Version April 2008 EN 3

agru SP 315-S User’s Manual

Contents

1 Introduction........................................................................................................... 5

2 Safety Messages.................................................................................................. 5

2.1 The User's Manual ............................................................................................... 5

2.2 Explaining Icons ................................................................................................... 5

2.3 Safety Messages.................................................................................................. 5

2.4 Welder and Operator Obligations......................................................................... 7

2.5 Warranty............................................................................................................... 7

2.6 Transport and Storage.......................................................................................... 7

2.7 Identifying the Machine ........................................................................................ 7

3 Product Description and Principles of Operation ................................................. 7

3.1 Intended Use........................................................................................................ 7

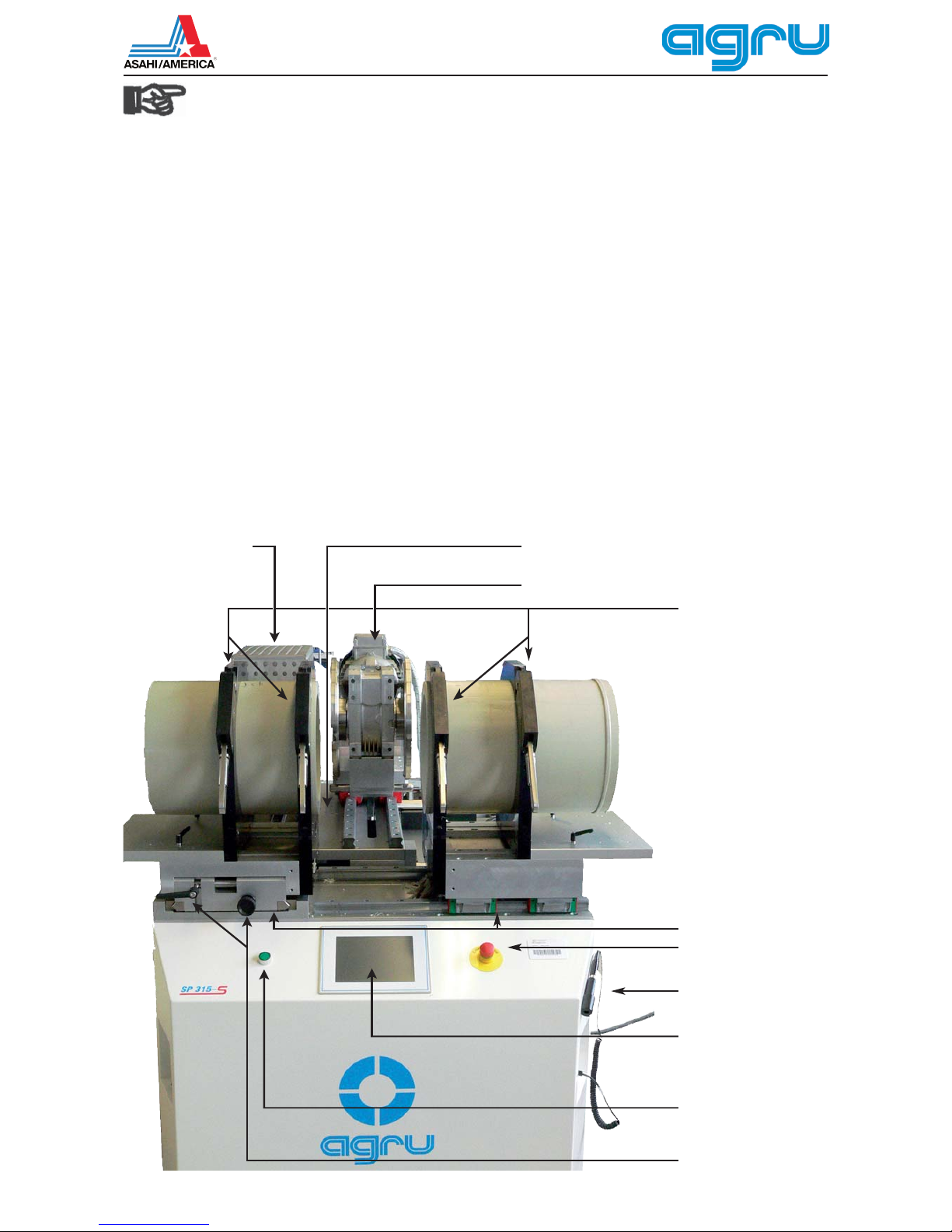

3.2 Machine Description............................................................................................. 8

3.2.1 Component Overview........................................................................................... 8

3.2.2 Touchscreen / Control Panel ................................................................................ 9

3.2.3 Ports and Switches............................................................................................. 10

3.2.4 Specifications ..................................................................................................... 10

3.3 Welding Process Overview ................................................................................ 11

4 Operation............................................................................................................ 12

4.1 Check-out, Turning on, Selecting the Display Language.................................... 12

4.2 Entering Traceability Data for the Joint............................................................... 13

4.3 Configuring the Machine .................................................................................... 14

4.4 Changing Key Data of the Welding..................................................................... 15

4.5 Definition of Key Welding Data for Additional Materials ..................................... 16

4.6 Welding Process ................................................................................................ 17

4.6.1 Facing the Pipe Butts ......................................................................................... 17

4.6.2 Checking Pipe Alignment ................................................................................... 19

4.6.3 Pre-heating the Pipe Butts and Inserting the Heating Element.......................... 19

4.6.4 Heat-Soaking Phase .......................................................................................... 20

4.6.5 Change-over Phase ........................................................................................... 20

4.6.6 Joining Phase..................................................................................................... 20

4.6.7 Cooling Phase.................................................................................................... 20

4.6.8 End of Welding ................................................................................................... 20

4.7 Aborted Welding Process................................................................................... 21

5 Printing and Transferring Welding Reports......................................................... 22

5.1 The Print Menu and Printing/Transferring Reports............................................. 22

5.2 Showing Reports in Memory, Reprinting Tags ................................................... 23

5.3 Deleting Reports from Memory .......................................................................... 23

6 System Data....................................................................................................... 23

6.1 Setting the Date and the Time of Day ................................................................ 23

6.2 Enabling Automatic Heating ............................................................................... 23

7 Service and Repair............................................................................................. 24

8 Service and Repair Contact ............................................................................... 25

P.O. Box 653 • 35 Green Street, Malden, MA 02148 • Tel: (800) 343-3618, (781) 321-5409