6

within the device. The sphere is then pushed down

inside the barrel using the ramrod until the de-

sired spring tension has been reached. The ram-

rod should not be removed too quickly, otherwise

the suction its removal produces may pull the

sphere out with it. The position of the sphere may

only be checked using the observation holes. Never

look into the barrel!

•Before launching, ensure that no one is in the way

of the trajectory. To launch, the cord of the launch-

ing lever is briefly pulled perpendicularly to the

lever.

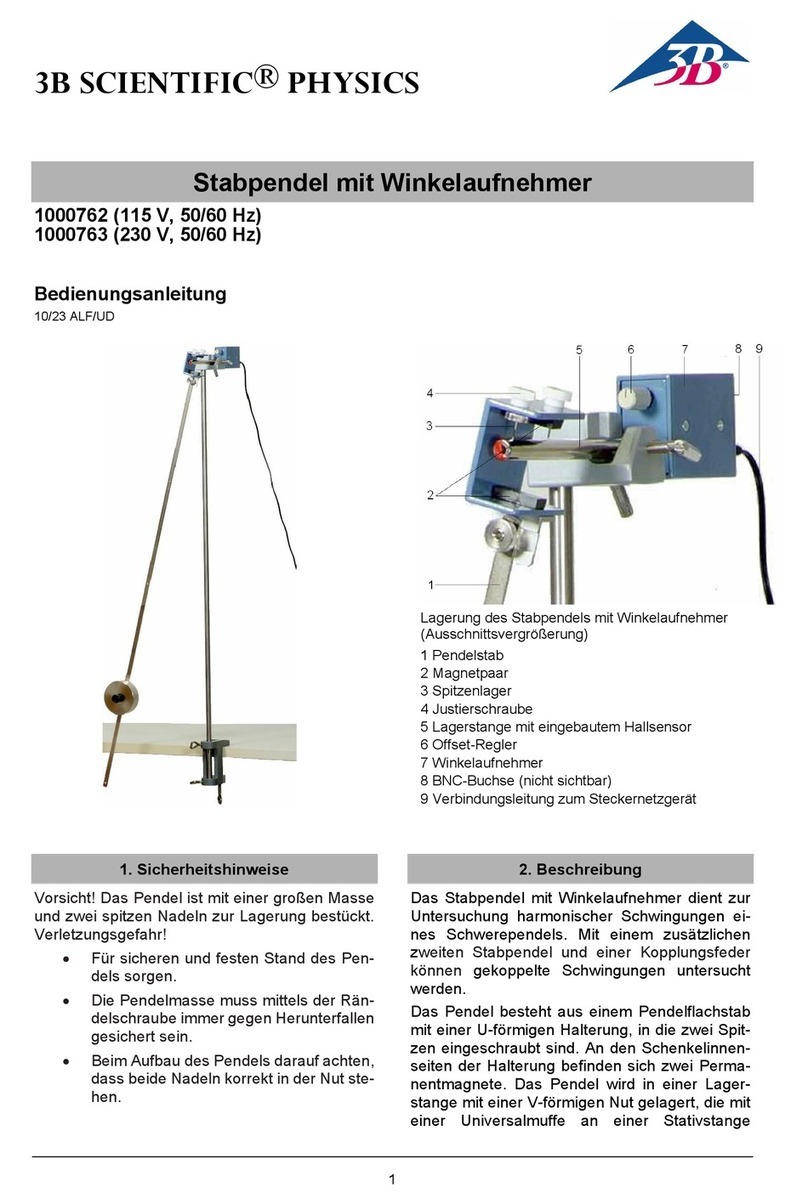

•The pendulum 8can be removed by undoing the

bearing screw 4and turned by 180° so that it is

installed with the rear of the projectile catcher

9pointing towards the launcher (experiments on

elastic collision). The counter bearing 5is designed

so that the pendulum hangs at a slight angle if the

bearing screw is only light tightened. This means

that the projectile catcher is not precisely in front

of the launch aperture of the launcher. For this rea-

son, the bearing screw should be tightened until

the catcher and the launch aperture are in line.

•After turning the pendulum round, or if necessary,

the guide 3for the swing pointer 6should be

adjusted so that the pointer just touches it when

the pendulum is suspended at rest. The screw on

the guide should only be finger-tightened to avoid

the appearance of pressure on the pendulum rod.

•Maintenance: the ballistic pendulum principally

requires no maintenance. If necessary some non-

acidic grease (Vaseline) can be applied to the bear-

ing screw 4and the knurled screw bn. Other than

in the vicinity of the scale, the apparatus may be

cleaned using acetone, ethanol (white spirit) or

petroleum ether as required. Avoid submerging the

equipment in water.

4. Experiment procedure and evaluation

4.1 Ballistic pendulum

4.1.1 Experiment setup

•The experiment setup corresponds to Fig. 1 for

experiments on inelastic collision. For experi-

ments on elastic collisions, the pendulum should

be turned round by 180° (cf. Section 3 “Opera-

tion”).

4.1.2 Experiment procedure

•It is practical for these experiments to enter the

experiment number, the spring tension (1, 2 or

3), the type of collision (inelastic “i” or elastic “e”),

the number of extra weights used and the mea-

sured angle ϕ. In order to obtain the most accu-

rate experiment results, after one shot, a second

should be performed with the swing pointer not

having been reset to 0° in between. This mini-

mizes the unavoidable frictional losses of the

swing pointer.

•Example experiment sequence:

No Spring Type of Extra Angle ϕ

tension collision weights

11 i0 17.5

22 i0 25.0

33 i0 36.0

41 i2 9.5

52 i2 13.5

63 i2 19.0

71 e0 29.5

82 e0 42.0

93 e0 60.0

4.1.3 Experiment evaluation

4.1.3.1 Inelastic collision

•The following equation is valid for the swinging

pendulum due to conservation of energy

Epot = Ekin (1)

where the potential energy is

Epot = mtot g∆h(2)

Here is mtot the total mass of the pendulum in-

cluding the projectile and any extra weights, gis

the acceleration due to gravity and ∆his the dif-

ference in height of the center of gravity of the

pendulum at rest and at the maximum extent of

its swing.

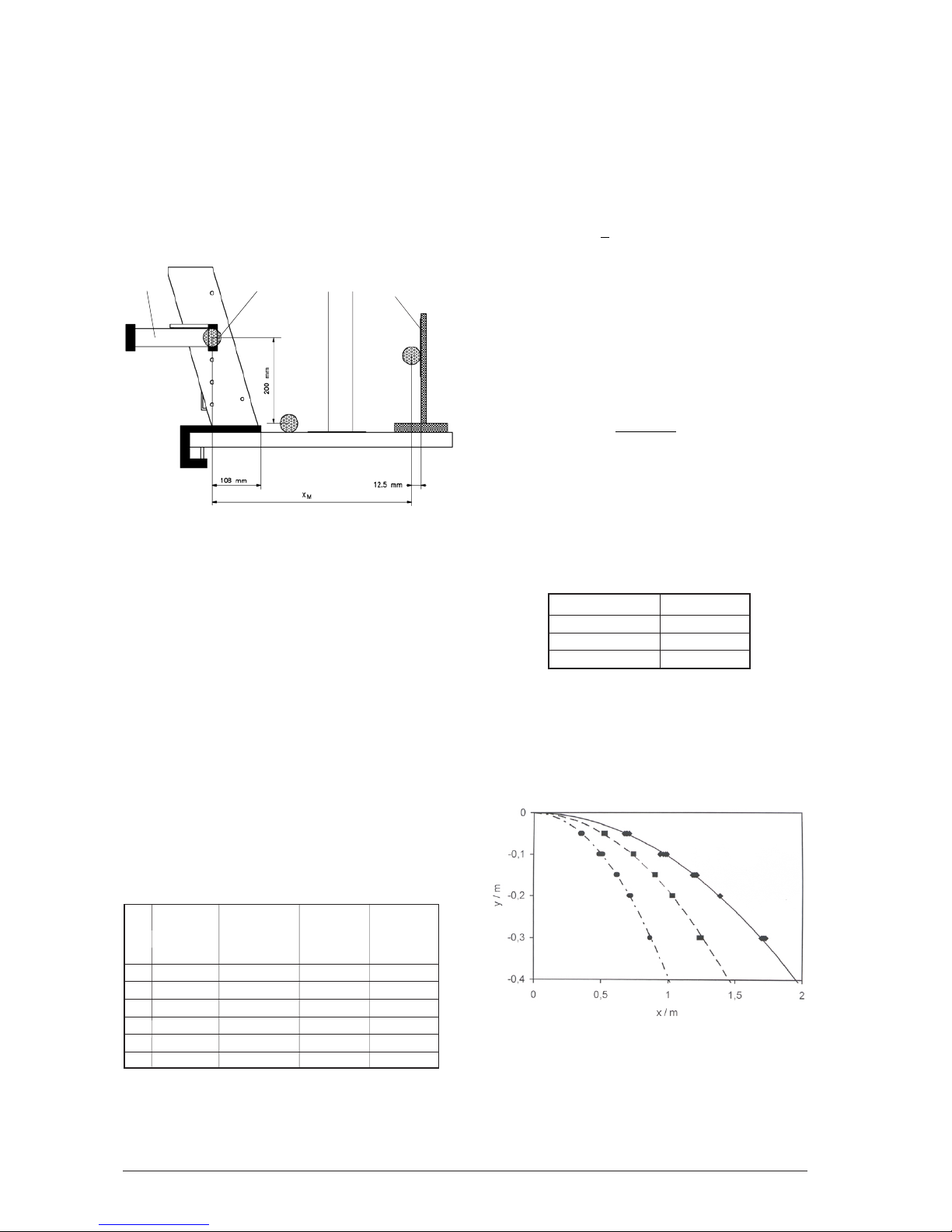

•From the measured angle ϕ and the measured

length Is to the center of gravity according to Fig.2

the following is derived:

∆h= Is(1 – cos ϕ) (3)

Fig. 2: Determining the required lengths. Distance between center of gravity

and axis of rotation (Is) should be measured including the projectile and any

additional weights when the collision is inelastic. To perform the measure-

ment, the pendulum may, for example, be balanced on a ruler mounted on

its side. The distance between the center of the projectile and the axis of

rotation is IK= 280 mm.

•The kinetic energy can be calculated from the

moment of inertia Itot relative to the axis of rota-

tion and the maximum angular speed ωaccord-

ing to the equation

EI

kin tot

=1

2

2

ω

(4)

•If Equations 2 and 4 are inserted into Equation 1

and ∆h eliminated using Equation 3 then the

equation can be rearranged to: