SSI T Series User manual

INSTALLATION AND OPERATION MANUAL

T-SERIES ULTRASONIC CLEANING TANKS

REVISION REVISION DESCRIPTION DATE

A Released 02/25/2003

B ECN 1296 10/01/2014

C French warnings added 02/02/2016

D U dates 02/21/2017

CAUTION: Failure to install the equipment properly and follow

operations listed in this manual may result in equipment damage and/or

injury.

T-Series Manual. Rev D. Page 2 of 22.

TABLE OF CONTENTS

1. S ecial Safety Instructions......................................................................................................4-7

2. Introduction to Ultrasonics......................................................................................................8-9

3. Selection of Cleaning Liquids...................................................................................................10

4. Ultrasonic Cleaning Guidelines................................................................................................11

5. Descri tion................................................................................................................................12

6. S ecifications............................................................................................................................13

7. Initial Ins ection.......................................................................................................................14

8. Pre aration For Use..................................................................................................................15

9. Setu Procedure........................................................................................................................16

10. Ultrasonic Cleaning...................................................................................................................17

11. O tions......................................................................................................................................18

12. General Servicing......................................................................................................................19

13. Safety Summary........................................................................................................................21

14. Contact Information..................................................................................................................22

T-Series Manual. Rev D. Page 3 of 22.

SPECIAL SAFETY INSTRUCTIONS SECTION 1

CAUTION: READ BEFORE U ING THE EQUIPMENT.

Failure to respect all of the warnings in this manual could lead to severe and/or

fatal electrical shock.

DO NOT – o erate the unit without ro er electrical grounding.

DO NOT – use ada ter lug or cut off ground terminal of lug.

DO NOT – erform maintenance on the equi ment without un lugging ower cord and disconnecting transducers.

CAUTION: Ignoring any of the warnings in this manual could result in

personal injury and/or property damage.

ALWAYS – Consult ublished safety regulations and manufacturer's data sheet. Inform o erating ersonnel of

toxicity.

ALWAYS – Use ro er eye rotection, gloves, and rotective clothing when using equi ment.

DO NOT – Use flammable solvents in the equi ment.

DO NOT – O erate the equi ment with solvent in a water based cleaning solution. A solvent layer underneath the

water may su er-heat and ex el cleaning solution from the tank when the ultrasonics are first a lied.

DO NOT – Allow cleaning solution to come in contact with the human body. Use a rack, basket, or tongs to insert

or remove arts from the solution. Remove harmful va or/fumes from work area.

DO NOT – Place tank on a flammable or combustible surface.

T-Series Manual. Rev D. Page 4 of 22.

SPECIAL SAFETY INSTRUCTIONS SECTION 1

CAUTION: Ignoring any of the warnings in this manual could result in

equipment and/or parts damage.

ALWAYS – Fill a heated tank to ro er working height to minimize burnout or de-bonding.

USE ONLY – Cleaning solutions that are com atible with arts to be cleaned.

DO NOT – Use strong corrosive liquids such as strong acids or owerful caustics directly in the cleaning tank.

Stainless steel is attacked by some agents and the ultrasonics will accelerate corrosive action.

DO NOT – Boil the cleaning solution. Boiling may overheat and damage the transducers.

DO NOT – Dro or lace items to be cleaned directly on the bottom of the tank.

DO NOT – Energize the equi ment while the tank is em ty.

T-Series Manual. Rev D. Page 5 of 22.

SPECIAL SAFETY INSTRUCTIONS – FRENCH SECTION 1

PRUDENCE: LIRE AVANT D'UTILI ER L'APPAREIL.

Le non-respect de tous les avertissements dans ce manuel pourrait causer des

chocs électriques graves et/ou fatal.

NE PAS – Utiliser l'a areil sans mise à la terre électrique a ro riée.

NE PAS – Utiliser d'ada tateur ou de cou er la borne de rise de terre.

NE PAS – Effectuer la maintenance sur l'équi ement sans débrancher le cordon d'alimentation et de débrancher les

transducteurs.

PRUDENCE: Ignorer tout les avertissements dans ce manuel pourrait de

provoquer des blessures et/ou des propriété dommages.

TOUJOURS – Consulter les règlements de sécurité ubliés et la fiche technique du fabricant. Informer le ersonnel

d'ex loitation de la toxicité.

TOUJOURS – Utiliser une rotection oculaire a ro riée, des gants et des vêtements de rotection lors de

l'utilisation du matériel.

NE PAS – Utiliser de solvants inflammables dans l'équi ement.

NE PAS – Faire fonctionner l'équi ement avec un solvant dans une solution de nettoyage à base d'eau. Une couche

de solvant au-dessous de l'eau eut su er chaleur et d'ex ulser la solution de nettoyage à artir du réservoir lorsque

les ultrasons sont tout d'abord a liqués.

NE PAS – Laisser la solution de nettoyage à venir en contact avec le cor s humain. Utilisez un rack, anier, ou des

inces our insérer ou retirer des arties de la solution. Retirer nuisibles va eurs / fumées de la zone de travail.

NE PAS – Placer le réservoir sur une surface inflammable ou combustible.

T-Series Manual. Rev D. Page 6 of 22.

SPECIAL SAFETY INSTRUCTIONS – FRENCH SECTION 1

PRUDENCE: Ignorer toute les avertissements dans ce manuel pourrait causer

des équipements et/ou des pièces dommage

TOUJOURS – Rem lir un réservoir chauffé à la hauteur de travail adéquate our minimiser l'é uisement

rofessionnel ou décollement de chauffe.

UTILISATION SEULEMENT – Nettoyage solutions qui sont com atibles avec les ièces à nettoyer.

NE PAS – Utiliser de solides liquides corrosifs tels que des acides forts ou caustiques uissants directement dans le

réservoir de nettoyage. L'acier inoxydable est attaqué ar certains agents et les ultrasons va accélérer l'action

corrosive.

NE PAS – Faire bouillir la solution de nettoyage. Ébullition eut surchauffer et endommager les transducteurs.

NE PAS – Articles de chute ou de lacer à nettoyer directement sur le fond de la cuve

NE PAS – Dynamiser l'équi ement alors que le réservoir est vide.

T-Series Manual. Rev D. Page 7 of 22.

INTRODUCTION TO ULTRASONIC CLEANING SECTION 2

In recent years, ultrasonic energy has been harnessed to erform many tasks including cleaning for industry.

"Ultrasonic cleaning" is actually ultrasonic scrubbing. The rocess uses the cavitation of shock waves to create a

scrubbing action on any art introduced into a cleaning chamber.

An ultrasonic cleaning system consists of an electronic generator utilizing 60 cycles of alternating current and

transforming it into a higher frequency (HF) alternating current in the ultrasonic range. The generator is cou led to

one or several transducers in the cleaning chamber. The HF electrical energy from the generator out ut is converted

into mechanical energy inside the transducer elements. An ultrasonic transducer is a device that ex ands and

contracts when fed HF alternating current. The ex ansion-contraction frequency of the transducer element

corres onds to the alternating HF from the generator out ut current. The transducers are fastened to the chamber and

transfer ultrasonic motion to the tank walls and the liquid.

A sound wave in liquid has high ressure ahead and low ressure behind it. As the sound wave asses, the ressure

can reach a value below the liquid cohesive forces. This roduces numerous small em ty cavities in the liquid. Some

of these small cavities, or micro-bubbles, enter into resonance with the frequency of the sound. They start to wildly

oscillate and finally colla se, releasing strong shock waves. In a high-intensity cavitation field, bubbles im lode

millions of times er minute releasing owerful shock waves. The waves im inge against any submerged object in

the liquid. Cavitation shock waves are the tools behind the scrubbing action observed in ultrasonic cleaners.

Although many frequencies are roduced in an ultrasonic cleaning tank, there is a basic frequency corres onding to

the fundamental resonance between the generator and the transducer. The most common fundamental frequency for

ultrasonic cleaning falls between 20kHz and 60kHz. Frequencies below 20kHz may be more efficient cleaners due

to lower frequencies creating greater scrubbing effects. The roblem with frequencies below 20kHz are the annoying

audible subharmonics. Frequencies above 50kHz are generally used for cleaning small objects and orifices. Due to

shorter wave lengths, frequencies above 50kHz enable better enetration of acoustic energy in small o enings and

crevices. Higher frequencies, above 100kHz, have greater wave enetration. The issue with frequencies above

100kHz is the small resonant cavitation bubbles release far less energy at colla se time.

U er harmonics and subharmonics of the transducer main emission are always resent. In oorly designed

cleaners, subharmonics in the audible range can create environmental noise. Below are hysical and chemical

factors that influence the intensity of ultrasonic cavitation in liquids:

T-Series Manual. Rev D. Page 8 of 22.

INTRODUCTION TO ULTRASONIC CLEANING SECTION 2

TEMPERATURE

Increasing the tem erature increases the cavitation intensity until it reaches a maximum and then decreases. For

water, maximum cavitation is observed between 115°F and 140°F.

NATURE OF LIQUID

Water and aqueous solutions deliver more cavitational energy than organic solvents at equal acoustic energy density.

SURFACE TENSION

Liquids with a high surface tension (IE: water) deliver more cavitational energy than low surface tension solutions

(IE: organic solvents). Adding traces of soa to cavitating water could momentarily kill the cavitatonal energy more

than low surface tension solutions.

VISCOSITY

If everything else is equal, it is more difficult to cavitate high viscosity liquids or solutions.

VAPOR PRESSURE

Chemicals and liquids with high va or ressure (IE: at room tem erature) are more difficult to cavitate than low

va or ressure liquids (IE: mercury).

HYDROSTATIC-PRESSURE

It is easier to cavitate a liquid when reducing the hydrostatic ressure above the liquid surface. Reversely, an

increase in gas ressure ( ressurization) can momentarily decrease the cavitation intensity.

DISSOLVED GASES

The threshold of cavitation in a liquid de ends u on the small traces of dust or dissolved gases always resent. More

energy is needed to cavitate degassed than aerated water. Ultrasonics first degas (noiseless large air bubbles come to

the liquid surface) then roduce small cavitation bubbles oscillating in resonance before colla se (energy releasing

hase called va orous cavitation).

EXPOSURE TIME TO ULTRASOUND

Some transducers are driven to roduce short ulsed ultrasonic emissions. Measurements with ulses of varying

length revealed a time delay between the a lication of ultrasonic ower and the onset of cavitation. The longer a

liquid is ex osed to intense sound, the lower the threshold ressure at which cavitation occurs.

For the best ultrasonic cavitation, an a ro riate chemical is needed. Chemicals can range from standard alkaline to

a so histicated surface active com ound. Sonic Systems, Inc. has develo ed a number of such chemical additives.

T-Series Manual. Rev D. Page 9 of 22.

SELECTION OF CLEANING LIQUIDS SECTION 3

The selection of cleaning liquids is generally determined by the kind of soil to be removed and the material to be

cleaned. The cleaning solution used should act on the soil without attacking the art to be cleaned. Physical and

chemical ro erties of a cleaning solution are im ortant because the liquid transmitting the energy from the

transducers also artici ates in the cleaning rocess.

The cleaning solution aids in cleaning in two ways:

1. Mechanical action (cavitation).

2. Solvent action, hysical wetting or chemical attack on surface soil.

Recommendations for the most satisfactory solution in a articular ultrasonic a lication cannot safely be made

without considering the s ecific soil to be removed, the ty e of metal or material to be cleaned, and the subsequent

rocessing of the art following the cleaning stage. Other im ortant considerations in selecting a cleaning solution

include fire and health hazards, cost, and availability.

In selecting a s ecific ultrasonic cleaning solution, it is frequently quickest to begin with a solution that has roved

most satisfactory without ultrasonics. Generally, ultrasonics increase the cleaning effectiveness of the solution

ermitting a faster and more thorough cleaning.

T-Series Manual. Rev D. Page 10 of 22.

ULTRASONIC CLEANING GUIDELINES SECTION 4

The following suggestions aid the user in maximizing the ultrasonic cleaning ca abilities of the unit.

DEGASSING

Degassing is the removal of air tra ed in the cleaning solution. Air tra ed in the solution reduces the effectiveness

of ultrasonics. Air may become tra ed by adding/removing a work load, turbulating the solution such as a filtration

system or adding liquid to the tank. Degassing is accom lished by running the ultrasonics, heating the liquid or by

letting the solution remain static.

CHEMISTRY/SOAP

The right chemistry can greatly increase the effectiveness of ultrasonic cleaning. Es ecially hel ful, are surfactants

that reduce the surface tension of the solution. A reduction in surface tension allows for better ultrasonic cavitation.

The reduced surface tension gives better wet-ability of the arts. The increased wet-ability allows dirt to become

tra ed in the cleaning solution. Due to their chemical ro erties, some enzymatic detergents are much harder to

create cavitation and require a longer degas time. Enzymatics have low amounts of wetting agents that tra air in the

solution. In addition, enzymatics are ty ically recommended for use in low tem eratures not conducive for

cavitation. If using an enzymatic soa , the minimum amount s ecified on the label should be used and the degas

time should be increased to at least five minutes. Actual degas time will de end on chemistry/soa being used.

TEMPERATURE

The most effective tem erature range for ultrasonic cleaning is between 115º F and 140º F. For correct tem erature

selection of your s ecific solution, lease refer to the cleaning solution manufacturer’s recommendation.

WARNING: Before adding chemicals to the cleaning tanks, consult the special

safety instructions located in ECTION 1 of this manual.

T-Series Manual. Rev D. Page 11 of 22.

DESCRIPTION SECTION 6

A T-Series tank is one or more banks of transducers integrated into the bottom of welded stainless steel stand alone

tank. The tank is connected to a generator with coax cables. Sonic Systems offers these tanks in a variety of sizes.

The art numbers for tanks breaks down into the first letter being a “T” for T-Series. The next laceholder becomes

the number of transducer banks. The next laceholder becomes the nominal width of the tank in increments of 4

inches. The next laceholder becomes the nominal length of the tank in increments of 4 inches. The art number is

then followed by a dash and then the tank height in inches. The art number is then followed by a dash and then the

o erational frequency in kHz. A sam le art number would be T234-12-27. The breakdown of the sam le serial

number is a T-Series tank, containing two transducer banks, a nominal width of 12 inches, a nominal length of 16

inches, a nominal de th of 12 inches and an o erational frequency of 27 kHz. Custom sizes can also be designated

as T2XX-27. This could be the same tank configuration, only there is no sizing designated. It is also ossible for a

custom tank to be designated a unique model number.

T-Series Manual. Rev D. Page 12 of 22.

SPECIFICATIONS SECTION 7

O erating Tem erature 0 – 45°C Ambient 10 to 90% humidity, non-condensing

Power Requirements Power su lied by ultrasonic generator(s)

O erational Frequency 27 or 40kHz nominal frequency de ending on model

Nema Rating Nema 1, IP10

Each system is identified by serial number on tag the back anel of the unit. Both the model number and the serial

number are required in any corres ondence with the com any.

POWER REQUIREMENTS

The transducer banks of the ultrasonic cleaning tank are solely owered by Sonic Systems ultrasonic generators.

Failure to do this could resent injury to ersonnel or damage to equi ment.

T-Series Manual. Rev D. Page 13 of 22.

INITIAL INSPECTION SECTION 8

MECHANICAL CHECK

The system you have received was thoroughly tested before shi ment. It has been rotected as com letely as

ossible from the rigors of trans ortation. However, since it is im ossible to insure com lete absence of in transit

damage, a thorough ins ection of the unit should be made rior to use.

1. Before un acking or uncrating, check the external conditions of the carton or crate and note any signs of

rough handling.

2. After removing the unit from its ack, ins ect the external surfaces for dents, cuts, breakage and other signs

of damage. Check all external fittings to see that they have not loosened.

*NOTIFY THE CARRIER AND THE MANUFACTURER IMMEDIATELY OF ANY DAMAGE.

3. If damage to the shi ing carton is evident, request the carrier be resent when the generator is un acked.

4. Check the equi ment for damage and ins ect the cabinet and anel for dents and scratches.

CLAIM FOR DAMAGE

If the 2700/4000 Series is mechanically damaged or fails to meet s ecification u on recei t, notify SSI or our

re resentative immediately. Retain the shi ing carton and acking material for the carrier's ins ection as well as for

subsequent use in returning the unit if necessary.

PACKAGING FOR RESHIPMENT

1. Whenever ossible, use the original shi ing carton and acking material for reshi ment.

2. If the original acking material is not available, wra the instrument in heavy a er or lastic.

3. Use a strong shi ing container. If a cardboard carton is used, it should be at least 200 lbs. test material.

4. Use shock absorbing material around all sides of the instrument to rovide a firm cushion and to revent

movement inside the container. Allow for a minimum of two inches between the instrument and the

container wall on each side.

5. Protect the unit by means of cardboard s acers inserted between the system and the shi ing carton. Make

sure the instrument cannot move in the container during shi ment.

6. Seal the carton with a good grade of shi ing ta e.

7. Mark the container: FRAGILE, ELECTRONIC IN TRUMENT.

T-Series Manual. Rev D. Page 14 of 22.

PREPARATION FOR USE SECTION 9

MOVEMENT OF CLEANING TANK

Never trans ort a cleaning tank while it contains liquid. Com letely drain tank before moving. Ultrasonic cleaning

tanks can be quite heavy. It is recommended to trans ort the tank into the working osition using the original

shi ing ackage and trans orting with a allet jack or forklift to the working location. Once in osition, the tank

may be slid from the shi ing ackage. When lifting a cleaning tank it is recommended to su ort the tank from the

bottom or from tank flanges (if equi ed).

T-Series Manual. Rev D. Page 15 of 22.

SET-UP PROCEDURE SECTION 10

It is always necessary to match the generator to the load in order to achieve maximum efficiency and the most

desirable system o eration. SSI always matches the generator to the load at the factory for o timal unit efficiency.

To ensure correct set-u , follow the "CONNECTION AND OPERATION" instructions furnished with the

associated generator. Further information on transducer matching or available transducers can be obtained by

contacting SONIC SYSTEMS, INC. ENGINEERING DEPARTMENT.

WARNING: Ensure the generator is located in an area where cleaning

solution from the tank can not splash onto it.

CONNECTION TO GENERATOR

Sonic Systems transducers must be used only with Sonic Systems generators. The generators are connected to the

transducers via a coaxial cable. The coaxial cable has a connector on the generator end and is either hardwired or has

a connector on the transducer end. Systems with multi le coaxial cables are numbered and then hooked u to their

res ective terminals on the generator and the transducer.

WARNING: Failure to use the generators in any manner other than specified

can result in injury to personnel or damage to the equipment

UTILITY HOOKUPS

All Sonic Systems cleaning tanks come equi ed with a drain fitting. If the unit is not equi ed with an o tional

drain valve, add one at this time and connect it to a drain line. Standard drain line size is ¾”NPT stainless steel

female i e thread. Some units are equi ed with an o tional ½”NPT stainless steel female fill ort. If your unit has

the o tional fill ort, tie the ort to a water source.

CONNECTION TO MAINS POWER

Always check voltage and am ere rating of heaters and/or filtration system before connecting to a rece tacle or hard

wiring. A higher voltage and/or am eres than rated can cause an electrical fire if not ro erly installed. If there are

questions on installation, electrical information is available through Sonic Systems, Inc. Engineering De artment.

T-Series Manual. Rev D. Page 16 of 22.

ULTRASONIC CLEANING SECTION 11

Before cleaning commences, the tank must be filled with a water/detergent solution. The solution requires degassing

for maximum cleaning efficiency. To do this the o erator should roceed as follows:

1. Fill the tank to the desired level.

2. Add a detergent to the water.

3. Turn the generator switch on.

4. Run the tank for 5 to 10 minutes to degas the water for maximum cleaning efficiency.

U on com letion of the above fill and degassing o eration, the unit is ready for normal use. All that is required is to

immerse the rack or basket load of ware in the tank, and turn the generator switch on.

When the detergent solution becomes heavily contaminated, drain the tank and refill with a clean solution. Drain the

tank at the end of the cycle. Draining the tank consists of merely o ening of the drain valve. Residue may be rinsed

from the bottom by rinsing off with warm water.

T-Series Manual. Rev D. Page 17 of 22.

OPTIONS SECTION 12

Sonic Systems cleaning tanks are available with many o tions. Below are listings for some of the available o tions.

STRIP HEATER

The heaters are located inside the tank wra . Set the thermostat to the desired tem erature and turn on the main

ower switch. The unit now heats the liquid and maintains the set tem erature.

IMMERSION HEATER

The heater is located on the back side of the tank. The heater thermostat is located inside the heater housing. On the

bottom of the housing is the electrical cord to be lugged into a wall rece tacle. Set the thermostat to the desired

tem erature. The unit heats the liquid and maintains the set tem erature.

FILTRATION SYSTEM

The filtration system consists of a um , a 10" filter housing, and a ressure gauge. Re lace filters with only the

same size and ty e as marked on the filter housing. The ressure gauge is an indicator when the filter element needs

re lacement. When the ressure rises 5 si above normal o erating ressure, the element should be re laced. To

o erate the system, lug the electrical cord located on the switch housing in the front of the tank into a wall

rece tacle or hard wire into a disconnect. To o erate the filtration system, turn "ON" the um switch.

WARNING: As with ultrasonic operation, heater and filtration options require

a certain liquid level be maintained in order to prevent injury to personnel or

damage to the equipment.

T-Series Manual. Rev D. Page 18 of 22.

GENERAL SERVICING SECTION 13

CAUTION: Disconnect power cord before servicing. All parts of the circuit

present shock hazards while power cord is connected.

MAINTENANCE

The SSI Ultra-braze is a lead zirconate com osite (sandwich) transducer assembly. It is ruggedly designed and

constructed to rovide high energy conversion and reliable erformance. The assembly consists of a nose iece

nickel-brazed to the tank bottom, a cou ler disc (center electrode), bolt and insulators, and a com ression block. In

normal use, the transducer will never require service.

TANK BOTTOM EROSION

The radiating surface of the tank, although made of heavy gauge, heavy quality stainless steel, eventually becomes

somewhat itted due to the ultrasonic action. This is normal in high ower ultrasonic equi ment and no cause for

concern.

TANK RUSTING

The tanks are fabricated with stainless steel and are resistant to rust. When iron work is rocessed through the tank

and free iron makes direct contact with the tank walls or bottom over a eriod of time, s ots of rust may be induced

on the stainless surface. If this should become a roblem, rust may be removed and the surface assivated by the

following technique:

1. Clean any oil film from the surface.

2. Add a 1/3 solution of commercial grade nitric acid.

3. Let set for a roximately 20 minutes.

T-Series Manual. Rev D. Page 19 of 22.

TROUBLESHOOTING GUIDE SECTION 14

SYMPTOMS PROBABLE CAUSE RECOMMENDATIONS

No ultrasonic

ower

1. Problem with generator.

2. Faulty coax cable.

3. Problem with transducers.

1. Check generator.

2. Check cable for o en or short circuit.

3. Check transducers for o en or short circuit.

Reduced cleaning

ower

1. Im ro er cleaning solution.

2. Solution not degassed.

3. Solution not u to tem erature.

4. Parts basket is not ro er design.

5. Im ro er loading of arts.

1. Use recommended cleaning solutions.

2. Run ultrasonics to hel degas solution.

3. O erate cleaning solution between

120 – 140°F.

4. Restrictive access baskets or lastic baskets can

reduce the cavitational field. Use a large o en

weave basket for o timal erformance.

5. Im ro er orientation or stacking of arts can

lead to a reduced ultrasonic field.

T-Series Manual. Rev D. Page 20 of 22.

Table of contents

Popular Cleaning Equipment manuals by other brands

Numatic

Numatic TGB 8572/200T Original instructions

Ryobi

Ryobi EXPAND-IT RYSWP25 Operator's manual

HURAKAN

HURAKAN HKN-GP1000 instruction manual

Tekmar

Tekmar Target TG-300 Instructions and care

Getinge

Getinge Castle 7900 installation instructions

Nilfisk-Advance

Nilfisk-Advance Liberty SC50 Instructions for use

Dynaset

Dynaset KPL 270-200-1250x8 Operation instructions

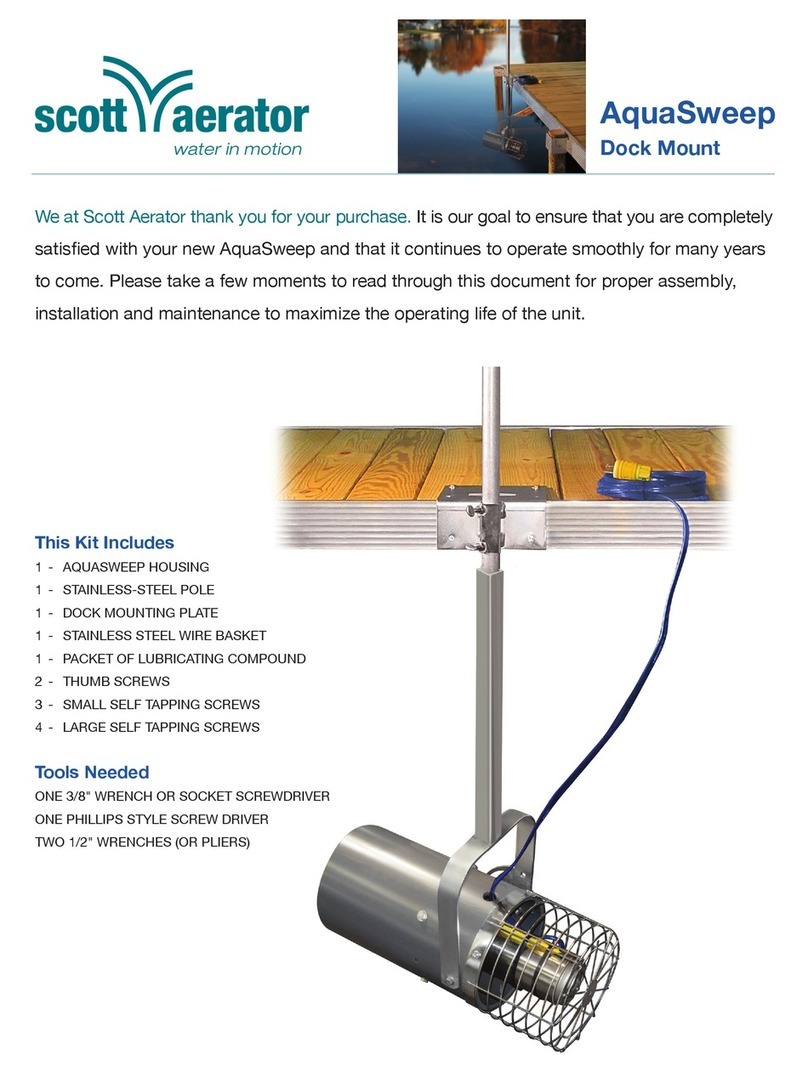

Scott Aerator

Scott Aerator AquaSweep 15000 quick start guide

Fantom Professional

Fantom Professional PROMAX 600 CM2 Assembly

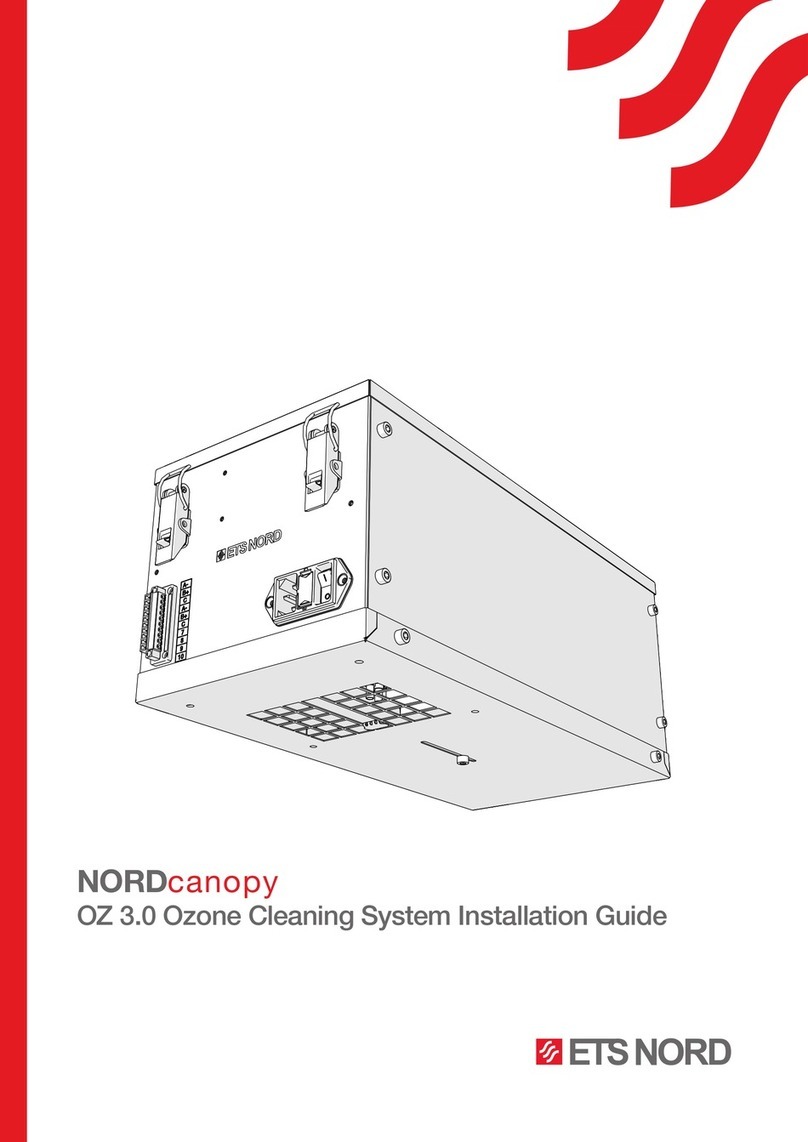

ETS NORD

ETS NORD NORDcanopy OZ 3.0 installation guide

Flowplant

Flowplant DTK500 Original instructions

Ghibli & Wirbel

Ghibli & Wirbel SB 143 L08 Use and maintenance