Akai VS-X9EGN User manual

Other Akai VCR System manuals

Akai

Akai VS-J4600 User manual

Akai

Akai AVR250 User manual

Akai

Akai VS-G205 User manual

Akai

Akai VS-G415EA User manual

Akai

Akai VS-K606N-E3(S) User manual

Akai

Akai VS-K203M-E7 User manual

Akai

Akai VS-2EGN User manual

Akai

Akai SHOWVIEW VS-G245EDG User manual

Akai

Akai VS-606EA User manual

Akai

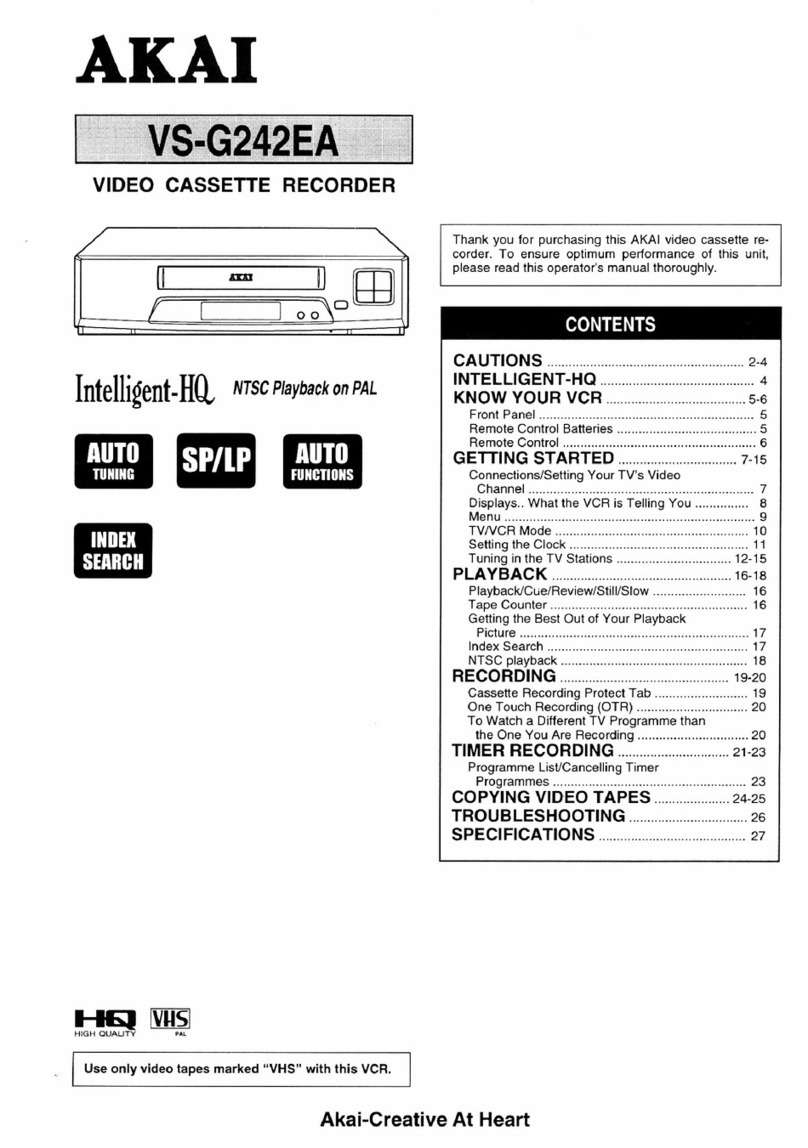

Akai VS-G242EA User manual