Allevi 2 User manual

1

Allevi 1

User Guide

Allevi 2

User Guide –1.6.0

2

B U I L D W I T H L I F E

3

Table of Contents

WELCOME 4

SPECIFICATIONS 5

SAFETY AND COMPLIANCE 5

GETTING STARTED 6

WHAT’S IN THE BOX 7

ALLEVI 2DIAGRAM 8

SETTING UP YOUR PRINTER 9

SETTING UP YOUR SOFTWARE 10

YOUR FIRST BIOPRINTS 13

PRINTING SINGLE MATERIAL STRUCTURES 14

PRINTING DUAL MATERIAL STRUCTURES 24

MAINTENANCE & TROUBLESHOOTING 30

RESETTING PASSWORDS 30

TROUBLESHOOTING AND CONTACT US32

4

This User Manual will help get you started using your Allevi

bioprinter.

In the first section of this guide you will learn about the basic

components of your Allevi, how to set it up, download the

correct software, and load bioinks.

The second section of this guide will provide you with instructions

on using the Allevi software to print a single material structure.

The third section will teach you how to print a dual material

structure.

Finally, the fourth section will teach you how to bioprint for

your desired application.

Following this guide will help ensure that you are getting the

most out of your machine. We can’t wait to see what you will

create!

5

SPECIFICATIONS

WARNING: The Allevi 2 includes moving parts that can cause injury. Never

reach inside the printer while it is in operation.

WARNING: Do not leave the printer unattended while it is in operation.

WARNING: Always wear safety goggles when using the printer.

WARNING: Extruders heat to high temperatures. Always allow time for extruders

to cool before handling.

CAUTION: Always power off the printer before reaching inside.

Mechanical

Dimensions: 12 x 12 x 12 in

30.5 x 30.5 x 30.5 cm

Construction: Aluminum Frame

Build Structure: Tissue Culture Plates

XYZ Position Precision: 5 microns

Electrical

Power/Voltage Requirements: 6Amp AC

Desktop Adaptor

Connectivity: USB

Software

Bundle: Modified Repetier Host

Supported File Types: gcode

Operating System: Windows, Mac OSX, Linux

Printing

Print Technology: Fused Deposition

Manufacturing

Build Volume: 5.1 x 3.5 x 2.4 in (42.8 in3)

13 x 9 x 6 cm (702 cm3)

Layer Resolution: 100 microns

Print File Type: Gcode

Extruders

Max Temp (E1): 160°C

Max Temp (E2): 70°C

Min Temp: Room temperature

Pressure Range: 0-120PSI (0-820kPa)

LED Range: 405 nm

6

Let’s Get Started!

7

WHAT’S IN THE BOX

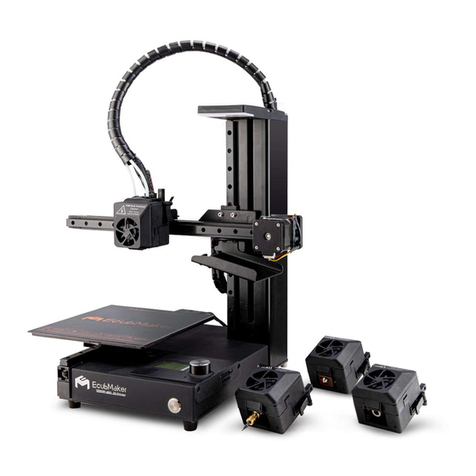

Allevi 2 Printer Safety Goggles USB Cable

Power Adapter Starter Bioink Kit Compressor Hose

Air Compressor*

*Air compressor arrives separately

8

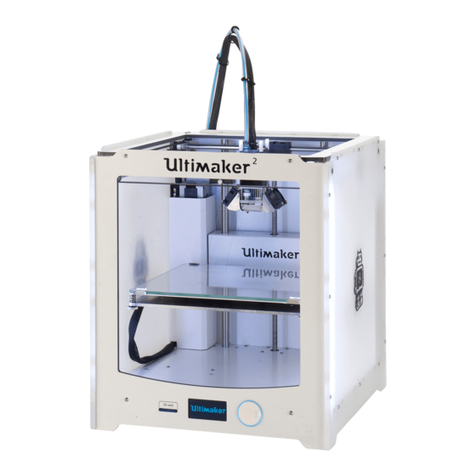

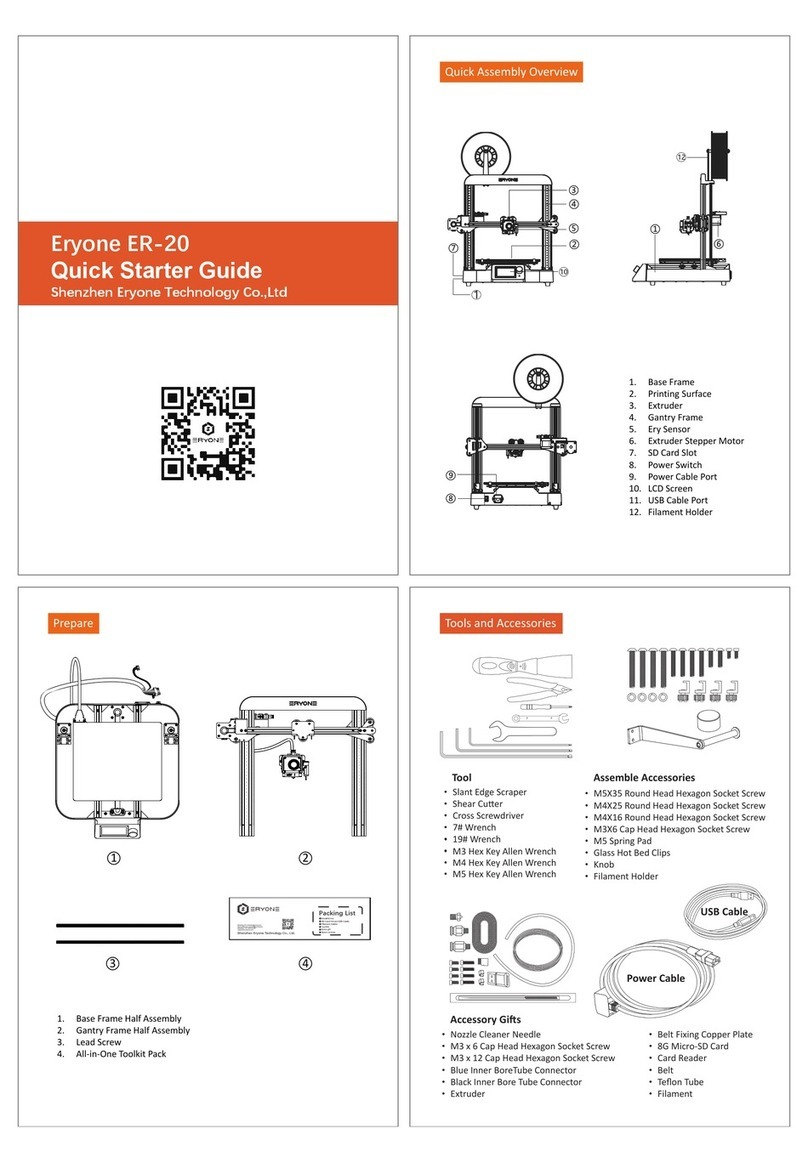

ALLEVI 2 DIAGRAM

A. Air Compressor Lines

B. Dual Extruder (Left: Extruder 1, Right: Extruder 2)

C. Build Plate

D. Power On/Off

9

GETTING STARTED

Setting up your printer

1. Carefully remove your printer from the packaging by grasping the printer frame firmly with

both hands.

2. Use the power cable to connect the printer to a power supply via the port located on the

right side of the printer (labelled Step 2).

3. Power on the printer by pressing the power button located front of the printer.

4. Attach the air compressor to the printer by connecting the compressor hose to nozzle on the

left side of the printer (labelled Step 4). This can be a tricky maneuver, so for more in-depth

directions on connecting the air compressor, watch this quick video. The air compressor

must remain turned on for the entirety of the print. We recommend keeping the air

compressor set to a pressure significantly higher than your print pressure. This is so that as

the air compressor loses some pressure and refills, your print is not affected. The air

compressor’s pressure can be adjusted by turning the black knob. It has a max pressure of

120PSI.

Step 4

Step 2

10

Setting up your software

The following steps will take you through the software installation process. This process is also

instructions.

1. Download and install FTDI Drivers.

a. Windows: FTDI Drivers (Right-click to “Run As Administrator”)

b. MacOSX: FTDI Drivers.

2. Download the installer for your operating system from the Allevi Software page.

3. Double-click desktop application to run Bioprint.

4. In the setup window, create a username and password to use with Bioprint and then proceed to

register your printer. For the ‘Serial Number’ field, put the name of your institution or lab. Finally

select “Keep Access Control Enabled.”

5. Login using the login menu in the top right corner of the screen.

6. To close the software, quit from the taskbar.

NOTE: Your username and password are computer specific so the one you create will

always have to be used for that computer. You can use the same username, password, and

serial number multiple times on different computers.

11

7. Install Repetier Host.

Close window if Repetier-Host Server opens in your browser and continue.

8. Open Repetier-Host. Go to “Config” > “Printer Settings” and assign the following values.

9. Download the Slic3r Config Bundle file.

10.In Repetier Host, go to the Slicer tab and click “Configuration”

12

11.Go to “File”> “Load Config Bundle…” and select the Slic3r Config Bundle file you just

downloaded.

Troubleshoot: Sometimes when you type in bioprint/ or bioprint:9999/ on the web browser nothing

appears. When this happens open command prompt in the start menu.

In command prompt type “ipconfig”, Find the IPv4 number. Navigate back to your browser and type

this number followed by 9999 into your navigation bar to access Bioprint.

13

Let’s Start Printing!

14

BIOPRINTING WITH ONE MATERIAL

Slicing One STL

You can design STL files on any CAD software, such as SolidWorks or Autodesk Fusion 360.

Alternatively, you can find a host of STL files in the “Getting Started”folder. To begin we will use a

predesigned STL file.

1. Load the Pediatric-Bronchi.STL file into Repetier-Host.

a. Move the object on the bedplate using the arrows highlighted on the left.

b. Save, copy, or scale object with the items on the right.

c. Assign the STL to an extruder by using with the extruder drop down menu.

2. Enter your print settings.

a. Select the “Slicer” tab to assign preconfigured Slic3r settings to slice the file.

b. Speed and layer height are defined.

15

3. Select the configuration tab to adjust settings important for bioprinting. Print, filament, and printer

settings are accessible under ‘Settings.’

a. Layer Height –Determines how thick or thin your layers are. This is a property typically

determined by the material type.

b. Speed –Determines how fast the extruder will move during the print. Remember to change all

the speeds in the column to the desired number

Recommendation: 2-6 mm/s is good for a small accurate design (example: lattice). 8-16 mm/s is

good for a large design (example: ear). Speed is a print parameter that is very dependent on

material and pressure.

16

c. Nozzle Diameter –Enter the number that accurately depicts your nozzle tip inner diameter

4. Once your settings have been saved, you are now ready to slice the file.

5. You can view the printer movement by viewing the g-code created by your slicer file.

Note: If no g-code is generated, check that your nozzle diameter is thin enough.

a. Save your g-code file.

NOTE: Your layer height must be less than your nozzle diameter to correctly slice

NOTE: Once the changes have been made, remember to save and label your settings.

17

Printing One STL

1. Navigate to the Bioprint Window and log in.

2. Navigate to the Bioprint window and Upload the G-code file.

NOTE: You can sort your gcode files by name, date, or size by clicking the wrench.

18

3. Connect your printer to your computer.

4. First, home the Z-axis.

5. Second, home the E-axis.

19

6. Third, home the X/Y-axis.

7. Use the dropdown menu to select “Petri Dish.” Click the button “Select Well Plate.”

NOTE: If you want to print in multiple wells, all you need to do is select that option. Our

software will automatically replicate your single gcode file across all the wells.

20

Loading Material into Syringe

For this print we will use Pluronic F127. Place some pluronic into the fridge to allow it to liquify.

Watch this video to learn how to prepare Pluronic to print with your Allevi 2. We suggest filling your

syringe with about 3 ml of material for your first print.

Calibrating Extruder

1. Attach a 30 gauge 0.25” (pink) needle to the syringe, load syringe into the extruder 1

canister, and tighten knob.

2. Now set and test pressure for extrusion.

a. Set pressure by manually increasing the settings using the +/- buttons. Test the

pressure by pressing extrude.

NOTE: Bioinks will be loaded differently depending on the type of material it is.

Other manuals for 2

1

Table of contents

Other Allevi 3D Printer manuals