IL

Il.

VI.

VIL.

VIIL

X.

SECTION

1

SERVICE

MANUAL

TABLE

OF

CONTENTS

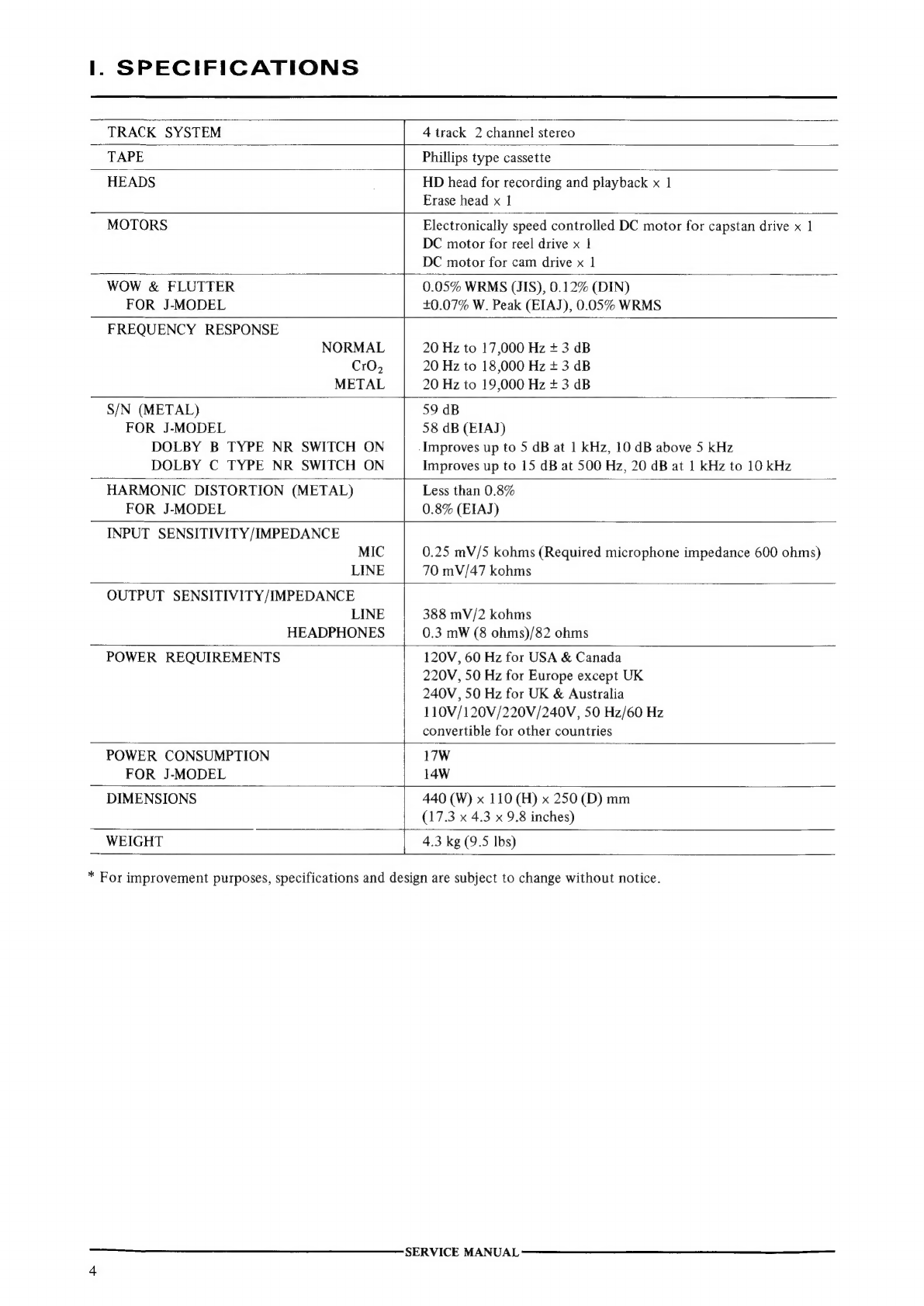

SPECIFICATIONS.

5.00002.

65

gee

Stew

bw

HR

ee

ee

eee

4

DISMANTLING

OF

UNIT

................

0.

eee

eee

ees

5

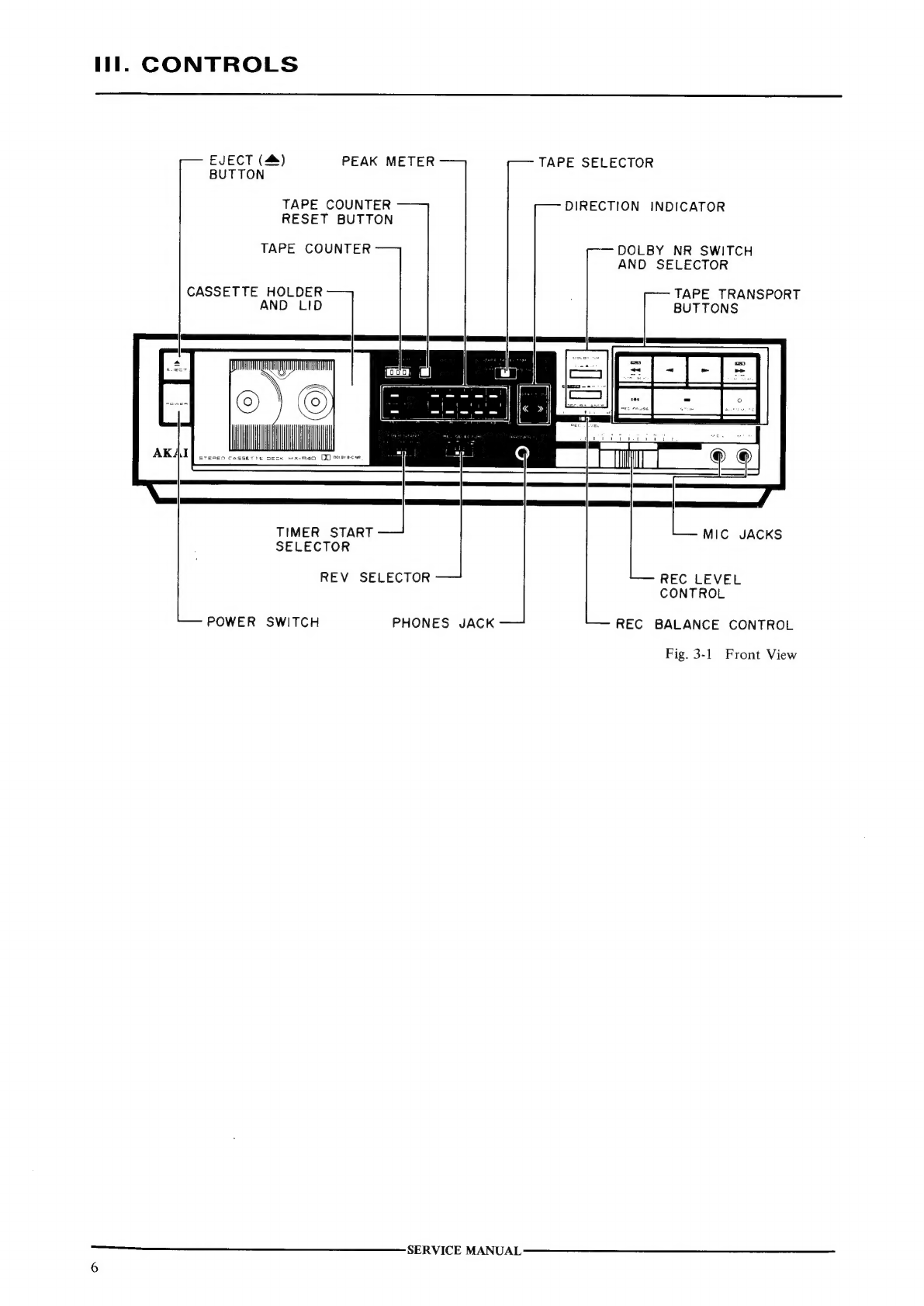

CONTROLS

|

2

esi

scc

cose

e

cok

we

ted

Bhs

Bin

eines

EERE

a

EARS

6

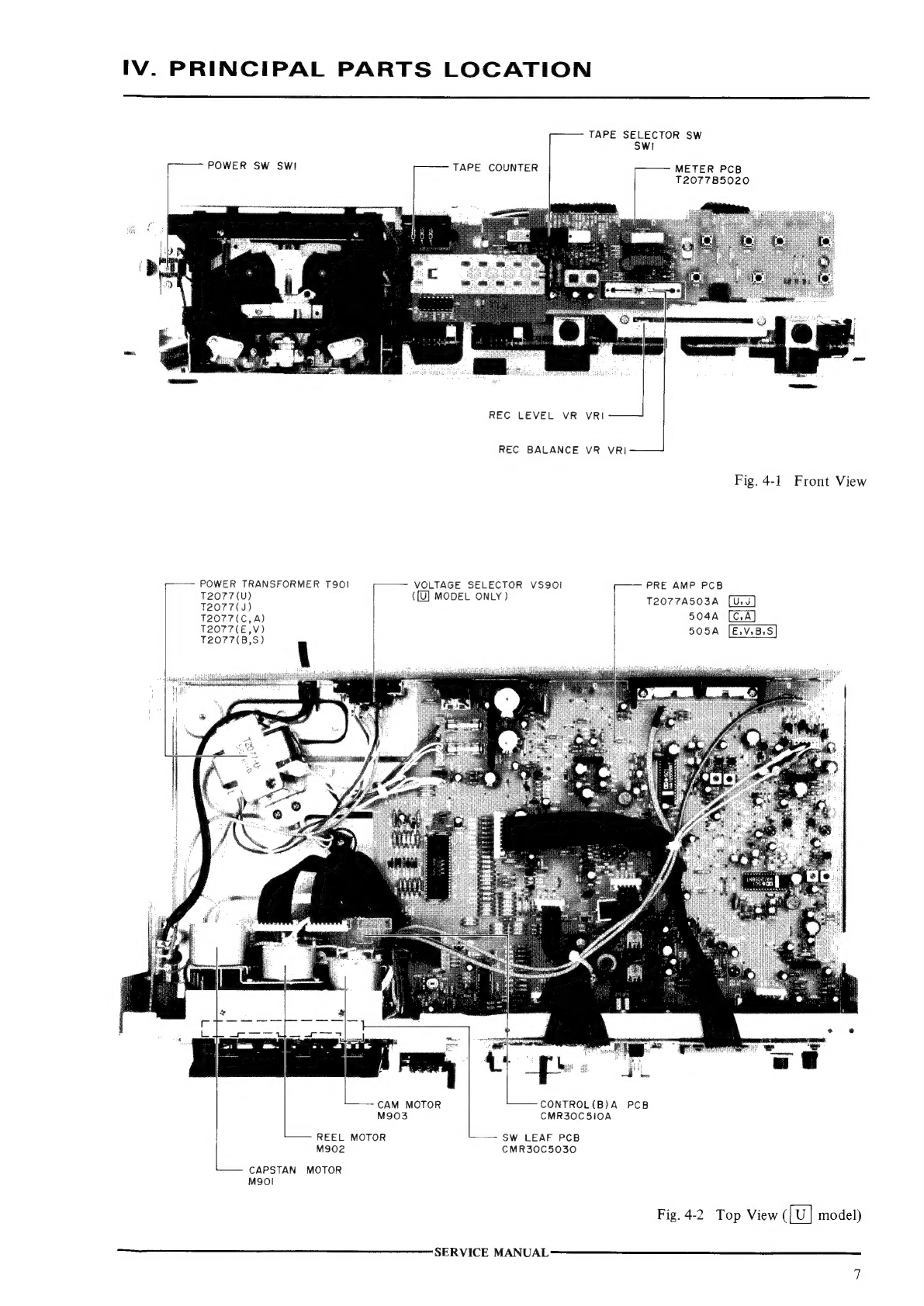

PRINCIPAL

PARTS

LOCATION

...........

0.0.0.

ee

eee

eee

ene

7

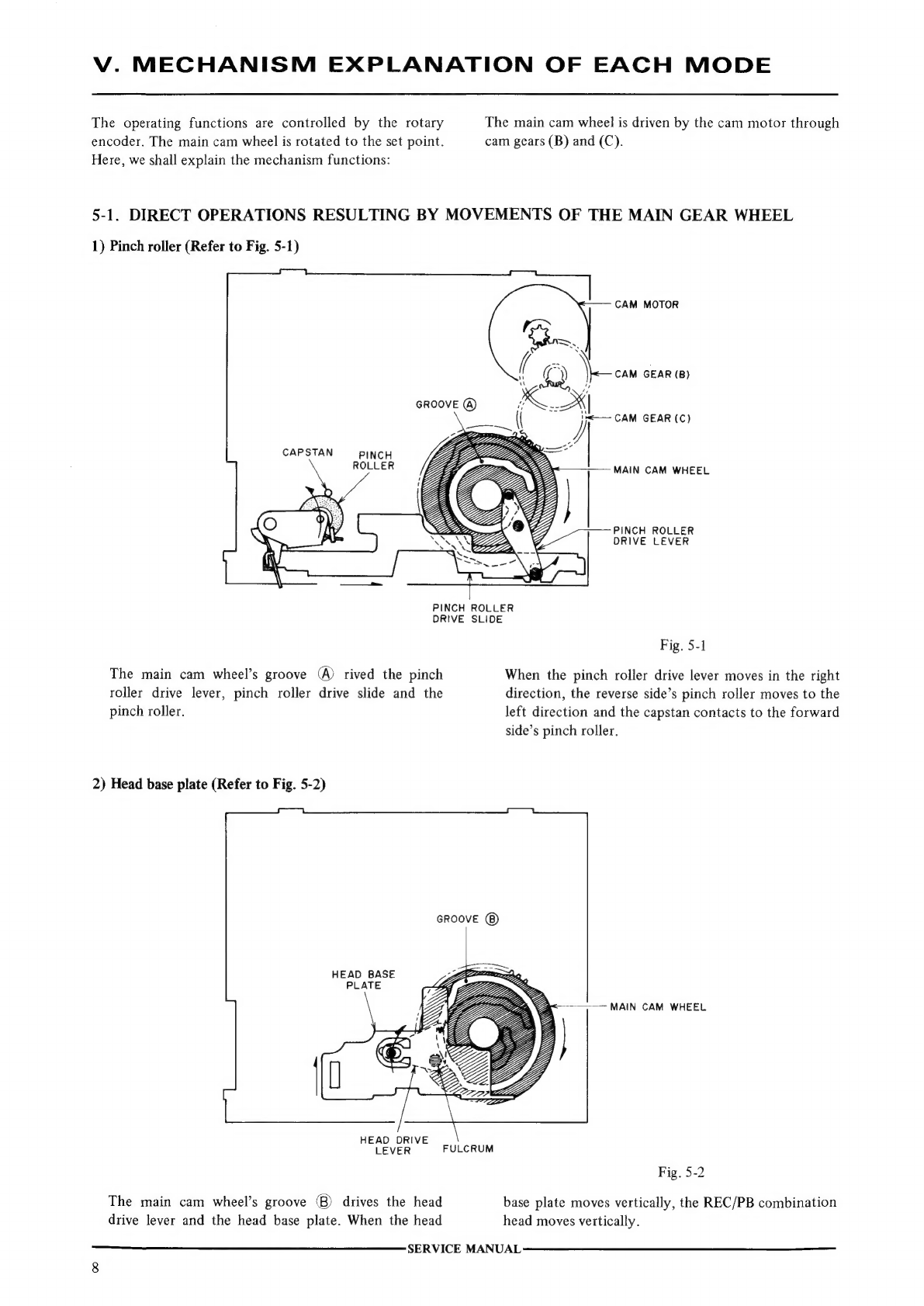

MECHANISM

EXPLANATION

OF

EACH

MODE..................

8

5-1.

DIRECT

OPERATIONS

RESULTING

BY

MOVEMENTS

OF

THE

MAIN

GEAR

WHEEL

.....

8

FIXING

PROCEDURES

FOR

CAM

WHEEL

AND

ROTARY

ENCODE

PCB.....

11

MECHANICAL

ADJUSTMENT

..........

0.000000.

02:

eae

eee

12

7-1.

PINCH

ROLLER

PRESSURE

MEASUREMENT

...............

12

7-2.

WINDING

TORQUE

MEASUREMENT

IN

EACH

MODE

........

12

7-3.

TAPE

SPEED

ADJUSTMENT

..........

2.0.0.0...

0000s

eee

12

HEAD

ADJUSTMENT

..

2.2.2.0...

.

cece

cece

eee

ees

13

8-1.

TAPE

GUIDE

HEIGHT

ADJUSTMENT.....................

13

8-2.

HEAD

HEIGHT

ADJUSTMENT

......................0...

13

8-3.

REC/PB

HEAD

AZIMUTH

ALIGNMENT

ADJUSTMENT

........

13

ELECTRICAL

ADJUSTMENT

..........0..

0.000.000

ee

eee

eee

ee

14

9-1.

QUICK

REVERSE

SENSITIVITY

ADJUSTMENT..............

14

9-2.

PRE-AMP

ADJUSTMENT...............

0.0.0...

.0

000000.

1S

PC

BOARD

TITLES

AND

IDENTIFICATION

NUMBERS............

16

For

basic

adjustments,

measuring

methods,

and

operating

principles,

refer

to

GENERAL

TECHNICAL

MANUAL.

SERVICE

MANUAL