Alfalaval IM 15 User manual

Covering:

Standardmachines

MachinesdeliveredwithATEX/IECExCertificationinaccordancewithDirective204/34/EU

ESE0284-EN02022-

Originalmanual

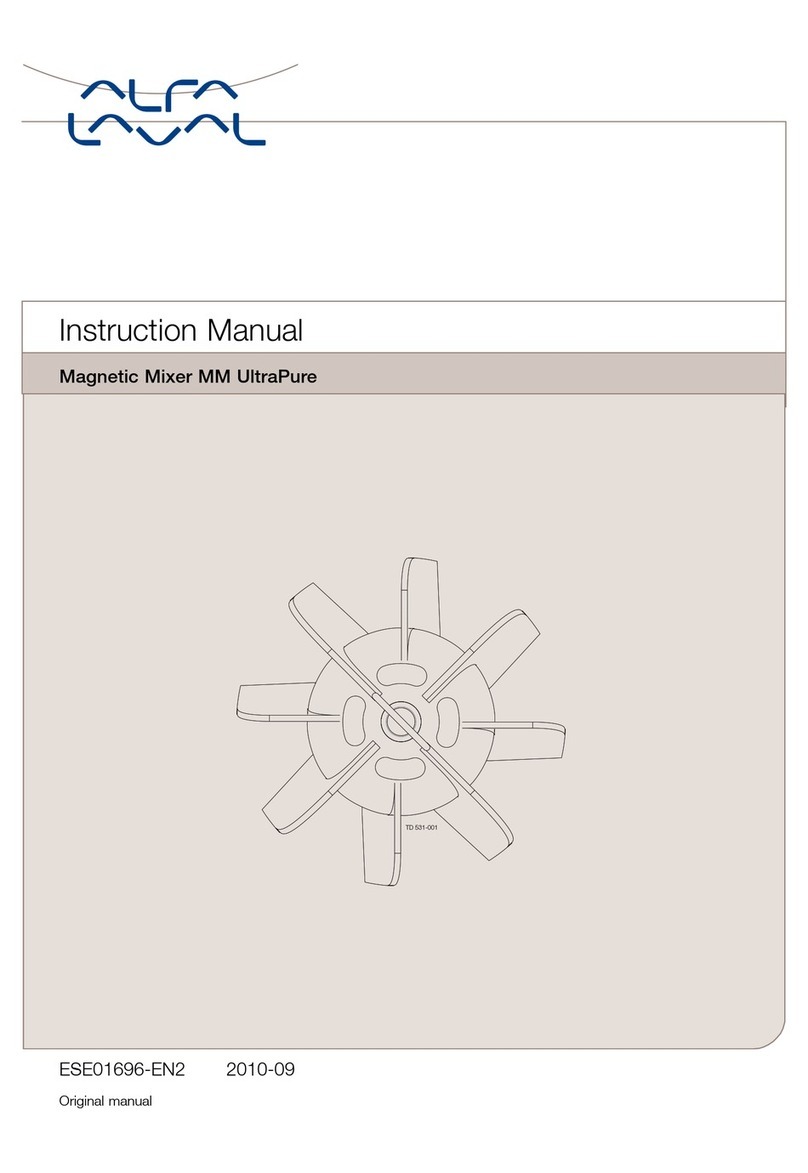

InstructionManual

AlfaLavalIM15RotaryJetMixer

Tableofcontents

Theinformationhereiniscorrectatthetimeofissuebutmaybesubjecttochangewithoutpriornotice

1.DeclarationsofConformity.................................................................5

2.Safety..........................................................................................7

2..Importantinformation.............................................................................7

2.2.Warningsigns.....................................................................................7

3.Introduction..................................................................................8

3..Introduction........................................................................................8

3.2.Intendeduse......................................................................................8

3.3.Patentsandtrademarks.........................................................................9

3.4.Marking............................................................................................9

3.5.ATEX/IECExmarking.............................................................................0

3.6.ATEX/IECExtemperatureclassandcode......................................................

4.Installation....................................................................................13

4..Generaldescription...............................................................................3

4.2.Functioning........................................................................................4

4.3.Generalsafetyandinstallationinstructions.....................................................6

4.4.SpecificconditionsforsafeuseinaccordancewithATEX/IECExcertification..............8

5.Operation.....................................................................................22

5..Normaloperation.................................................................................22

5.2.Safetyprecautions................................................................................23

6.Maintenance..................................................................................24

6..Preventivemaintenance..........................................................................24

6.2.ServiceandrepairofATEX/IECExcertifiedmachines.........................................25

6.3.Topassembly.....................................................................................26

6.4.Bottomassembly.................................................................................28

6.5.Hubsubassembly................................................................................30

6.6.Stemsubassembly...............................................................................32

6.7.Gearsubassembly................................................................................34

6.8.Replacementofcollarbushes...................................................................36

6.9.Replacementofballraces.......................................................................38

6.0.Replacementofmaincollars....................................................................40

7.Troubleshootingguide.....................................................................42

8.Technicaldata................................................................................44

8..IM5RotaryJetMixerwith2nozzles..........................................................44

8.2.IM5RotaryJetMixerwith4nozzles..........................................................45

8.3.Performancedata.................................................................................46

9.Productprogramme.........................................................................47

9..StandardconfigurationforAlfaLavalIM5RotaryJetMixer................................47

9.2.Availableadd-ons.................................................................................47

10.Partslistsanddrawings,servicekitsandtools..........................................48

0..Partsdrawingandlistofparts-IM5with2nozzles........................................48

0.2.Partsdrawingandlistofparts-IM5with4nozzles........................................50

0.3.Serviceintervals...................................................................................52

0.4.Tools...............................................................................................52

3

Tableofcontents

Theinformationhereiniscorrectatthetimeofissuebutmaybesubjecttochangewithoutpriornotice

11.Generalinformation.........................................................................53

..Service&repair...................................................................................53

.2.Howtoorderspareparts........................................................................53

.3.HowtocontactAlfaLavalKoldingA/S.........................................................53

4

1DeclarationsofConformity

EU EU

EUDeclaration Declaration

Declarationof of

ofConformity Conformity

Conformity

TheDesignatedCompany

AlfaLavalKoldingA/S,Albuen3,DK-6000Kolding,Denmark,+4579322200

Companyname,addressandphonenumber

Herebydeclarethat

RotaryJetMixer

Designation

IM5

Type

Serialnumberfrom209-000to2030-99999

isinconformitywiththefollowingdirectiveswithamendments:

-MachineryDirective2006/42/EC

-ATEXDirective204/34/EUandthefollowingharmonizedstandardsareused:

ENISO80079-3:201,ENISO80079-37:201,DS/ENISO/IEC80079-34:2011,AnnexA,paragraphA.5.3Rotatingmachines

ECTypeExaminationCertificateno.Baseefa0ATEX088XandIECExBAS9.0087X

IIGExhIIC85ºC...75ºCGa

Marking:IIDExhIIICT85ºC...T40ºCDa

TheQAN(QualityAssuranceNotification)iscarriedoutbySGSFimkoOy,Särkiniementie3,Helsinki00211,Finland.NotifiedBodyNo.0598.

EUTypeExaminationCertificationiscarriedoutbySGSFimkoOy,Särkiniementie3,Helsinki00211,Finland.NotifiedBodyno.0598.

IECExCertificateofConformityiscarriedoutbyBaseefaLtd.,RockheadBusinessPark,StadenLane,Buxton,DerbyshireSK179RZ,United

Kingdom.IECExAcceptedCertificationBody(ExCB).

Thepersonauthorisedtocompilethetechnicalfileisthesignerofthisdocument.

GlobalProductQualityManagerLarsKruseAndersen

TitleName

Kolding,Denmark2022––08

PlaceDate(YYYY-MM-DD)Signature

This Declaration of Conformity replaces Declaration of Conformity dated 20 9-06-0

5

1DeclarationsofConformity

UK UK

UKDeclaration Declaration

Declarationof of

ofConformity Conformity

Conformity

TheDesignatedCompany

AlfaLavalKoldingA/S,Albuen3,DK-6000Kolding,Denmark,+4579322200

Companyname,addressandphonenumber

Herebydeclarethat

RotaryJetMixer

Designation

IM5

Type

Serialnumberfrom209-000to2030-99999

isinconformitywiththefollowingdirectiveswithamendments:

-TheSupplyofMachinery(Safety)Regulations2008

-TheEquipmentandProtectiveSystemsIntendedforuseinPotentiallyExplosiveAtmospheresRegulations206

ENISO80079-3:201,ENISO80079-37:201,DS/ENISO/IEC80079-34:2011,AnnexA,paragraphA.5.3Rotatingmachines

UKEx Type Examination Certificate no. BAS22UKEX007 X and IECEx BAS 9.0087X

IIGExhIIC85ºC...75ºCGa

Marking:IIDExhIIICT85ºC...T40ºCDa

TheUKQAN(QualityAssuranceNotification)iscarriedoutbyBaseefaLtd.,RockheadBuisnessPark,StadenLane,Buxton,DerbyshireSK17

9RZ,UnitedKingdom,NotifiedBodyNo.1180.

UKTypeExaminationCertificationiscarriedoutbyBaseefaLtd.,RockheadBuisnessPark,StadenLane,Buxton,DerbyshireSK179RZ,

UnitedKingdom,NotifiedBodyNo.1180.

IECExCertificateofConformityiscarriedoutbyBaseefaLtd.,RockheadBusinessPark,StadenLane,Buxton,DerbyshireSK179RZ,United

Kingdom.IECExAcceptedCertificationBody(ExCB).

Signedonbehalfof:AlfaLavalKoldingA/S

GlobalProductQualityManagerLarsKruseAndersen

TitleName

Kolding,Denmark2022––08

PlaceDate(YYYY-MM-DD)Signature

DoCRevison_0_2022

6

2Safety

Unsafepracticesandotherimportantinformationareemphasizedinthismanual.

Warningsareemphasizedbymeansofspecialsigns.

Always Always

Alwaysread read

readthe the

themanual manual

manualbefore before

beforeusing using

usingthe the

themixer! mixer!

mixer!

2.1Importantinformation

W W

WARNING ARNING

ARNING

Indicatesthatspecialproceduresmustbefollowedtoavoidseriouspersonalinjury.

CAUTION CAUTION

CAUTION

Indicatesthatspecialproceduresmustbefollowedtoavoiddamagetothemixer.

NOTE NOTE

NOTE

Indicatesimportantinformationtosimplifyorclarifyprocedures.

2.2Warningsigns

Generalwarning:

ATEX/IECExwarning:

7

3Introduction

RotaryJetMixerIM15

3.1Introduction

ThismanualhasbeenpreparedasaguideforthepersonswhowillbeoperatingandmaintainingyourAlfaLavalIM5

RotaryJetMixer.Thekeytolonglifeforyourmixerwillalwaysbeasystemofcarefullyplannedmaintenanceprocedures;

youwillappreciatethatamixerwhichhasaroughjobtodowillneedmorefrequentattentionthanoneworkingin

idealconditions.

Note Note

Note:GetthebestandmosteconomicalperformancefromyourRotaryJetMixer.Insufficientpreventivemaintenance

meanspoorperformance,unscheduledstops,shorterlifetimeandextracosts.Goodpreventivemaintenanceonthe

contrarymeansgoodperformance,nounscheduledstopsandsuperiortotaleconomy.

Youwillfindtheinformationcontainedinthismanualsimpletofollow,butshouldyourequirefurtherassistance,ourTechnical

Departmentwillbepleasedtohelpyou.Pleasequotethetypeandserialnumberwithallyourenquiries;thiswillhelpusto

helpyou.Thetypeandserialnumberareplacedonthegearhouseofthemixer.

Note: Note:

Note:Theillustrationsandspecificationscontainedinthismanualwereeffectiveatthedateofprinting.However,as

continuousimprovementsareourpolicy,wereservetherighttoalterormodifyanyunitspecificationonanyproduct

withoutpriornoticeoranyobligation.

TheEnglishversionoftheinstructionmanualistheoriginalmanual.Wemakereservationsinregardtopossiblemistranslationsin

languageversionsoftheinstructionmanual.Incaseofdoubt,theEnglishversionoftheinstructionmanualapplies.

Important Important

Important

information: information:

information:Beforeinstallingthemachineandsettingitintooperation,carefullyreadtheGeneralSafetyand

InstallationInstructions(page6)andthespecialconditionsforsafeuseinaccordancewithATEX/IECEx

directive204/34/EU(page8)andtakeallnecessaryprecautionsaccordingtoyourapplicationand

localregulations.

3.2Intendeduse

Itistobeverifiedbytheend-user:

-thattherotaryjetmixerisinconformitywithrespecttotank,vesselorcontainersizeinwhichitwillbeused.

-thattheconstructionmaterials(bothmetallicandnon-metallic)arecompatibilitywithproduct,flushingmedia,cleaning

media,temperaturesandpressureundertheintendeduse.

Therotaryjetmixerisintendedforuseinclosedtank,vesselorcontainer.Ifusedinopenenvironmentsee4.3Generalsafety

andinstallationinstructions(page6).

8

3Introduction

RotaryJetMixerIM15

3.3Patentsandtrademarks

ThisInstructionManualispublishedbyAlfaLavalKoldingA/Swithoutanywarranty.Improvementsandchangestothis

InstructionManualmayatanytimebemadebyAlfaLavalKoldingA/Swithoutpriornotice.Suchchangeswill,however,

beincorporatedinneweditionsofthisInstructionManual.

AlfaLavalKoldingA/S.Allrightsreserved.

AlfaLavalIM5RotaryJetMixerproducthaspatentsintheEPOmemberstatesandinothercountries.TheAlfaLavallogotype

isatrademarkoraregisteredtrademarkofAlfaLavalCorporateAB.Otherproductsorcompanynamesmentionedhereinmay

bethetrademarksoftheirrespectiveowners.Anyrightsnotexpresslygrantedhereinarereserved.

3.4Marking

AlfaLavalRotaryJetMixersaremarkedtoallowforrecognitionoftypeofmachine,machinename,serialnumberandmanufac-

turingaddress.Themarkingisplacedonthegearhouseofthemixer.

Serial Serial

Serialnumber number

numberexplanation explanation

explanation

Machinessuppliedwithorwithoutstandarddocumentation:

yyyy-xxxxx:serialnumber

yyyy:year

xxxxx:5digitsequentialnumber

9

3Introduction

RotaryJetMixerIM15

3.5ATEX/IECExmarking

TheAlfaLavalIM5RotaryJetMixeriscertifiedascategoryIcomponent.TheATEXcertificationiscarriedoutbytheNotified

BodySGSFimkoOy,whohasissuedthecertificateno.Baseefa0ATEX088X.

TheIECExcertificationiscarriedoutbytheCertificationBodySGSBaseefaLtd.,whohasissuedthecertificateno.IECExBAS

9.0087X.

Note Note

Note

Explosionprotectiontypeisconstructionalsafety“c”.

ThemarkingontheATEX/IECExcertifiedAlfaLavalIM5RotaryJetMixer5isasfollows(forinformationonmarkingposition

seesection3.Introduction):

Serial Serial

Serialnumber number

numberexplanation explanation

explanation

Machinessuppliedwithorwithoutstandarddocumentation:

yyyy-xxxxx:serialnumber

yyyy:year

xxxxx:5digitsequentialnumber

10

3Introduction

RotaryJetMixerIM15

3.6ATEX/IECExtemperatureclassandcode

Themaximumsurfacetemperaturedependsmainlyonoperatingconditionswhicharethetemperatureofthecleaning/mixing

fluidandtheambienttemperature.

Gr Gr

Group oup

oupII II

IIEPL EPL

EPLGa Ga

Ga

Thegastemperatureclassiscorrectedwithasafetymarginof80%duetoarequirementforGroupllEPLGaequipment.

Thegastemperatureclassdependsonthecleaning/mixingfluidtemperatureortheambienttemperature,whicheverofthe

twoisthehighest.

Tablefordeterminingtemperatureclass(gasatmospheres)

Gas

Temperatureclass

Cleaning/mixing

fluidtemperature,

Tp(°C)

Ambienttemperature,

Tamb(°C)

85°C(T6)≤+68°C≤+68°C

00°C(T5)≤+80°C≤+80°C

35°C(T4)≤+08°C≤+08°C

75°C≤+40°C≤+40°C

Gr Gr

Group oup

oupIII III

IIIEPL EPL

EPLDa Da

Da

Thedusttemperatureclassdependsonthecleaning/mixingfluidtemperatureortheambienttemperature,whicheverofthe

twoisthehighest.

Nodustlayerisconsidered.

Tablefordeterminingtemperatureclass(dustatmospheres)

Dust

Temperaturecode

Cleaning/Mixing

fluidtemperature,

Tp(°C)

Ambienttemperature,

Tamb(°C)

T85°C≤+85°C≤+85°C

T00°C≤+00°C≤+00°C

T35°C≤+35°C≤+35°C

T40°C≤+40°C≤+40°C

Exampleofgasclassdetermination

Cleaning/mixingfluidtemperatureis67°Candambienttemperatureis75°C.

Gasclass=T5

ATEX/IECExmarkingontheequipment:

IIGExhIIC85°C…75°CGa

IIDExhIIICT85°C…T40°CDa

11

.

12

4Installation

RotaryJetMixerIM15

4.1Generaldescription

TheAlfaLavalIM5RotaryJetMixerisamediadrivenandmedialubricatedtank/reactormixer.Allmaterialsareselectedfor

contactwithfood,andthemachineisself-cleaningi.e.allinternalandexternalsurfacesarecleaned.

ForuseinexplosivehazardzonestheAlfaLavalIM5RotaryJetMixerATEX/IECExversioncanbeused,provideditis

installedaccordingtosafetyinstructionsinlocalregulations.

The The

TheRotary Rotary

RotaryJet Jet

Jet

Mixing Mixing

Mixingtechnology technology

technology

T T

Traditional raditional

raditional

Mixing Mixing

Mixingtechnology technology

technology

RoundpumpingPropellermixing

A=RotaryJetMixerA=Liquidfeed

B=GasB=Product

C=Product

D=Liquidfeed

13

4Installation

RotaryJetMixerIM15

4.2Functioning

TheAlfaLavalIM5RotaryJetMixerisplacedinsidethetank/reactorundertheliquidsurfaceoftheliquidvolumetobemixed.

Themixeriscombinedwithanexternalrecirculationloop.Thefluidofthetank/reactorisrecirculatedthroughthisloopand

reintroducedinthetank/reactorthroughtheAlfaLavalIM5RotaryJetMixer.Themorefluidbeingrecirculated,the

moreeffectivemixingisobtained.

Themixershouldbeplacedinthecentreofthefluidtobemixed.Minimum½mundertheliquidsurface.

A:normalliquidlevelB:PossibleliquidorpowdersupplyC:Possiblegassupply

Theflowoffluidtobemixedpassesfromthetankintothemixerthroughaturbine,whichissetintorotation.Theturbinerotation

isthroughagearboxtransformedintoacombinedhorizontalrotationofthemixerbodyandaverticalrotationofthenozzles.

Machines Machines

Machineswith with

with2 2

2nozzles nozzles

nozzles

Thecombinedmotionofthemixerbodyandthenozzlesensuresafullyindexedtankmixing.After¼revolutionsoftheHub

withnozzles(03/4revolutionsofthemixerbody),onecoarsemovementpatternhasbeenestablishedwhichwhenprojected

onthetanksurfacelooksasFigure.Duringthefollowingcycles,thispatternisrepeated3times,eachofwhichisdisplaced

¼ofthemeshinthepattern.Afteratotalof45revolutionsoftheHubwithnozzles(43revolutionsofthemachinebody),a

complete“mixingpattern”hasbeenlaidout,andthefirstpatternisrepeated.Thisfeatureeliminates"deadvolumes"inthe

tank,andmakestheAlfaLavalIM5RotaryJetMixerveryefficientautomatictankcleaningmachine,whenthetankisempty.

FirstcycleSecondcycleThirdcycleForthcycle

14

4Installation

RotaryJetMixerIM15

Machines Machines

Machineswith with

with4 4

4nozzles nozzles

nozzles

Thecombinedmotionofthemixerbodyandthenozzlesensuresafullyindexedtankmixing.After55/8revolutionsofhubwith

nozzles(55/8revolutionsofthemixerbody),onecoarsemovementpatternhasbeenestablishedwhichwhenprojectedon

thetanksurfacelooksasfigure.Duringthefollowingcycles,thispatternisrepeated7times,eachofwhichisdisplaced/8

ofthemeshinthepattern.Afteratotalof45revolutionsofthehubwithnozzles(43revolutionsofthemixerbody),acomplete

mixingpatternhasbeenestablished,andthefirstpatternisrepeated.Thisfeatureeliminates"deadvolumes"inthetank,and

makestheAlfaLavalIM5RotaryJetMixeraveryefficientautomatictankcleaningmachine,whenthetankisempty.

Figure:FirstcycleFigure2:Fullpattern

General General

Generalfor for

forboth both

both2 2

2and and

and4 4

4nozzle nozzle

nozzlemachines machines

machines

Thespeedofrotationoftheturbinedependsontheflowratethroughthemixer.Thehighertheflowrateis,thehigherthe

speedofrotationwillbe.InordertocontroltheRPMofthemixerforawiderangeofflowrates,theefficiencyoftheturbine

canbechangedbyusing00%or0%turbine/inletguide.

Apartfromthejetflowthroughthenozzles,fluidisleakingthroughthetopofthemixer,atthehubandthroughthebottom

cover.Theleakagesbetweenthemovingpartsatthetopandatthehubarecleaningthegabsandthuspreventingbuild-up

ofmaterialthatmightcauseextrafriction.Theflowthroughthebottomcoverisrequiredtoensureproperlubricationof

thegearbox.

Thenumberofrotationsrequiredforasatisfactorymixingofagiventankvolumedependsontheenergyinput(kw/m3tank

volume),theviscosityoftheliquid,requiredmixingtime,andnumberofmixerspertank.

Itispossibletoaddfluid,gasorsolidsintherecirculationloop.Theseingredientswillveryeffectivelybemixedintothe

entiretank/reactorvolume.

Whenthetank/reactorisemptytheAlfaLavalIM5RotaryJetMixercanbeusedasatankcleaningmachine.

15

4Installation

RotaryJetMixerIM15

4.3Generalsafetyandinstallationinstructions

TheAlfaLavalIM5RotaryJetMixershouldbeinstalledinverticalposition(uprightorupsidedown).Itisrecommendedto

installafilterinthesupplylineinordertoavoidlargeparticlestocloginsidethemachine.Beforeconnectingthemixerintothe

system,allsupplylinesandvalvesshouldbeflushedtoremoveforeignmatter.

Fordeviceswithtaperedthreadconnectionstothedownpipe,itisrecommendedthatyousecuretheconnectioninamanner

appropriatefortheapplication.Subjecttotheintendeduseenvironmentandanyinhouseuserrequirementsorpolicies,a

liquidthreadlockingadhesivesuchasLoctiteNo.243orequivalentcouldbeused.Othermethodscouldbeacceptable

andsubjecttocustomerpreference.

Note: Note:

Note:Themachineshallbeinstalledinaccordancewithnationalregulationsforsafetyandotherrelevantregulations

andstandards.

InEU-countriesthecompletesystemmustfulfiltheEU-MachineDirectiveanddependingofapplication,theEU-Pressure

EquipmentDirective,theEU-ATEX/IECExDirectiveandotherrelevantDirectivesandshallbeCE-markedbeforeitisset

intooperation.

ElectricalequipmentsuchasmagneticvalvesandelectricactuatorsmustnotbeinstalledinEx-zoneswithouttypeapproval

andmarking,correspondingtotheEX-classinquestion.

W W

War ar

arning: ning:

ning:Precautionsshallbemadetopreventstartingofthemixingoperation,whilepersonnelareinsidethe

tankorotherwisecanbehitbyjetsfromthenozzles.

Forinformationonuseinpotentialexplosiveatmospheresseeparagraph4.4Specificconditionsforsafeuseinaccordancewith

ATEX/IECExcertificationpage8.

TheAlfaLavalIM5RotaryJetMixerasdeliveredhasbeentestedatthefactorybeforeshipping.Fortransportationreasons,

thenozzleshavebeenscrewedoffafterthetest.Inordertosecurethenozzlesagainstfallingoffduringnormalcauseofservice

duetovibrationsandotherexternalstrainsitisimportantthatthenozzlesaretightenedproperlyaftermounting.Ifnot,the

nozzlesmaybeblownoffduringmixingandcausedamageontank,valvesandpump.Thisisespeciallyimportantifmixersare

installedintanksandvesselswithinthetransportationsectorintrucks,railcarsandonboardships.

Normally,itissufficienttotightenthenozzleswiththespecifiedtorque.However,dependingontheapplicationandlocal

policiesextrasecuringmaybepreferred.

16

4Installation

RotaryJetMixerIM15

W W

With ith

ith2 2

2Nozzles: Nozzles:

Nozzles:

.Clampmachinefirmlyinavice:PlacemachineontopofvicewithHubw.nozzlesdownwardsasillustratedonthefigure.

ClampontheHub.Toprotectmachineuserubberjawsonthevice.

2.Settorquewrenchatthespecifiedtighteningtorque.

3.Tightennozzlewiththetorque.

Recommendedtighteningtorque:50Nm.

W W

With ith

ith4 4

4Nozzles: Nozzles:

Nozzles:

.Clampmachinefirmlyinavice:PlacemachineontopofvicewithHubw.nozzlesdownwardsasillustratedonthefigure.

ClampontheHub.Toprotectmachineuserubberjawsonthevice.

2.Settorquewrenchatthespecifiedtighteningtorque.

3.Holdonenozzlewithflatspannertocounteractwhiletighteningtheoppositenozzlewiththetorquewrench.

Rubberjawmountedupside

down

Protectwithrubberpad

Recommendedtighteningtorque:50Nm.

Method Method

Methodfor for

fortightening tightening

tighteningthe the

thenozzles nozzles

nozzles

Checkthatthemachineisinoperatingconditionbyinserting3/6"hexScrewdriver(toolNo.TE34A)inscrewintopof

TurbineshaftandeasilyturnTurbineshaftclockwise.Ifanyresistanceisrecognised,themachineshouldbedisassembledto

localisethecause.

17

4Installation

RotaryJetMixerIM15

4.4SpecicconditionsforsafeuseinaccordancewithATEX/IECExcertication

Dir Dir

Directive ective

ective204/34/EU 204/34/EU

204/34/EU

NOTE NOTE

NOTE

Explosionprotectiontypeisconstructionalsafety“c”.

W W

War ar

arning: ning:

ning:Operated Operated

Operatedin in

ina a

ahazar hazar

hazardous dous

dousar ar

area ea

ea

Theunitmybeoperatedinahazardousareaonlywhencompletelyfilledwithcleaning/mixingfluid/steam.

Ifamediumotherthanthemixing/cleaningfluid/steamispassedthroughtheequipmenttheflowmustnot

behighenoughtocausetheequipmenttooperate.

W W

War ar

arning: ning:

ning:Operating Operating

Operatingguidance guidance

guidance

TheunitshallbeoperatedinlinewithguidanceprovidedbyIEC/TS60079-32-fortankcleaning.

W W

War ar

arning: ning:

ning:T T

Temperatur emperatur

emperature e

eclass class

classand and

andambient ambient

ambienttemperatur temperatur

temperature e

erange range

range

Themaximumsurfacetemperaturedependsmainlyonoperatingconditionswhicharethetemperatureof

themixing/cleaningfluidandambienttemperature.

Thetemperatureclassandambienttemperaturerangeareshowninparagraph3.6ATEX/IECExtemperature

classandcode,page.

W W

War ar

arning: ning:

ning:Max. Max.

Max.permitted permitted

permittedtemperatur temperatur

temperature e

e

Whenworking:

Themaximumpermittedmixing/cleaningfluidtemperatureandambienttemperatureis20°C.

Whennotworking:

Themaximumpermittedambienttemperatureis40°C.

W W

War ar

arning: ning:

ning:Draining Draining

Drainingusing using

usingcompr compr

compressed essed

essedair air

air

Drainingusingcompressedairmustnotbedoneinexclassifiedzone.

Drainingusingcompressedairispossibleinnonexclassifiedzones(seepage47).

W W

War ar

arning: ning:

ning:Earthing Earthing

Earthing

Allmetalandotherconductiveordissipativematerialshouldbeconnectedtoearthwiththeexceptionofvery

smallitems.

ForfurtherinformationseeIEC/TS60079-32-:203Explosiveatmospheres–Part32-:Electrostatichazards,

guidance.Withfocusonclause6.2.3,7.2.,7.3,7.9.2,3.

W W

War ar

arning: ning:

ning:Earthed Earthed

Earthedwhen when

whenin in

inuse use

use

Theunitmustbeeffectivelyearthedatalltimeswheninuse.

18

4Installation

RotaryJetMixerIM15

4.4SpecificconditionsforsafeuseinaccordancewithATEX/IECExcertification

W W

War ar

arning: ning:

ning:Max. Max.

Max.permitted permitted

permittedsteaming steaming

steamingtemperatur temperatur

temperature e

e

Themaximumpermittedsteamtemperaturetroughthemachineandambienttemperatureis40°C.

W W

War ar

arning: ning:

ning:Steaming Steaming

Steamingtanks tanks

tankslarger larger

largerthan than

than00 00

00m³ m³

m³

Tankswithcapacitieslargerthan00m³thatcouldcontainaflammableatmosphereshouldnotbesteam

cleaned,assteamcleaningtanksproducesanelectrostaticallychargedmist.Tankssmallerthan00m³may

besteamcleaned.

ForfurtherinformationseeIEC/TS60079-32-:203Explosiveatmospheres–Part32-:Electrostatichazards,

guidance.Withfocusonclause7.0and8.5.

T T

Tank ank

anksize size

sizeinformation information

information

NOTE:Thetankcleaningmachinehasbeencertifiedbyaccreditednotifiedbodyandcanoperateintankshavinganenclosed

volumeupto00m³aslongasallATEX/IECExwarningsintheinstructionmanualarecompliedwith.

General General

Generalguidelines guidelines

guidelinesfor for

fortanks tanks

tankslarger larger

largerthan than

than00 00

00m m

m3 3

3: :

:

Tankslargerthan00m³mustnotbesteamcleaned–SeeguideIEC/TS60079-32-:203clause7.0.5and8.5

Tousetheunitintankslargerthan00m³ispossibleundercertainconditions.

Itisnecessarytoknowthecurrentfactorssuchastanksize,cleaningsolventandproduct.

Additivescanbeusedinthecleaningsolvent,or,forexample,thetankcanbefilledwithnitrogen.Thebasicguidelinesare

describedintheguideIEC/TS60079-32-:203.

Itmustbeensuredthattheequipollentlybondingofallconductivemetalobjectsisinaccordancewithnationalregulations

foruse.

Thecleaningfluidconductivitymustcorrespondtotheproductsinthegroup“Highconductivity”,cf.IEC/TS60079-32-:203

clause7.and7.2.

Highconductivity>0000pS/m

Mediumconductivitybetween25×εrpS/mand0000pS/m

Lowconductivity<25×εrpS/m

Forliquidswithadielectricconstantofaround2,(e.g.hydrocarbons),theseclassificationsreduceto:

Highconductivity>0000pS/m

Mediumconductivitybetween50pS/mand0000pS/m

Lowconductivity<50pS/m

FollowingaguidancedocumentsuchasIEC/TS60079-32-:203toestablishsafeuseofmachineryandprocessistheusers

ownresponsibilityandisnotcoveredbytheATEX/IECExcertificationforthisunitexceptfortanksupto00m3.Forfurther

informationseeIEC/TS60079-32-:203Explosiveatmospheres–Part32-:Electrostatichazards,guidancewithfocuson

clause7..3,7..4,7.2.,7.2.4.

19

4Installation

RotaryJetMixerIM15

4.4SpecificconditionsforsafeuseinaccordancewithATEX/IECExcertification

W W

War ar

arning: ning:

ning:Pr Pr

Process ocess

ocessgenerated generated

generatedelectr electr

electrostatic ostatic

ostatic

Theusermustaddresstheelectrostatichazardsgeneratedfromtheprocessoftheequipmentinaccordance

withguidancedocumentIEC/TS60079-32-:203.

W W

War ar

arning: ning:

ning:Electr Electr

Electrostatically ostatically

ostaticallycharged charged

chargedliquid liquid

liquid

Liquidscanbecomeelectrostaticallychargedwhentheymoverelativetocontactingsolidsorthesprayingof

liquidscanalsocreateahighlychargedmistorspray.Theliquidmustbemadeelectricallyconductiveby

additivesorotherwise.

ForfurtherinformationseeIEC/TS60079-32-:203Explosiveatmospheres–Part32-:Electrostatichazards,

guidance.Withfocusonclause7..3,7..4,7.2.,7.2.4.

W W

War ar

arning: ning:

ning:Appr Appr

Appropriate opriate

opriatecleaning cleaning

cleaningfluid fluid

fluid

Thecleaningfluidshouldbeappropriatefortheapplication(e.g.sonochemicalreactioncantakeplacebetween

thecleaningfluidandtheresidueofprocessfluid/powder/compoundwhichcangenerateheatorahybridmixture).

ChemicalreactionsinZone20-Hybridmixtures:

End-usermustensurethatthecleaningfluiduseddoesnotcreateahybridmixtureaccordingtoIEC

60079-0-:205AnnexI.inconnectionwithpowder/dustresiduesinthetankinzone20.

Thisshouldensurethattheatmospheredoesnotchangetoaclassificationthatliesoutsidethemachine's

certifiedscope.Whenthemachineisusedforcleaningtankscontainingpotentiallyflammabledustatmospheres,

andapotentiallyflammablefluidisusedasthecleaningfluidthenanassessmentofthehybridmixtureshallbe

undertakenbytheuser,priortooperation.

ForfurtherinformationseeIEC60079-0-:205Explosiveatmospheres–Part0-:Classificationofareas–

Explosivegasatmospheres.Withfocusonclause3.6.6andAnnexI–Hybridmixtures.

W W

War ar

arning: ning:

ning:Appr Appr

Appropriate opriate

opriatemixing mixing

mixingfluid fluid

fluid

Themixingfluidshouldbeappropriatefortheapplication(e.g.sonochemicalreactioncantakeplacebetween

themixingfluidandtheresidueofprocessfluid/compoundwhichcangenerateheat).

W W

War ar

arning: ning:

ning:Mixing Mixing

Mixingconditions conditions

conditions

WhentheIMmachineisusedformixing,itshallbefullysubmergedinthetankliquidanditshallonlybeused

forsubmergedmixing/blendingofliquids.

20

Other manuals for IM 15

1

Table of contents

Other Alfalaval Mixer manuals

Alfalaval

Alfalaval MM UltraPure User manual

Alfalaval

Alfalaval HPM M-15 User manual

Alfalaval

Alfalaval ALTB-SB-20 User manual

Alfalaval

Alfalaval ALS User manual

Alfalaval

Alfalaval ALS-ME-GR-30 40LF-S3 Series User manual

Alfalaval

Alfalaval ESE02185-EN8 User manual

Alfalaval

Alfalaval ALTB-SB-30 User manual

Alfalaval

Alfalaval LeviMag User manual

Alfalaval

Alfalaval ALT series User manual

Alfalaval

Alfalaval IM 15 User manual