use explicitly permitted in this instruction manual.

The manufacturer shall not be liable for misprints.

3 Product description

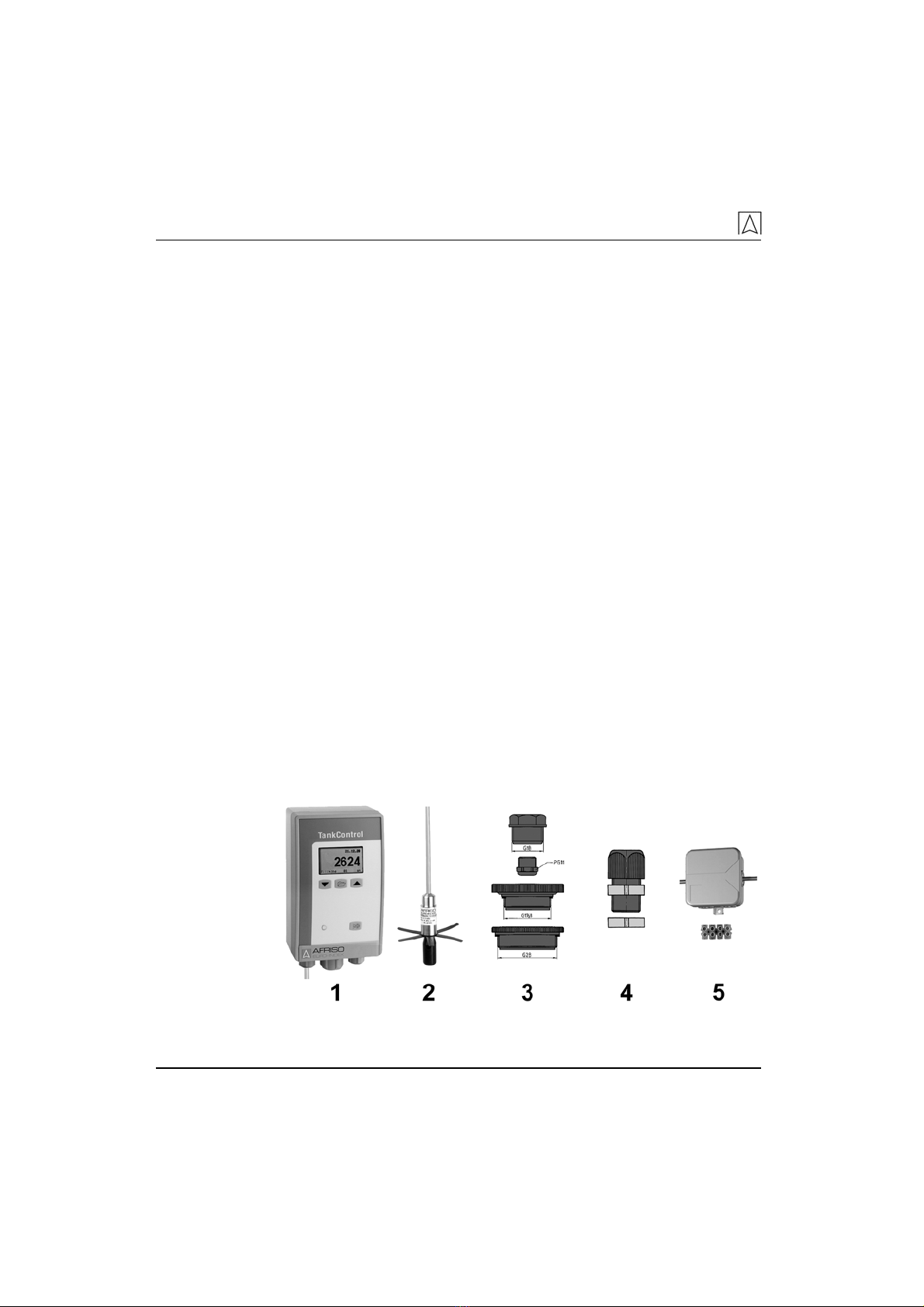

3.1 Scope of delivery

Fig. 1: Scope of delivery TankControl 01

Product description

TankControl 01 7

1Control unit with probe cable

2Submersible probe for fuel oil/diesel with probe cable

3Screw connector kit G1 x G1½ x G2

4Mounting kit for withdrawal flange at plastic battery tanks

5Moisture-proof junction box with terminal strips and fastening

material

Bag of accessories (not shown) with 2 screws and 2 dowels for

wall mounting

3.2 Properties

The hydrostatic level measurement system consists of a control unit

with digital display and a submersible probe with integrated pressure

measuring cell. The system displays the level in litres, cubic metres,

percent or liquid level in millimetres. When the level falls below or

exceeds an adjustable minimum or maximum value, the control unit

triggers visual and, if desired, audible (can be muted) alarms. Two

additional relay contacts are available for external alarm devices, for

level control or for connection to telecommunication or building con-

trol systems. An integrated microprocessor records, stores and dis-

plays important information such as fuel consumption or calculation

of reach (based on past consumption values).

3.3 Application example

Fig. 2: Application example TankControl

Product description

8 TankControl 01

3.4 Key functions

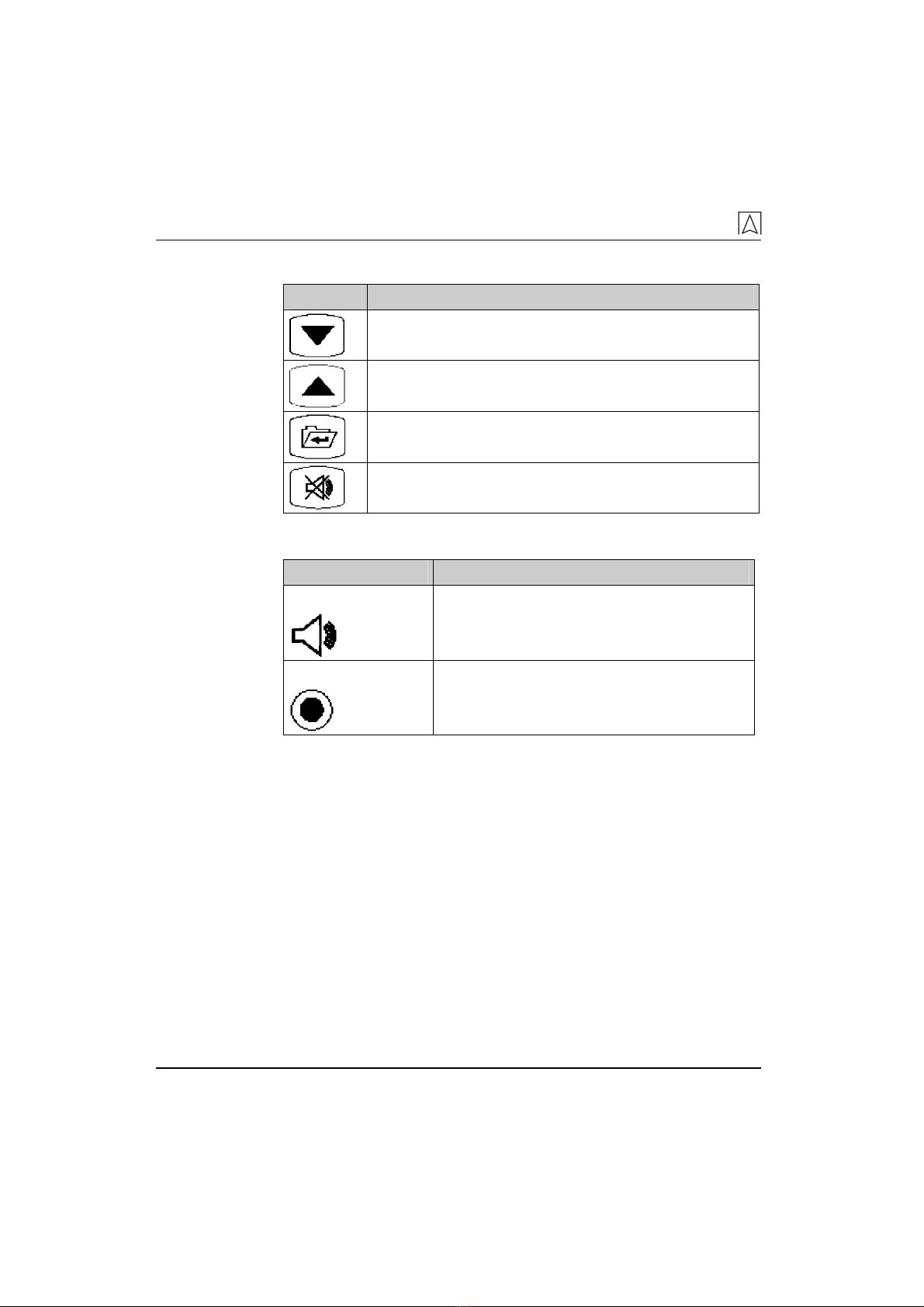

Keys Function

Scroll down/left.

Scroll up/right.

Display main menu.

Make selection and confirm, select.

Mute key: Switch off buzzer during an alarm condition

and display the alarm acknowledgement menu.

3.5 Overview of the signals

Alarm signal Setting

Audible alarm Buzzer sounds during an alarm condition,

depending on the settings.

Visual alarm Red LED always lights up during an alarm

condition.

Product description

TankControl 01 9

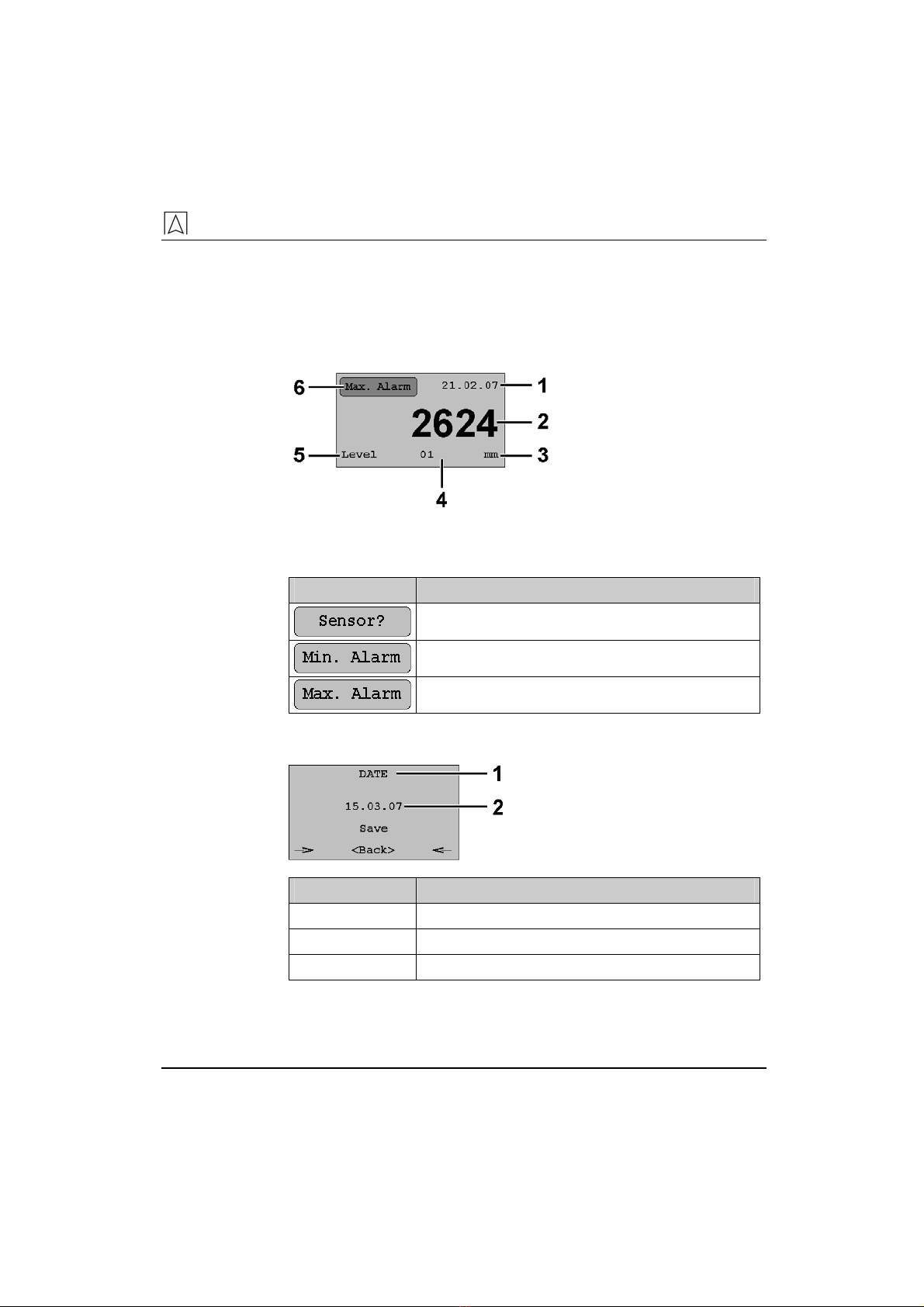

3.6 Overview of the screen structure

The screen backlighting is automatically switched off 5 minutes after

the last time a key was pressed. Pressing any key automatically

switches the screen backlighting on.

Display

1Date

2Current measured

value

3Unit of measurement

4Probe number

5Measured parameter

6Alarm message

Fig. 3: Display

Alarm message Meaning

Sensor failure

Minimum alarm

Maximum alarm

Menu

1Menu title

2Menu item

Display Meaning

Save Save the changed value

<Return> Back to previous menu without saving

ÆÅ

Highlights the currently selected menu item

Product description

10 TankControl 01

3.7 Overview of the menu structure

Technical specifications

TankControl 01 11

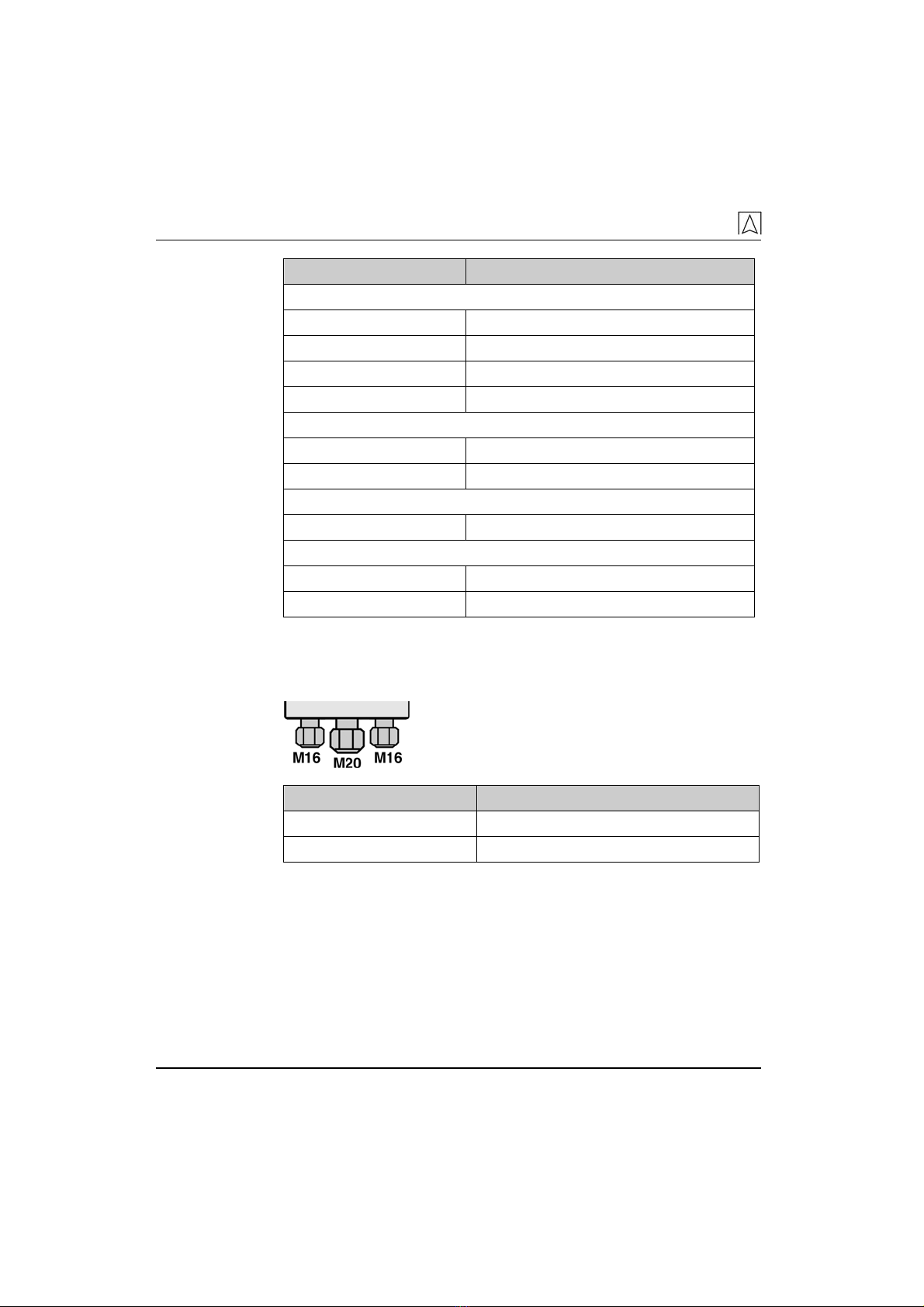

4 Technical specifications

Table 1: Technical specifications control unit

Parameter Value

General specifications

Dimensions housing

(W x H x D)

100 x 188 x 65 mm

Length of probe cables 15 m

Housing material Plastic ABS

Operating temperature range

Ambient 0 °C to +45 °C

Storage -5 °C to +80 °C

Voltage supply

Nominal voltage AC 230 V ± 10 %

Rated power 5 VA

Electrical safety

Protection class II EN 60730

Protection IP 54 EN 60529

Electromagnetic compatibility (EMC)

Interference According to EN 61000-6-4

Noise immunity According to EN 61000-6-2

Table 2: Technical Specifications submersible probe for fuel

oil/diesel

Parameter Value

General specifications

Dimensions (Ø x L) 24 x 53 mm

Weight 360 g

Length of probe cable 5 m

Pressure range 0-300 mbar

Accuracy* ≤± 1.0 % FSO, IEC 60770

Temperature error ≤± 1.5 % FSO, 0 to +40 °C

Technical specifications

12 TankControl 01

Parameter Value

Material

Housing Stainless steel 1.4305

Cable PVC fuel oil-resistant

Spacer POM, PE

Other wetted parts Ceramics, silicon, silicon glue, Viton

Operating temperature range

Medium -25 °C to +70 °C

Storage -25 °C to +70 °C

Electrical safety

Protection IP 68 EN 60529

Electromagnetic compatibility (EMC)

Interference According to EN 61000-6-4

Noise immunity According to EN 61000-6-2

* Accuracy of the complete system relating to indication of the liquid

level in mm: < ±1.5 % FSO, IEC 60770

Screw connections at the control unit

Cable gland Cable diameter

M16 4.0-8.8 mm

M20 8.0-12.5 mm

4.1 Approvals, tests, conformities

TankControl complies with the EMC Directive (89/336/EEU and

92/31/EEU) and the Low Voltage Directive (73/23/EEU and

93/68/EEU).

Transport and storage

TankControl 01 13

5 Transport and storage

CAUTION Damage to the device due to improper transport.

X Do not throw or drop the device.

CAUTION Damage to the device due to improper storage.

X Protect the device from shock when storing it.

X Store the device in a clean and dry environment.

X Only store the device within the permissible temperature

range.

6 Installation

;

The installation site of the control unit is accessible and visible

at all times.

;

The installation site of the control unit is at eye level on a plane,

rigid and dry wall.

The provided moisture-proof junction box is not suitable for exterior

application.

X For exterior application use the exterior junction box, refer to

chapter 11, page 30.

Installation

14 TankControl 01

1. Open the control unit.

2. Mount the control unit to the wall.

B 1 Mount the screw to the wall.

2Hang the bottom part to the screw.

ADrill the fastening holes in the bot-

tom part with a Ø 5 mm drill.

Mount the bottom part to the wall

with the screws shipped with the

unit.

3Fixate the bottom part by screwing the

lug to the wall.

3. Mount the junction box at the required location to connect the

cable of the submersible probe and the control unit.

4. Route the cable of the control unit into the junction box.

5. Push the screw connector (screw connector kit or mounting kit,

refer to chapter 6.4, page 18) onto the cable of the submersible

probe; ensure proper orientation.

Installation

TankControl 01 15

6. Route the cable of the submersible probe to the junction box

and connect the two cables using the enclosed terminal strip.

Only connect identical wire colours.

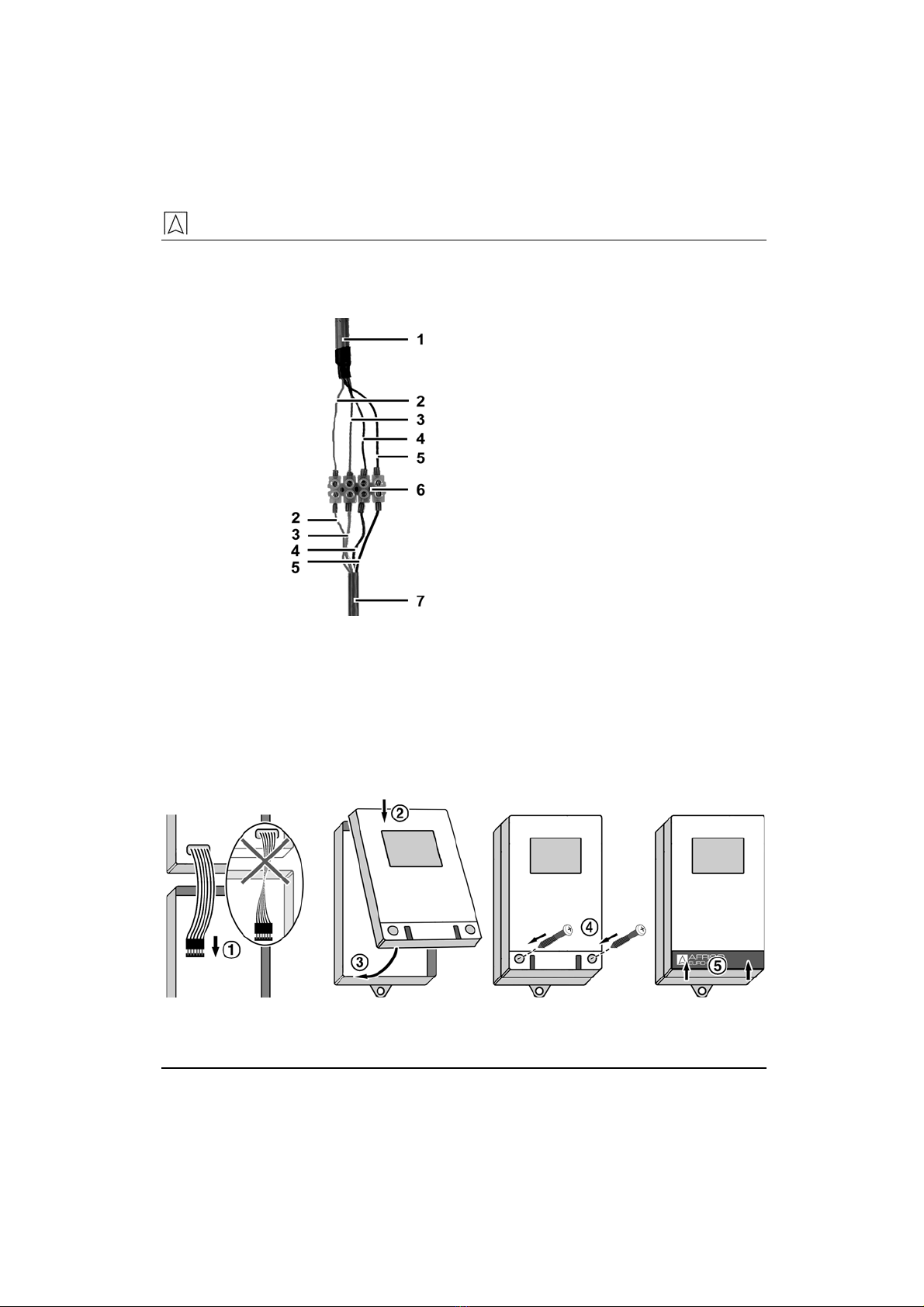

1Control unit

2White (U+)

3Green (signal)

4Brown (U-)

5Yellow-black/yellow-green (shield)

6Terminal strip

7Submersible probe

Fig. 4: Cable connection control unit and submersible probe

7. A transparent hose sticks out from the cable end of the sub-

mersible probe. This hose supplies the pressure sensor with

atmospheric pressure; it must not be closed or bent.

Do not completely close the junction box in order to prevent in-

correct measurements.

8. Connect the unit electrically as described in chapter 6.1 on

page 16.

9. Connect the control unit.

Installation

16 TankControl 01

6.1 Electrical connection

The probe cable for the submersible probe is factory-connected.

;

Mains voltage is interrupted and cannot be switched on by acci-

dent.

Fig. 5: Wiring diagram

Connecting a relay

1. Route the relay cable through the centre screw connection.

2. Connect the relay cable to "Relay A" or "Relay B":

If no error condition is present, the relay is de-energised. In the

case of an alarm, the relay is energised.

NO Relay – Normally Open Not connected to connection A or B

NC Relay – Normally Closed Connected to connection A or B

Connecting the unit to mains

1. Route the mains cable trough the right screw connection.

2. The phase must be connected to terminal L1, the neutral con-

ductor to terminal N and the protective conductor to terminal .

Installation

TankControl 01 17

6.2 Zero calibration of the submersible probe

;

The submersible probe is in air.

;

Submersible probe and control unit are connected.

;

Mains voltage is connected and on.

X Set the current level to „000000 mm“, refer to fig. 11, page 23.

ª

The zero point of the submersible probe was set.

6.3 Installing the submersible probe

1Spacer

2Star

3Pressure sensor

1. Plug the star onto the pressure sensor. Watch out for the posi-

tion of the fins on the star.

2. Use the spacer to screw the star to the pressure sensor.

3. Suspend the submersible probe into the tank from the top.

4. Adjust the cable seat in the screw connection in such a way that

the probe tip just reaches the tank bottom. The measurement

hole in the submersible probe must not be in the oil sludge.

The amount of oil below the measurement hole of the sub-

mersible probe is not detected.

Installation

18 TankControl 01

6.4 Mounting the submersible probe to the tank

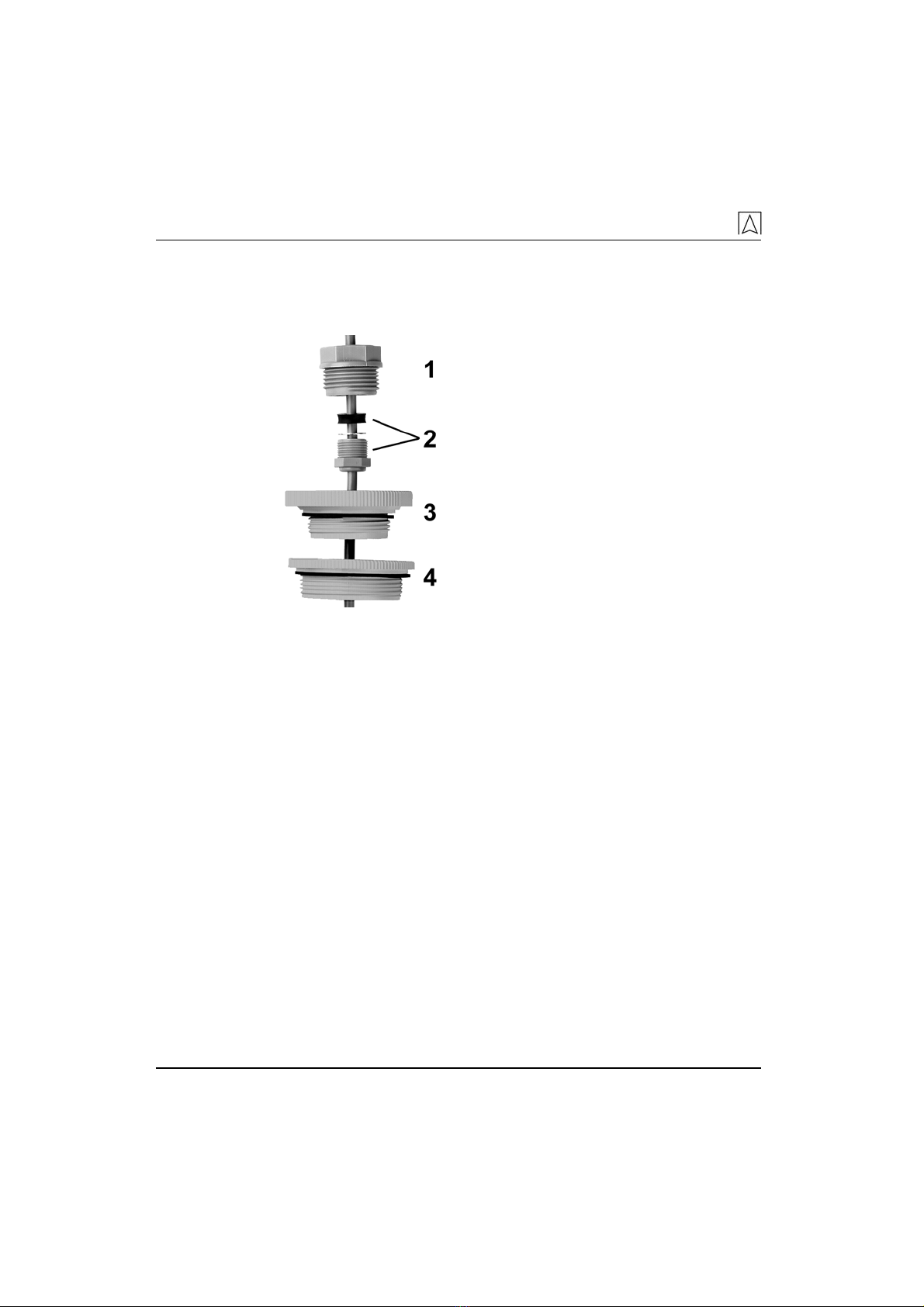

Screw connector kit

1. Free 1", 1½" or 2" connection in the tank: Mount and seal.

11" screw connector

2Used to fixate the cable

31½" screw connection

42" screw connector

Fig. 6: Mounting to tank with screw connector kit

2. Tighten the connector so that the cable can no longer move and

that the connection is smell-tight.

Installation

TankControl 01 19

Mounting kit

1PG 9 cable gland

2Mounting flange

Fig. 7: Mounting to tank with mounting kit

1. In a mounting flange with union nut, in a screwable cap or in a

free blind connection: Remove the mounting flange, the cap or

the blind connection from the tank and drill a 15 mm hole.

Never drill holes into the tank.

Make sure no chips can get into the tank when drilling.

2. Insert the enclosed PG 9 gland and fasten it with the enclosed

nut.

3. Fixate the cable of the submersible probe at the correct length;

make sure the connection is smell-tight.

Commissioning

20 TankControl 01

7 Commissioning

The accuracy of the measured values displayed depends on the ac-

curacy of the tank data determined and entered.

7.1 Password

In order to avoid inadvertent changes, a password must be entered

before changes can be made. After the entry, the password is active

for 15 minutes. For any later changes, the password must be entered

again.

The password is 186900. The password was deduced from the year

1869 when the company AFRISO was founded.

Fig. 8: Entering the password

Table of contents

Other Afriso EURO-INDEX Measuring Instrument manuals