JET motors are rated using a

continuous duty cycle rather than

“peak” or “max developed”

horsepower claims. Using the

continuous duty cycle provides

an accurate representation of the

power output of the JET motors

so you can make the best tool

buying decision for your work

shop environment.

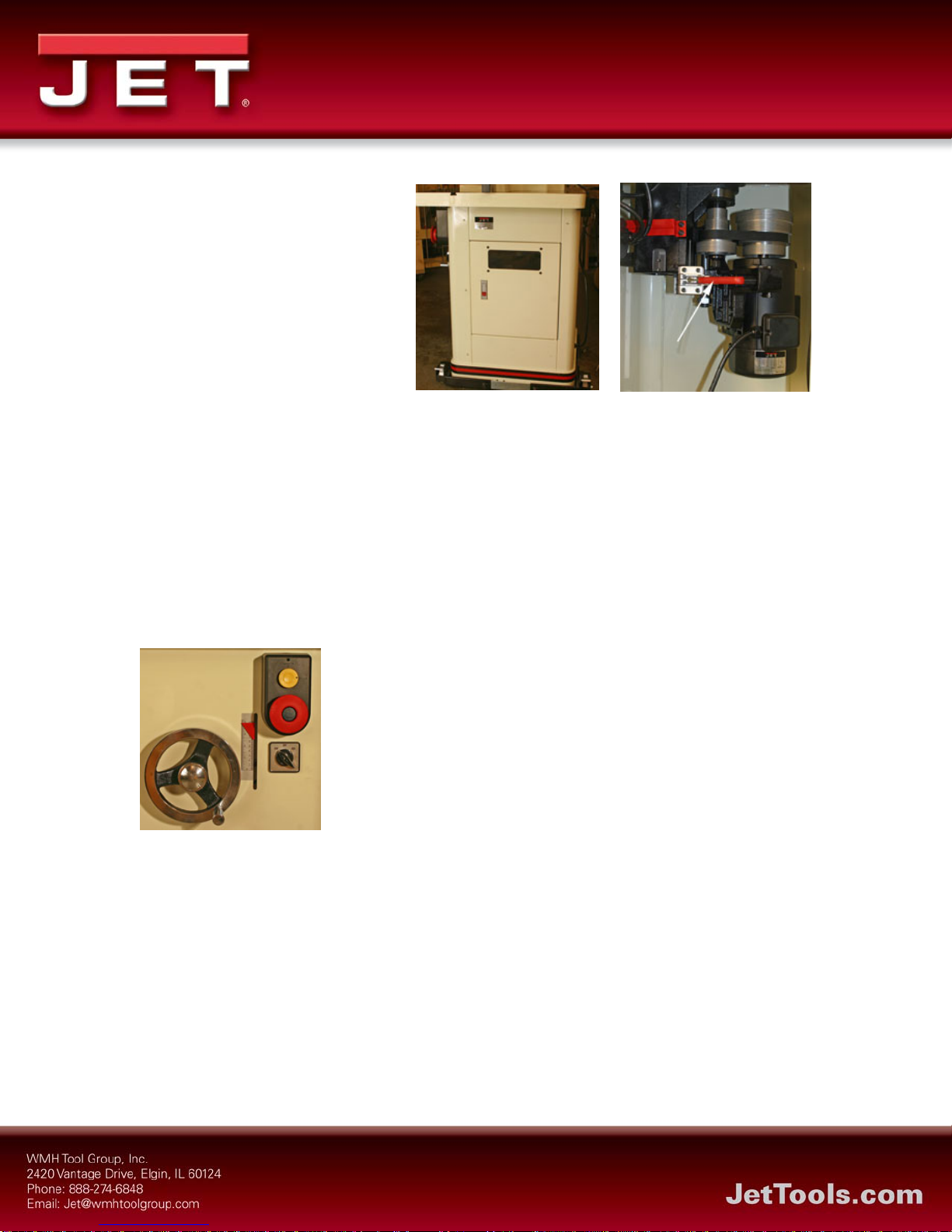

A heavy-duty magnetic On/Off

switch controls the JET JWS-

35X Heavy-Duty Shaper. The

switch box is equipped with a

magnetic “key” that when removed prevents unauthorized startups. The magnetic switch

protects the JET JWS-35X Heavy-Duty Shaper from power fluctuations that could

damage the motor. It also prevents the motor from restarting should the power go out and

then come back on unexpectedly. The motor/cutter rotation can be reversed using a

switch on the front of the JET JWS-35X Heavy-Duty Shaper cabinet for different cutters

and special setups.

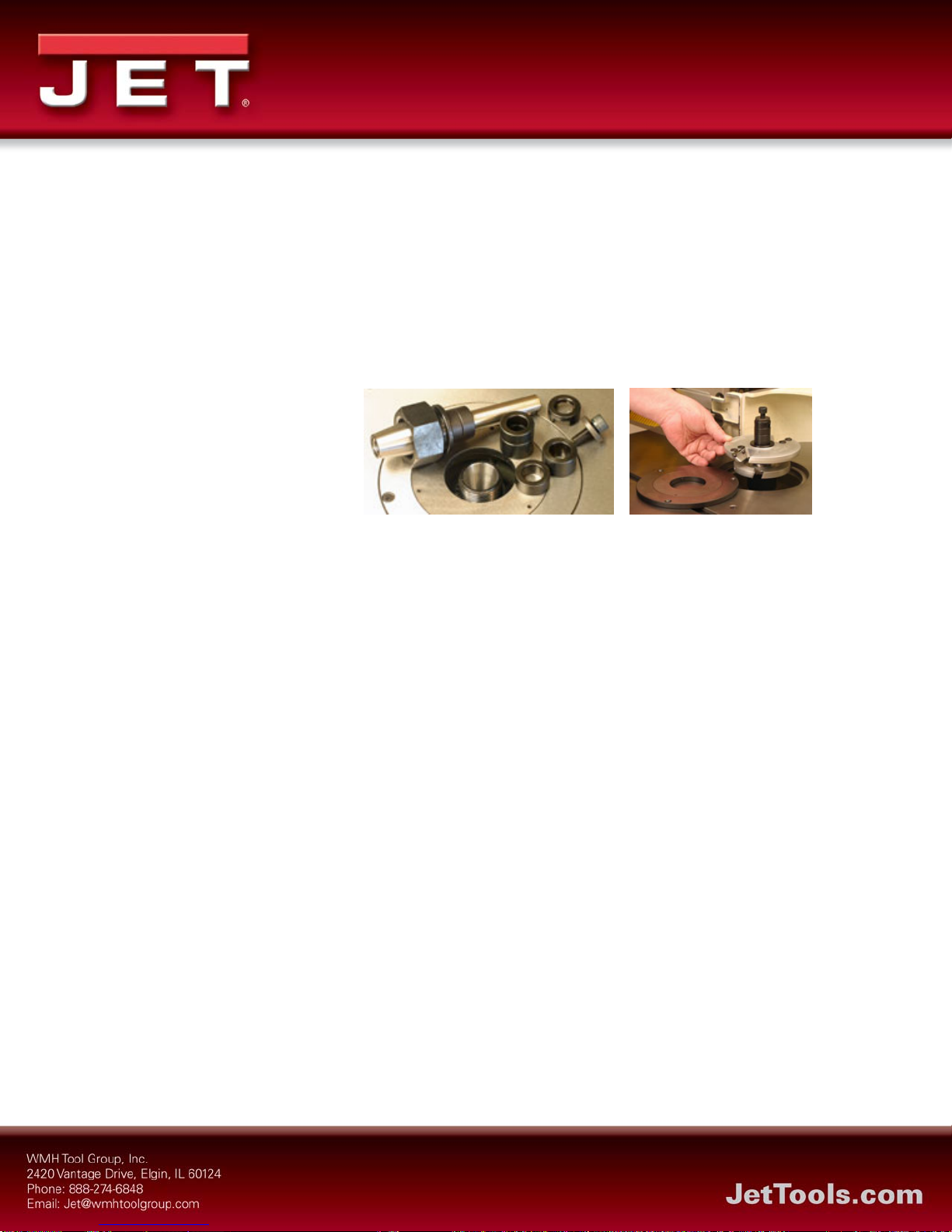

A large door in the cabinet side (left) provides easy access to the motor

and belt system. It even has a large window through which the belt

position can be confirmed.

The entire motor mount and spindle assembly (right) is heavy-duty for

maximum accuracy and durability. The belt tension release lever

(arrow) makes changing speeds fast and easy.

The JET JWS-35X Heavy-Duty Shaper has four spindle

speeds, 4000, 6000, 8000 and 10,000RPM. The speeds are

generated by a set of precisely machined stepped pulleys on

the motor and spindle shaft. The JET JWS-35X Heavy-Duty

Shaper connects the pulleys with a Poly-V-belt, known for

smooth power transmission, resistance to slipping and low

heat buildup.

The controls on the front of the

cabinet are easy to reach and

use. The magnetic On/Off

switch protects the motor and

you. The large cast iron

handwheel makes bit height

changes fast and easy.

Moving the Poly-V-belt between pulley positions is fast and

tool-free. A single lever releases belt tension. Move the belt

and flip the lever again to tension the belt for use. An easy to

reach belt tension adjuster is built into this release system

should the belt stretch.

A large access door in the base cabinet provides access to the belt mechanism and motor.

The door even has a window that allows the user to quickly confirm that the belt is in the

desired position without needing to open the door.