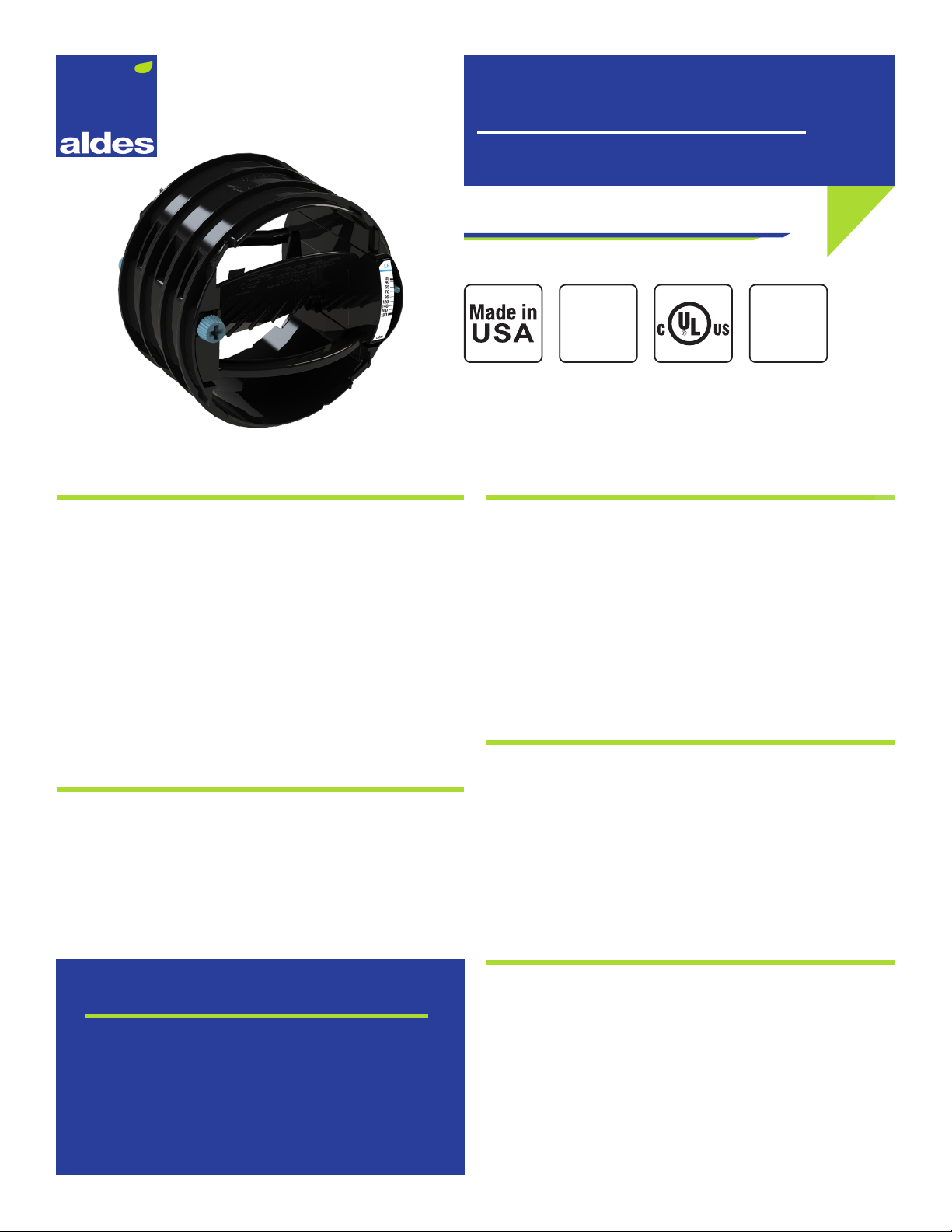

Product Description

The Aldes CAR3 Constant Airflow Regulator is a pressure

independent balancing damper that automatically regulates

airow in duct systems to constant levels. The CAR3 requires

no electric or pneumatic power or sensors, and works solely o

system pressure.

Unlike traditional manual dampers, the CAR3 compensates

for changes in duct pressure caused by stack eect, operable

windows and doors, wind, loading lters, etc. The CAR3 provides

a low-cost solution to maintaining the correct airow balance of

ventilation systems, improving system performance and indoor

air quality, which can provide significant savings on annual

operating costs.

Key Features

• Dual-side airow adjustment dial and CFM indicator allows

you to set or change the airow quickly, in supply or exhaust

applications, without removing the CAR3 from the duct.

• Modulating rotary damper automatically responds to

changes in duct pressure to maintain set ow.

• Resin is enhanced with antimicrobial, anti-static, and ame

retardant additives for increased safety and durability.

CAR3

AIRFLOW & ZONE CONTROL

WARRANTY

7 YEARS

Patent

pending

CONSTANT AIRFLOW REGULATOR

Construction

• CAR3 constructed of amorphous thermoplastic resin

enhanced with antimicrobial, anti-static, and ame retardant

additives to improve material performance, reduce need for

maintenance, and increase safety.

• CAR3 is UL 2043 safety classied and labeled for ame and

smoke generation (File No. R39897).

• Double lip gasket around the circumference ensures a tight,

no-leak t.

Maintenance

The CAR3 needs no maintenance when used in normal

conditions. The addition of antimicrobial and anti-static

additives in the material increases the longevity and reliability

of the CAR3. There is no risk of dust deposit or obstruction

because the CAR3 has no airways subject to clogging. If the

intended application includes air heavily loaded with dust or

grease, access to the CAR3 will be possible through the terminal

device or with an access panel or door.

Warranty

Guaranteed for 7 years, from date of shipment, against all

defects in material or workmanship, provided that the material

has been installed and used under normal conditions. This

warranty is limited to the repair or replacement of the material.

APPLICATIONS

• Automatic balancing of round duct.

• Balance supply or exhaust/return duct in high-rise

building.

• Sized to t inside standard rigid round ducting,

take-os, tees, and more.

• New construction or retrot.