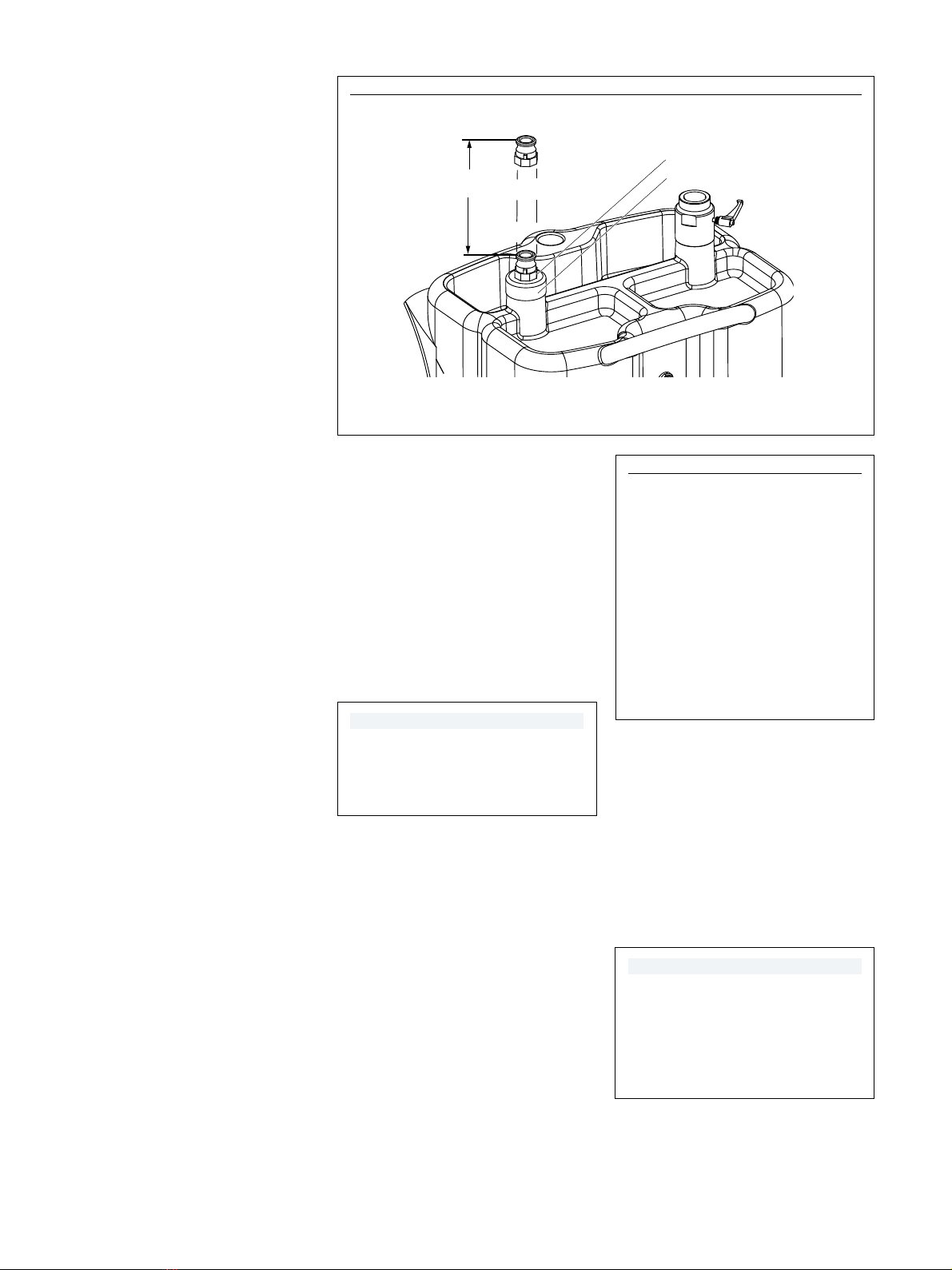

Empty tank

Before the tank approaches maximum fill (as

seen through the sight-gauge (19), empty

the tank by connecting camlock fitting (5) to

an evacuation system. The length of suction

pipe (2) ensures that it clears the tank

bottom to prevent solids and sediments from

being sucked into and damaging the

evacuation pump.

Sediments may build up high enough to

start clogging the suction pipe (2) before the

next scheduled tank purge. A stop-gap

feature has been designed into the suction

pipe (2) to enable oil evacuation to proceed

temporarily (→Fig. 1, page 4).

1 Apply wrench to camlock fitting (5) and

turn counter-clockwise. If necessary,

secure plug (4) with pipe wrench to hold

stationary.

2 Raise suction pipe (2) to maximum

height of 1 5/8in (41 mm).

3 Connect camlock fitting (5) to evacuation

system and complete emptying of tank.

4 Schedule tank purge as soon as possible

before tank fills up with sediments

and solids.

5 Upon completion of tank purge, turn

camlock fitting (5) clockwise as far down

as possible to reset suction tube (2)

height.

Purge tank

It may not be possible to safely purge the

tank of solids and sediments on the tank

bottom using the suction of an evacuation

system. We recommend the following steps

to completely purge the tank bottom of

sediments:

1 Evacuate tank of all fluids using

evacuation system.

2 Remove plug (22) on lower

connection (21).

3 Flush tank with water and normal

detergent until tank bottom is free of all

solids and sediments.

4 Reinstall plug (22) and check for leaks.

5 Turn camlock fitting (5) clockwise as far

down as possible to reset suction

tube (2) height.

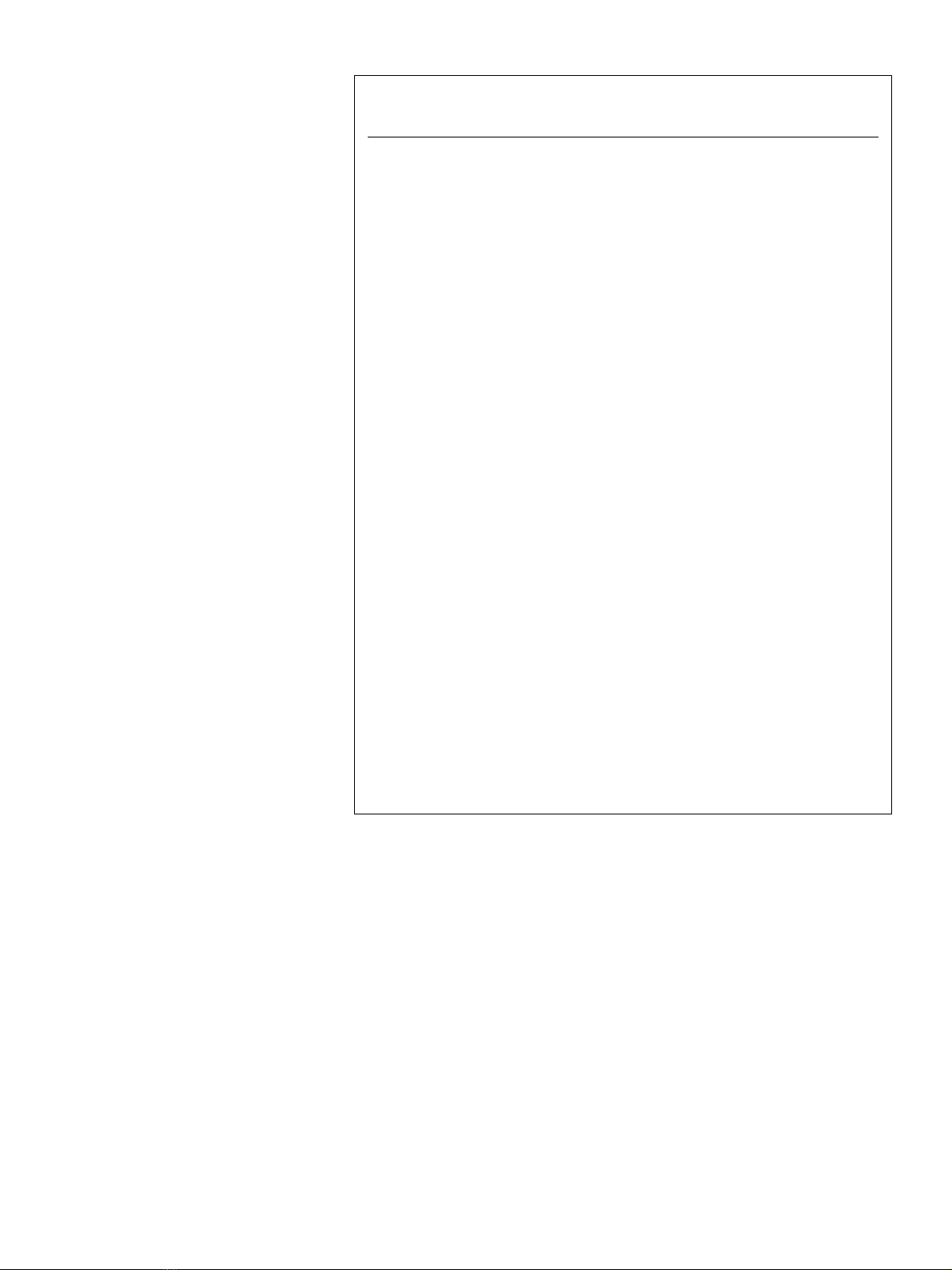

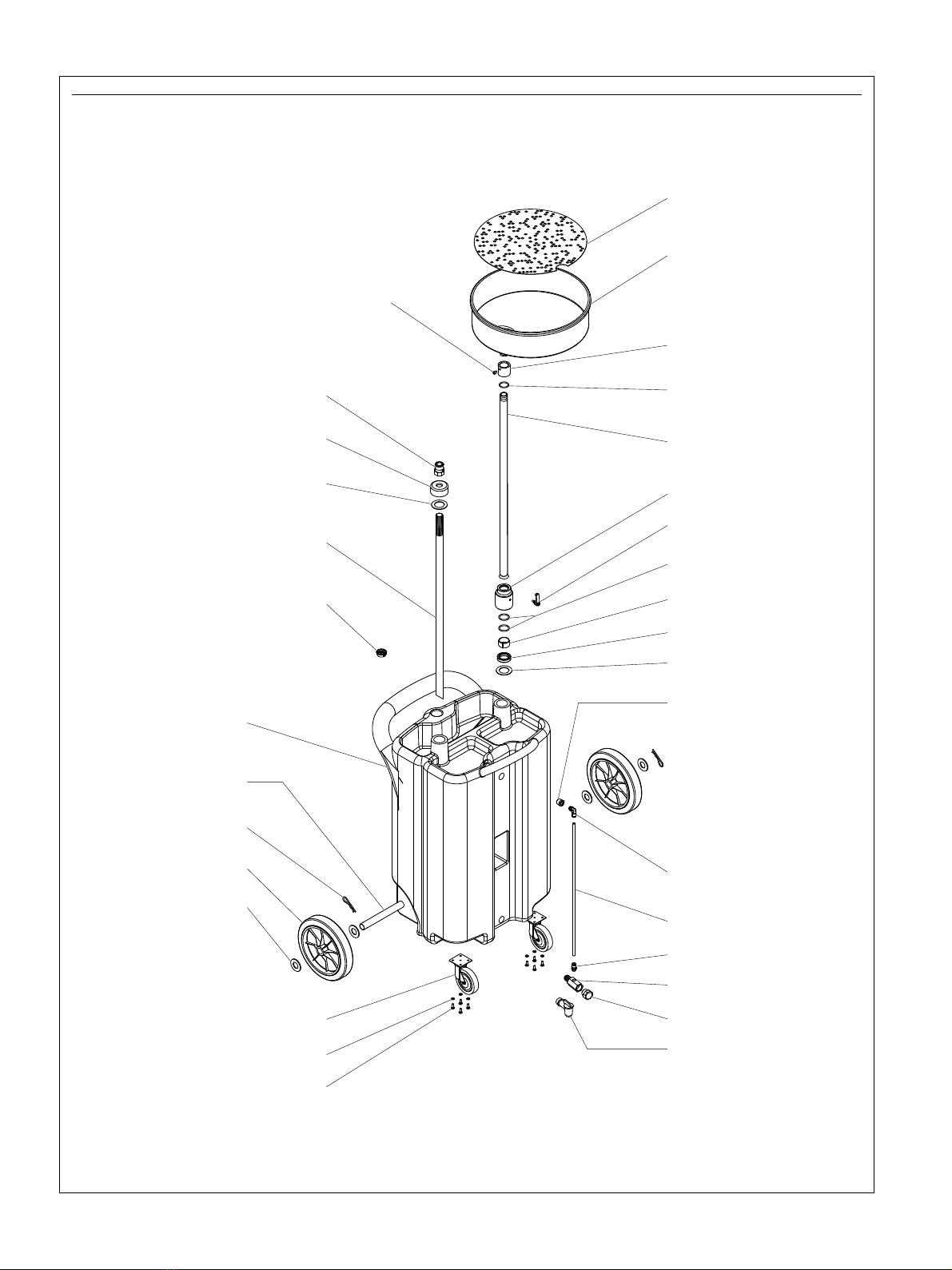

Parts list

Item Description Part number Quantity Kit number

1 Plastic cap 343341 1

2 Pipe, suction 1 393808-9

3 Seal, 2 in 2 393808-7, 393808-8,

393808-9

4 Plug, 2 in 1 393808-9

5 Connector, camlock 3/4in 343343 1 393808-9

6 Screw, SH cap 1 393808-6

7 Screen 343326 1

8 Funnel assembly 343327 1

9 O-ring 4100 1 393808-5, 393808-6

10 Bushing 1 393808-6

11 Drain tube 1 393808-7

12 Fitting, pipe holder 1 393808-7

13 Knob 343340 1 393808-7

14 O-ring 4131 2 393808-5, 393808-7,

393808-8

15 Lock-ring, split 1 393808-7, 393808-8

16 Ring-nut 1 393808-7

17 Adapter, 1/2in external × 1/4in internal 1 393808-4

18 Compression fitting (elbow) 1 393808-4

19 Sight gauge 1 393808-4

20 Compression fitting (straight) 1 393808-4

21 Lower connection 1 393808-10

22 Plug, 3/4in NPT 1 393808-10

23 Spigot, plastic - 3/4in NPT 343349 1) 1

24 Screw, cross head - M6 × 16 8 393808-1

25 Washer, lock 8 393808-1

26 Wheel, castor 2 393808-1

27 Washer, flat - 26 mm 4 393808-2, 393808-3

28 Wheel rubber 2 393808-3

29 Pin, cotter 2 393808-2, 393808-3

30 Axle 1 393808-2

31 Plastic tank 1

Part numbers left blank are not available separately.

1) Accessory - not part of drain assembly

5