Alfalaval GJ BB User manual

Other Alfalaval Cleaning Equipment manuals

Alfalaval

Alfalaval SaniMagnum User manual

Alfalaval

Alfalaval Emmie User manual

Alfalaval

Alfalaval GJ Tote Blast Station User manual

Alfalaval

Alfalaval Toftejorg SaniJet 20 User manual

Alfalaval

Alfalaval PlusClean User manual

Alfalaval

Alfalaval GJ A2 User manual

Alfalaval

Alfalaval Toftejorg TJ20G User manual

Alfalaval

Alfalaval Toftejorg TZ-89 User manual

Alfalaval

Alfalaval Emmie User manual

Alfalaval

Alfalaval GJ PF User manual

Alfalaval

Alfalaval Toftejorg MultiJet 65 User manual

Alfalaval

Alfalaval Toftejorg SaniJet 25 User manual

Alfalaval

Alfalaval Toftejorg SaniMidget SB User manual

Alfalaval

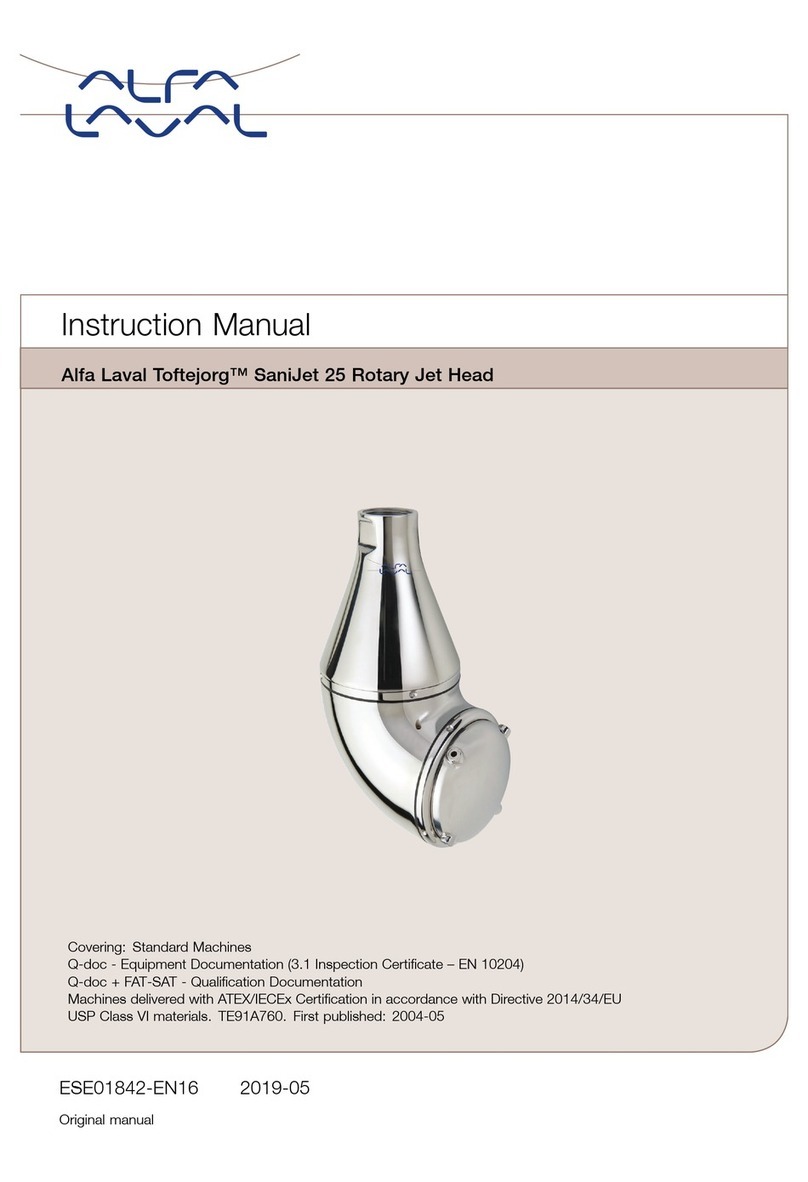

Alfalaval Toftejorg SaniJet 25 Operation instructions

Alfalaval

Alfalaval Gunclean Toftejorg 270FT Mark 1 User manual

Alfalaval

Alfalaval Toftejorg SaniJet 20 User manual

Alfalaval

Alfalaval Toftejorg User manual

Alfalaval

Alfalaval Gunclean Toftejorg TZ-75 User manual

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual