ALL-FILL B-SV-600 User manual

A.F.I. Publication: 1240410

Issue: 1

Date: April 2010

Model B-SV-600

Model B-SV-600

Touch Screen Control Panel

Touch Screen Control Panel

Users Manual

Users Manual

ALL-FILL, Inc.

418 Creamery Way

Exton, PA. 19341 USA

(610) 524-7350 · FAX (610) 524-7346

www.all-fill.com

Title Page

INTRODUCTION.............................................................................................................1

Control Panel....................................................................................................................1

Figure 1 – Model B0SV-600 Filler Control Panel..........................................................1

Control Power Switch.................................................................................................1

Power Indicator ..........................................................................................................1

Reset Switch ..............................................................................................................2

Touch Screen Operation...................................................................................................2

START/STOP................................................................................................................2

MENU SCREENS .........................................................................................................3

Status Messages...........................................................................................................3

Menus & Selections..........................................................................................................4

USING THE CONTROLS ..............................................................................................7

Startup and Initial Operation.............................................................................................7

Test Menu Operations...................................................................................................8

Setting Up Filling ..............................................................................................................9

Picking a Run Program Number...................................................................................9

Setting up Target Weight and Feedback Operation....................................................10

Setting up Auger and Agitator.....................................................................................12

Controlling a Cutoff and Delay After Fill......................................................................13

Specifying Level Control and Product Infeed Operation.............................................14

Starting and Running Filling Production .........................................................................15

Displaying Production Information ..............................................................................16

Production...................................................................................................................16

Production Product Feed Control.............................................................................16

Production Servo Feedback.....................................................................................17

Production A&D Scale Feedback .............................................................................18

Troubleshooting and Service..........................................................................................19

Status Messages.........................................................................................................19

Table 1 – Status Message Troubleshooting .............................................................20

REFERENCE ..................................................................................................................21

System Menus................................................................................................................21

Select Run Program Number......................................................................................21

System Setup .................................................................................................................21

Recycle Control...........................................................................................................21

Reset Production Stats ...............................................................................................22

End of Fill Control .......................................................................................................22

System Configuration .....................................................................................................22

Setup Menus ..................................................................................................................23

Setup Target Weight ...................................................................................................23

Product Name ..........................................................................................................23

Target Weight ...........................................................................................................23

Feedback Control.....................................................................................................23

Feedback Sec./Wt....................................................................................................24

Feedback Samples ..................................................................................................24

Setup Auger and Agitator............................................................................................24

Auger Revolutions....................................................................................................24

Auger Speed ............................................................................................................25

Agitator Control ........................................................................................................25

Agitation Off Delay ...................................................................................................25

Setup Cutoff and Delay After Fill ................................................................................26

Model B-SV-600 Touch Screen Control Panel Users Manual

AFI Publication 1240410

•

Issue: 1

•

April 2010

CONTENTS

Cutoff Control ...........................................................................................................26

Delay After Fill ..........................................................................................................27

Setup Level Control and Product Infeed.....................................................................27

Level Control ............................................................................................................27

Pause Delay.............................................................................................................27

Low Level Agitation ..................................................................................................28

Infeed Control...........................................................................................................28

On/Off Time ..............................................................................................................28

Test Menus .....................................................................................................................29

Test Auger and Agitator...............................................................................................29

Empty Hopper ..........................................................................................................29

Jog Auger .................................................................................................................30

Test Agitator..............................................................................................................30

Test Cutoff, Product Feed & EOF/Run Signal ............................................................31

Test Cutoff ................................................................................................................31

Test EOF Signal .......................................................................................................31

Test Product Feed ....................................................................................................32

Status Indicators.......................................................................................................32

Test Servo and A&D Scale Feedback.........................................................................33

Status Menu....................................................................................................................33

Production ......................................................................................................................34

Production Product Feed Control ...............................................................................34

Production Servo Feedback .......................................................................................34

Production A&D Scale Feedback................................................................................34

APPENDIX .....................................................................................................................35

Run Program Worksheet................................................................................................37

Menu & Selection Reference .........................................................................................39

INDEX .............................................................................................................................42

© 2010 All-Fill, Inc.

4/10 · Printed in the U.S.A.

No liability is assumed with respect to the use of any information contained in this publication. While every precaution has been taken in the

preparation of this publication, All-Fill, Inc.assumes no responsibility for errors or omissions nor is any liability assumed for damages resulting

from the use of information contained in this publication. This publication, as well as operational details described herein, are subject to

change without notice.

Model B-SV-600 Touch Screen Control Panel Users Manual

AFI Publication 1240410

•

Issue: 1

•

April 2010

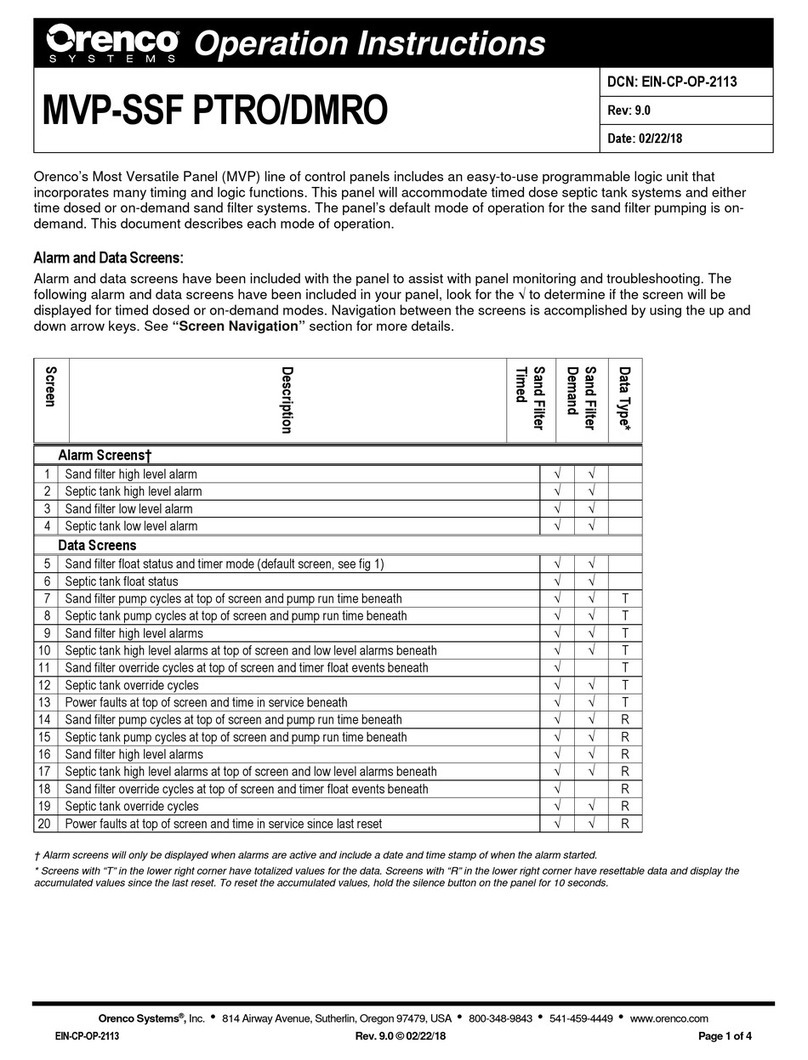

The ALL-FILL Model B-SV-600 Filler provides accurate, reliable, integrated control of filling

from a single touch screen control panel. This section is intended for new or unfamiliar users

of ALL-FILL Touch Screen controls. If you have not had previous experience with these type

controls, you should first read this section to understand the basic concepts and general

operation of the controller. Subsequent sections of this manual can be used to setup and

operate your ALL-FILL Model B-SV-600 Filler.

The Touch Screen Control Panel allows you to control and operate your ALL-FILL filler

directly from the touch screen panel. There’s no need to learn any special computer terms

or complicated programming procedures. All messages are in plain English. The Control

Panel included on your Model B-SV-600 Filler is shown in Figure 1. Controls are described

in the following.

Model B-SV-600 Touch Screen Control Panel Users Manual

1

AFI Publication 1240410

•

Issue: 1

•

April 2010

INTRODUCTION

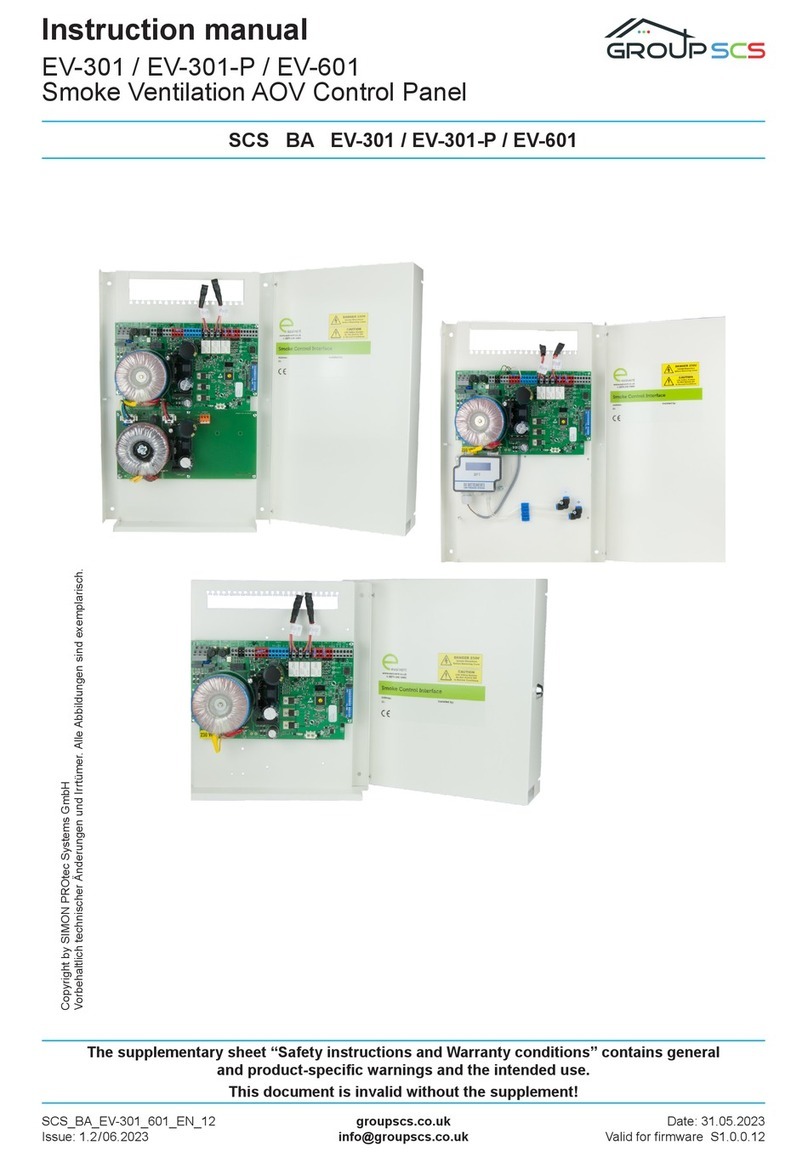

Control Panel

Figure 1

Model B-SV-600 Filler Control Panel

COM

CPU

PWR

Control Power Switch

On/Off, lighted pushbutton located below the keypad that controls electrical power to the

Touch Screen controls. Using this switch during operation halts the machine in mid-cycle. It

should only be used in emergencies. The Touch Screen control panel draws very little power

when not in production, and turning the controller off at the end of a shift or day may be

potentially more damaging than any savings offered by turning electrical power off.

Power Indicator

A green lamp that lights to indicate that control power is available.

Reset Switch

Pressing the black RESET BUTTON will restore power to the system after an EMERGENCY

STOP situation. It also brings all devices to their “home” position, and prepares the machine

to enter “run” mode.

All major machine setup, production, and testing are performed using the Touch Screen

panel on the Control Panel. This screen provides simple, direct selection of all operations,

control settings, and production data display. This section provides a description of the dif-

ferent screens and selections available, as well as a sample exercise to practice using the

controls.

START/STOP

Model B-SV-600 Touch Screen Control Panel Users Manual

2

AFI Publication 1240410

•

Issue: 1

•

April 2010

Touch Screen

Operation

Selects operating mode of the equipment. Pressing START initiates a fill cycle. STOP halts

the sequence. PAUSE momentarily halts filling, SINGLE CYCLE allows only a single con-

tainer to index, filled, and leave. EXIT allows access to other menus and screens.

MENU SCREENS

Model B-SV-600 Touch Screen Control Panel Users Manual

3

AFI Publication 1240410

•

Issue: 1

•

April 2010

Provides access to other menus and screens, including:

SYSTEM MENUS Provides access to selections to choose the Setup

Program to use, and to display configuration data.

SETUP MENUS Provides access to selections that define how filling

is performed.

TEST MENUS Provides access to selections that allow individual

operation of equipment and components for testing,

troubleshooting, and adjustment.

STATUS MENUS Provides access to selections about production and

statistical data.

PRODUCTION Provides access to displays and settings to allow

“fine-tuning” during production.

EXIT Leaves the Menu Screens menu.

Status Messages

A single line message indicating the current operational state of the filler. The following mes-

sages may appear:

E-STOP SWITCH WAITING FOR

IS ACTIVATED RECYCLE TIME

SYSTEM READY LOW LEVEL PAUSE

PRESS START BUTTON WAIT FOR PRODUCT

PRESS INITATION SW. OPERATOR PAUSE

TO DISPENSE PRODUCT CHECK PAUSE BUTTON

CUTOFF IS OPEN WAIT FOR INITIATION OR

CHECK SWITCH OR DELAY FOOT SWITCH

AUGER IS TURNING RELEASE INITIATION OR

DISPENSING PRODUCT FOOT SWITCH

DELAY AFTER FILL AC INVERTER

POWER UP DELAY

CLOSING CUTOFF SERVO DRIVE

CHECK CLOSING TIME NOT READY

SYSTEM IS RUNNING

A series of interactive, English-language menus and selections provide operational control

of the filler. Each menu has an associated group of selections in that general category to

allow you to select and specify control in an organized, logical manner. Selections in each

menu allow you to enter values from a given range, such as Target Weight; or make a

choice between different functions, such as agitate during filling, agitate continuously, or turn

agitation off. Individual descriptions of each Menu Selection are provided in the REFER-

ENCE section of the publication. The following describes each Menu in general.

System Menu

The System Menu provides selections to choose what Setup Program to use for produc-

tion, and to display service-related configuration information. Menu includes:

● Select Run Program Number

● System Setup

Recycle Time

Recycle Control

Reset Production Stats

End of Fill Control

● System Configuration

Setup Menu

The Setup Menu contains selections that let you choose filling operations (such as fill

amount, agitation control, cutoff control, etc.) at the machine. Selections made in the Setup

Menu are saved together as a numbered Run Program stored in memory of the control

panel. Selections include:

● Setup Target Weight

Product Name

Target Weight

Feedback Control

Feedback Sec./Wt.

Feedback Samples

● Setup Auger and Agitator

Auger Revolutions

Model B-SV-600 Touch Screen Control Panel Users Manual

4

AFI Publication 1240410

•

Issue: 1

•

April 2010

Menus & Selections

Auger Speed

Agitation Control

Agitation Speed

Agitation Off Delay

● Setup Cutoff and Delay After Fill

Cutoff Control

Open Time

Close Time

Delay After Fill

● Setup Level Control and Product Infeed

Level Control

Pause Delay

Low Level Agitation

Infeed Control

Off Time

On Time

Test Menu

The Test Menu allows you to individually operate machine equipment when not currently in

production. These selections can be used to perform maintenance or adjustments on the

machine. Test Menu includes:

● Test Auger and Agitator

Empty Hopper

Jog Auger

Test Agitator

Jog Rev.

Auger Speed

Agitator Speed Option

● Test Cutoff, Product Feed & EOF/Run Signal

Test Cutoff

Test EOF Signal

Test Prod. Feed

Cutoff Switch

Level Control

Initiation Switch

Agit. Run

C/W Raise

C/W Lower

E-Stop Switch

● Test Servo and A&D Scale Feedback

Weight

A&D Scale String

A&D Scale Setup

C/W Raise/Lower

Status Menu

The Status Menu lets you see filling production values and amounts while the machine is

running. Although you can’t change values in this menu, you can display them to later adjust

your setup program, filling accessories, etc. Status selections include:

Model B-SV-600 Touch Screen Control Panel Users Manual

5

AFI Publication 1240410

•

Issue: 1

•

April 2010

● Auger Rev.

● Setup Auger Revolutions Adjustment

● Setup Auger Speed Adjustment

● CPM

● Auger Speed

● Setup Auger Revolutions Adjustment

● Setup Auger Speed Adjustment

● Auger

● Agitator

● Cutoff

● Infeed

● EOF Signal

● Production Counts

● Low Level Pause Counts

● Low Level

● Cutoff Switch

● Initiation

● E-Stop

Production

The Production menu provides a quick and easy method of accessing setup selections and

settings that may require adjustment or “tuning” while in filling production. Included are:

● Production Product Feed Control

Low Level Control

Low Level Agitation

Pause Delay

Low Level Pause Count Display

Low Level Status

Agitation Status

Infeed Status

Infeed Control

On/Off Time

● Production Servo Feedback

Target Weight

Feedback Rate

Feedback Control

Feedback Weight Display

Auger Revolution Display

C/W Raise/Lower Status

● Production A&D Scale Feedback

Avg. Scale Weight Display

Auger Revolution Display

Sample Counts Display

Target Weight

Feedback Samples

Feeedback Control

Last Scale Weight Display

Hi/Lo Limit Display

Model B-SV-600 Touch Screen Control Panel Users Manual

6

AFI Publication 1240410

•

Issue: 1

•

April 2010

After becoming familiar with the operating controls and displays (see “INTRODUCTION”),

you can use this section to learn how to setup and run the filler from the control panel.

Installation of the machine is described separately and contained in the documentation

package accompanying your order.

It is recommended that all installation and connections be completed before attempting any

of the setup, calibration or production procedures contained in the following.

After installing the filler and connecting the required electrical and pneumatic inputs, the

machine can be started and initially operated to ensure that all components are functioning

correctly. After electrical power is turned-on, the following screen appears on the touch

screen panel.

Model B-SV-600 Touch Screen Control Panel Users Manual

7

AFI Publication 1240410

•

Issue: 1

•

April 2010

USING THE

CONTROLS

Startup and Initial

Operation

You can use this screen to verify and record:

•Model Designation

•Wiring Diagram

•Human/Machine Interface (HMI) touch screen panel Version

•Programmable Logic Controller (PLC) Version

After recording this information, use the Control Power switch on the panel. The Main Status

screen should appear.

Test Menu Operations

The Test Menu provides selections to individually operate and test various components and

devices of the machine. You can use the following to test these devices prior to any setup or

operation.

1. Press STOP from the START/STOP menu. Test functions can only be accessed when

machine is stopped.

2. Press MENU SCREENS and press TEST MENUS. Press EXIT.

3. Select the following screens from the Test Menu:

•Test Auger and Agitator

•Test Cutoff, Product Feed & EOF/Run Signal

•Test Servo and A&D Scale Feedback

4. When selected, use switch icon graphics to turn equipment on & off or verify the on/off

status of limit switches, contacts, etc. Make required adjustments as needed.

Upon successful completion of this testing, you can proceed to the following to start setting

up the filling controls.

Model B-SV-600 Touch Screen Control Panel Users Manual

8

AFI Publication 1240410

•

Issue: 1

•

April 2010

Setup of the filler component consists of the following major procedures:

•Picking a Run Program number.

•Setting up Target Weight and Feedback Operation

•Setting up Auger and Agitator

•Controlling a Cutoff and Delay After Fill

•Specifying Level Control and Product Infeed Operation

Procedures to perform these setup operations are provided in the following. The Appendix

of this manual contains a Setup Run Program Worksheet that can be used to help you

develop and record Setup selections and entries.

Picking a Run Program Number

The Touch Screen controls provide the ability to store up to 50 different setup run programs

for use with different containers, products, fill amounts, etc. Use the following to set up and

store setup programs.

Model B-SV-600 Touch Screen Control Panel Users Manual

9

AFI Publication 1240410

•

Issue: 1

•

April 2010

Setting Up Filling

•Press MENU SCREENS and SYSTEM MENUS. Press EXIT.

•From the SYSTEM MENU screen, Press SELECT RUN PROGRAM NUM-

BER to choose a number. Press the corresponding number from 1-5 or use the è

to choose from 6-50.

Setting up Target Weight and Feedback Operation

The Setup Target Weight screen provides access to selections to define product name, tar-

get filling weight, and filling amount feedback operation. Use the following procedure to

specify these settings in your Run Program.

1. Press MENU SCREENS and SETUP MENUS. Press EXIT. The SETUP TAR-

GET WEIGHT screen should appear. If not, use è/çuntil the Setup Target Weight

screen appears.

Model B-SV-600 Touch Screen Control Panel Users Manual

10

AFI Publication 1240410

•

Issue: 1

•

April 2010

2. Press PRODUCT NAME to associate a container, product, or batch with a particular

Run Program. Any alphanumeric character (0-9/A-Z) can be used, at up to 10 charac-

ters in length.

3. The total amount of material to be dispensed during filling is defined with the TARGET

WEIGHT selection. You should enter the desired, final, filled weight. Feedback control

selections (see following) use this Target Weight value for feedback calculation and cor-

rection.

4. Press FEEDBACK CONTROL to select the type of feedback used for correction of fill

weights. The following selections are available:

Servo – Defines a raise/lower signal used as feedback to the filler. Typically, servo

raise/lower signals are provided by a checkweigher. When selected as “Servo” the

Feedback Sec./Wt. selection is used to specify how fill weights are corrected (see Step

5).

A&D Scale – Defines a scale to provide feedback correction to the filler. When selected

as “A&D Scale” the Feedback Samples selection is used to specify how fill weights are

corrected (see Step 6).

None – Feedback not used.

5. If Feedback selected as “Servo” the FEEDBACK SEC/WT selection defines the

amount of time that is required to change auger revolutions based on weight value. This

value should match the same value on the weighing equipment.

6. If Feedback selected as “A&D Scale” the FEEDBACK SAMPLES entry selects the

total amount of weight sampling data collected at the A&D Scale during weighing used

in calculation of feedback adjustment. Generally, greater sampling may achieve greater

accuracy, however adjustment may require several fill cycles to complete.

7. Proceed to the following to continue setup of auger revolutions and agitator operation.

Model B-SV-600 Touch Screen Control Panel Users Manual

11

AFI Publication 1240410

•

Issue: 1

•

April 2010

Setting up Auger and Agitator

The Setup Auger and Agitator screen provides access to selections to select how many

auger revolutions are performed during a fill cycle and operation of the agitator drive within

the hopper of the filler. Use the following procedure to setup auger revolutions and agitator

operation in your Run Program.

1. Press MENU SCREENS and SETUP MENUS. Press EXIT. Use èuntil SETUP

AUGER AND AGITATOR screen appears.

Model B-SV-600 Touch Screen Control Panel Users Manual

12

AFI Publication 1240410

•

Issue: 1

•

April 2010

2. The AUGER REVOLUTIONS selection defines the amount of product dispensed dur-

ing a fill cycle. The amount of product dispensed per revolution is a function of the auger

(or pump) size as well as physical characteristics of the product (i.e., density).

!!! IMPORTANT !!!

DO NOT enter a value less than one-half (0.5) a revolution.

3. Press AUGER SPEED to select the desired operating speed of the servo fill motor.

Speed settings will vary according to amount of fill, desired accuracy levels, as well as

production rates. Use numeric keypad for desired rpm and press ENT.

4. The on/off control and duration of product agitation can be controlled with the AGITA-

TOR CONTROL selection. Selections are available for continuous agitation, agitation

during filling only, and no agitation. Operation of slow speed agitation will depend on

product type, environmental factors, and specific product characteristics.

5. Press the area adjacent to Agitation Control to select agitation speed. Product agitation

should generally match auger speed. If faster auger speed is selected, product agitation

should be selected at a faster setting.

6. Press AGITATION OFF DELAY to momentarily delay turning agitation off to accom-

modate high cycle rates and operation with other equipment.

7. When entries are complete, record settings on the Run Program Worksheet (see

“Appendix”) and press the èto continue.

Controlling a Cutoff and Delay After Fill

The Setup Cutoff and Delay After Fill screen provides access to selections to control a cutoff

device (if used), and select a variable delay to occur after a fill cycle. A delay after fill can be

used to coordinate operation of the auger filler with other equipment, or to allow product to

settle and distribute into a container. Use the following procedure to control a cutoff device

and select a Delay After Fill in your Run Program.

1. Press MENU SCREENS and SETUP MENUS. Press EXIT. Use èuntil SETUP

CUTOFF AND DELAY AFTER FILL appears.

Model B-SV-600 Touch Screen Control Panel Users Manual

13

AFI Publication 1240410

•

Issue: 1

•

April 2010

2. Product cutoff devices that can be installed at the funnel of the filler can be controlled

using the CUTOFF CONTROL selection. Types of cutoff devices used will vary with

design, product characteristics, and other accessories used at the filler. The following

types of cutoff control are available.

None – No Cutoff control required.

By Time – Specifies a period of time for the cutoff to open and close. The actual time is

specified in the OPEN TIME and CLOSE TIME entries.

Limit Switch – Specifies a period of time to delay the closing of the cutoff. The limit

switch determines cutoff opening and filling. The opening time is not selectable in this

mode.

Open Time – Specifies the amount of time that it takes to fully open the cutoff, prior to

the start of the fill. Entries can be made in this window only if cutoff control has been

selected as “Time.”

Close Time – Specifies the amount of time (delay) that it takes to fully close the cutoff,

after the fill is completed, can be specified. Entries can be made in this window when

cutoff control has been selected as either “Time” or “Limit Switch.”

3. Press DELAY AFTER FILL to coordinate operation of the auger filler with other

equipment, or to allow product to settle and distribute into a container.

4. When entries are complete, record settings on the Run Program Worksheet (see

“Appendix”) and press the èto continue.

Specifying Level Control and Product Infeed Operation

These setup screens specify how the filler hopper is re-supplied with product from (external)

infeed equipment. The following selections are available.

Model B-SV-600 Touch Screen Control Panel Users Manual

14

AFI Publication 1240410

•

Issue: 1

•

April 2010

1. Use LEVEL CONTROL to specify operation of the Level Control switch installed in the

hopper cover at the filler. It can be selected as “On” or “Off.” When entered as “On” a

signal is generated indicating a low level condition exists. When selected as “On,” the

Pause Delay and Low Level Agitation selections (see following) can be further used to

specify low level control.

2. The PAUSE DELAY key provides a delay to occur between detection of a low level

condition in the hopper and a system pause. This selection can be used to allow infeed

equipment to deliver product to the hopper without excessive “pausing” of production.

3. The LOW LEVEL AGITATION key allows the product agitator blade in the hopper to

operate at low product levels to ensure that product is fed into flights of the auger before

re-supply occurs. When selected as “On,” slow speed agitation operates despite the set-

ting in the “Auger and Agitation“ setup menu.

4. INFEED CONTROL selects the type of signal used to actuate external product infeed

equipment. Selections are available for Pulse, Continuous, or None. When selected as

“Pulse,” pulse width can be defined using the On/Off Time entries. Infeed Control entries

will depend upon the type and wiring of external product infeed equipment used. You

may need to refer to wiring information of this external equipment to determine the cor-

rect entry.

5. The ON/OFF TIME selection specifies pulse width of external equipment used for

product re-supply.

6. When entries are complete, record settings on the Run Program Worksheet (see

“Appendix”).

Use the following as a guideline for starting and running filling production with the B-SV-600

using the touch screen Control Panel.

1. Verify that hopper contains sufficient product and that empty containers are available.

2. Clear any accumulated product or debris.

3. Turn power on at the Control Panel.

4. Press SYSTEM MENUS to choose which Setup Program to use and other System

Setup entries.

5. After selecting the Run Program number, press for other System Setup entries. Press

SYSTEM SETUP for recycling control and times, reset any accumulated production

count statistical totals, and define the End Of Fill (EOF) signal for external equipment.

Model B-SV-600 Touch Screen Control Panel Users Manual

15

AFI Publication 1240410

•

Issue: 1

•

April 2010

Starting and Running

Filling Production

6. Press START on the Main screen and verify system operation from the Status

Messages appearing at the top of the Main screen. Status messages are described

elsewhere in this manual.

Displaying Production Information

The Status Menu screens provide complete summaries of all relevant filling production totals

while in operation. These screens are available from the STATUS MENUS Menu Control

key.

Production

The screens available from the Production Menu provide a quick and easy method of

accessing setup selections and settings that may require adjustment or “tuning” while in fill-

ing production. The following can be selected and displayed from this Menu Screen selec-

tion.

Production Product Feed Control

Model B-SV-600 Touch Screen Control Panel Users Manual

16

AFI Publication 1240410

•

Issue: 1

•

April 2010

Displays:

Low Level Pause Count

Low Level

Agitator

Infeed

Settings:

Low Level Control

Low Level Agitation

Pause Delay

Infeed Control

Off Time

On Time

Production Servo Feedback

Model B-SV-600 Touch Screen Control Panel Users Manual

17

AFI Publication 1240410

•

Issue: 1

•

April 2010

Displays:

C/W Raise/Lower

Feedback Weight

Auger Revolutions

Settings:

Target Weight

Feedback Rate

Feedback Control

Table of contents

Other ALL-FILL Control Panel manuals