Notesaboutthelasercutparts

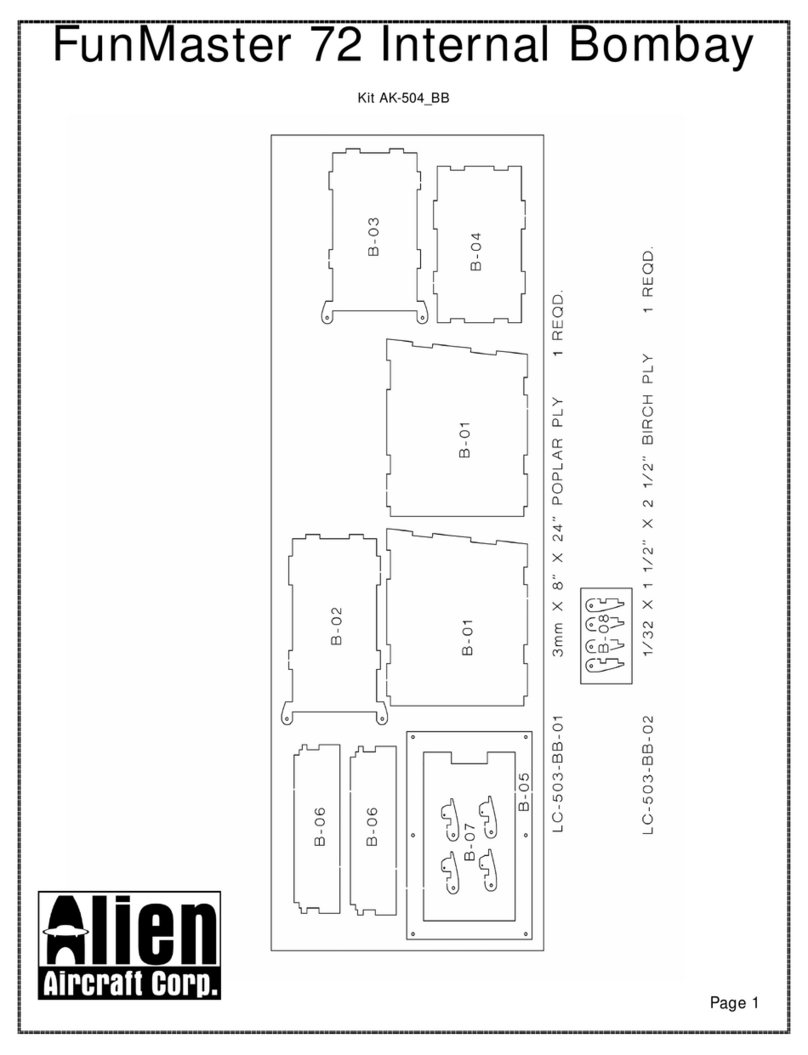

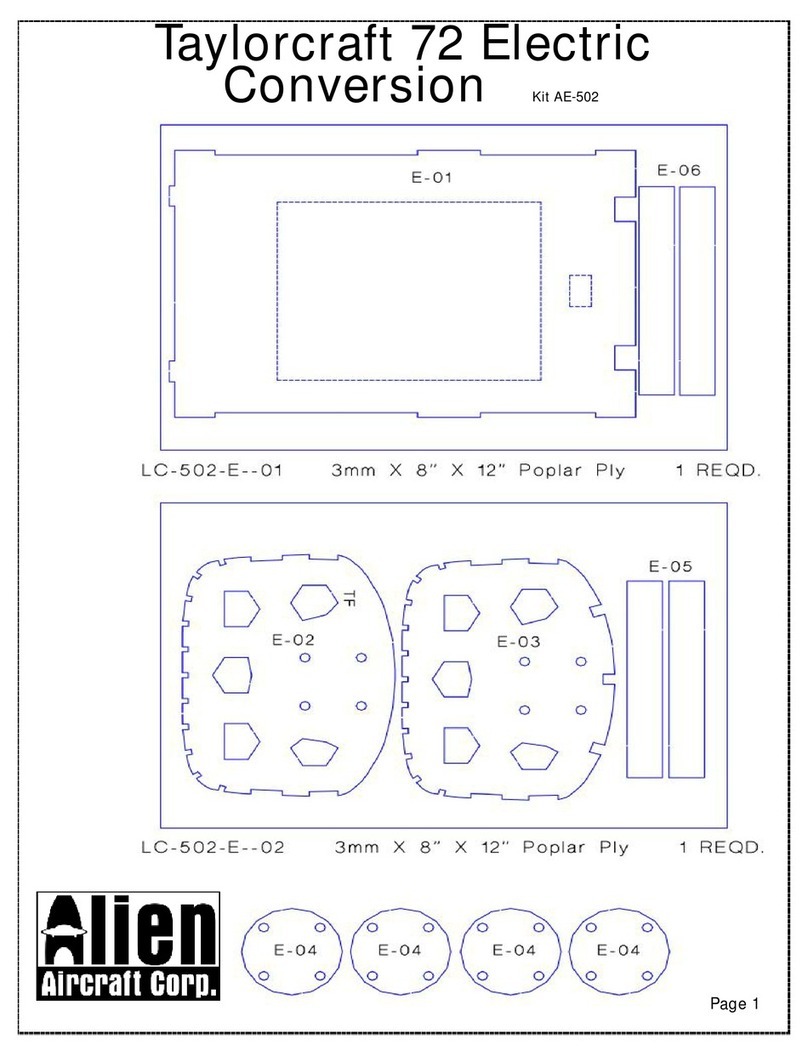

1...Thefirstthingthatyouneedtodo istoidentifyandmarkthepartnumbers onthelasercut

partsusingthedrawingsonthefollowingpagesasaguide.

2...Itispossiblethat severalofthelasercutpartsmay not becompletelycutthrough.Ifthisisthecaseyoucanfreethepartfrom

thesheetquicklyusinganX-acto knife.

3...Theslightdiscolorationontheedgesof thelasercutpartsmayberemovedbylightlysandingtheedgeswith400 gritsandpaper.

KitContents:

Yourkitcontains thefollowingparts. Pleasecheckyourkitforanymissingordamagedpartsbeforestartingconstruction.

WoodBag:

Qty... .Name. ... . ... . ... . ... . ... . ... . ...Description

1. . ...LC-505-01 . ... . ... . ... . ... . ... . ...3mmX4” X24” LaserCutPOPLAR PLY

1. . ...LC-505-02 . ... . ... . ... . ... . ... . ...3mmX8” X24” LaserCutPOPLAR PLY

1. . ...LC-505-03 . ... . ... . ... . ... . ... . ...3mmX4” X24” LaserCutPOPLAR PLY

1. . ...LC-505-04 . ... . ... . ... . ... . ... . ...3mmX8” X24” LaserCutPOPLAR PLY

1. . ...LC-505-05 . ... . ... . ... . ... . ... . ...3mmX4” X24” LaserCutPOPLAR PLY

1. . ...LC-505-06 . ... . ... . ... . ... . ... . ...3mmX8” X24” LaserCutPOPLAR PLY

1. . ...LC-505-07 . ... . ... . ... . ... . ... . ...3mmX8” X24” LaserCutPOPLAR PLY

1. . ...LC-505-08 . ... . ... . ... . ... . ... . ...3mmX8” X24” LaserCutPOPLAR PLY

1. . ...LC-505-09 . ... . ... . ... . ... . ... . ...3mmX8” X24” LaserCutPOPLAR PLY

1. . ...LC-505-10 . ... . ... . ... . ... . ... . ...3mmX8” X24” LaserCutPOPLAR PLY

1. . ...LC-505-11. . ... . ... . ... . ... . ... . ..1/8” X4” X24” Laser CutBALSA

1. . ...LC-505-12 . ... . ... . ... . ... . ... . ...1/8” X4” X24” Laser CutBALSA

1. . ...LC-505-13 . ... . ... . ... . ... . ... . ...1/8” X4” X24” Laser CutBALSA

1. . ...LC-505-14 . ... . ... . ... . ... . ... . ...1/8” X4” X24” Laser CutBALSA

1. . ...LC-505-15 . ... . ... . ... . ... . ... . ...1/8” X4” X24” Laser CutBALSA

1. . ...LC-505-16 . ... . ... . ... . ... . ... . ...1/8” X4” X24” Laser CutBALSA

1. . ...LC-505-17 . ... . ... . ... . ... . ... . ...1/8” X4” X24” Laser CutBALSA

1. . ...LC-505-18 . ... . ... . ... . ... . ... . ...1/8” X4” X24” Laser CutBALSA

2. . ...LC-505-19 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

2. . ...LC-505-20 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

2. . ...LC-505-21 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

2. . ...LC-505-22 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

1. . ...LC-505-23 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

2. . ...LC-505-24 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

1. . ...LC-505-25 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

1. . ...LC-505-26 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

1. . ...LC-505-27 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

1. . ...LC-505-28 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

1. . ...LC-505-29 . ... . ... . ... . ... . ... . ...3/32” X4” X24” Laser CutBALSA

1. . ...LC-505-30 . ... . ... . ... . ... . ... . ...1/16” X4” X24” Laser CutBirchPly

1. . ...LC-505-31 . ... . ... . ... . ... . ... . ...1/32” X4” X12” Laser CutBirchPly

9. . ...TailSheet. . ... . ... . ... . ... . ... . ..1/16” x4” x24” Balsa

3. . ...WingSheet. ... . ... . ... . ... . ... . ..3/32” X4” X24” Balsa

1. ... . .Windshield. ... . ... . ... . ... . ... . ...015” x3” x7” Plastic

Page 2