AG Cubicle Duo User manual

2

OPERATION MANUAL

CONTENTS

Section 1 INTRODUCTION

1.1 Foreword

1.2 Improvements and changes

1.3 Service parts

1.4 Machine identification

1.5 Standard warranty policy

1.6 Quality of translations

Section 2 SAFETY PROCEDURES

2.1 Accident prevention

2.2 Safety signs

2.3 Before starting machine

2.4 When operating machine

2.5 Maintenance and servicing

2.6 Transportation

2.7 Cleaning and storing

2.8 Proper use (intended products)

2.9 No liability for consequential damage

Section 3 SPECIFICATIONS AND DESCRIPTION

3.1 Description

3.2 Technical specification

3

Section 4 PUTTING THE MACHINE TO WORK

4.1 Charging the machine

4.2 Isolating the machine electrics

4.3 Circuit breaker

4.4 Machine familiarization

4.5 Setting the metering plate to suit your product needs

4.6 Setting the conveyor speed to suit your product needs

4.7 Setting the auger speed to suit your product needs

4.8 Lowering and starting the brush

4.9 Loading the machine

4.10 Dispensing the product

4.11 Driving the machine

4.12 Blockage removal

Section 5 MAINTENANCE

5.1 Greasing points

5.2 Conveyor belt tension / alignment

5.3 Auger drive chain tension adjustment

5.4 Agitator drive chain tension adjustment

5.5 Sweeping brush replacement

5.6 Storing the machine

5.7 Service schedule

5.8 Trouble shooting

4

SECTION 1 INTRODUCTION

1.1 FOREWORD

This manual will assist the operator to set, operate and maintain the AG Duo dispenser to

produce a safe and efficient operation of the machine. This manual should be read carefully

before putting the machine to work.

1.2 IMPROVEMENTS AND CHANGES

Garnett Farms Engineering Ltd are continually improving their products to meet and exceed

the customer’s needs and therefore reserve the right to make improvements and changes

when practical to do so, without incurring any obligation to make changes and additions to

equipment which has been sold previously.

1.3 SERVICE PARTS

Use genuine and guaranteed Garnett Farms Engineering Ltd products on AG Products

machinery to ensure maximum life and guaranteed performance. These are available direct

from AG Products or through your local AG Products dealer.

When ordering service parts always quote the model of machine and serial number.

1.4 MACHINE IDENTIFICATION

The model and serial number of the dispenser are stamped on a plate located behind the

black cover on the rear of the machine.

5

1.5 STANDARD WARRANTY POLICY

NEW MACHINE WARRANTY

All new machines supplied by Garnett Farms Engineering Ltd are warranted to the original

purchaser, under normal use and service, to be free from defects in material and

workmanship for a period of 12 months from the date of delivery to the original purchaser.

To qualify for the full benefit of this warranty, the dealer must ensure that the warranty

registration details have been returned to Garnett Farms Engineering Ltd within 30 days

from the date of delivery. Using the machine implies the knowledge and acceptance of

these instructions and the limitations contained here in this manual. Garnett Farms

Engineering Ltd reserves the right to suspend the operation of these warranty conditions

unless and until the purchaser has paid in full for the goods or parts in question.

LIMITATION AND EXCLUSIONS

Garnett Farms Engineering Ltd and the authorised AG Products dealer shall not be liable to

the original purchaser under any circumstance for injuries, death, property damage or

damages of any kind whatsoever directly, consequential or contingent to any person or

property. This warranty shall not extend or apply to temporary repairs or in respect of loss

or any expense incurred for labour, additional machinery, rental or of any other reason or

purpose.

Garnett Farms Engineering Ltd will not be liable under this warranty for any repairs carried

out without its prior consent to the work being done. Any fault should be reported to your

local AG Products dealer or direct to Garnett Farms Engineering Ltd as soon as the fault is

discovered. Continued use of the machine could cause further failures for which Garnett

Farms Engineering Ltd cannot be held liable and may also have safety implications.

Authorisation must be given by Garnett Farms Engineering Ltd Warranty Manager –no

other employee, dealer or other person is authorised to give any warranties on behalf of AG

Products. Subject to the conditions and exclusions noted in this limited warranty, Garnett

Farms Engineering Ltd shall repair or replace free of charge any warranted parts which in

the manufactures opinion show evidence of such defect provided that any such part is

returned to AG Products if requested within 30 days of the repair being carried out.

Any parts on which warranty is given become the property of Garnett Farms Engineering Ltd

and as previously stated must be returned to AG Products if requested. All warranty claims

must be submitted to AG Products by an authorised AG Products dealer within 20 days of

the repair being carried out. The submission of a claim form is not a guarantee of payment.

And any decision reached by Garnett Farms Engineering Ltd is final.

6

This limited warranty by Garnett Farms Engineering Ltd does not cover:-

1) Damage or depreciation caused by normal wear and tear. Any parts which have been

subject to alteration, modification or fitment of non-genuine AG Products parts,

wilful or accidental damage, damage caused by foreign objects (e.g., stones, metals

and any other materials other than those suitable for the machines intended use).

2) Damage or depreciation caused by neglect or failure to carry out proper

maintenance as recommended in the operators manual.

3) Damage or depreciation caused by abnormal or improper use in accordance with AG

Products recommendations and/or as per the operating instructions.

4) Environmental damage

TRANSFER OF WARRANTY

Garnett Farms Engineering Ltd may at its sole discretion allow this warranty to be

transferred to a new owner for the balance of the warranty period, subject to all of the

warranty conditions being met at the original point of sale and up to the date of resale. AG

Products will give prior written consent and the new owner must complete an AG Products

warranty registration form and return it to Garnett Farms Engineering Ltd within 30 days of

purchase date for the remainder of the warranty to be valid.

WARRANTY ON PARTS

Garnett Farm Engineering Ltd warrants that any part or components supplied by AG

Products in accordance with this limited warranty are free from defects in material or

workmanship from the date of sale to the original purchaser for 6 months. Garnett Farm

Engineering Ltd will at its option, either repair or replace the defective part free of charge.

Parts replaced or repaired by Garnett Farm Engineering Ltd under warranty conditions will

have the remainder of the machine warranty period applied.

Garnett Farms Engineering Ltd. Cannot be held responsible for any failures or safety

implications arising from the use of non-genuine parts. Use of non-genuine parts may

seriously affect the machines performance and safety.

7

1.6 QUALITY OF TRANSLATIONS

Where instructions for use are translated from the original language into others, expert

translators or specialists shall be responsible for the translation including checking and

proofreading, and:

• Have basic competences in communication, particularly technical communication.

• Are familiar with the subject area.

• Are fluent in the original and target languages, preferably native speakers in the target

language.

Colloquial expressions and untypical regional variations of names and product features

should be avoided.

The translated instructions for use should be edited by qualified persons specializing in

writing and translating for the target groups.

8

SECTION 2 SAFETY PROCEDURES

2.1 ACCIDENT PREVENTION

The following safety instructions are applicable for all chapters of this manual.

Accident prevention programs can only prevent accidents with the co-operation of the

persons responsible for the operation of the equipment.

For safety of yourself and others, operate equipment with care and do not take unnecessary

risks, which could cause an accident.

Please read all safety instructions contained in this operators manual with the utmost care

and also observe all safety signs attached to the AG Dispenser. Please ensure these

instructions are made available and are understood by all other uses of the AG Dispenser.

You are advised to refrain from any working methods which may be hazardous.

All relevant accident prevention regulations governing the operation of agricultural

machinery, as well as other generally acknowledged health and safety regulations must be

strictly observed.

CAUTION

This symbol will appear throughout this manual whenever your safety, the

safety of others or the machinery is involved.

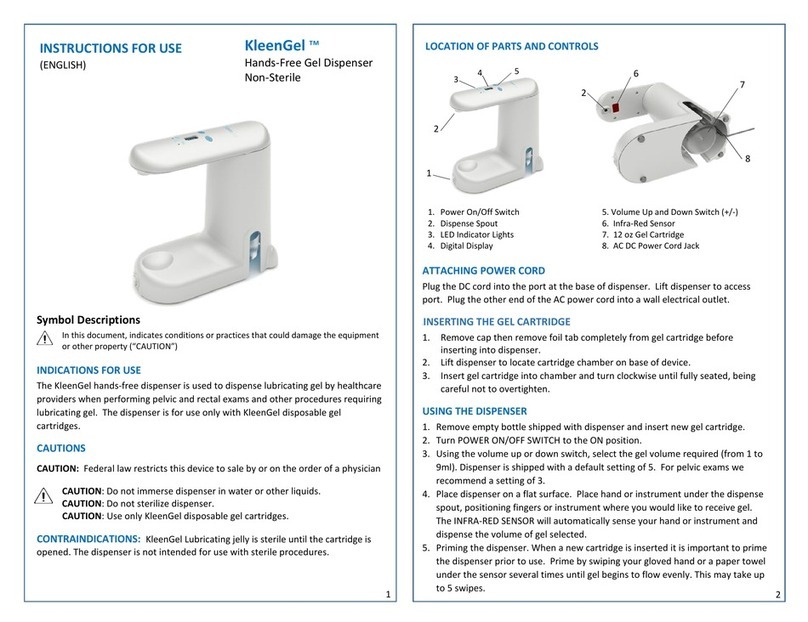

2.2 SAFETY SIGNS

The following signs appear on the machine and are for your safety and the safety of other

people. Ensure that you identify each symbol and understand its warning.

These safety signs must be kept in a legible condition and must be replaced if

damaged or missing.

9

Standard safety signs used

Switch off electrics and remove isolator switch

Keep a safe distance from the machine to avoid injury to body and eyes

Don't reach into the hopper / gain access into the hopper due to the risk

of rotating parts

Risk of electric shock

Read operators manual before operating the machine

Use of a dust mask is advised in dusty conditions

10

2.3 ACCIDENT PREVENTION BEFORE STARTING THE MACHINE

If moving the AG dispenser by overhead lifting use the designated lifting points, see section

4 (transportation). Ensure that the slings / chains are rated accordingly, and that the angles

of the slings / chains are set in accordance to lifting regulations. Ensure the lifting device has

enough capacity to lift the AG dispenser.

Ensure bystanders are at a safe distance when moving the AG dispenser by overhead

slinging.

The AG dispenser should only be used if all safety devices, e.g. detachable guards, are fitted

securely and in proper working order.

Check there are no foreign objects interfering with the AG dispenser.

Ensure that no person is working on, inside or in the local area of the AG dispenser, at any

time during all stages of use.

Always perform a walk round inspection before starting the machine.

2.4 ACCIDENT PREVENTION WHEN OPERATING THE AG DISPENSER

The AG dispenser must not be put into operation until the end user has read and

understood the operators manual. If in any doubt contact your dealer or Garnett Farms

Engineering Ltd employees.

One person should use the AG dispenser only. When the operator identifies someone

approaching or is to close for their safety, the operator should stop operating until the

person is clear before starting again.

Bystanders need to keep a safe distance from the AG dispenser while it is being operated.

Warn bystanders and give them time to move before starting.

In the event of a malfunction, immediately stop the AG dispenser and secure in a stationary

position. All malfunctions must be rectified immediately.

Do not work around the AG dispenser in loose clothing that might get caught up in moving

parts. Do not go under the AG dispenser unless it is securely blocked and secure.

Always replace all guards after making any adjustments to the AG dispenser, replace any

missing or damaged guards immediately.

Never approach the AG dispenser whilst the machine is being operated.

Keep hands and feet away from moving parts i.e. conveyor belt / auger / top agitator/

brush. Do not reach into the bin due to entanglement of the auger and agitator.

Inspect bedding material before loading to ensure it does not contain any foreign objects.

11

If manually loading the bin, follow manual handling recommendations.

Certain types of bedding product could demand the use of PPE due to its fine particles or

the material is a skin irritant. In this case wear gloves, goggles, face mask and overalls.

Ensure your driving line is free from obstruction and bystanders.

2.5 ACCIDENT PREVENTION WHEN SERVICING AND ADJUSTING THE MACHINE

The AG dispenser must only be serviced / maintained by a competent person who

understands the workings of the machine and the risks involved in carrying out this type of

work.

Ensure the AG dispenser is on the ground or if in an elevated position, that it is securely

supported.

Isolate the machine and remove the switch knob before performing any maintenance or

service work.

All defects which might affect the safe operation of the AG dispenser must be immediately

rectified.

OEM replacement parts and accessories from AG Products have been specially designed and

tested for use with the AG dispenser. The use of none genuine OEM parts which have not

been tested by AG products may under certain circumstances have a negative influence on

the machine and may therefore adversely affect its safe and reliable operation and the

safety of the operator or bystanders.

AG Products cannot therefore be held liable for damage or injury caused by the use of none

genuine OEM replacement parts or accessories.

If running the machine during maintenance or adjustment, keep a safe distance away from

moving parts. Always stop the machine before making any further adjustments and replace

all guards once your work is complete.

2.6 TRANSPORTATION

NEVER TOW THE AG DUO DISPENSER

To prevent damage to the AG dispenser the machine should only be moved by one of the

following methods:

1. using a trailer with appropriate ramps to allow the machine to be driven onto it. Once on

the trailer the machine should be secured by using the securing points on the four corners

of the machine chassis.

2. using overhead lifting by slinging the AG dispenser with the four dedicated lifting points.

12

4 X M12 lifting eyes with the correct SWL will be required for overhead lifting. These are to

be screwed into the top of the hopper once the blanking bolts have been removed (blanking

bolts illustrated on the picture above). Please ensure any lifting slings or chains have

adequate lifting capacity and have been tested before lifting.

13

2.7 ACCIDENT PREVENTION WHEN CLEANING AND STORING MACHINE

Do not run the machine while cleaning

If cleaning the machine with a steam cleaner or pressure washer, follow recommended

precautions given by the washing equipment manufacturer.

Wear appropriate PPE (Personal Protective Equipment).

When storing the machine ensure the bin and conveyor are empty of product.

2.8 PROPER USE

Always make sure the AG dispenser is in good working condition and that it is used properly

for its intended purpose and entirely in accordance with the instructions given in this

manual. Any defects which might affect the safe operation of the AG dispenser must be

rectified immediately.

The AG dispenser is intended for use for transporting and distributing bedding material into

cattle cubicles. Any uses other than that intended such as transportation of none bedding

products, will automatically exempt Garnett Farms Engineering Ltd or the supplier from its

liability in respect of ensuing damage. Such cases of improper use will therefore be entirely

at the users own risk.

The AG dispenser is manufactured in accordance with recognised safety requirements.

Nevertheless the use of the AG dispenser does not preclude the risk of injury to the user or

third parties and or the risk of damage to the AG dispenser itself or to other materials or

items of equipment.

Improper use also comprises failure to observe the instructions as given in this operators

manual and the recommended maintenance and service requirements.

14

2.9 NO LIABILITY FOR CONSEQUENTIAL DAMAGE

It is the responsibility of the owner / operators to ensure that foreign objects, e.g. stones,

metal objects etc. are not allowed to enter the AG dispenser. Failure to observe this may

result in damage to the machine and / or injury to the operator or others.

Any claims for damages not directly incurred by the AG dispenser cannot be accepted. By

the same token, Garnett Farms Engineering Ltd cannot be held liable for any consequential

damage resulting from incorrect use of the AG dispenser.

SECTION 3 SPECIFICATIONS AND DESCRIPTION

3.1 DESCRIPTION

The AG Duo is a fully electric machine consisting of a driven axle for ease movement, a bin

which holds the bedding product, a brush for sweeping cubicles, an auger and agitator

which move the product in the bin and a conveyor to dispense the product.

3.2 TECHNICAL SPECIFICATION

Size of basic machine is as follows (all dimensions are approximate).

15

SECTION 4 PUTTING THE MACHINE TO WORK

4.1 CHARGING THE MACHINE PRIOR TO USE.

Please read the charger operators manual.

It is important that the machine is only charged with the charger supplied with the machine,

please read the enclosed operating instructions included in the charger box before use.

When the machine is fully charged the screen on the Duo dash will read 100%, the machine

is now ready to use.

16

4.2 ISOLATING THE MACHINE ELECTRICS

The isolator switch is located on the right-hand side to the rear of the machine. Once turned

off the red switch knob can be removed.

4.3 CIRCUIT BREAKER

The circuit breaker is located behind the rear black cover and is housed inside the speed

changing box. Access to this box is gained by removing the four corner screws in the box lid.

17

If you find that the circuit breaker has tripped the breaker can be set by pushing the brown

lever back into position as shown in the following pictures. If for any reason the breaker

trips out straight after resetting, please isolate the machine and contact your local dealer or

AG Products.

Circuit breaker in the closed ON position.

Circuit breaker in the open OFF position.

18

4.4 Machine Familiarization

Once the machine is fully charged and ready for use it is advised that all operations are

checked and found to be in full working condition.

1.Ensure there are no bystanders around the AG Duo.

2. Check there are no foreign objects in the hopper.

3. Check all operations and familiarize yourself with the switch position, actions and

forward and reverse drive speeds.

4. It is advisable to complete several dry runs to get used to the switches and speed of

the machine.

19

4.5 SETTING THE METERING PLATE TO SUIT YOUR BEDDING PRODUCT AND NEEDS

Before using the machine with bedding products the metering plate must be adjusted to

provide a suitable gap in order to obtain the desired bedding flow rate.

The size of the gap will determine the rate of flow at which the bedding product flows onto

the conveyor belt and will vary in size between all bedding products and your needs. The

ideal gap will be found through fine tuning.

Follow the procedure below,

Only adjust the metering plate by means of moving the adjusting handle from left

to right.

Moving the adjusting lever to the right will reduce the hole size reducing product flow.

Moving the lever to the left will increase the hole size increasing product flow.

20

4.6 SETTING THE CONVEYOR SPEED

The speed control box is located behind the rear moulded black cover, it is recommended

that this cover is left off until after you are happy with the speed and quantity of bedding

being dispensed.

The potentiometer for changing the conveyor speed has buttons to press which will alter

the speed of the conveyor belt which in turn will increase or decrease the distance of the

product being dispensed (max speed 9.9, min speed 0.1).

4.7 SETTING THE AUGER SPEED

The potentiometer for changing the conveyor speed has buttons to press which will alter

the speed of the auger which in turn will increase or decrease the amount of product being

dispensed (max speed 9.9, min speed 0.1).

Table of contents

Popular Dispenser manuals by other brands

Whirlpool

Whirlpool Vessi Use and care guide

Grundfos

Grundfos Vaccuperm VGS-141 Installation and operating instructions

PGP

PGP Neptune Cleaning and maintenance

KWC

KWC Rodan RODX627H Installation and operating instructions

Bras

Bras TURIA 12 Operator's manual

Ratiomed

Ratiomed MEG 289.1060 Original operating instructions

Georgia Pacific

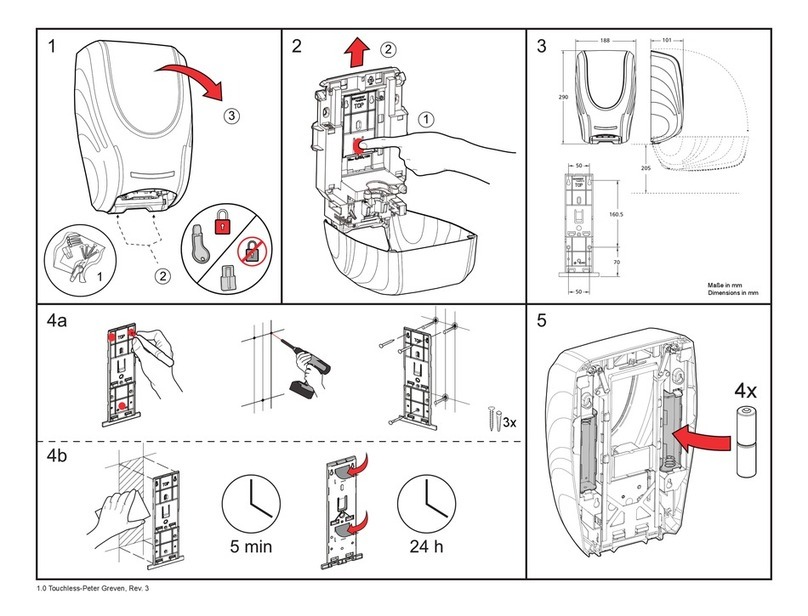

Georgia Pacific enMotion installation instructions

KS

KS RONDA ESPUMA Installation and maintenance guide

Georgia Pacific

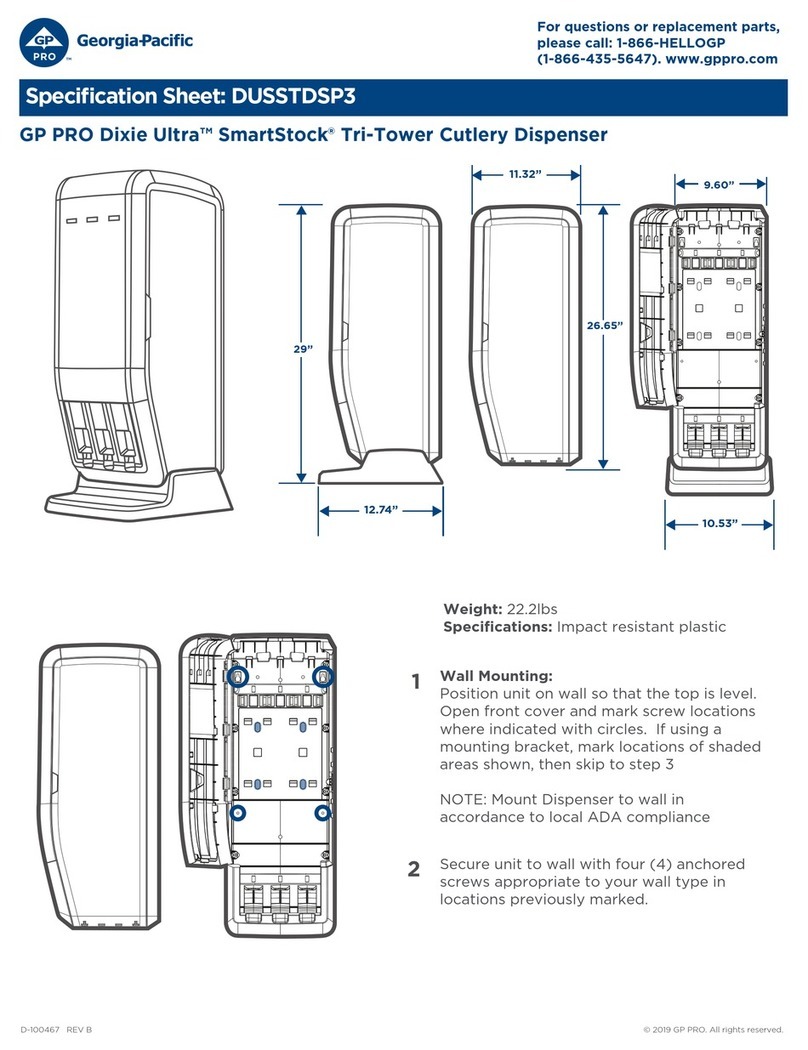

Georgia Pacific GP PRO Dixie Ultra SmartStock Tri-Tower Mounting instructions

Graco

Graco PR70 Series operation & maintenance

Boekel

Boekel 1456XL operating instructions

Start

Start ZCM 1000 Instruction