ARL5000 Operation Manual OP5000.1.1.7.R1ENG

3

1. Welcome

Sincerely thank you for buying Radar level transmitter!

This manual introduces the application, feature, function, installation and setup of Radar level transmitter level

transmitter so that users can know, install, use and maintain this instrument.

2. Overview

ARL5000 is characterized by 26G electromagnetic wave and the measurement will be not affected by the influence of

noise, water vapor, temperature, pressure, dust, gas volatilization etc. With excellent anti-interference ability, it can work

effectively in harsh environments.

Equipped with a new micro processor, ARL5000 is more ideal in rate signal analysis, processing capacity, which greatly

improves the stability and accuracy of measurement. ARL5000 features in non-contact level measurement, simple

structure and easy installation and it can be widely used in complicated working conditions such as reaction kettle, solid

liquid silo, high temperature and high pressure.

3. Measuring Principle

The narrow microwave pulses are emitted via an antenna, reflected from the measured media surface and then received

by antenna system again. The received signals are transmitted to electronic circuit and some are automatically

converted to level signals. (The process, the electromagnetic wave reaches the target and is reflected back to the

receiver, occurs instantly. because the microwave travels very fast.)

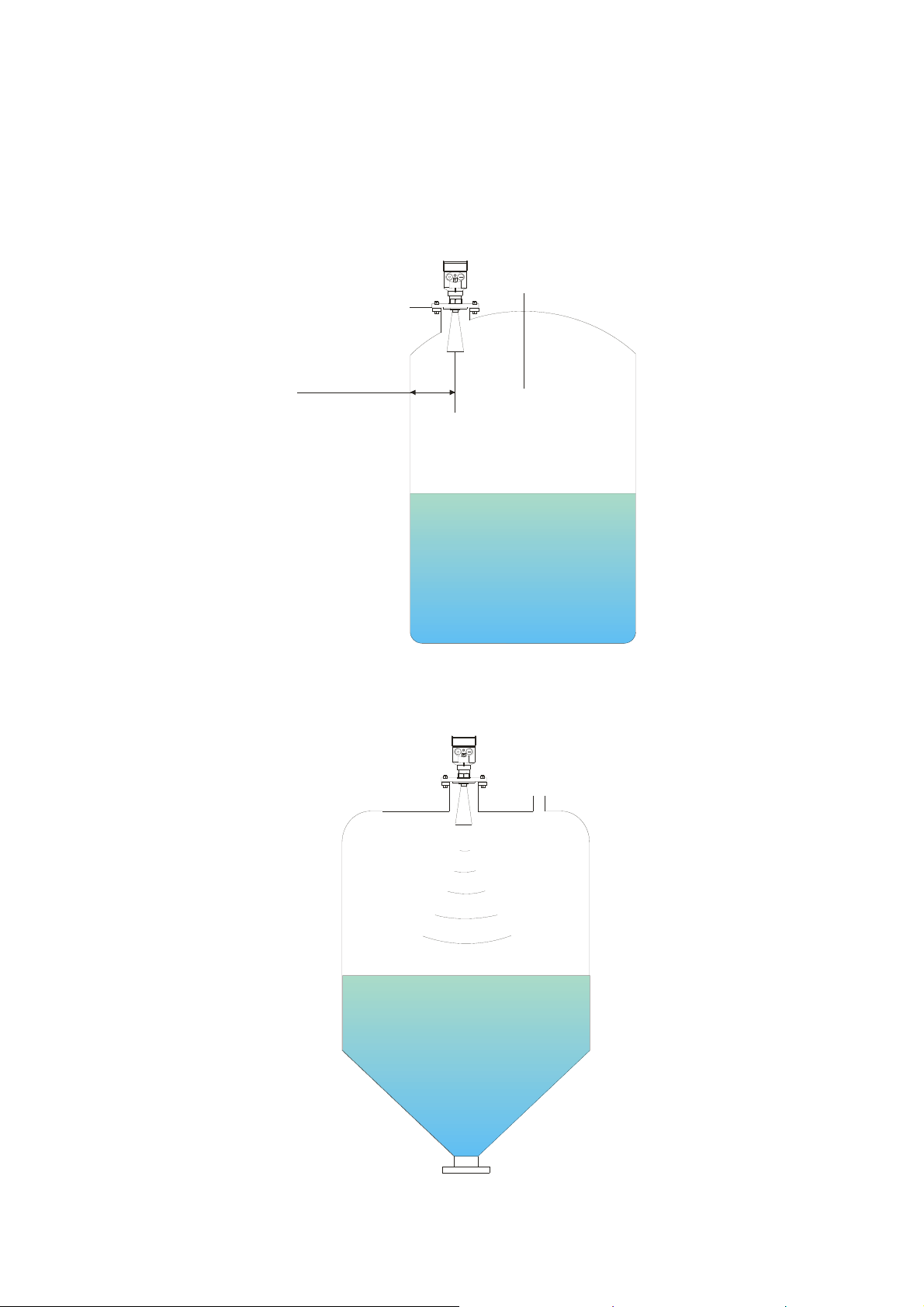

ABCD

100 00.%

0 000.%

Measurement datum plane:Screw thread Bottom and Flange Sealing Surface

Note: When the radar level is used, please make sure that the highest material level can not reach the

measuring blind are (As shown in D area).

4. Features

Non-contact radar, free of wear and pollution

Small measuring blind area, ideal for small tank measurement

Not affected by working conditions such as corrosion, foam, noise, water vapor, dust, vacuum, etc.

Small antenna, simple installation

Shorter wavelength, better reflection on inclined solid surface

High signal-to-noise ratio, excellent performance under fluctuating conditions

High frequency, ideal for the measurement of solid and dielectric constant

Small beam angle & focus energy to enhance radar echo capacity

Support HART / RS485 communication for on-site debugging

A Range Setting

B Low Lever Adjustment

C High Level Adjustment

D Blind Area