3

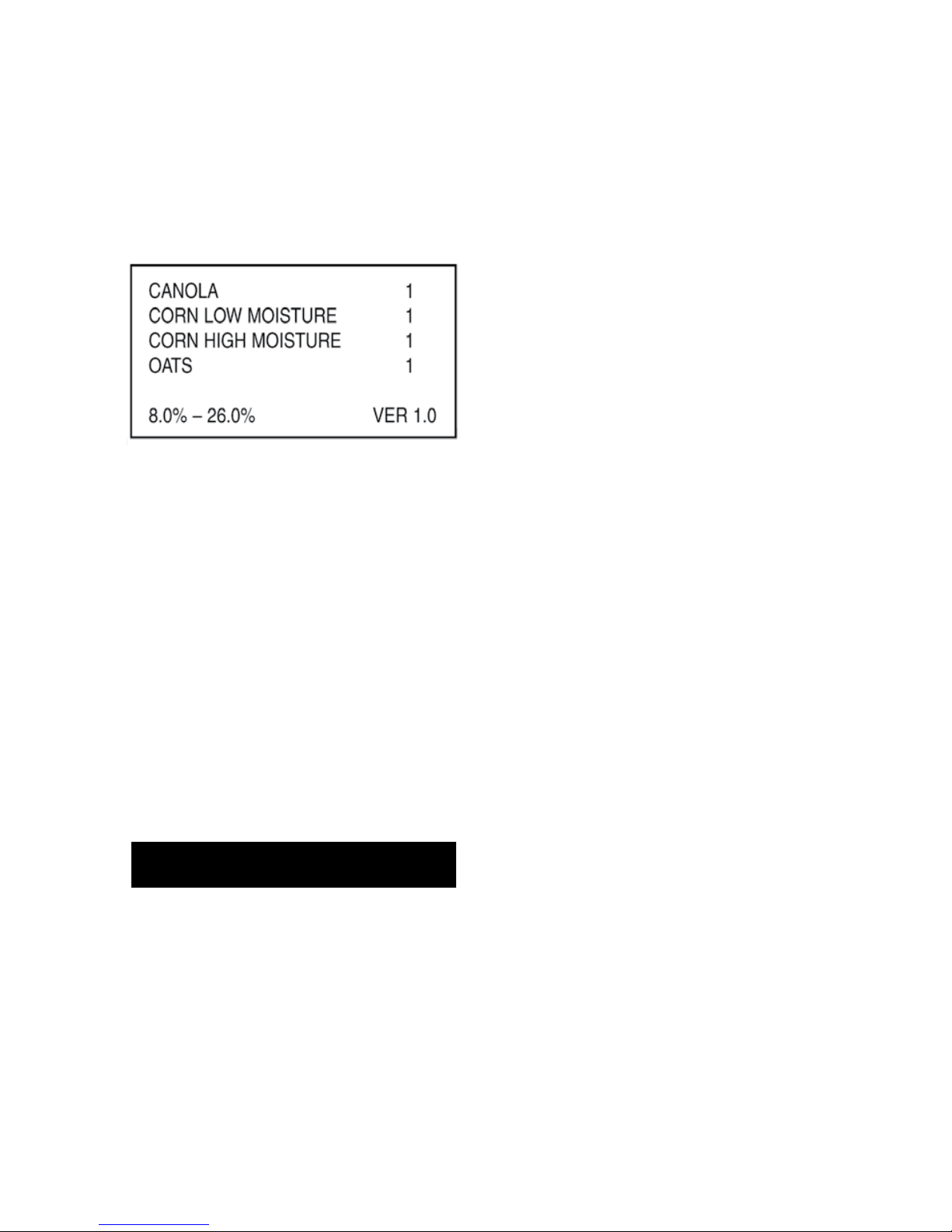

SELECTING THE GRAIN OPTION

Selecting the GRAIN option will display a

list of up to four (4) grains at a time. Use

the UP/DOWN arrows to scroll through

the list. When the cursor points to a grain

to be selected, it will indicate it is enabled:

1, or disabled: 0, status. Press the ENTER

button to enable or disable that grain.

All enabled grains will be displayed on the

initial display when the tester is turned

on. Those grains that are enabled can be

selected by using the UP/DOWN arrows.

Disabled grains can be enabled at any

time by following the previous steps. After

selecting grains, press the ENTER button

to return to GRAIN screen.

Press the MENU button to return to the

previous screen.

NOTE: There must be at least one grain

enabled,soiftheuserdisablesallthegrains,

a message will be displayed prompting the

user to enable at least one grain.

GENERAL INFORMATION

Matching Elevator Moisture

All other electronic grain moisture testers,

portable or commercial, are calibrated to

an industry standard like the ASAE Stan-

dard. Oven Drying, Microwave Drying or

another standard is used for determining

absolute moisture.

This tester takes a different approach. Cal-

ibration data was developed with respect

to the most widely used commercial grain

elevator testers in the North American

market. The user can select a calibration

curve that is based on the moisture read-

ings of a commercial grain elevator mois-

ture tester. The accepted industry practice

is for farmers to sell their grain according

to the readings given by their local grain

elevator. So the test equipment that the

grain elevator operator uses becomes the

standard, not absolute moisture.

Unfortunately, the elevator tester measure-

ments and absolute moisture may not be

the same. Therefore, it is more important

for the user to know what the elevator

tester reads, rather than to know the

absolute moisture. However, the Moisture-

Match tester does have an absolute scale

(Industry Standard) for reference.

Not only is it possible for different brands

of commercial testers to give different

results, it is also possible for the same

brand and model commercial testers

to produce different readings. The next

feature described below allows the user to

make fine tuning adjustments to track with

the specific commercial tester that his

local grain elevator uses.

Calibration to a Specific Commercial

Tester (MoistureMATCH Technology)

Calibration adjustments are usually made

by adding an offset to the entire calibration

curve. This can cause problems because

when a tester is adjusted at low moisture,

it can throw off the calibration at high

moisture and vice versa.

With the MoistureMATCH™ tester, when

a calibration adjustment is entered, it

impacts the moisture curve immediately

surrounding the specific moisture that is

being adjusted; the rest of the curve is not

affected.

OPERATION