WHEEL SKATE

MODEL NO: WS680.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

9Familiarise yourself with this product’s application and limitations, as well as the specific warnings below relating to their use.

9Ensure the Wheel Skates are in sound condition and good working order. Take action for immediate repair or replacement of damaged

parts. Use genuine parts only. The use of improper parts may be dangerous and will invalidate the warranty.

9Wheel Skates should only be used in suitable, well lit areas.

9Wheel Skates must be used in pairs at either the front or rear of the vehicle. They must never be used diagonally.

9Keep general area clean and tidy and free from obstructions.

9Use Wheel Skates on level and solid ground, preferably concrete. Avoid tarmacadam as Wheel Skates may sink in.

9Maintain the Wheel Skates in good condition (use an authorised service agent).

9Ensure there are no passengers in the vehicle.

9Ensure the Wheel Skates are free to move and that there are no obstructions in the area of use.

9When not in use store Wheel Skates in a safe, dry, childproof area.

▲DANGER: Use the Wheel Skates for manoeuvring or positioning of vehicles in interior situations. They are not designed for use

outdoors.

8DO NOT start or drive the vehicle whilst it is raised on wheel skates.

8DO NOT use the Wheel Skates for purposes other than that for which they are intended.

8DO NOT allow untrained persons to operate the Wheel Skates.

8DO NOT leave the vehicle unattended whilst it is raised on the Wheel Skates.

8DO NOT operate the Wheel Skates when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT get the Wheel Skates wet or use in damp or wet locations or areas where there is condensation.

8DO NOT exceed the rated capacity of the Wheel Skates. Remember that the front of a vehicle is usually heavier than the rear.

8DO NOT use the Wheel Skates to lift or support a vehicle in order to do work underneath it.

9Maintain correct balance and footing when moving vehicle. Ensure the floor is not slippery and wear non-slip shoes.

9Ensure there are no obstructions beneath the vehicle when it is to be lowered.

9Ensure all non-essential persons keep a safe distance whilst the Wheel Skates are in use.

IMPORTANT - We recommend that at least 2 persons are involved in manoeuvring the vehicle when supported on wheel skates. The

vehicle’s weight provides a large amount of inertia which has to be overcome to get the vehicle moving and more importantly, stopped.

WARNING! The warnings, cautions and instructions discussed in this manual cannot cover all possible conditions and situations

that may occur. It must be understood that common sense and caution are factors which cannot be built into this product, but must be

applied by the operator.

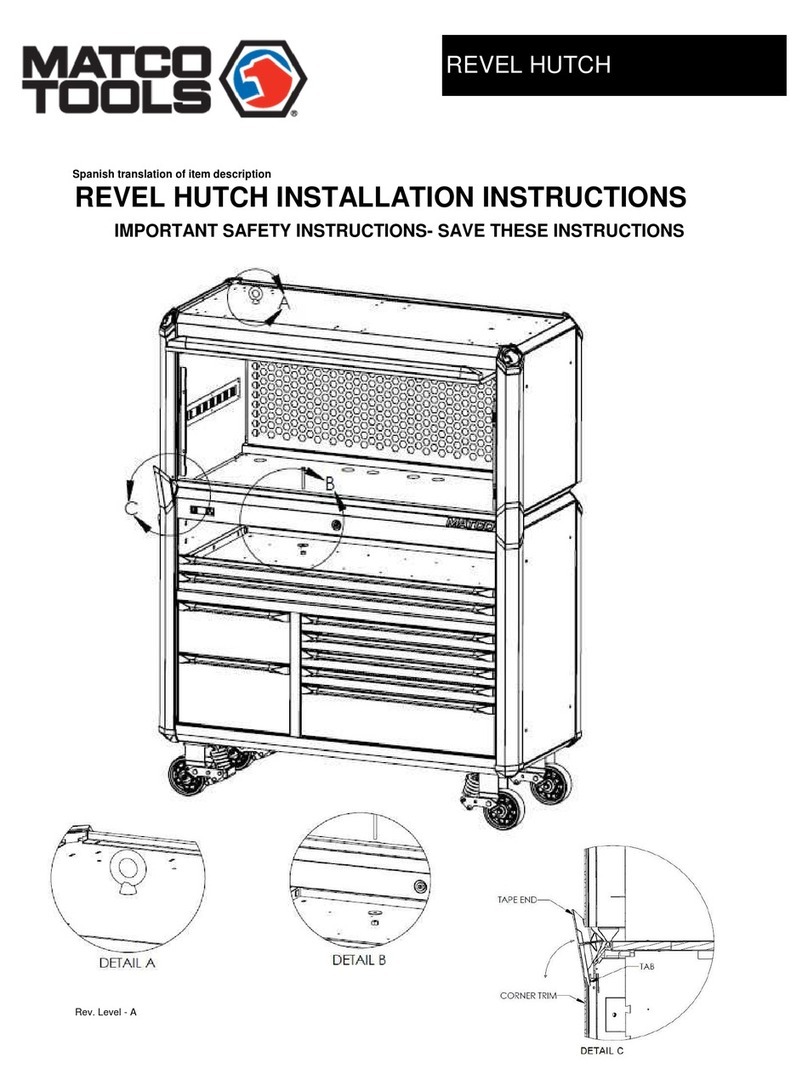

2. INTRODUCTION

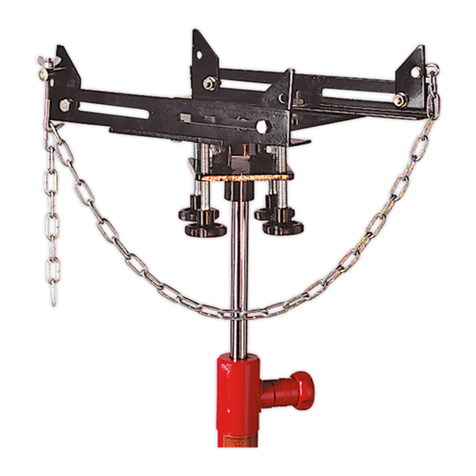

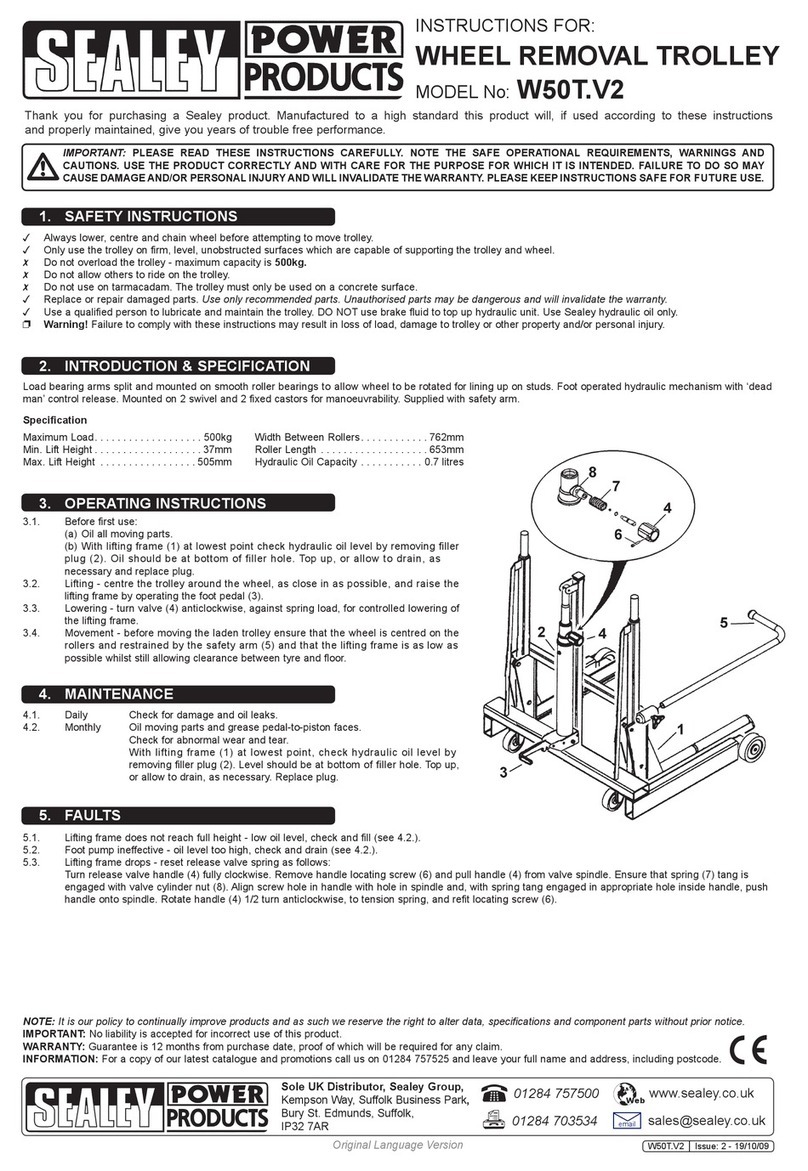

Steel tube chassis with four Ø100mm nylon castors. Pedal operated hydraulic lifting action with safety locking pin when under load. Composite

rollers cradle vehicle’s tyre and are capable of handling up to 240mm profile. Suitable for body shops, garages, showrooms or anywhere a

disabled vehicle needs moving on an even surface.

3. SPECIFICATION

Lifting capacity per Skate: ...............................................680kg

Maximum Opening: .......................................................540mm

Maximum Tyre Profile:...................................................240mm

Wheel Ø: ....................................................................Ø100mm

Weight (Each):...................................................................17kg

4. PREPARATION

4.1. Ensurethattheareawherethevehicleistobemovedisclearofanyobstructions.Theoorsurfaceshouldbesmoothandlevel.

4.2. Takenoteofanyfeaturesintheoorthatmaycatchtheskatewheelssuchasoormountedpoweranddatapoints,roomdivider

tracks,drainagefeatures,ordamagetotheoorsurface.

4.3. Enlistasufcientamountofpeopletomovethevehiclesafely.

8DO NOTattempttomovethevehicleintoanareawherethereisinsufcientspacetomanoeuvrethevehiclesafely.

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear safety

footwear

WS680.V2 Issue 1 06/11/18