1

General

All installations must be in accordance with the regulations in force

in the country of use.

These instructions must be given to the user on completion of

installation.

Installers and service engineers must be able to demonstrate

competence and be suitably qualified in accordance with the

regulations in force in the country of use.

To ensure continued and safe operation it is recommended that the

appliance is serviced annually.

The manufacturer, offers a maintenance service. Details available on

request.

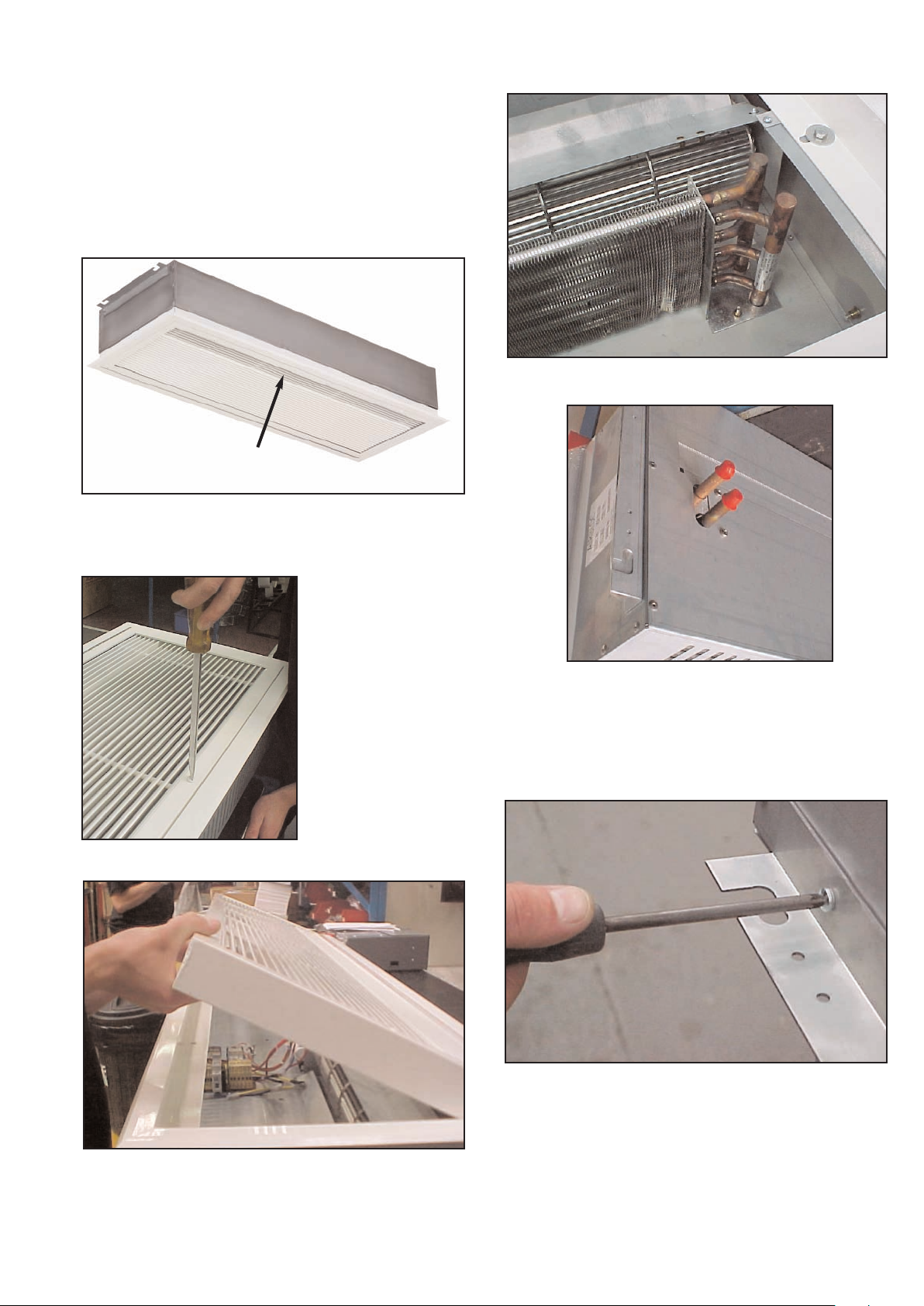

The air curtain inlet/outlet grille and case air inlet slots must not be

obstructed during use.

Fixing details

Airbloc units should be installed horizontally directly over the door

opening. It is recommended that the air curtain is installed on the

inside of the building, within the open room space against a wall or

ceiling. Care must be taken to allow complete free air movement

into the inlet grilles of the unit to ensure correct working operation

of the air curtain. The discharge opening should be as close to the

top of the door as possible and to cover the entire door width.

Electrical

The appliance must be earthed.

It is recommended that the electrical supply to the air curtain is via

an appropriate switched isolator in accordance with the regulations

in force in the country of use and must be via a fused double pole

isolator having a contact separation of >3mm in all poles.

Supply 230V 50Hz.

Time switches and thermostats can be installed at the discretion and

responsibility of the installer.

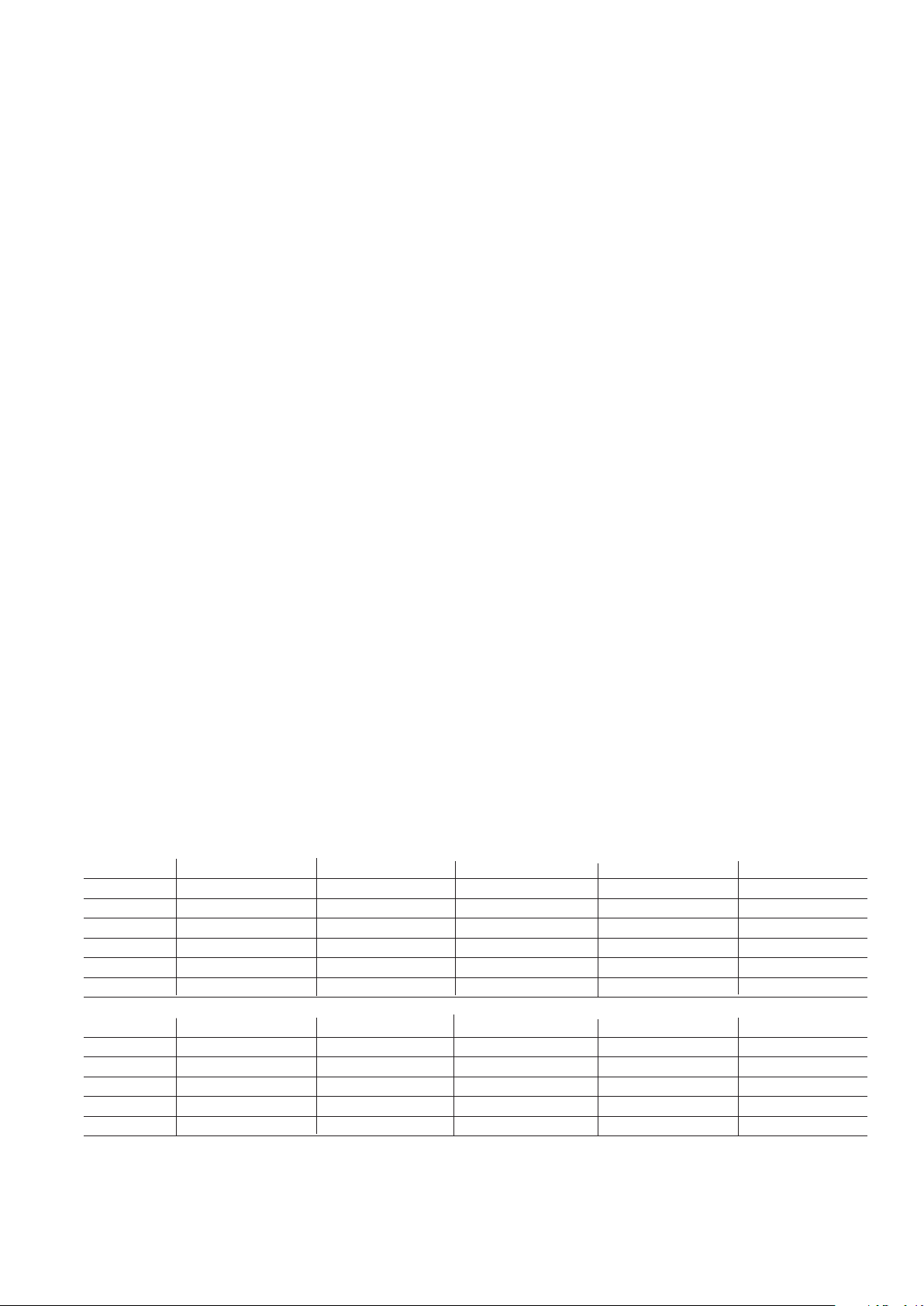

Model ACR100SA ACR150SA ACR200SA ACR120HA ACR180HA

Weight 28kg 34kg 49kg 38kg 55kg

Case size 395 x 200 x 1180mm 395 x 200 x 1480mm 395 x 200 x 1980mm 550 x 221 x 1150mm 550 x 221 x 1750mm

Motor rating 240V 50Hz 0.4A 240V 50Hz 0.4A 240V 50Hz 1.3A 240V 50Hz 2.1A 240V 50Hz 2.1A

Cut out size 405 x 1190 405 x 1490 405 x 1990 560 x1160 560 x 1760

Flange width 25mm 25mm 25mm 25mm 25mm

Note Dimension 200/221 refers to the height from the ceiling face to the outside of the case.

Clearance distances

It is recommended that a minimum clearance of 100mm is allowed

around the case sizes detailed below. The clearance allows for

cable entry and prevents combustible surfaces overheating. The

minimum mounting height (floor to grille) is 1.8m.

For cut out details see table below.

Health and Safety

Sole liability rests with the installer to ensure that all site safety

procedures are adhered to during installation.

Sole liability rests with the installer to ensure that protective safety

wear such as hand, eye, ear and head protection is used during

installation of the product.

Do not rest anything especially ladders against the product.

Standards

Units conform to european electrical standard BS EN 60335-2-

30:1997 and to the following european CE directives:

73/23/EEC low voltage; 89/336/EEC and 98/68/EEC electromagnetic

compatability.

1. Technical specification & safety

details

Model ACR100SW09 ACR150SW12 ACR200SW18 ACR120HW12 ACR180HW18

Weight 28kg 34kg 49kg 40kg 58kg

Case size 395 x 200 x 1180mm 395 x 200 x 1480mm 395 x 200 x 1980mm 550 x 221 x 1150mm 550 x 221 x 1750mm

Element rating 9kW 12kW 18kW 12kW 18kW

Motor rating 240V 50Hz 0.4A 240V 50Hz 0.4A 240V 50Hz 1.3A 240V 50Hz 2.1A 240V 50Hz 2.1A

Cut out size 405 x 1190 405 x 1490 405 x 1990 560 x 1160 560 x 1760

Flange width 25mm 25mm 25mm 25mm 25mm