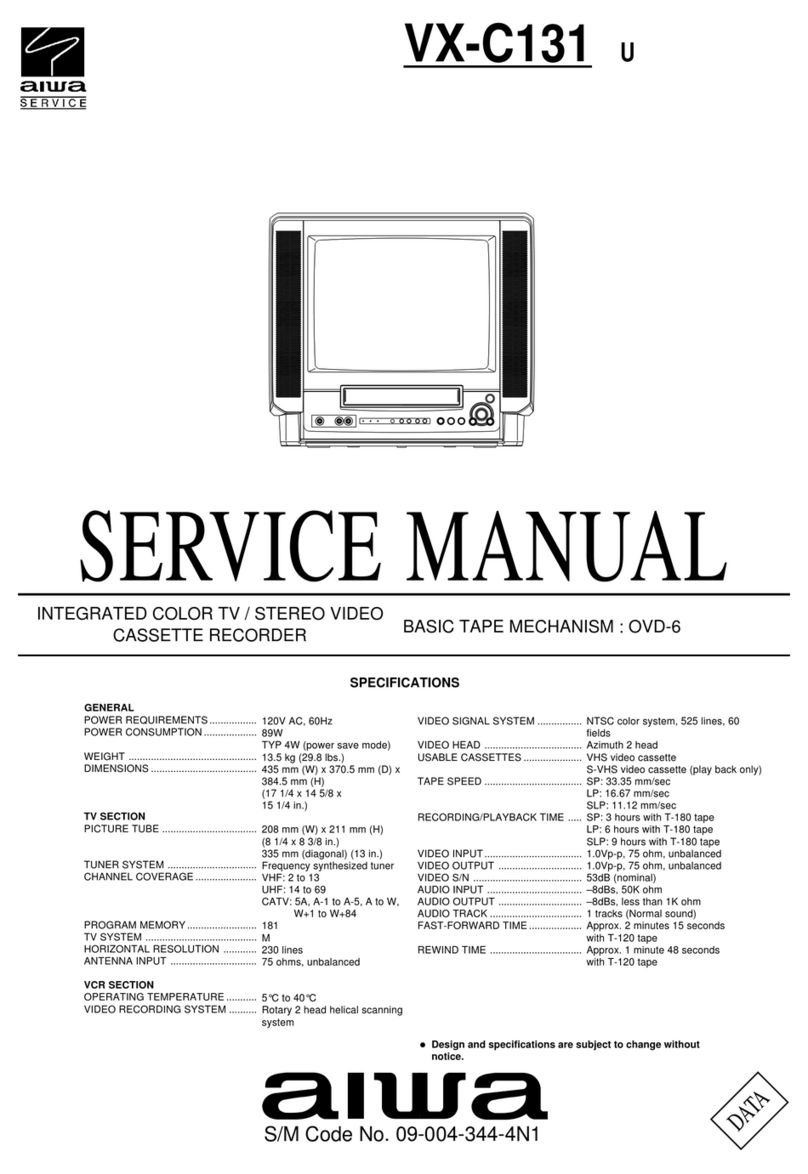

–7 –

Color bar signal of a pattern generator

PRECAUTIONS BEFORE STARTING ADJUSTMENT

Satisfy the following setting conditions before starting adjustment.

• Allow warm-up of 20 minutes or longer. (Do not turn off during

warm-up.)

• Set all picture quality controls of users' setting to initial set-up,

unless otherwise specified.

• Picture quality reset

1. Select "Picture" on the screen menu and press enter button.

2. Select "Normal" and press enter button.

3. Select "Reset" and press enter button.

• Set the pattern generator’s output level to 1.0Vp-p (across 75 Ω

load).

Because the video signal output from a pattern generator is used as

the adjustment signal input during adjustment, the video signal

output from the pattern generator must conform with the

specifications. Measure the output waveform across 75 Ωload.

Confirm that the synchronizing signal has an amplitude of about

0.3 V, the video signal portion has an amplitude of about 0.7 V and

the burst signal has an amplitude of about 0.3 V with flat envelope.

Confirm that ratio of the burst signal amplitude and the red signal

amplitude is 0.30 : 0.66. If the output signal does not conform with

the specifications, calibrate the pattern generator. (Refer to pattern

generator operation manual.)

Use the LEADER: LCG 404 for the pattern generator.

Fig. 1-1

Approx.

0.3V

Approx. 0.3V

Burst signal

1 Vp-p

White (Approx.

75%)

Approx. 0.7V

Yellow

Cyan

Green

Magenta

Red

Blue

Black

75% white

TV display

1-1. Precautions

(1) Receive the white raster signal, and then perform aging for at

least 20 minutes.

(2) Demagnetize the area surronding the CRT with a degausser

before making adjustments.

(3) Set the picture quality for each mode to the factory setting.

(4) Position the front screen facing the east as much as possible.

1-2. Purpose

(1) Beam landing adjustment (purity magnet)

Set the left/right balance of beam landing. If there is a

discrepancy in this adjustment, a color irregularity will occur.

After completion of the landing adjustment, it is necessary to

perform convergence adjustment.

Color

irregularity

Color

irregularity

Before adjustment After adjustment

ADJUSTMENT

SET-UP FOR ADJUSTMENT 1. CRT ADJUSTMENT