12 13

Control Unit Operation

Unlocking the system

After start up, or after 5 minutes without user input, the system will

automatically lock to prevent tampering. The Unlock LED will light up

to indicate this. To change any settings, simply press AND HOLD the

Unlock Button for 2 seconds then release to activate controls.

Positioning or transferring patient on bed

To position the patient on the mattress or to generally

manoeuvre or transfer the patient, press the transfer button.

This will inflate the mattress to maximum pressure and

provide a stable surface. The system will automatically revert to the

previous mode after 20 minutes.

Auto Patient Profiling

The system is programmed to automatically sense the profile

of the patient - when the sensor in the head end of the

mattress detects more than 20 degrees incline then it will

switch to incline mode and automatically add more pressure into the mattress.

Note: only provide the minimum incline necessary for intubation or feeding

- excessive inclines can limit the effectiveness of the mattress.

Auto Sensor Adjustment

After initial inflation, the system will automatically enter a

weight detect mode. During this 7 minute period, all

comfort lights will flash on and off. If a patient is on the

mattress at this time, then the system will auto calculate the correct pressure

setting. This auto detect mode can be used at any time by pressing the comfort

button once only. It is best if the system is in static mode and the patient is

totally reclined for more accuracy. The auto setting can be overridden at any

time by pressing and holding the comfort button and then manually selecting.

Control Unit Operation

Static Mode

Static mode can be selected to cease any alternation

whilst remaining at the programmed or selected comfort

setting. This can be beneficial for meal breaks when the

bed is inclined for back support. It gives a stable surface

and a break from therapy. Static Mode will automatically

revert back to Active Mode after 1 hour.

Alarms and Diagnostics:

The control unit features an audio visual alarm

diagnostic which will activate if there is a malfunction.

If the left button flashes and alarms, it indicates that

there is a problem with the mattress or an air leak inside the control unit. If

the right button flashes and alarms, it indicates that there is an electrical or

mechanical malfunction within the control unit itself.

Both these audio alarms can be silenced by pressing the mute button.

This will mute the alarm for 20 minutes. If the malfunction has not been

resolved however, the alarm will re-activate.

For more information on alarms and faults with the system, please see the

Troubleshooting section of this manual.

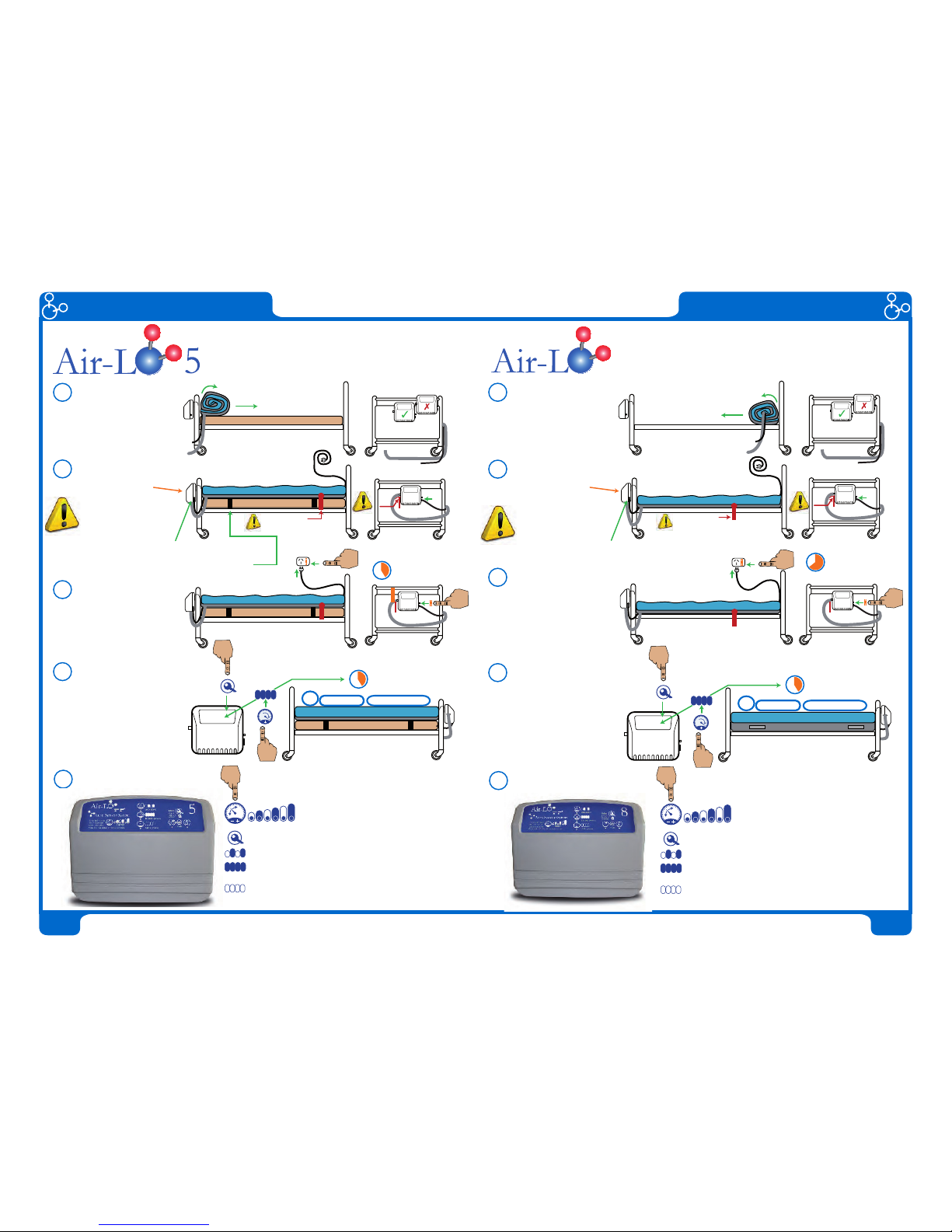

CPR Operation - AirLo3 CPR Operation - AirLo5/AirLo8

1

1

2

The CPR operation of this system

is located at the Control Unit. It

is designed to be easy to find and

activate quickly in the event of a CPR

emergency.

Step 1: Squeeze side levers.

Step 2: Whilst both side levers are

still squeezed, pull out to detach.

The CPR operation for these systems

is located along the right hand side

of the mattress near the head end. A

red location tag indicates its position.

Step 1: Locate the tag and lift the

flap to expose the CPR twist valve.

Step 2: Twist right to “CPR” position