Stainless steel housing in a metal hull

—To isolate the stainless

steel housing from the metal hull, slide the isolation ring onto the

housing. Apply

additional

sealant to the surfaces of the ring that

will contact the hull, filling any cavities in and around the ring.

Installing

Caution

: Never pull, carry, or hold the multisensor by the cable as

this may sever internal connections.

1. From outside the hull, push the housing into the mounting hole

using a twisting motion to squeeze out excess marine sealant

(see Figure 3).

Align the arrow on the lip of the housing to point

forward toward the bow.

If the multisensor is not installed on the

centerline of the boat, angle the housing slightly toward the

centerline to align it with the water flow.

2. From inside the hull, slide the washer onto the housing.

Aluminum hull less than 6mm

(

1/4"

)

thick

—Use an

additional rubbery, fiberglass, or plastic washer.

Never

use

bronze since electrolytic corrosion will occur.

Never

use wood

since it will swell, possibly fracturing the plastic housing.

Warning

:

Stainless steel housing in a metal hull only

—Be

sure the washer contacts the hull. Do not tighten the hull nut

with the washer against the isolation ring as the housing will not

be firmly installed. If necessary, sand the isolation ring until the

washer rests against the hull.

3. Screw the hull nut in place

being sure

the arrow on the lip of the

housing is still positioned forward toward the bow.

Plastic housing

—

Do not

clamp tightly on the wrenching flats,

possibly causing the housing to fracture.

Plastic hull nut

—

HAND-TIGHTEN

only.

Do not

over tighten.

Metal hull nut

—Tighten with slip-joint pliers.

Cored Fiberglass Hul

l—

Do not

over tighten, crushing the hull.

Wood hull

—Allow the wood to swell before tightening the nut.

4. Remove any excess marine sealant on the outside of the hull to

ensure smooth water flow over the multisensor.

Warning: The O-rings must be intact and well lubricated to

make a watertight seal.

5. After the marine sealant cures, inspect the O-rings on the insert

(replace if necessary) and lubricate them with the silicone

lubricant supplied.

Warning

: Be sure the insert is fully inserted into the housing,

and the cap nut is screwed on completely.

6. Slide the paddlewheel insert into the housing with the

arrow on

the top pointing forward toward the bow

. Screw the cap nut

several turns until the threads are engaged. The arrow on the

top of the insert, the cable exit, and the arrow on the lip will all

be aligned. Continue to tighten the cap nut.

Be careful

not to

rotate the housing and disturb the sealant.

HAND-TIGHTEN

only.

Do not

over tighten.

Warning

: Always attach the safety wire to prevent the insert

from backing out in the unlikely event that the cap nut fails or is

screwed on incorrectly.

7. Attach the safety wire.

Plastic housing

—Attach the safety wire to one eye in the hull

nut. Keeping the wire taut throughout, lead the wire in a

counterclockwise direction and thread it through one eye in the

cap nut. Thread the wire through the eye a second time. Then

lead the wire through the eye in the insert. Twist the wire

securely to itself.

Metal housing

—Wrap one end of the safety wire tightly around

the housing and twist it together with the long end. Keeping the

wire taut throughout, lead the wire straight up and through one

eye in the cap nut. Thread the wire through the eye a second

time. Then lead the wire counterclockwise and through the eye

in the insert. Twist the wire securely to itself.

Caution

: If your multisensor came with a connector, do not

remove it to ease cable routing. If the cable must be cut and

spliced, use Airmar’s splash-proof Junction Box No. 33-035 and

follow the instructions provided. Cutting the cable or removing

the waterproof connector, except when using Airmar’s junction

box, will void the multisensor warranty.

8. Route the cable to the instrument

being careful

not to tear the

cable jacket when passing it through the bulkhead(s) and other

parts of the boat. To reduce electrical interference, separate the

multisensor cable from other electrical wiring and the engine.

Coil any excess cable and secure it in place with zip-ties to

prevent damage.

9. Refer to the instrument owner’s manual to connect the

multisensor to the instrument.

Checking for Leaks

Warning

: DO NOT leave the boat in the water unchecked for

several days.

When the boat is placed in the water,

immediately

check around

the thru-hull multisensor for leaks. Note that very small leaks may

not be readily observed.

Do not

leave the boat in the water for

more than 3 hours before checking it again. If there is a small

leak, there may be considerable bilge water accumulation after 24

hours. If a leak is observed, repeat “Bedding” and “Installing”

immediately

(see pages 2 and 3).

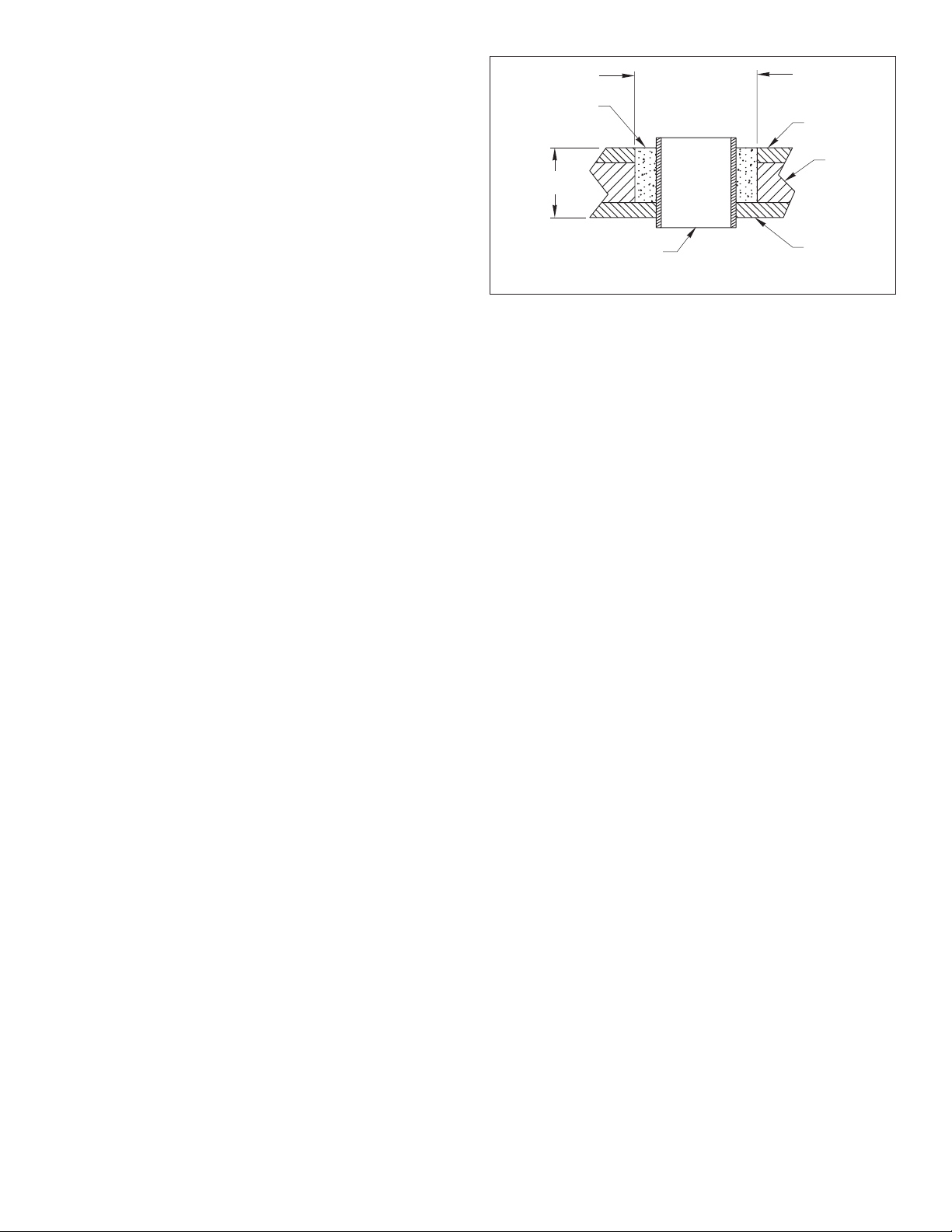

Installation in a Cored Fiberglass Hull

The core (wood or foam)

must

be cut and sealed carefully. The

core

must

be protected from water seepage, and the hull

must

be

reinforced to prevent it from crushing under the hull nut allowing

the housing to become loose.

Warning

: Always wear safety goggles and a dust mask.

1. Drill a 3mm or 1/8" pilot hole from inside the hull. If there is a rib,

strut, or other hull irregularity near the selected mounting location,

drill from the outside. (If the hole is drilled in the wrong location,

drill a second hole in a better location. Apply masking tape to the

outside of the hull over the incorrect hole and fill it with epoxy.)

2. Using a 51mm or 2" hole saw, cut the hole from outside the hull

through the

outer

skin only

(see Figure 4).

3. From inside the hull, use a 60mm or 2-3/8" hole saw to cut

through the

inner

skin and most of the core. The core material

can be very soft. Apply only light pressure to the hole saw after

cutting through the inner skin to avoid accidentally cutting the

outer

skin.

3

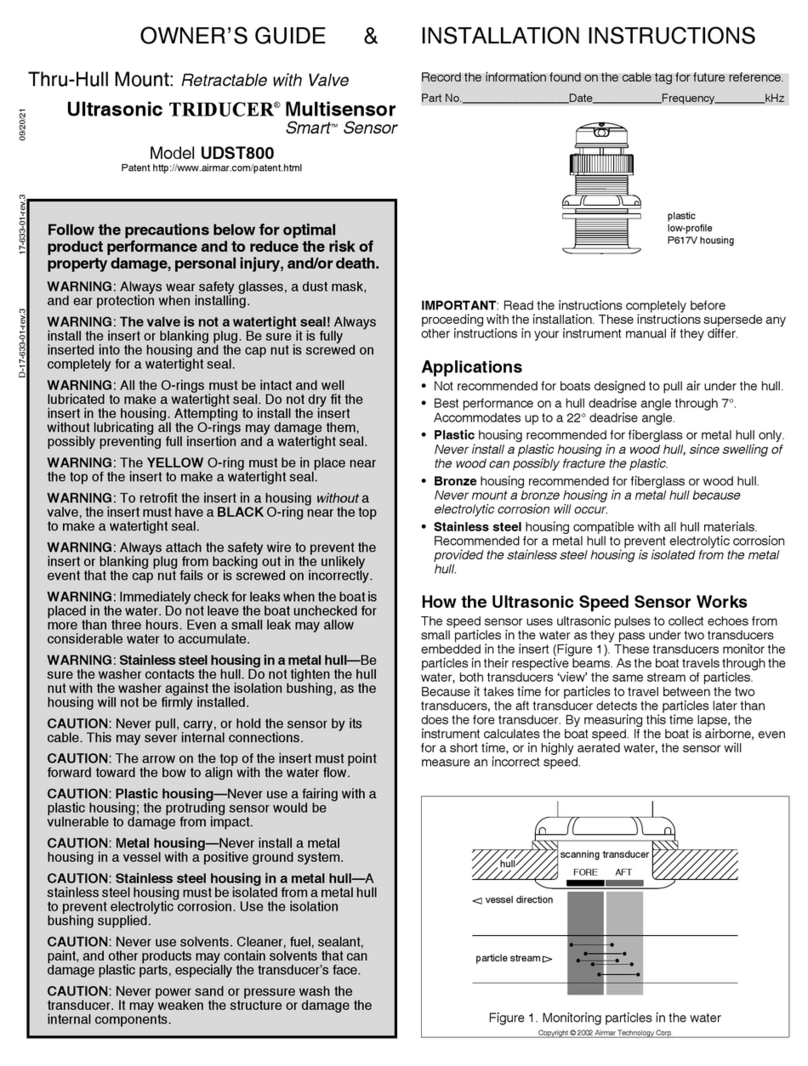

Figure 4. Preparing a cored fiberglass hull

inner skin

core

outer skin

solid or hollow cylinder

pour in

casting

epoxy

9-12 mm

(3/8-1/2")

larger than the

hole through the

hull’s outer skin

hull thickness

Copyright © 2005 Airmar Technology Corp.