Ceiling Boom-Z

Datum / Date: 10.01.2017 | Änderungen vorbehalten | Subjects to change w thout not ce

TD

TD TD

TD –

––

–

65009

6500965009

65009

A

AA

A

DKZ

Assembly instructions

Assembly instructionsAssembly instructions

Assembly instructions

(original language German)

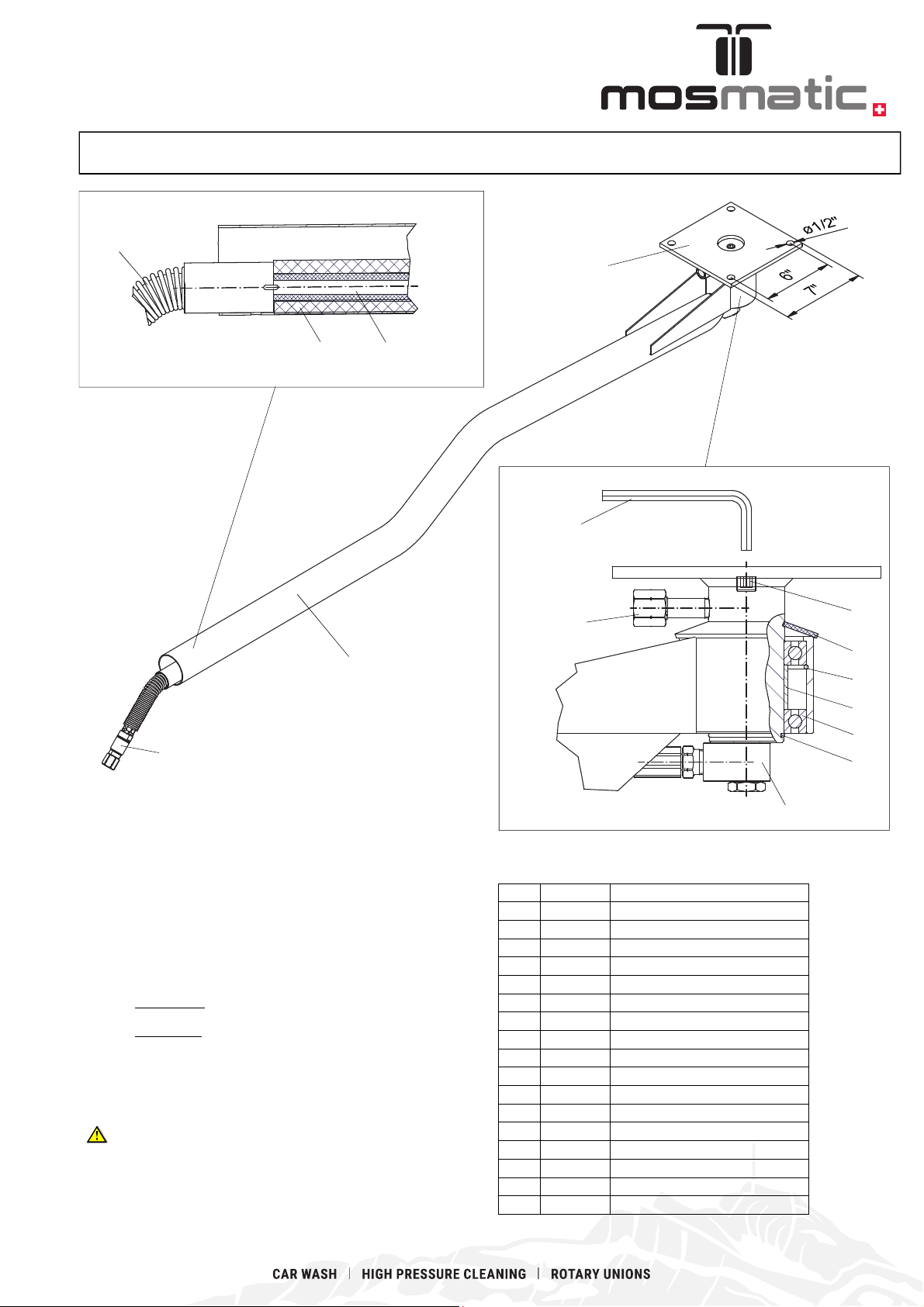

1. Install the ceiling boom (15) with the mounting plate (16) to the

concrete ceiling or to the steel beam.

2. Tightly fasten the high pressure hose or the high pressure pipe

connection coming from the high pressure pump, to either top

or side connection.

-for side inlet: mount adapter (1) on the side and plug top

inlet with stud bold (13).

-for top inlet: mount adapter (1) on top and plug side inlet

with stud bold (13).

3. Tightly fasten the high pressure hose with lance or brush to the

swivel (9).

We recommend checking swivel-connections once a year for

normal wear and tear.

No greasing required.

V-1346 (please order separately)

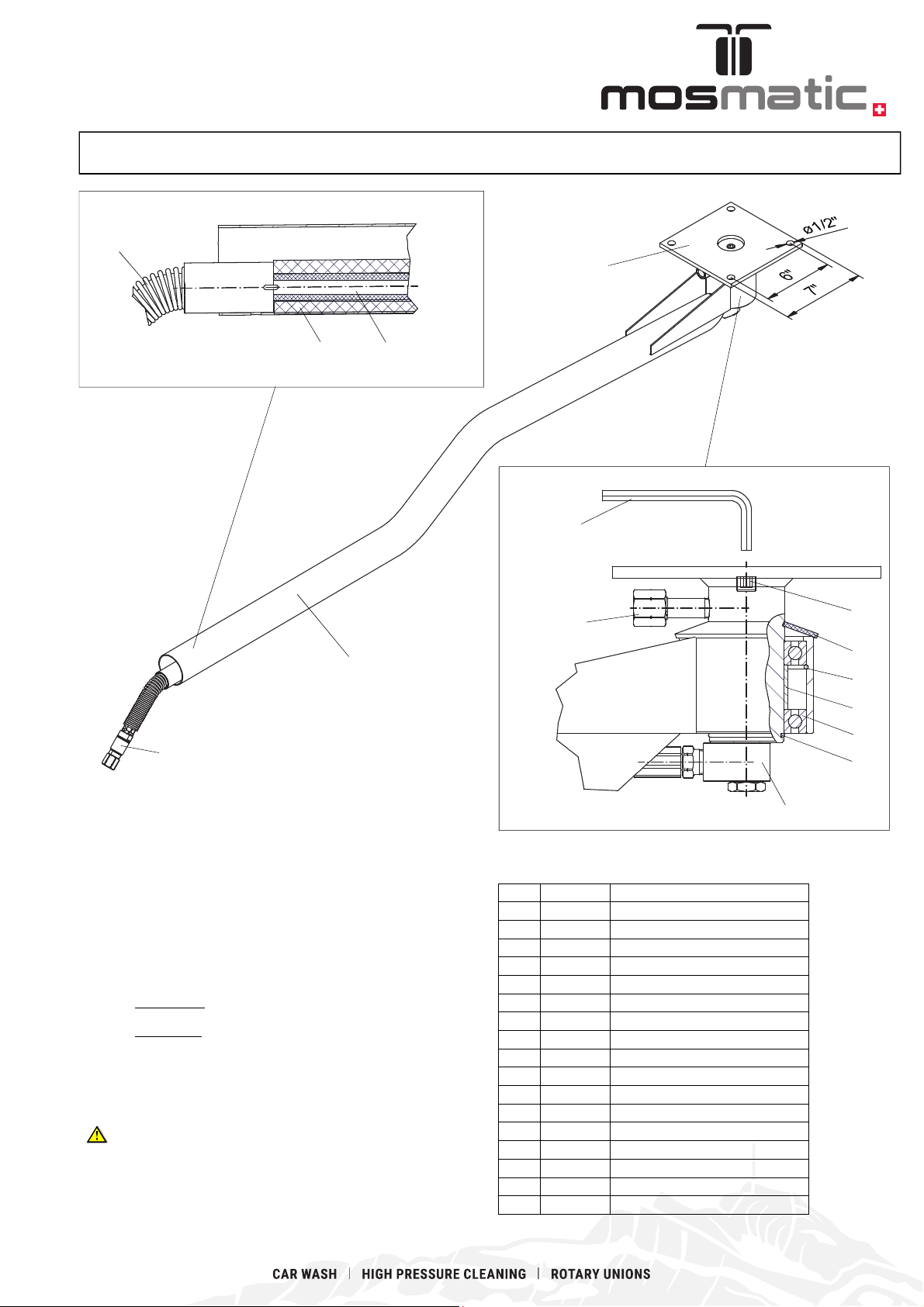

Pos. Art. Nr. Description

1 51.909 Adapter 3/8“NPT-F

2 37940 Rubber cone

3 38155 Retaining ring for shaft

4 37569 Spacer

5 12295 Ball bearings

6 37840 Retaining ring for shaft

7 40.019 Swivel 90°

8 40.502 Seal-Kit for Swivel 90° (*)

9 30.654 Swivel 3/8“NPT-F

10 901.858 Tension spring

11a 901.860 HP-Hose for arm L= 4‘ 9“

11b 901.861 HP-Hose for arm L= 5‘1“

11c 901.863 HP-Hose for arm L= 5‘ 5“

11d 901.864 HP-Hose for arm L= 5‘ 9“

12 900.275 Insulation hose, black

13 901.043 Stud bolt G1/4“kM

14 901.080 Hexagon socket wrench