Caution: To avoid damage, do not exceed maximum allowable system pressure.

Always check the pressure switch operation after re-setting.

Pressure Adjustment

Adjusting the operating pressure range of the Pressure Switch is accomplished by the Range and Differential spring nuts located

under the pressure switch cover. The Range spring nut controls the cut-in or turn on pressure set point, while the Differential spring

nut sets the operation cut-out or turn off pressure set point. Since the range adjustment changes both the high and low operating

points, it is recommended to always adjust the Range spring nut first.

Adjustment Instructions

Set the switch pressure range by first removing the nut

securing the pressure switch cover and remove the

cover from the switch to access the adjustment spring

nuts. Refer to the Figure 4 and adjust the pressure

switch as follows:

Range – Adjust Range spring nut (A) until the

desired operating point (cut-in) of 85 psi (5.8 bar) on

falling pressure is obtained. Turning the Range nut (A)

clockwise will increase the setting.

Keep in mind the range adjustment changes both the

high and low operating points but should always be

adjusted for the low operating point.

Differential – Set the operating point (cut-out) on

rising pressure to maximum by adjusting the Differential

spring nut (B). Turning the nut (B) clockwise increases

the pressure difference between the high and low

operating points by increasing the high operating point

only.

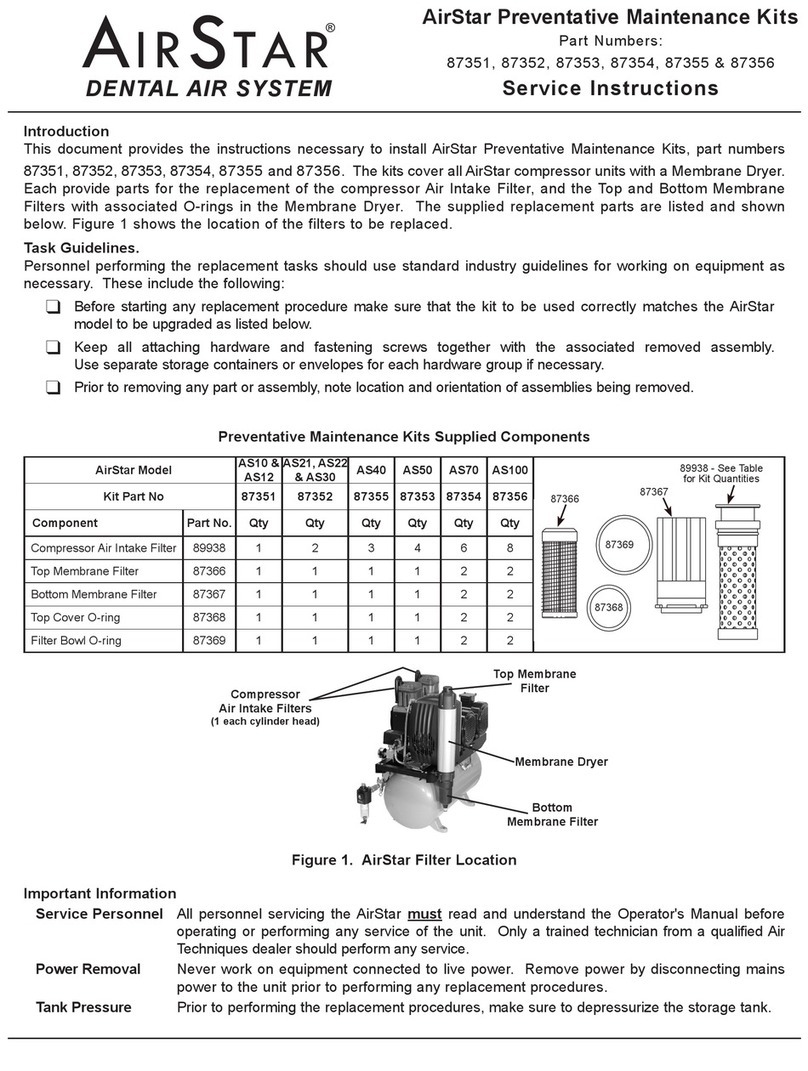

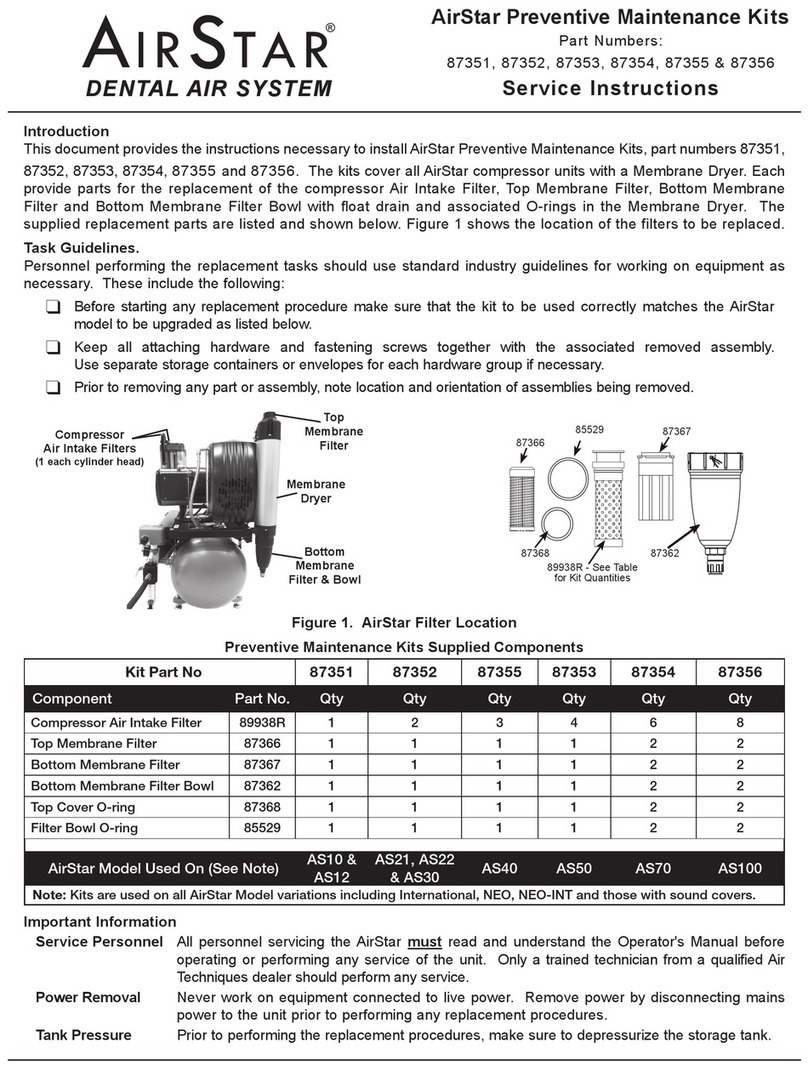

Kit Replacement Procedure. Refer to Figures 2 through 4 and

replace the pressure switch by performing the following steps.

1. Use a Phillips head screwdriver to loosen the screw securing

the pressure switch cover and remove the cover.

2. Disconnect wires from the pressure switch. Tag if necessary.

3. Proceed to step 4 if no unloader is connected to the pressure

switch. If an unloader is connected perform the following:

a. Use a torx screwdriver to loosen the screw securing

the unloader to the pressure switch and remove the

unloader.

b. Remove the hoses connected between the Cooler

and Membrane Dryer. Discard the unloader and

associated hoses.

c. Replace the removed hose between the Cooler and

Membrane Dryer with the Flamex tubing supplied with

the kit.

4. Using a 15/16-inch open end wrench, loosen the pressure

switch by turning counter-clockwise. Remove and discard.

5. Install the replacement pressure switch and tighten by turning

clockwise using a 15/16-inch open end wrench.

6. Refer to Figure 4 and connect the wires to the pressure switch.

7. Turn on the compressor and check the pressure switch. Adjust

the switch by performing the Pressure Adjustment Procedures

below.

8. Install the cover onto the pressure switch and secure by

tightening the 5/16-inch acorn nut.

Figure 3. Pressure Switch Replacement

STEP 1

STEP 3.bSTEP 3.a STEP 3.c

Torx

Screw

Unloader Discard the unloader

and associated hoses.

Unloader

Flamex 10mm

Tubing

10.25 inches long

(1 piece)

STEPS 4 & 5 STEP 8

15/16-inch

Wrench

STEP 2

Figure 4.