Notesaboutthelasercutparts

1...Thefirstthingthatyouneedtodoistoidentifyandmarkthepartnumbersonthelasercutpartsusingthedrawingsonthefollowingpagesasaguide.

2...It ispossiblethat severalofthelasercutpartsmaynotbecompletelycutthrough.IfthisisthecaseyoucanfreethepartfromthesheetquicklyusinganX-actoknife.

3...Theslightdiscolorationontheedgesofthelasercut partsmayberemovedbylightlysandingtheedgeswith400 grit sandpaper.

KitContents:

Yourkit containsthefollowing parts.Pleasecheckyourkitforanymissingordamagedpartsbeforestartingconstruction.

WoodBag: Qty.. ... .Name. . ... ... ... ... ... . ... ... ... ... ... . ... ..Description

2... ... .LC-501-01. ... ... ... ... . ... ... ... ... ... . ... ..3mm X5”X24””Laser CutPOPLAR PLY

2... ... .LC-501-02. ... ... ... ... . ... ... ... ... ... . ... ..3mm X7”X24””Laser CutPOPLAR PLY

1. ... ... .LC-501-03. ... ... ... ... . ... ... ... ... ... . ... ..3mm X5”X24””Laser CutPOPLAR PLY

1... ... .LC-501-04. ... ... ... ... . ... ... ... ... ... . ... ..3mm X7”X24””Laser CutPOPLAR PLY

1. ... ... .LC-501-05. ... ... ... ... . ... ... ... ... ... . ... ..3mm X7”X24””Laser CutPOPLAR PLY

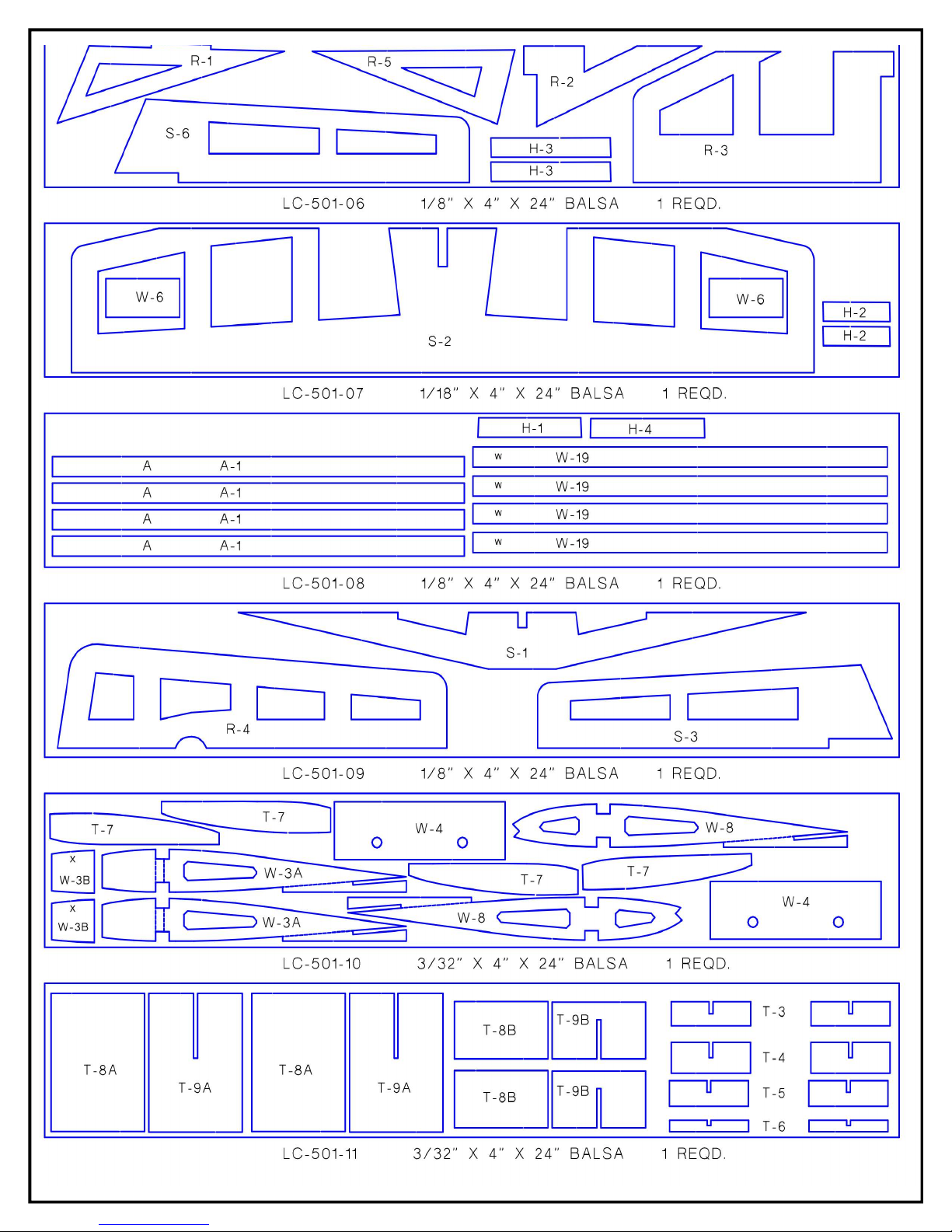

1... ... .LC-501-06. ... ... ... ... . ... ... ... ... ... . ... ..1/8” X4” X24” LaserCut BALSA

1... ... .LC-501-07. ... ... ... ... . ... ... ... ... ... . ... ..1/8” X4” X24” LaserCut BALSA

1. ... ... .LC-501-08. ... ... ... ... . ... ... ... ... ... . ... ..1/8” X4” X24” LaserCut BALSA

1... ... .LC-501-09. ... ... ... ... . ... ... ... ... ... . ... ..1/8” X4” X24” LaserCut BALSA

1... ... .LC-501-10. ... ... ... ... . ... ... ... ... ... . ... ..3/32”X4” X24” LaserCut BALSA

1. ... ... .LC-501-11. ... ... ... ... . ... ... ... ... ... . ... ..3/32”X4” X24” LaserCut BALSA

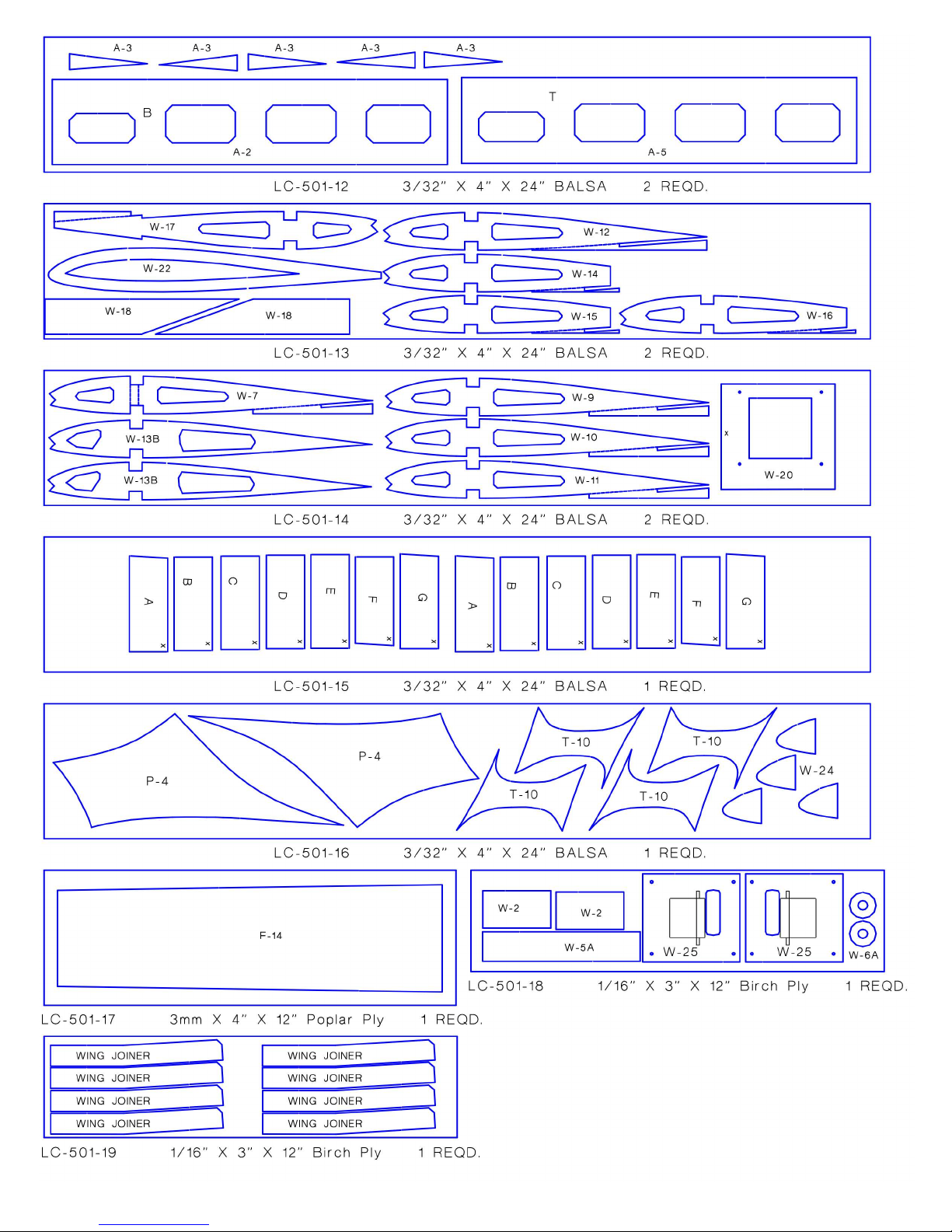

2... ... .LC-501-12. ... ... ... ... . ... ... ... ... ... . ... ..3/32”X4” X24” LaserCut BALSA

2... ... .LC-501-13. ... ... ... ... . ... ... ... ... ... . ... ..3/32”X4” X24” LaserCut BALSA

2. ... ... .LC-501-14. ... ... ... ... . ... ... ... ... ... . ... ..3/32”X4” X24” LaserCut BALSA

1... ... .LC-501-15. ... ... ... ... . ... ... ... ... ... . ... ..3/32”X4” X24” LaserCut BALSA

1... ... .LC-501-16. ... ... ... ... . ... ... ... ... ... . ... ..3/32”X4” X24” LaserCut BALSA

1... ... .LC-501-17. ... ... ... ... . ... ... ... ... ... . ... ..3mm X4”X12”LaserCutPOPLAR PLY

1... ... .LC-501-18. ... ... ... ... . ... ... ... ... ... . ... ..1/16”X3” X12” LaserCut BirchPly

1... ... .LC-501-19. ... ... ... ... . ... ... ... ... ... . ... ..1/16”X3” X12” LaserCut BirchPly

3. ... ... .FuselageSheet... ... ... . ... ... ... ... ... . ... ..1/8” x4” x24”Balsa

6. ... ... .Tail Sheet. ... ... ... ... . ... ... ... ... ... . ... ..1/16”x4”x24” Balsa

5. ... ... .Wing&CenterSection Sheet. ... ... ... ... . ... ..3/32”X4” X24” Balsa

4. ... ... .WingLeading EdgeSheet. ... ... ... ... ... . ... ..3/32”x3”x30” Balsa

4. ... ... .WingTrailingEdgeSheet. ... ... ... ... ... . ... ..3/32”x11/2” x18”Balsa

4. ... ... .WingTrailingEdgeSheet. ... ... ... ... ... . ... ..3/32”x1”x18” Balsa

1. ... ... .K-501PLAN A

1. ... ... .K-501PLAN B

5. ... ... .FuselageStringers... ... . ... ... ... ... ... . ... ..1/8” sq. X12” Balsa

1. ... ... .Nose Block... ... ... ... . ... ... ... ... ... . ... ..1/2” x3” x4”Balsa

4. ... ... .OutboardMainWing Spars.. ... ... ... ... . ... ..1/4” x3/8” x30”Balsa

1. ... ... .TipFloat FrontBlock... . ... ... ... ... ... . ... ..3/4” x1” x5”Balsa

1. ... ... .TipFloat RearBlock. ... . ... ... ... ... ... . ... ..1/2” x3/4” x5” Balsa

2. ... ... .WingLeading Edge.. ... . ... ... ... ... ... . ... ..3/8” x3/8” x30”Balsa

2. ... ... .Center SectionMainWingSpars. ... ... ... . ... ..1/4” x3/8” x5” Spruce

Hardware Bag

Qty.. ... .Name. . ... ... ... ... ... . ... ... ... ... ... . ... ..Description

4. ... ... .MotorMount BlindNuts. . ... ... ... ... ... . ... ..6-32 Blind Nuts

1... ... .Elevator JoinerDowel... . ... ... ... ... ... . ... ..1/4” x41/2” BirchDowel

2... ... .WingDowels. ... ... ... . ... ... ... ... ... . ... ..1/4” x1” BirchDowel

2... ... .WingBolts... ... ... ... . ... ... ... ... ... . ... ..1/4-20 x1” Nylon Screw

4. ... ... .Control Horn. ... ... ... . ... ... ... ... ... . ... ..Aileronand Tail ControlHorns

15... ... .Aileron Servo,Cowl &AileronHornScrews.. . ... ..#2X1/2”Sheet MetalScrew

4. ... ... .Tail ControlHornScrews. ... ... ... ... ... . ... ..2-56 x1/2” MachineScrew

40”.. ... .WingJoint Tape.. ... ... . ... ... ... ... ... . ... ..1”x40”DacronTape

Page2